Starrett 3840 Series User manual

TECHNICAL SUPPORT: (201) 962-8352

1

3840 Series

Micro Vickers/Knoop Hardness Tester

TECHNICAL SUPPORT: (201) 962-8352

2

Contents

1. Introduction

2. Main Technical Specifications

3. Installation and Regulation of the Instrument

3.1 Operational conditions

3.2 Unpacking and installation

3.3 Introduction to the operating board and its function keys

4. Usage of the Instrument

5. Calibration and Precautions of the Instrument

6. Accessories (The Packing List)

7. Optional Accessories

TECHNICAL SUPPORT: (201) 962-8352

3

1Introduction

Our advanced line of Micro Vickers Series hardness testers are state-of-the-art,

precise testing systems suitable for hardness analysis of metallic specimens in

metallography laboratories or production environments.

The Starrett micro-Vickers hardness testers are versatile and user-friendly

systems, designed for the accurate hardness testing of small precision parts, thin

materials, coatings, wires and case depth determinations. The 3840 series is our

entry level micro-Vickers hardness tester, covering the load range from 10g to

1kg.

Using guidelines to ASTM E-384/92 Vickers hardness testers standards, the 3840

Vickers hardness tester will offer unmatched repeatability. This micro Vickers

hardness tester can also measure Knoop hardness after installing an optional

knoop indenter. A perfect rugged performer suited for any environment, the

Starrett Vickers hardness testers are offered with a 1 year warranty and free

lifetime technical support.

2Technical Specifications

Test forces 0.098N(10gf), 0.245N(25gf), 0.49N(50gf), 0.9807N(100gf),

1.961N(200gf), 2.942N(300gf), 4.903N(500gf), 9.807N(1kgf)

Displayed Value Tolerance:See Table 9

Test Force Application Method: automatic loading and unloading

Amplification of the Microscope: 400× (for the measurement),

100× (for observation)

Dwell time of the test force: 0~60s (5 second as a unit)

Min. graduation value of the testing drum wheel: 0.25μm/grid

Max. height of the specimen: 70 mm

Distance between the center point of the indenter and the exterior panel: 98mm

X-Y Table Graduation: 25mm x 25mm

Weight: 55 lbs (25kg)

Power source: AC110V/50~60Hz

Overall dimension (L×W×H): (415×295×503)mm

TECHNICAL SUPPORT: (201) 962-8352

4

3 Unpacking, Operational Conditions and Installation

Unpacking and Installation

Cut the belt on packing crate; remove the anti-shock cushion and remove the

instrument and the accessories kit from the crate.

Place the instrument on the prepared solid working table; (for the

construction of the working table, see Fig 1)

IMPORTANT!

Do Not Discard Shipping Crate as This May

be Needed for Future Transportation.

General Safety Instructions

1. Never use clamps, straps, any other tooling or equipment to mount specimen to

the tester anvil.

2. Always use the proper anvil supplied.

3. Be sure to use proper indenter and weight for material and hardness to be tested.

180

300

φ80

Fig.1

TECHNICAL SUPPORT: (201) 962-8352

5

Hardness Tester Maintenance

1. Consult operation instructions for specific maintenance and adjusting procedures.

2. Keep the tool clean for best results.

3. Remove adjusting tools and wrenches. Form habit of checking that adjusting tools

are removed before using machine.

4. Keep all parts in working order. Check to determine that the parts will operate

properly and perform their intended function.

5. Check for damaged parts. Check for alignment, binding, breakage, mounting and

any other condition that may affect tool's operation.

6. Part that is damaged should be properly repaired or replaced. Do not perform

makeshift repairs. (Use the parts list provided to order replacement parts.)

Operating Conditions:

The 3840 series Micro Vickers Hardness Testers are a precise yet sensitive

instrument that should be handled with care. Please be sure to mount on a sturdy

bench in a clean temperature-controlled room for best results. This instrument

should be perfectly level before performing any tests.

