Subject to modifications

User Manual

TechnicalDescription

2.2A-10003-B06

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf •Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Page 3 of 40

Table of Contents

Page

Introduction ..................................................................... 4

Explanation of Symbols Used ............................................ 4

User’s Responsibility ......................................................... 4

Environmental Protection .................................................. 4

Service .............................................................................. 4

Safety Instructions

Appropriate Use ................................................................ 5

General Safety Instructions ............................................... 5

Regulation for Prevention of Accidents ............................. 5

Operation, Repair and Maintenance .................................. 5

Installation ......................................................................... 5

Installation

Tube Fittings, Screw-Type ................................................. 6

Main and secondary metering devices ........................ 6

Tube Fittings, Push-in Type ............................................... 6

Metering devices .......................................................... 6

Check valves ................................................................ 6

Connection of high-pressure

and pressure plastic tube ............................................. 7

- High-pressure range .................................................. 7

- Low-pressure range ................................................... 7

- Protective cap for push-in type fittings ....................... 7

Pressure Plastic Tubes and High-pressure Hoses ............ 8

Description

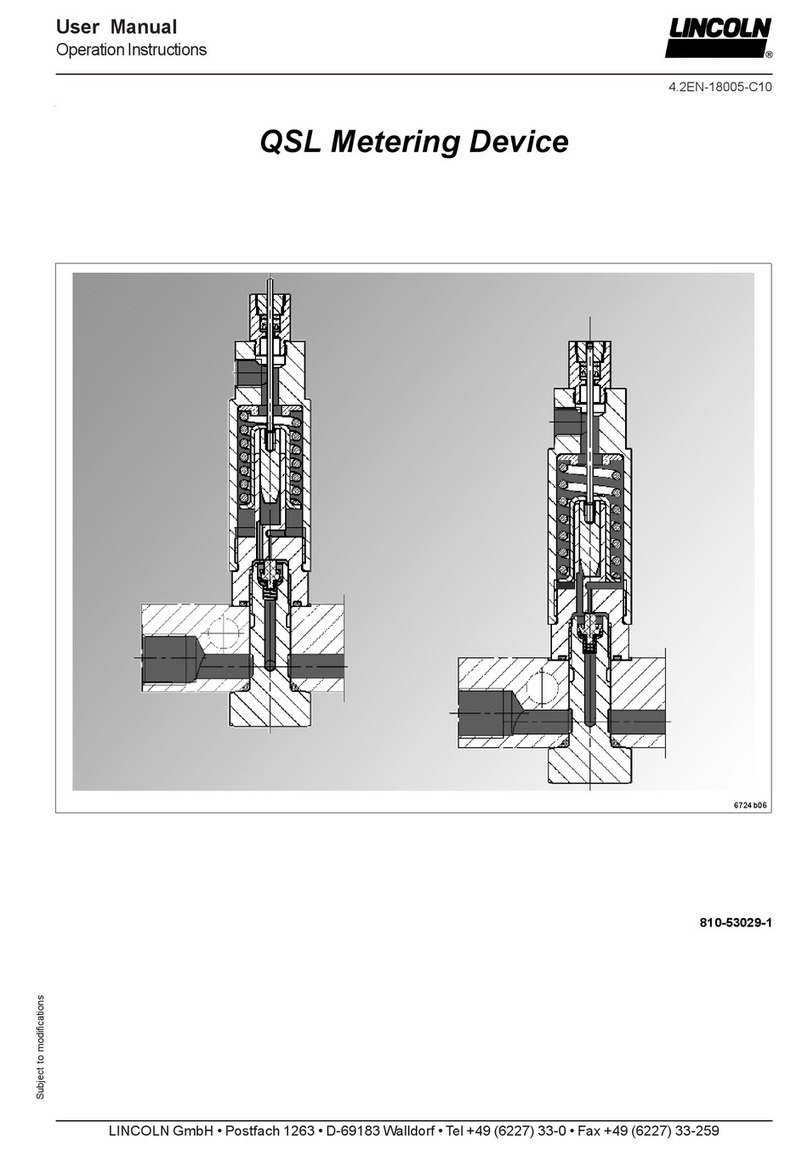

Progressive Metering Device Model SSV D ...................... 9

Progressive Plunger Metering Devices, General ......... 9

Features of a Progressive Metering Device ................. 9

Function Principle and Reliability ................................. 9

Further information can be found in the following manu-

als:

Technical Description QUICKLUB - Pump 203

Technical Description for “Electronic Control Units” of Pump

203:

Printed-Circuit Board 236-13857-1 - Variant H 1)

Printed-Circuit Board 236-13862-1 - Variant V10 - V13 1)

Printed-Circuit Board 236-13870-1 - Variant M 08 - M 15 1)

Printed-Circuit Board 236-13870-1 - Variant M 16 - M 23 1)

Installation Instructions

Parts Catalog

1) The model designation of the printed-circuit board is part of

the pump model designation indicated on the pump name-

plate. Example: P 203 - 2XN - 1K6 - 24 - 1A1.10 - V10

Page

Operation

Lubricant Distribution within the Metering Device ............ 10

General ...................................................................... 10

Metering Screws ......................................................... 10

When the lubricant supply is interrupted ..................... 10

Phase 1 + 2 ................................................................ 11

Phase 3 + 4 ................................................................ 12

Phase 5 + 6 ................................................................ 13

Phase 7 + 8 .................................................................14

Phase 9 + 10 .............................................................. 15

Phase 11 + 12 ............................................................ 16

Cross-porting of outlets, internal ................................. 17

Cross-porting of outlets, external ................................ 17

Monitoring of the Operation

System-dependent monitoring .................................... 18

Visual monitoring ........................................................ 18

Electrical monitoring ................................................... 19

Pressure relief valve ................................................... 19

Adjusting the Output by Using Metering Screws .............. 19

Adapting the Lubricant Output by Cross-porting of Outlets

Tube Fittings, screw type ........................................... 20

Tube Fittings, push-in type

(Main or secondary metering devices) ....................... 21

Planning and Layout

Instructions for Quicklub Progressive Systems................. 22

Troubleshooting ............................................................. 31

Selection Guide .............................................................. 32

Technical Data

Metering Devices ............................................................. 33

Push-in Type Fittings ....................................................... 33

Lines ................................................................................. 33

Tightening Torques .......................................................... 33

Metering Screws .............................................................. 33

Dimensions ...................................................................... 34

Metering device model SSV D 6 to SSV D 22 ............ 34

Applications

Multi-line and Progressive System ................................... 35

Extensibilities of multi-line and progressive systems .. 35

Single-nipple System, BDS (bearing dosage system) ...... 36

Extensibilities of the lubrication system ...................... 36

List of Lubricants ........................................................... 37