Status Pro Belt Tension Pro User manual

1

OPERATING INSTRUCTIONS

BELT TENSION MEASUREMENT SYSTEM

VERSION 2.2

2

Table of contents

Introduction .............................................................................. 3

Safety guidelines ...................................................................... 3

Notes on batteries/Rechargeable batteries.................................... 4

Instructions on caring for the instrument ...................................... 5

Maintenance ........................................................................ 5

Disclaimer .............................................................................. 5

Intended use ........................................................................... 6

Delivered items ....................................................................... 6

Product advantages................................................................... 6

Preparation measures ................................................................... 7

Connecting the measurement probe ............................................... 7

Operational elements ................................................................... 8

Overview ............................................................................... 8

Operating buttons..................................................................... 9

Operation ................................................................................10

General information on "belt tension“ ...........................................10

Measuring the belt span tension ................................................10

Measuring the belt tension .........................................................11

Measurement procedure ............................................................... 12

Checking the measurement probe – Frequency test............................12

Notes on positioning the measurement probe...................................13

Measurement step ...................................................................13

Measurement evaluation, green-yellow-red .....................................14

Storing measurements............................................................... 15

Procedure: ......................................................................... 15

Calling up stored measurements ..................................................15

Procedure: ......................................................................... 15

Switching off the instrument.......................................................15

PC-Software belt database (optional) ...............................................16

Belt Tension Pro PC-Software (optional) .........................................17

Appendix .................................................................................18

Specifications.........................................................................18

Menu structure .......................................................................19

Manufacturer data......................................................................20

3

INTRODUCTION

Thank you for choosing your new Status Pro measurement system - the Belt

Tension Pro.

We hope to be able to fulfill your expectations of this modern measurement

system.

Before making any measurements, be sure to read and follow the safety

guidelines and precautionary measures.

We wish you great success in using your new measurement system

SAFETY GUIDELINES

The Belt Tension Pro uses an extra bright, red LED (660 nm). For this reason,

it is not necessary to take measures to protect your eyes. However, do not

look directly into the bright measurement beam at close range.

Consider the following safety precautions.

Caution

Before making measurements, ensure that the instrument is switched off

(master switch) and secured against unintentional restarting.

• Personnel must be informed in a timely manner that measurements will

be performed.

• If necessary, clearly mark and cordon off the service area at or around the

machine, for example, by using lines or ropes.

• The measuring and setting of the belt tension must only be performed by

qualified, instructed technical staff while following the specific instruction

manual for the instrument as well as the extended documentation from

the supplier.

Caution

This instrument must not be operated in rooms with high humidity.Avoid

direct exposure to heat, for example, through sunlight. Moisture and rain, as

well as extreme heat or cold, will damage the instrument.

Note

Do not let the instrument drop or be bumped sharply. The delicate optic

s

could be damaged and the measurements made unusable.

Caution

For connecting the BeltTension Pro to a PC, only use the special BG 810000

cable. If a normal RS232 cable is used, the instrument can be damaged.

4

Notes on batteries/rechargeable batteries

If the instrument is not to be used for a long period of time, then the battery

/rechargeable battery must be removed. Otherwise, there is a risk of

discharging or ruining the battery/rechargeable battery, and consequently

damaging the instrument.

Caution

Regular batteries must not be recharged, heated, or disposed of in an open

flame (explosion hazard!).

Note

Please contribute to the protection of the environment.

Discharged batteries and rechargeable batteries should not be disposed of

along with household waste.They can be taken to collection sites for used

batteries or special waste.

Find out where these sites are located.

At the end of its service life, this product must not be

disposed of along with normal waste but must be taken to a

collection site for the recycling of electrical and electronic

devices.

The materials can be reused according to how they are

labeled. By recycling, reusing the materials or other forms of

reusing old equipment, you will make an important

contribution to the protection of our environment.

5

Instructions on caring for the instrument

The Belt Tension Pro has been developed for industrial use and is protected

against sprayed water and dust in accordance with IP55; the measurement

probe is protected in accordance with IP66. For cleaning the housing, a soft

cloth, with mild soapy water if necessary, should be used; the detector

surface should only be cleaned with alcohol.