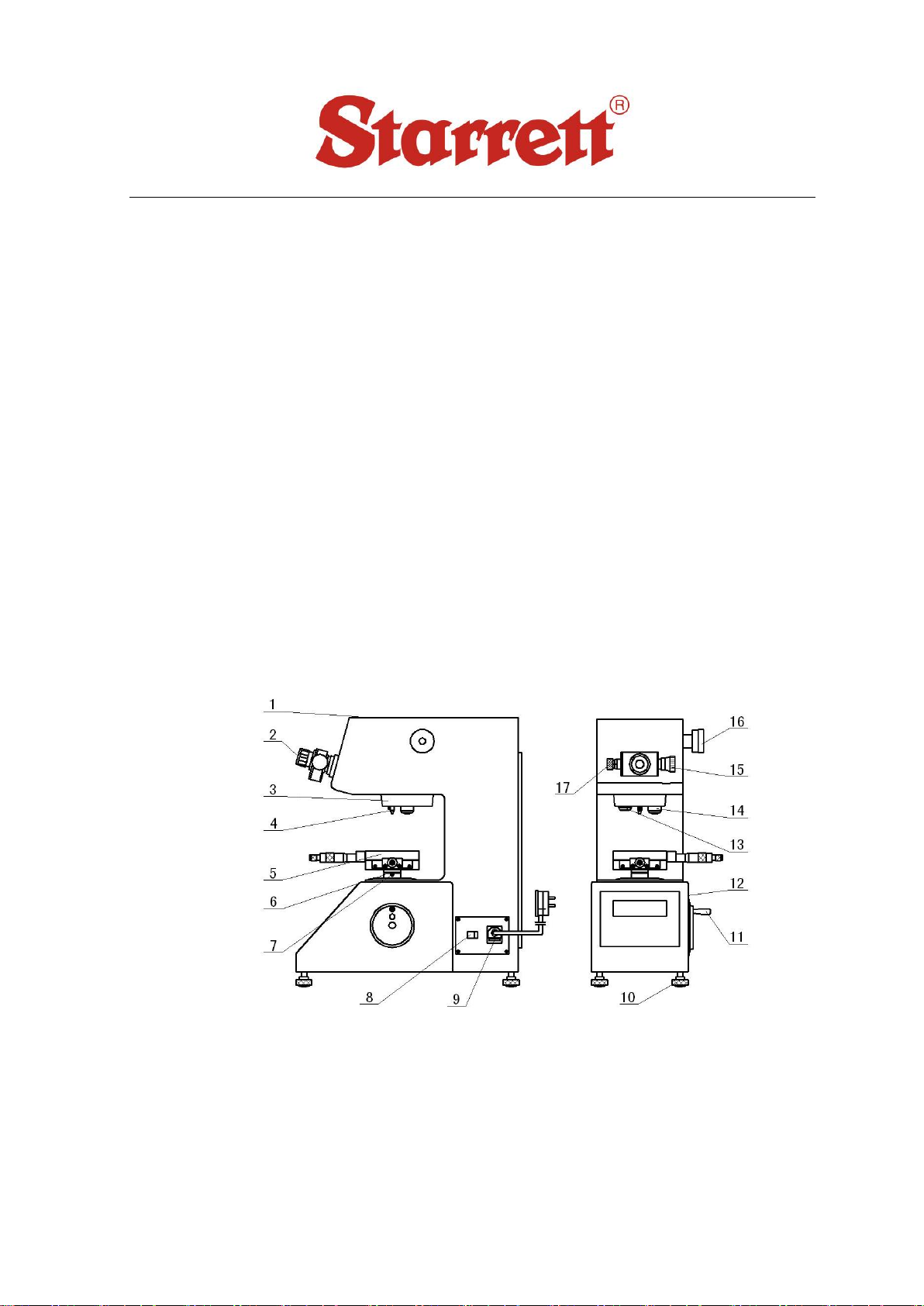

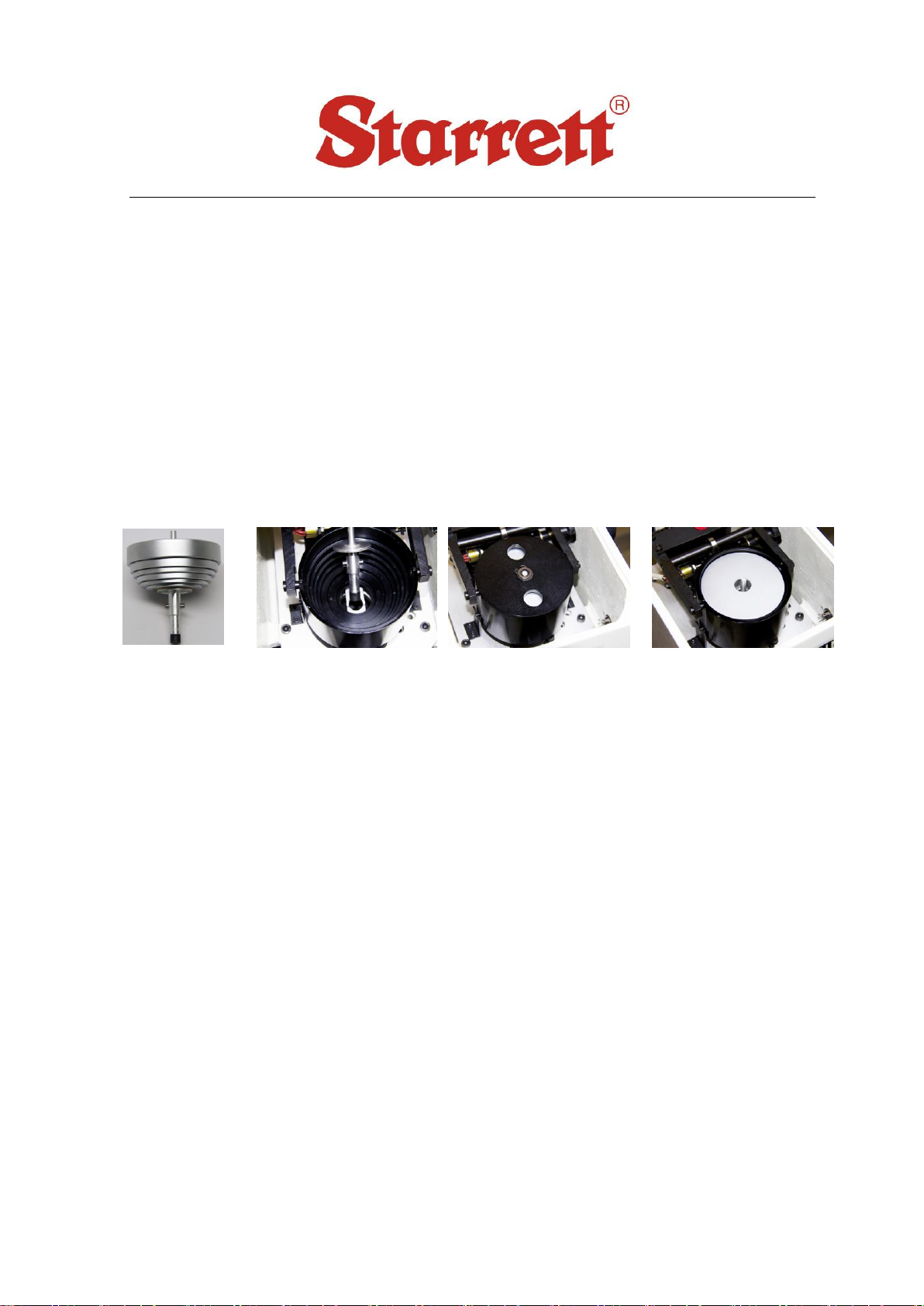

Fig.2

1. Upper Cover 2. Microscope 3. Rotating Plate 4. Indenter 5. Cross Testing Table

6. Up and Down Lead Screw 7. Screw 8. Power Switch 9. Power Cord and Fuse

10. Leveling Feet 11. Hand Wheel 12. Screen 13. 10× Objective 14. 40× Objective

15. Right Drum Wheel 16.Load-Change Hand Wheel 17. Left Drum Wheel

TECHNICAL SUPPORT: (201) 962-8352

6

Set Up –Installation:

Take out the 4 Leveling Feet (10) from the accessories kit and screw them in

the holes on the base panel of the instrument. Unpack the gauze band wrapped

on the Up and Down Lead Screw (6) and Hand Wheel (11) (Fig.2).

Gently remove the anti-shock paper on the indenter with both the hands. Clean

the indenter gently with rubbing alcohol.

Open the Upper Cover of the machine and remove the two Anti-Shock Screws as

shown in Fig.3.

Remove the protective paper on the

Weight Seat and remove the Weight

Seat Cover. Take the Weight shaft

(21) and Weights (22) out of the

accessories kit and clean them

thoroughly. (Clean the supporting

surface of the Weight Axis with cloth

dipped with some oil so as to protect

it against rust.) Put the six Weights

on the Weight Axis in the order from

small to big (see Fig 4).

Fig.3

21.Weight Shaft 22.Weights

23.Weight Shaft Peg 24. V-Shaped Groove

Fig.4

TECHNICAL SUPPORT: (201) 962-8352

7

Hold the top of the Weight shaft, put the Weight shaft into the Weight

Seat and rotate the Weight shaft so that the Weight shaft Peg (23) may

fall into the V-shaped Groove (24) of the lever.

Cover the Weight Seat with the Weight Seat Cover.

Rotate the Load-Change Hand Wheel (16) of testing force, so as to

make the Weight Seat move up and down smoothly on the groove;

Take the dust-protecting cover of the eyepiece tube out and insert

the Microscope (2) into the hole of eyepiece tube until its flush.

Take the X-Y Slide (5) out of accessories kit and clean off the rust

protecting oil on it.

Insert the shaft of the X-Y Stage into the hole on the Elevating Lead

Screw and tighten it with the Screw (7).

Take the supplied bullseye level out of the accessories kit and put it

on the X-Y slide, and then adjust the leveling feet accordingly.

