Sivu 3 / 19

Table of contents

General.................................................................................................................................................2

Read before use ...................................................................................................................................2

1. DECLARATION OF CONFORMITY......................................................................................................4

2. PURPOSE OF USE..............................................................................................................................5

3. SAFETY PRECAUTIONS......................................................................................................................5

4. IDENTIFICATION INFORMATION AND SPAREPARTS ........................................................................6

4.1. Identification plate ............................................................................................................................ 6

4.2. Maintenance services........................................................................................................................ 6

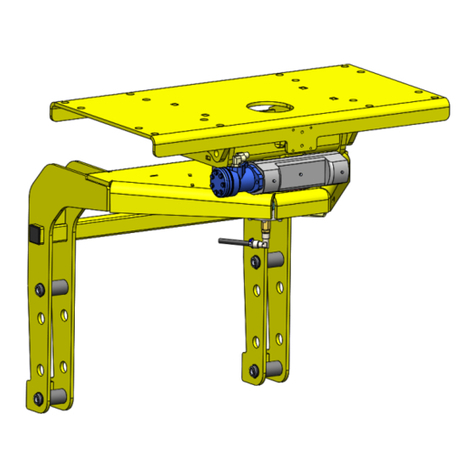

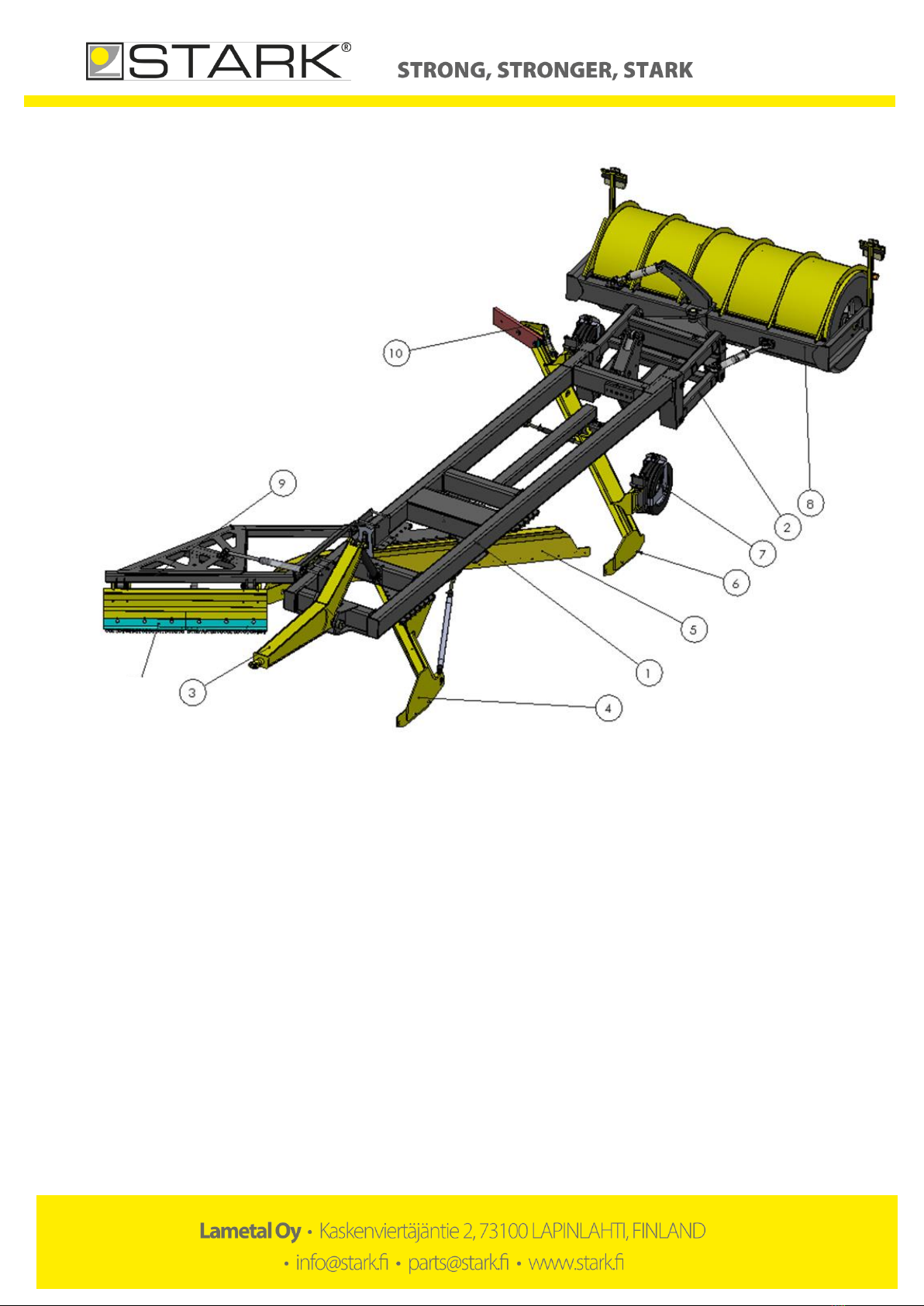

5. MAIN PARTS OF THE ROAD GRADER ...............................................................................................7