When cleaning the detector surface of the measurement probe, do not use

paper towels or materials that could scratch the detector surface. For

optimal operational conditions, the detector surface as well as the

connections should be protected from becoming soiled or, for example, from

coming into contact with oil or grease.

Maintenance

In case of any malfunction, contact the manufacturer. Do not open the

instrument yourself.

The warranty will expire if unauthorized persons attempt to repair or

otherwise tamper with the instrument.

Storage must always take place under dry conditions.

Transport the instrument only in its original case.

Note

The manufacturer assumes no responsibility for damages that arise as result

of improper maintenance or repair work by third parties.

DISCLAIMER

Status Pro GmbH is not liable for damages that arise as a result of improper

use. Knowledge of this handbook is also part of proper use. For this reason,

strictly follow the instructions in this handbook and in the technical

documents for the sensors. We can not be liable for errors that arise due to

not following the operating instructions.

6

INTENDED USE

•The Belt Tension Pro is a precision measuring instrument for

measuring the belt tension and rotary speed of industrial machines

and units.

Note

The Belt Tension must only be used for the purposes specified above.

Unintended usage, use of unsuitable components, or modifications in

regard to intended use can lead to malfunctions in operation for which

Status Pro GmbH assumes no liability.

DELIVERED ITEMS

This Belt Tension Pro measurement instrument is delivered in a durable

plastic case. A measurement probe and a 9 V battery are also supplied.

PRODUCT ADVANTAGES

• Precise measurement of belt tension

• Precise measurement of rotary speed

• Precise calculation of belt span tension

• Built-in frequency test for checking the measurement probe

• Required for recording in accordance with DIN EN ISO 9001ff

• Operational guidance and readout of measured values in a choice of 3

languages

• Simple and reliable operation

• Compact and handy design, rubber-coated for protection

7

PREPARATION MEASURES

CONNECTING THE MEASUREMENT PROBE

Remove the measurement probe from its case, insert the measurement probe

connector into the socket on the Belt Tension Pro. Secure the connector by

tightening both screws.

Caution

Do not over tighten the two screws.

Measurement probe

8

OPERATIONAL ELEMENTS

OVERVIEW

The operating buttons in “1” control various functions. The display in “2”

shows settings and measurement results. The measurement probe “3”

registers the characteristic frequency of the tensioned, free belt by using

pulsed light or the rotary speed, and communicates the measurement values

to the Belt Tension Pro.

Belt Tension Pro Overview

1. Operating buttons

2. Display

3. Measurement probe

1

2

3

9

OPERATING BUTTONS

The operating buttons control various functions.

1. ON/OFF switch or storage of measurements

2. ENTER

3. Strand length

4. Belt mass or belt type selection; in the storage mode,

readout of measurement results

5. Arrow c: Change values - increase

6. Arrow d: Change values - decrease

1

2

3

4

5, 6

10

OPERATION

Operating the Belt Tension Pro is simple and straight forward.

GENERAL INFORMATION ON "BELT TENSION“

Measuring the belt span tension

To calculate the belt span tension or trum force, the measured values of the

belt tension, the belt mass and the belt length are input. The calculated trum

force is compared with the nominal value that is defined during the design of

the drive.

The trum force is calculated using the following formula:

F = 4 • m • L2• f2

In this formula,

F = trum force in N

m = belt mass per unit length in kg/m

L = length of the free belt strand in m

f = measured characteristic frequency of the free belt in Hz

11

MEASURING THE BELT TENSION

The belt tension can only be measured when the drive is switched off and

stopped.

Caution

Before making measurements, ensure that the machine is switched off

(master switch) and secured against unintentional restarting.

The installed and tensioned drive belt is set into natural oscillation with a

short impulse or by striking it lightly.

This static characteristic frequency is measured by the probe by using light

pulses. There must be a sufficient amount of light reflected from the belt.

By using the measured data along with the mass of the belt and the length of

the free belt strand (from the integrated belt database, for example) the Belt

Tension Pro calculates the trum force.