TECHNICAL SUPPORT: (201) 962-8352

8

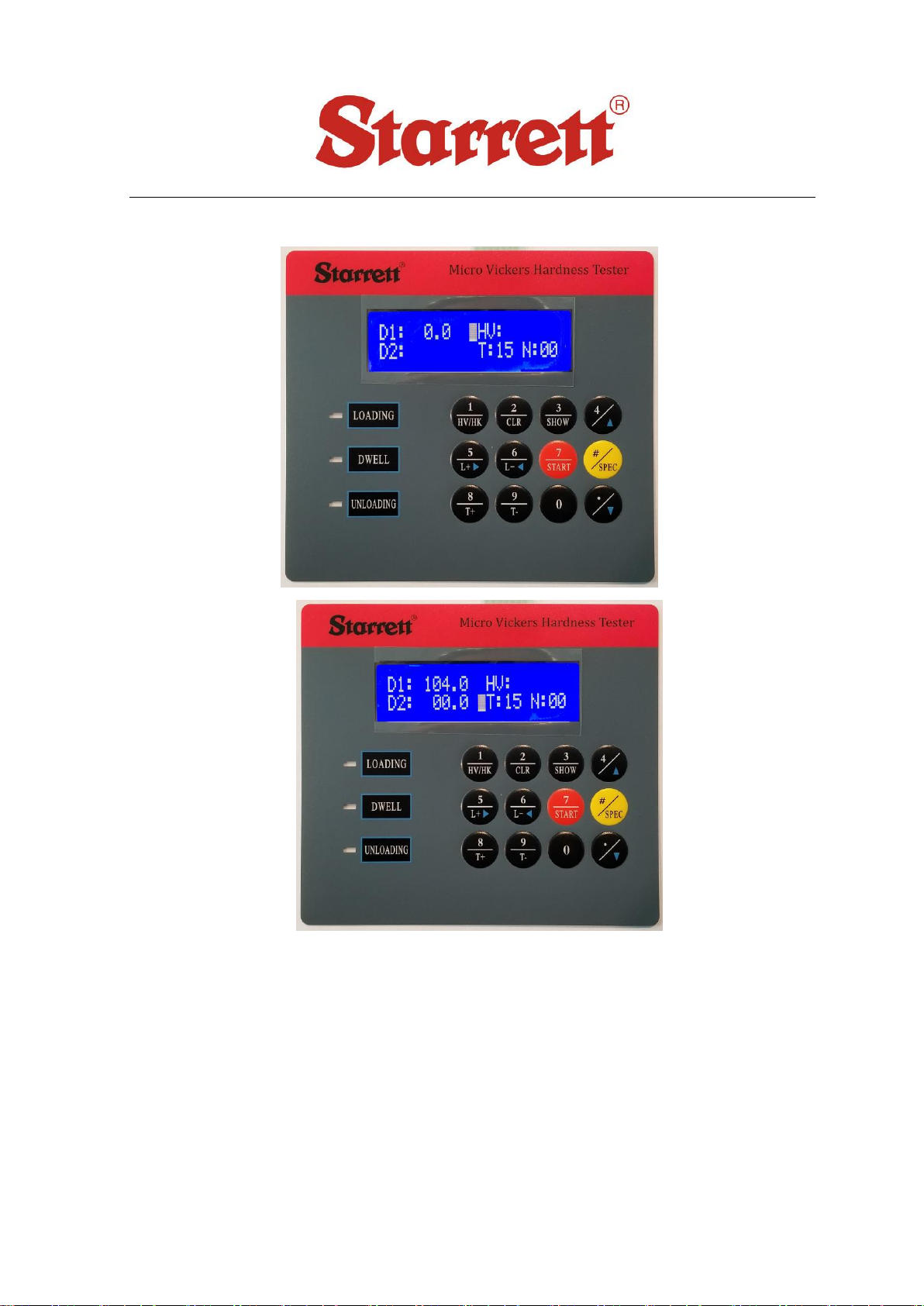

KEYPAD FUNCTIONS: (Fig.5).

Fig.5

Upper key:Digit 2

Lower key:Zero setting key, press this key to set the zero to digit.

2

CLR

Upper key: Digit 1

Lower key: The shifting key between Vickers and Knoop hardness

1

HV/HK

Upper key:Digit 8

Lower key:Time adding key, every pressing adds 5 seconds

8

T+

Upper key:Digit 9

Lower key: Time deducting key, every pressing shorten 5 seconds

9

T-

Upper key: Digit 5

Lower key: addition key for the luminosity of light source.

5

L+

TECHNICAL SUPPORT: (201) 962-8352

9

Upper key:Digit 6

Lower key: reduction key for the luminosity of light source.

6

L-

Upper key: Radix point.

Lower Key: After press SPEC key, press this key to let the Lower keys

become valid and the cursor will disappear.

·

#

SPEC

Double pressing this key means confirmation. For example: after key in D1

value 202, double press this key to confirm D1. As same, after key in D2

value 203.5 double press this key to confirm D2. The hardness value on the

screen will be “HV: 721.4”.

SPEC key is special function key. Single press this key, then press

key to let Upper keys become valid. And as the same, single press SPEC

key, then press

key to let Lower keys become valid.

Upper key: Digit 4.

Lower key: After press SPEC key, press this key to let all Upper

keys (digit keys) become valid and the cursor will blink.

4

7

START

Upper key: Digit 7.

Lower Key (Start key): Press this key to start the motor and apply test

force.

TECHNICAL SUPPORT: (201) 962-8352

10

4Usage of the Instrument

Slowly, gently rotate the Load-Change Hand Wheel to make the testing force

meet the requirements of the application.

Turn the Power Switch (8) on and the Screen (12) will show the Model of

hardness tester and then will display the main testing screen as shown below.

Adjusting Light Source: Press the “L+” or “L-” buttons to adjust the

brightness for your optimal vision.

