D2620-02-01

4~2 ELECTRICAL (Continued).

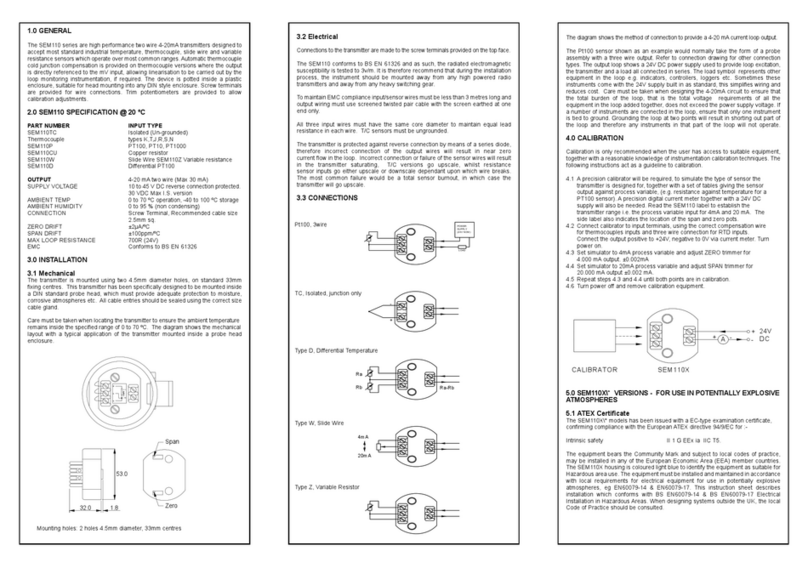

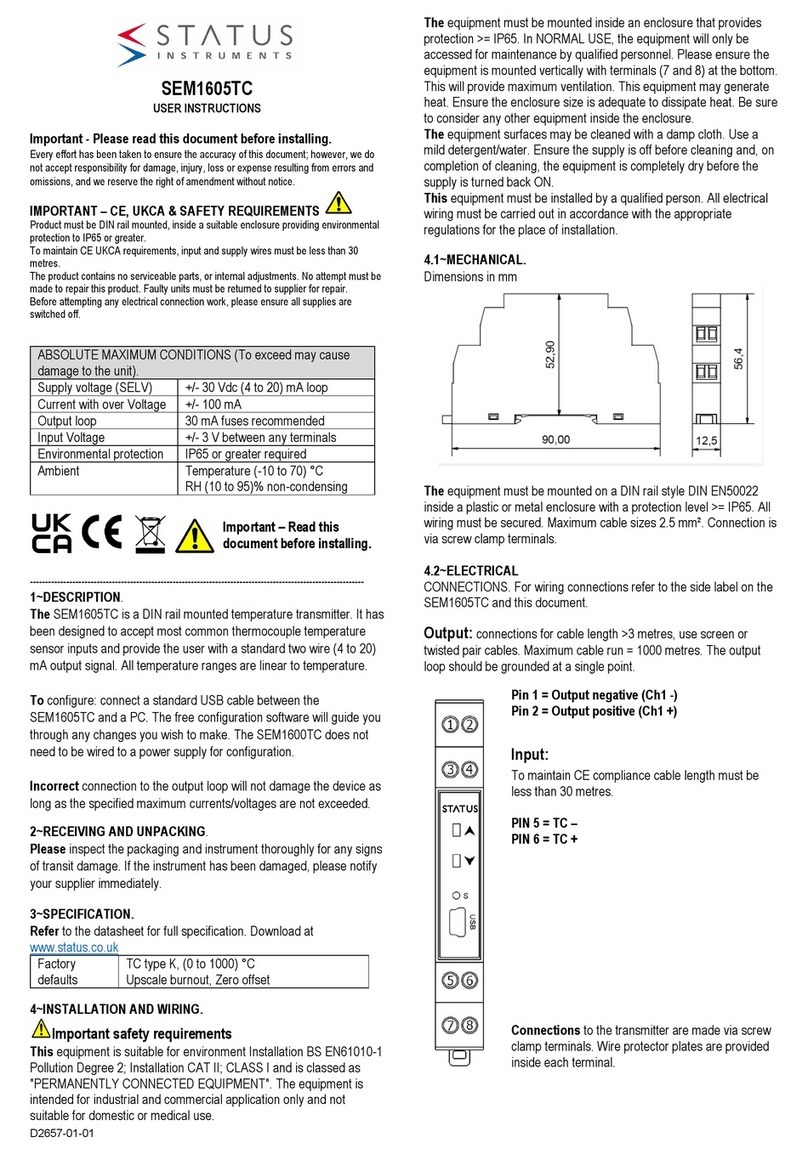

(4 to 20) mA Loop connections.