The readout of the measured values takes place according to the settings; for

example, frequency in Hertz or force in Newtons.

12

MEASUREMENT PROCEDURE

Please follow the instructions below. This will ensure that the measured

values are correct and will avoid erroneous measurement results.

CHECKING THE MEASUREMENT PROBE –FREQUENCY TEST

Built into the Belt Tension Pro software is an important and useful additional

function for checking the measurement probe, for example, before making a

measurement, see p. 18. During this "self-test", the Belt Tension Pro outputs a

nominal frequency of 25 Hz over the display. That is, the illumination of the

display is switched off and on at a frequency of 25 Hz. If it is functioning

properly, the measurement probe must readout this 25 Hz in the display. The

readout can vary in the range from 24.7 Hz to 25.3 Hz.

1. Switch on the Belt Tension Pro using the ON/OFF 1 button.

2. Switch to the "Freq-Test" using the ENTER button; see "Menu structure", p. 19.

3. Using the d/cbutton, switch on the frequency test; the display begins to

"flicker" at a nominal frequency of 25 Hz.

4. Hold the measurement probe up close to the display.

5. The measurement probe measures the display frequency; the result is indicated

in the display below on the right; an acoustic signal is output if the

measurement is successful.

Note

If the result deviates from the nominal value of 25 Hz (readout in display: 24.

7

– 25.3 Hz), then check the cables as well as the battery voltage.

If in doubt, contact the manufacturer.

6. Using the d/cbutton, switch off the frequency test; switch to the

measurement mode using ENTER.