Dwell Time Setting: The 900-390- is preset at 15 seconds since this is the

most common time needed for a micro Vickers test. You can adjust this time

by pressing the “T+” or “T-“ buttons. Each button press will add or subtract 5

seconds from the preset time.

Setting the Eyepiece: Turn the Rotating Plate (3) to make the 40×objective

(14) face in the front direction. The general amplification is 400×(The

eyepiece, objectives and specimen are in the focusing state).

Taking a Test: Place the supplied hardness test block or a known specimen

on the Testing Table and then rotate the Hand Wheel to raise the Testing Table.

Look through the Eyepiece to observe. When the hardness block or the

specimen comes into the distance of 1~2 mm under the Objective, at this

point, in the center of the vision field of the Eyepiece appears a bright spot,

which shows it is very close to the focusing plane. At this time, continue

raising the Testing Table up slowly until the hardness block or specimen

surface forms a clear image in the Eyepiece. If two moveable graduated lines

observed in the vision field of the Eyepiece seem vague, turn the eye guard on

the Eyepiece to bring into clear focus. You should now see the grain of the

block very clearly.

Turn the Indenter to the front direction of instrument. At this point, the

distance between the tip of Indenter and the plane of specimen is about

0.4~0.5 mm.

D1: 0.0 HV:

D2: T:15 N:00

TECHNICAL SUPPORT: (201) 962-8352

11

IMPORTANT! When testing an irregular-shaped specimen, take care not to

damage the indenter when turning the turret.

Press the red START button and the instrument will begin by putting the load

on. The red light by the Loading sign on the left side of the keypad will blink.

After the load has completed, the (Dwell) LED lights up, and at this time the

dwell time begins counting down to “0”. After the dwell time of test force is up,

the (Unloading) LED blinks, and the instrument automatically unloads the

testing force. The instrument will beep when this is done.

Measuring the Indentation:

Turn the 40×Objective to face in front direction, observe the indentation in the

eyepiece; rotate the Hand Wheel to focus microscope until the image quality

of indentation becomes clear.

