10

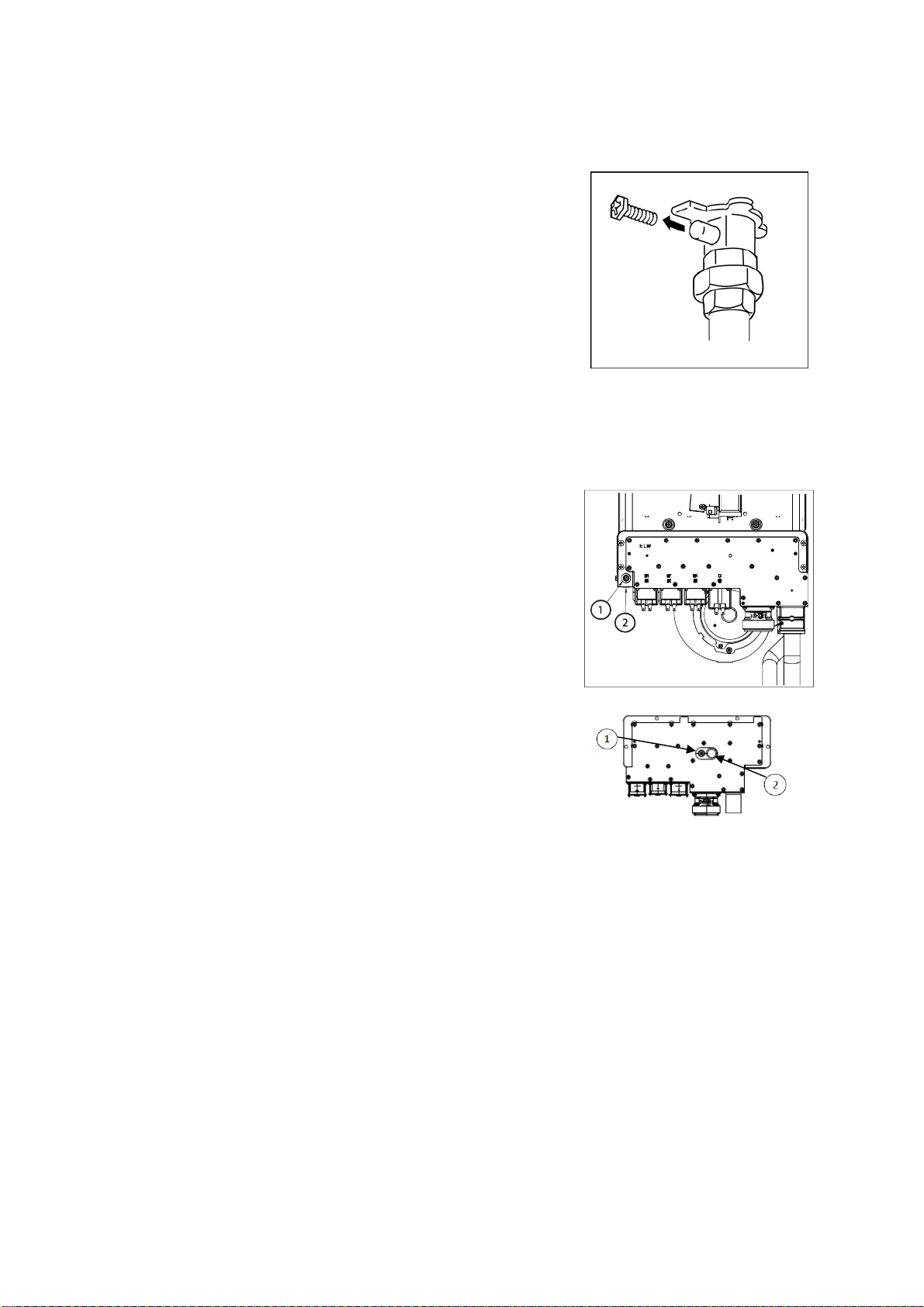

10) Oncetheheaterhasignitedandhasbeguntorun

continuously,locatetheManifoldadjustmentbuttons

onthecircuitboardlocatedintherightsideoftheunit

(Figure9).