6. ATTACHING THE ROAD GRADER......................................................................................................8

6.1. Attaching the road grader to the base machine ............................................................................... 8

7. OPERATING THE ROAD GRADER ......................................................................................................9

7.1. Operating instructions....................................................................................................................... 9

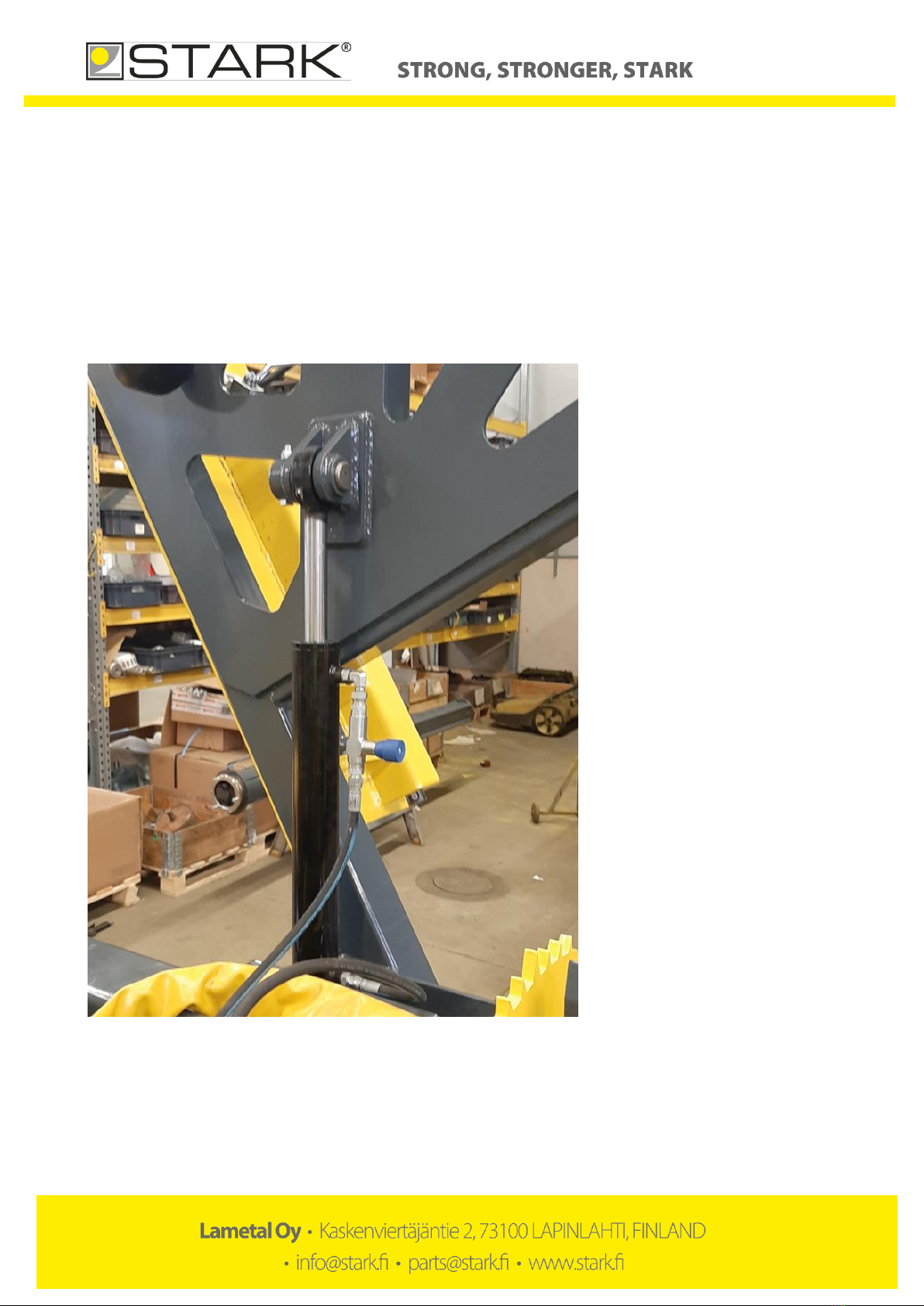

7.2. Grading adjustmets ........................................................................................................................... 9

7.3. Detaching the road grader .............................................................................................................. 10

7.4. Wireless controller .......................................................................................................................... 11

7.5. Removal of packed snow................................................................................................................. 12

7.6. Accessories ...................................................................................................................................... 12

8. MAINTAINING THE ROAD GRADER ................................................................................................13

8.1. General safety precautions for the use and maintenance.............................................................. 13

8.2. Minimum requirements of the base machine................................................................................. 13

8.3. Tightening torque............................................................................................................................ 13

8.4. Daily maintenance........................................................................................................................... 14

8.5. Maintenance after every 10 hours.................................................................................................. 14

8.6. Maintenance after 50 hours or weekly........................................................................................... 14

8.7. Lubrication points............................................................................................................................ 15

9. HYDRAULICS...................................................................................................................................16

9.1. 8-hose hydraulics............................................................................................................................. 16

9.2. 4-hose hydraulics............................................................................................................................. 17

9.3. 2-hose hydraulics............................................................................................................................. 18

10. WARRANTY POLICY ......................................................................................................................19