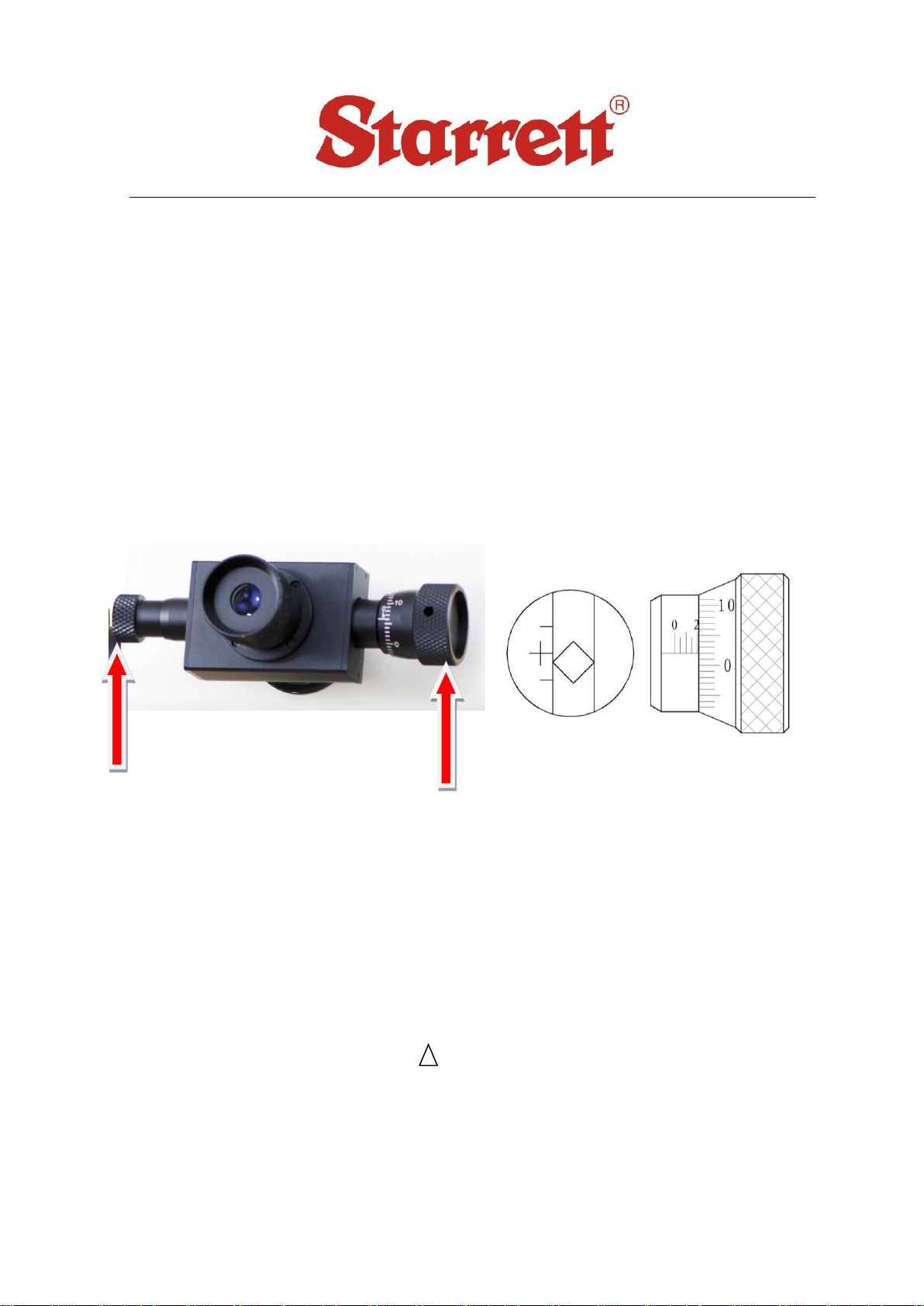

Rotate the Left Drum Wheel (17) as shown above to enable the inner side of

left graduated line tangent to the left tip of the diagonal line of the indentation.

Rotate the Right Drum Wheel (15) as shown above to enable the inner side of

right graduated line tangent to the right tip of the diagonal line of the

indentation (Fig.6).

Each rotation or cycle of the Right Drum Wheel is 50 grids. If it turns 4 cycles

and over 2 grids, that means 50×4+2=202 grids. This is the number that you

will be entering on the display using the keypad.

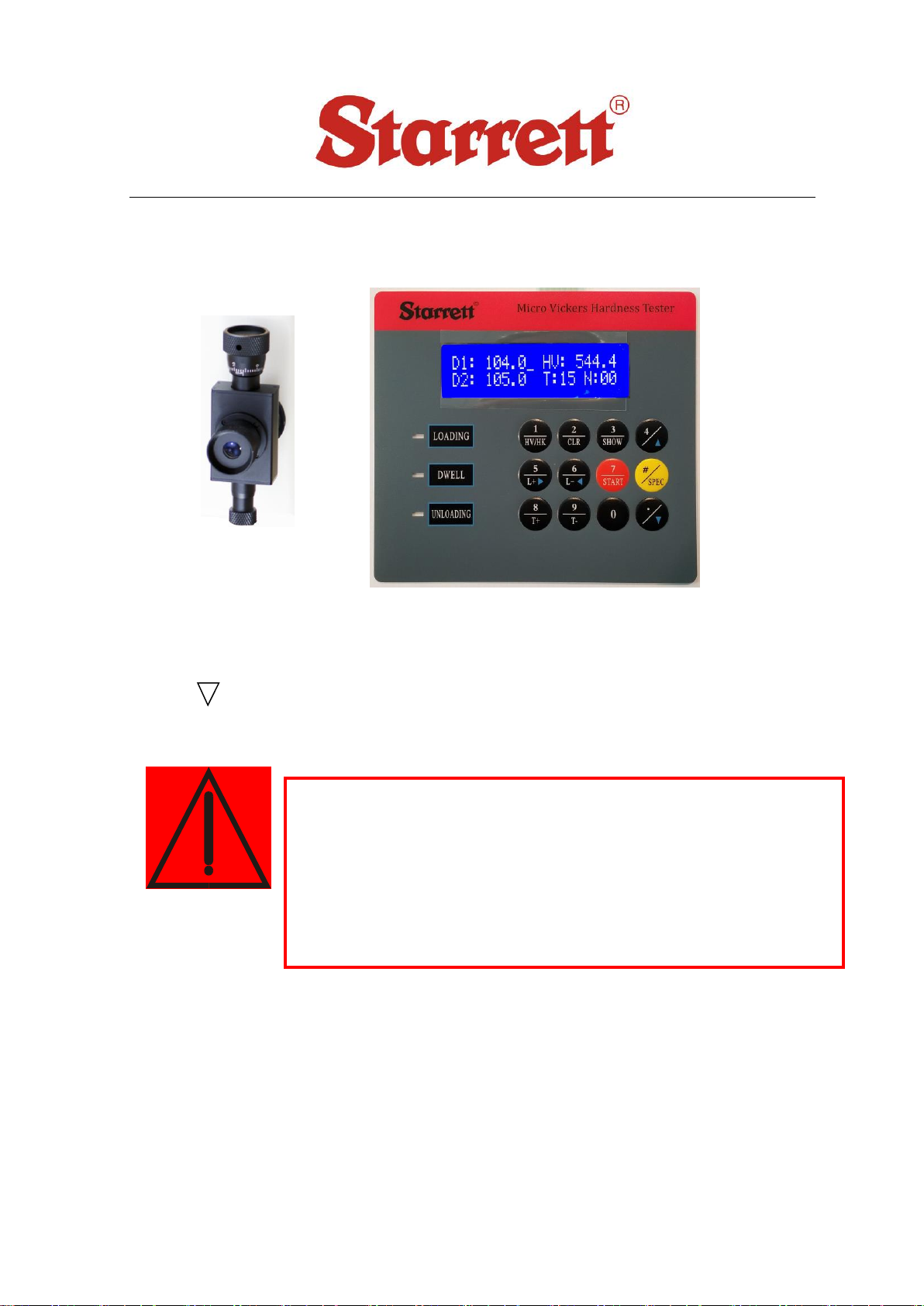

Once the measurement explained above has been obtained, you must now

press the “SPEC” key and “ “ key, the cursor will blink and now ready for

values to be entered. See picture below:

Fig.6

TECHNICAL SUPPORT: (201) 962-8352

12

Key in digit 202, then press “SPEC” key TWICE to confirm D1 value. The cursor

will move to D2 and is ready for the second measurement.