11) Pressandholdthemaximumpressuresetbutton.

Verifyfromthebelowtablethattheappropriate

pressureisreadfromthemanometer.Ifthepressure

needsadjustment,usetheManifoldpressureincrease

anddecreasebuttonstoadjusttothecorrectpressure,

whilecontinuingtoholddownthemaximumpressure

setbutton.

12) Pressandholdtheminimumpressuresetbutton.

Verifyfromthetablesbelowthattheappropriate

pressureisreadfromthemanometer.Ifthepressure

needsadjustment,usetheManifoldpressureincrease

anddecreasebuttonstoadjusttothecorrectpressure,

whilecontinuingtoholddowntheminimumpressure

setbutton.

ManifoldGasPressureMaximumandMinimumValues

SettingListforManifoldPressuresNR83DVC(GQ‐2457WS‐FFAUS)

SettinglistforGasManifoldpressure(NR83‐DVC)

ManifoldPressureforNR83‐DVC(inchH2O)Coveroff

Dip7=OFFDip8=OFFDip7=ONDip8=OFFDip7=OFFDip8=ONDip7=ONDip8=ON

Ventlengthadjustment

MinimumLengthShortLengthLongLengthMaximumLength

NoVenting

Gastype/VentlengthMax.valueMin.valueMax.valueMin.valueMax.valueMin.valueMax.valueMin.valueMax.valueMin.value

NG/Minlength2.571.002.531.002.490.962.490.96

(Verticaltermination)*(2.53)(0.97)(2.46)(0.95)(2.46)(0.95)(2.40)(0.93)

NG/Maxlength2.531.002.490.962.490.962.490.96

(Verticaltermination)*(2.46)(0.95)(2.46)(0.95)(2.40)(0.93)(2.36)(0.92)

2.651.04

LP/Minlength3.731.363.651.363.611.323.571.32

(Verticaltermination)*(3.61)(1.30)(3.53)(1.30)(3.53)(1.30)(3.49)(1.28)

LP/Maxlength3.651.363.611.323.571.323.571.32

(Verticaltermination)*(3.53)(1.30)(3.53)(1.30)(3.49)(1.28)(3.45)(1.28)

3.81

1.41

*Usethesesettingswhentheunitterminatesusingtheverticalraincap

ManifoldPressure(inchH2O)CoverOff

ModelNameGasTypeSupplyPressure

(inchH2O)MaxValueMinValue

NG 7.93.460.87N‐0931M/NR111‐SV,

N‐0931M‐ASME/NC250‐SV‐ASMELP11.03.650.94

NG7.93.150.75

N‐0931M‐OD/NR111‐ODLP11.04.370.98

NG 7.93.450.94N‐0931M‐DV/NR111‐DV,

N‐0931M‐DV‐ASME/NC250‐DV‐ASMELP11.04.020.91

NG7.92.851.00

NR83OD(GQ‐2457WSUS)LP11.04.251.40

NG7.9NR83‐DVC/NR83DVC(GQ‐2457WS‐

FFAUS)LP11.0

Refertothe“SettinglistforgasManifoldpressure

(GQ‐2457WS‐FFAUSandNR83‐DVC)”below

ManifoldPressure(inchH2O)Coveroff

Dip7=OFFDip8=OFFDip7=ONDip8=OFFDip7=OFFDip8=ONDip7=ONDip8=ONVentlength

adjustmentMinimumShortLongMaximum

GastypeMax.valueMinvalueMax.valueMinvalueMax.valueMinvalueMax.valueMinvalue

NG2.750.902.700.852.700.852.650.80

LP3.851.253.801.253.751.203.701.20

FIGURE9