13

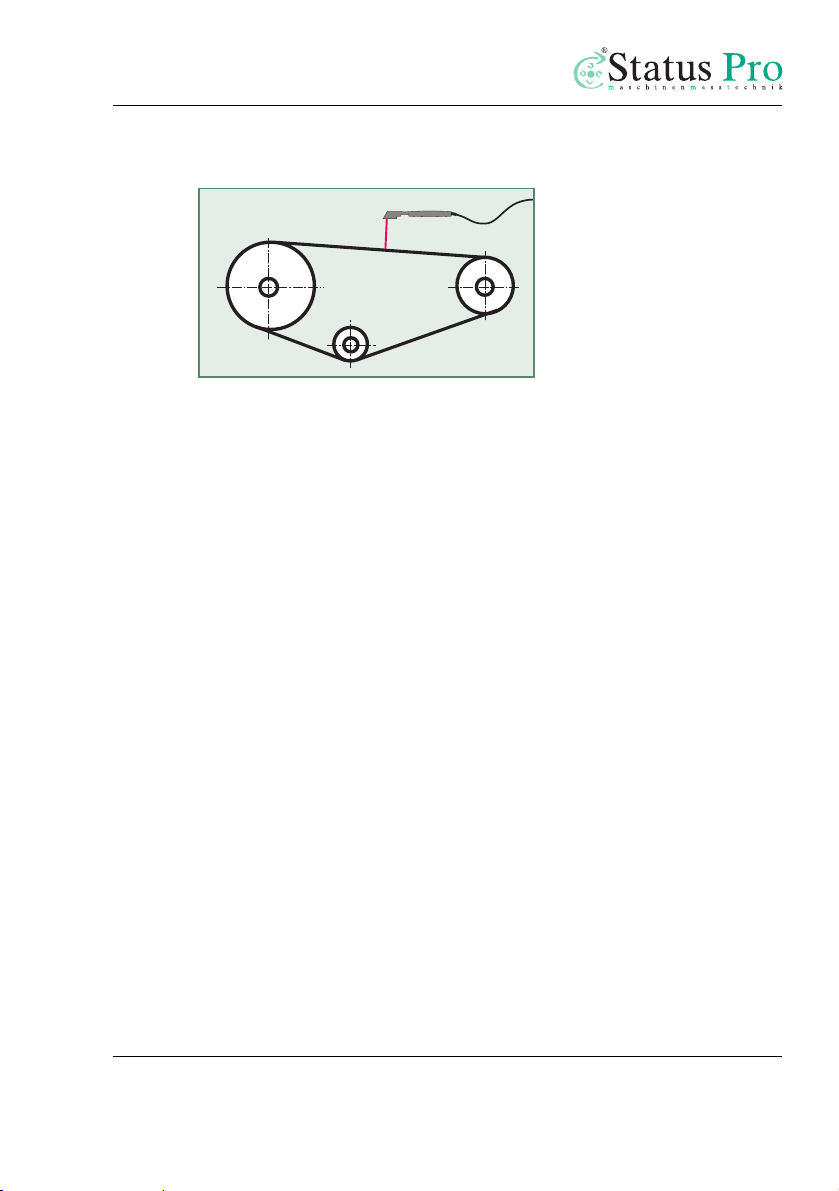

NOTES ON POSITIONING THE MEASUREMENT PROBE

The distance between the drive belt and the measurement probe should be

between 3 - 20 mm. The measurement of the belt tension should take place

at the longer strand of the belt, in the middle between the two drive rollers.

MEASUREMENT STEP

1. Switch on the Belt Tension Pro using the ON/OFF 1 button. The instrument is

ready for taking measurements.

2. Input the belt strand length and belt mass, see "Menu structure" p. 19.

3. Alternatively, select the belt data from the implemented belt database, see the

next page.

4. Set the drive belt into natural oscillation by striking it.

5. Hold the measurement probe over the drive belt at approximately the center of

the free belt span length. The distance from the belt can be between 3 and 20

mm.

6. In the display, the readout is in Newtons or Hertz. A successful measurement is

acknowledged by a longer acoustic signal.

7. If the measurement is invalid, then the message "Instab“ appears in the display;

a short acoustic signal sounds.

8. Check the setup and repeat the measurement.

9. The measured value is displayed (in Hz or N).

14

MEASUREMENT EVALUATION,GREEN-YELLOW-RED

When using the Belt Tension Pro, you will only be provided with a raw

measurement result, for example, the force in "Newtons". You can evaluate

the measurement results directly by using the indicator bar as well as the

green-yellow-red markings below the display:

The position (trend) of the indicator bar indicates if the measured values lie

below (left, belt too loose) or above (right, belt too tight) the nominal

values.

In the above example, the result is in the green area (measured value OK);

the trend shows that the force is tending more to be too small than to be too

large.

In addition, an evaluation of the measurement result is shown in the display

using distinct symbols (to the right, near the measured value):

√: = Good

+: = Acceptable

-: = Bad

Status bar with markings:

green: OK, within tolerance

yellow: result is close to tolerance

red: bad measurement result

15

STORING MEASUREMENTS

For documentation purposes, you may store the measurements that have

been made in the instrument. The instrument has internal storage for up to

255 measurements. Using the optional Belt Tension Pro PC-Software,

convenient options are available for producing measurement data reports.

Procedure:

1. Measurement performed, measured value is displayed.

2. Press button ²"ON/OFF“ 1, Storage No. X appears in the display.

3. Using TSarrow buttons 5, 6, select Storage No.

4. Confirm with ENTER, Store? appears in the display.

5. Confirm with ENTER OK or cancel using button ²"Store“ 1 Esc.

6. After storing, the message Stored in X appears in the display.

CALLING UP STORED MEASUREMENTS

You may call up measurements stored in the instrument at any time.

Procedure:

1. Press button ²"ON/OFF“ 1, Storage No. X appears in the display.

2. Using TSarrow buttons 5, 6, select Storage No.

3. Press button 4; the measurement result appears in the display.

4. If necessary, select an additional Storage No. using TSarrow buttons 5, 6 and

display using button 4.

5. To end, press button ²"ON/OFF“ 1 twice.

SWITCHING OFF THE INSTRUMENT

•Press ²ON/OFF and hold down until Off… appears in the display.

16

PC-SOFTWARE BELT DATA BASE (OPTIONAL)

There are approx. 200 data records for common standard drive belts in the

Belt Tension Pro software.

This facilitates the input of necessary belt data.

Note

Please consult the continually updated belt database at

www.statuspro.de.

1. Switch on the Belt Tension Pro.

2. Press button 4 to input the mass of the belt, see Overview p. 9 as well as "Menu

structure" p.19“.