TECHNICAL SUPPORT: (201) 962-8352

13

Turn the Eyepiece by 900.Measure the other diagonal line length the same

way you did the first measurement. Key in digit 203.5; double press “SPEC”

key to confirm D2 value. The screen will show hardness value automatically:

“HV: 721.4”.

If the operator is not sure of the correctness of present measurement, please

key in D1 and D2 values (grids) again.

After this measurement is completed, press the “SPEC” key; then press the

“ ” key to let the cursor disappear. The instrument is now ready for the next

test.

If you find the Indenter does not face in front direction after you

pressed “START”, it is prohibitive to turn the Rotating Plate(turret)

until the loading, dwelling and unloading process is completed.

(3 LED’s are all out). Only when the entire testing cycle has

completely finished, the position of the Indenter can be changed,

otherwise, the instrument will be damaged.

TECHNICAL SUPPORT: (201) 962-8352

14

5Calibration and Precautions

The Eyepiece

If the graduated lines observed in the vision field of the Eyepiece are

blurry or not clear, you should adjust the clarification by slightly turning

the eye guard in front of the eye piece accordingly.

The Eyepiece should be inserted to the bottom of eyepiece tube with no

space between them, otherwise it would affect the correctness of the

measurement.

When a larger vision field on the specimen is observed, turn 10×Objective

to face in front direction of instrument. At this time, the general

amplification is 100×and it is for observation purposes only.

If the indention observed from the Eyepiece is too small or too large and it

would affect the measurement accuracy, please select new test force again

to meet the needs of requirement for measurement and repeat the test.

Due to the difference of surface roughness and flatness on the specimen,

the indentation may be deformed, therefore, two diagonal line length of

indentation should be measured in two mutually perpendicular

directions.

When testing the Knoop hardness value, only the long diagonal line length

of indention should be measured. The Knoop hardness value (HK) will be

displayed directly.

Calibrating the eye piece:

The zero position of the Eyepiece was calibrated before the instrument

was re-crated. During usage over time, it may be the cause of an error,

therefore, zero position setting should be carried out periodically. As soon

as an error appears, the zero position shall be regulated.

TECHNICAL SUPPORT: (201) 962-8352

15

Regulation Method: Turn the Drum Wheels to enable inner sides of

two graduated lines to come close together until the point that no light is

visible between them. This doesn’t mean one line on top of the other. Its

more like one line is to the side of the other. The “0” positions of Right

Drum Wheel also should be aligned as well. If the “0” positions are not

aligned, loosen the screw, align the zero positions, then fasten the screw

(Fig.7).

Fig. 7

The Indenter

The diamond Indenter and indenter axis are important parts of the

instrument, and hence it is necessary to take care not to collide with the

Indenter during the operation.

In order to assure the precision of the measurement, it is important to

keep the Indenter clean. If it is covered with grease or dust, it should be

cleaned carefully with absorbent cotton dipped with rubbing alcohol.

The round column of the Indenter is marked with a red dot. When

changing the indenter, take care to make the red dot face the front

direction when it is reloaded, and the focus of the diagonal lines of the

indentation should be aligned with the red dot. It is possible to make the

alignment of the cross-shaped line in the eyepiece with the diagonal lines

of the indentation. If the indentation observed is not aligned with the

cross-shaped line, please unscrew the screw on the Indenter, turn the

Indenter a bit and the fasten the screw, and then make the alignment

again through tests until the alignment is all right to your satisfaction (See

Fig.8)

Fig.8

Loosen the screws and

align “0”positions again

TECHNICAL SUPPORT: (201) 962-8352

16

Usage Method of Knoop (HK) Hardness

Sample Introduction of Knoop Hardness

The distinguishing characteristic of Knoop test is the improvement on the

indenter’s design. You only need to measure the long diagonal line length of

indentation, therefore the relative error of measurement becomes smaller.

Compared to the micro Vickers test, when press the test force with same value, the

indentation of a Knoop hardness test is shallower, hence, it is suitable to test the

thin sheet parts. It is used to test brittle and hard materials such as enamel, glass,

agate, man-made precious stone, ceramic metals, etc.

Usage of Hardness Tester

When replacing the Knoop indenter, the red point on the outer cylinder of indenter

should face to front of the machine (see Fig.9).