3. Press button 4 again; now, using the T/Sbuttons, select the belt data from

the implemented PC-Software belt database.

4. Acquire the belt data using the ENTER button.

5. The instrument is now ready for making measurements.

17

BELT TENSION PRO PC-SOFTWARE (OPTIONAL)

The associated PC-Software facilitates the use of the Belt Tension Pro in

practice, and serves to evaluate measurements that have been made. In

addition, you can easily manage the belt database and customize it through

updates.

See the accompanying documentation entitled "Belt Tension Pro PC-

Software“.

Caution

For connecting the Belt Tension Pro to a PC, only use a special BG

810000 cable.

If a regular RS232 cable is used, the instrument can be damaged.

18

APPENDIX

SPECIFICATIONS

SP BELT-PRO:

Measurement range 1 - 500 Hz

Modulation 5 kHz

Sensor test 25 Hz with OK message

Readout error +/- 0.3 Hz

Resolution +/- 0.1 Hz

Operation -20°...+85°C; -68°...+185° F

Storage -40°...+105°C; -40°...+221°F

Humidity 20 .. 95 %

Housing plastic (PVC); IP20

Measurement sensor plastic; IP66

Housing dimensions WxHxD 75 x 115 x 35 mm; 2.95 x 4.53 x 1.38 inches

Carrying-case dimensions 230 x 220 x 75 mm; 9.06 x 8.66 x 2.95 inches

Display 2 line LCD 12 x 60 mm (0.47 x 2.36 in) with

background illumination

Languages language selection for three languages

Input limits free belt strand: 30 - 9,999 mm

Input limits belt mass: 0.001 - 9.999 kg/m

Number of storage locations 255

Voltage supply 9 V alkaline battery, type E-Block 6LR61

Interface RS232, DSUB9

19

MENU STRUCTURE

Set strand length

using arrow buttons

UP/DOWN

Display

Hz/N/rpm menu option

Language option

Measurement

Mode

Units option

Sensitivity

Backlight

Frequency test

System status

Contrast

Set belt mass

using arrow buttons

UP/DOWN

Safety

enquiry

Value saved,

message displayed

Saved value

shown in

display

Belt type displayed

Set belt type

using arrow buttons

UP/DOWN

Set display type

using arrow buttons

UP/DOWN

Hz, N, rpm

and press ENTER

Set language

using arrow buttons

UP/DOWN

Germ., French, Engl.

and press ENTER

Set units using arrow

buttons UP/DOWN

mm, inch

and press ENTER

Set sensitivity using arrow

buttons UP/DOWN

Value 1 ... 50

(1 = highest sens.,

50 = lowest sens.)

Set display contrast

using arrow

buttons UP/DOWN

Value 24 ... 63

and press ENTER

Set backlight ON/OFF

using arrow

buttons UP/DOWN

and press ENTER

Set frequency test ON/OFF

using arrow

buttons UP/DOWN

and press ENTER

Overview

Version

Battery capacity

Temperature

Belt type 0 set

or no belttypes saved

Set memory No.

using arrow buttons

UP/DOWN

At the lower left in the display of the Belt Tension Pro, each active function

key appears superimposed on the corresponding menu item.

20

MANUFACTURER DATA

Publication No. HB 135E

3rd edition, August 2010

Copyright 2010

Status Pro Maschinenmesstechnik GmbH

Mausegatt 19

De-44866 Bochum

All rights reserved. This handbook or parts thereof may not be copied or

reproduced in any other manner without the prior consent of Status Pro

GmbH. The technical accuracy and completeness remain reserved and can be

changed without notification. Comments on any errors in this handbook are

welcome at any time.

www.statuspro.de

Table of contents

Other Status Pro Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

AEMC

AEMC A196-24-BK user manual

Delmhorst

Delmhorst F-2000R Operation manual

AYTU BioSience

AYTU BioSience mioxsys user manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS EX602D01 Installation and operating manual

Datalogic

Datalogic VLASE IR 1109-1 42 Series user manual

Keysight

Keysight N432A Service guide