Operate the key on operation board to enable the testing

method change to “HK”, the Knoop hardness test

method.

7.2.3 The operation method is just as same as that of micro Vickers

hardness test, see Section 4.

7.2.4 Only required to measure the long diagonal line length of the indentation; then

input the read digit. The Knoop hardness value (HK) will be displayed on the

screen.

D1: 0.0 HK:

T:10 N:00

Fig.9

Fig.9

TECHNICAL SUPPORT: (201) 962-8352

17

Hardness

Symbol

Max Allowed Tolerance of Display Value ±%

Hardness HV

50

100

150

200

250

300

350

400

450

500

600

700

800

900

1 000

1 500

HV 0.01

HV

0.015

10

HV 0.02

8

HV

0.025

8

10

HV 0.05

6

8

9

10

HV 0.1

5

6

7

8

8

9

10

10

11

HV 0.2

4

6

8

9

10

11

11

12

12

HV 0.3

4

5

6

7

8

9

10

10

11

11

HV 0.5

3

5

5

6

6

7

7

8

8

9

11

HV 1

3

4

4

4

5

5

5

6

6

6

8

HV 2

3

3

3

4

4

4

4

4

5

5

6

HV 3

3

3

3

3

3

4

4

4

4

4

5

HV 5

3

3

3

3

3

3

3

3

3

4

4

HV 10

3

3

3

3

3

3

3

3

3

3

3

HV 20

3

3

3

3

3

3

3

3

3

3

3

HV 30

3

3

2

2

2

2

2

2

2

2

2

HV 50

3

3

2

2

2

2

2

2

2

2

2

HV 100

3

2

2

2

2

2

2

2

2

2

1 When the indentation diagonal length is less than 0.020 mm, the table will not display the value.

2 For intermediate values, the maximum allowable error can be obtained by interpolation.

3 When the Micro Hardness Tester value in the table is 0.001mm or indentation diagonal length of the

average of 2% of the maximum permissible error given, please select the higher value.

TECHNICAL SUPPORT: (201) 962-8352

18

7.3 The Max. Allowed Tolerance of Displaying Value

Hardness

Scale

Test

Force(N)

Max Allowed Tolerance of Display Value %

Hardness Value(HK)

50

100

150

200

250

300

350

400

450

HK0.01

0.098

5

6

7

9

9

10

11

-

-

HK0.025

0.245

5

5

5

6

6

7

7

8

8

HK0.05

0.49

5

5

5

5

5

5

5

6

6

HK0.1

0.98

5

5

5

5

5

5

5

5

5

HK0.2

1.961

5

5

5

5

5

5

5

5

5

HK0.3

2.942

5

5

5

5

5

5

5

5

5

HK0.5

4.903

5

5

5

5

5

5

5

5

5

HK1

9.807

5

5

5

5

5

5

5

5

5

The specimen

The surface of the specimen must be clean or penetration and/or

measuring results may be distorted. Please clean the specimen with

alcohol or other safe cleaner.

When thin filaments, thin pieces and small parts are used as the

specimens, the fine wire testing table, thin specimen testing table and the

fork-shaped testing table should be used to hold the specimens

respectively on the X-Y SLIDE for the measurement. If the specimen is too

small to be held by the testing table, the specimen should be inlayed and

polished for the measurement.

TECHNICAL SUPPORT: (201) 962-8352

19

5Packing List:

The main instrument (including a micro Vickers Indenter, a 40X Objective and

a 10X Objective)

Item

Descriptions

Quantity

1

Weights

6 PCS

2

Weight Shaft

1 PC

3

Cross Testing Table

1 PC

4

Thin Specimen Testing Table

1 PC

5

Fork-Shaped Testing Table

1 PC

6

Fine Wire Testing Table

1 PC

7

Screw Drivers

2 PCS

8

Leveling Feet

4 PCS

9

Bullseye Level

1 PC

10

Power Cord

1 PC

11

Prepare Fuses (1A)

2 PCS

12

10×Digital Micro Eyepiece

1 PC

13

Vickers Hardness Blocks

2(one mid range

HV0.2 block and one

high HV1 block)

14

Operation Manual

1 PC

Other Starrett Test Equipment manuals

Starrett

Starrett SR160 User manual

Starrett

Starrett SR300 User manual

Starrett

Starrett SR160 User manual

Starrett

Starrett MTH-330 User manual

Starrett

Starrett MTH-550 User manual

Starrett

Starrett MTH-110 User manual

Starrett

Starrett SR200 User manual

Starrett

Starrett SR160 User manual

Starrett

Starrett DFC-2 User manual

Popular Test Equipment manuals by other brands

Progressive Electronics

Progressive Electronics PE395 instruction manual

Viavi

Viavi IFR 6000 Operation manual

Martindale Electric

Martindale Electric HANDYPAT HPAT500 instruction manual

MULTILANE

MULTILANE AT4039EML user guide

TESTING

TESTING RA 100 Concrete operating manual

Wetekom

Wetekom Scan 20000 instructions