Ensure all other aspects of the installation comply with the requirements of this

document. To maintain CE compliance, the (4 to 20) mA current loop must be tied to

a local earth at one point; this is normally at the power supply.

Use twisted pair or screened cables for cable lengths greater than 3 metres.

Maximum cable length 1000 metres.

.

5~USER CONFIGURATION.

IMPORTANT

READ COMPLETE SECTION BEFORE ATTEMPTING CONFIGURATION.

WARNING

For configuring or reading live data if using a grounded input or output, it is

important not to connect the programming USB lead to a mains powered computer.

It is possible to damage the instrument if connected in this way.

To avoid damage, use one of the following methods:

•Disconnect the input and output connectors before configuration, reconnect the

connectors after configuration.

•Use a laptop-type computer running from its battery power supply, not

connected to a mains supply. This is recommended for reading live device

data or offsetting a device if already installed in the field.

•Use a USB isolator between the computer and the device.

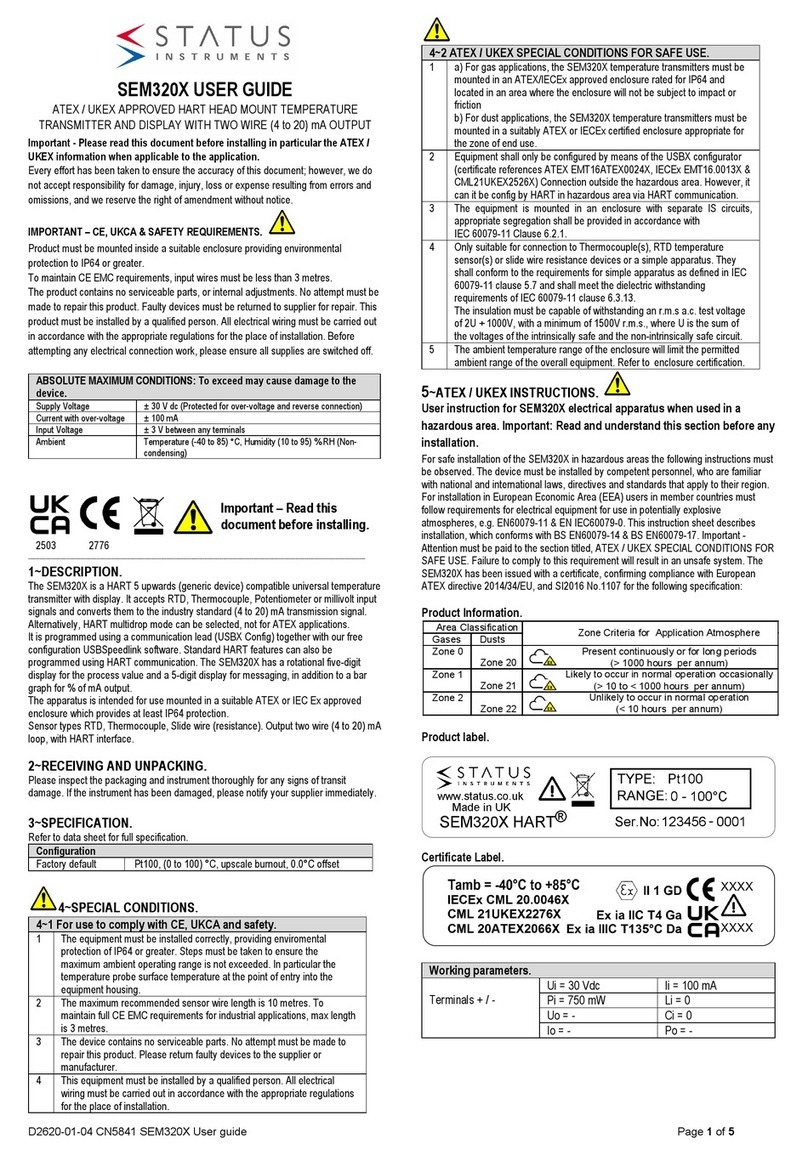

DISPLAY: The display provides five 7-segment characters for display of value and 5

14-segment characters for messages, together with a 10-segment bar graph, % of

output signal display and five icons. The display is capable of operating in an

ambient temperature range of (-20 to 85) °C, but at temperatures lower than -5 °C

(due to the slower LCD speed) scrolled messaging is not practical.

The display’s high contrast offers clear readouts at low as well as high ambient light

and direct sunlight.

The display layout is as follows:

Figure 3: Display layout.

1. Indicated HART communications

2. Main numeric value display

3. Signal out-of-range warning icon

4. Bar graph of output

5. % of output

6. Bespoke °C and °F temperature indication devices (mA not used)

display.

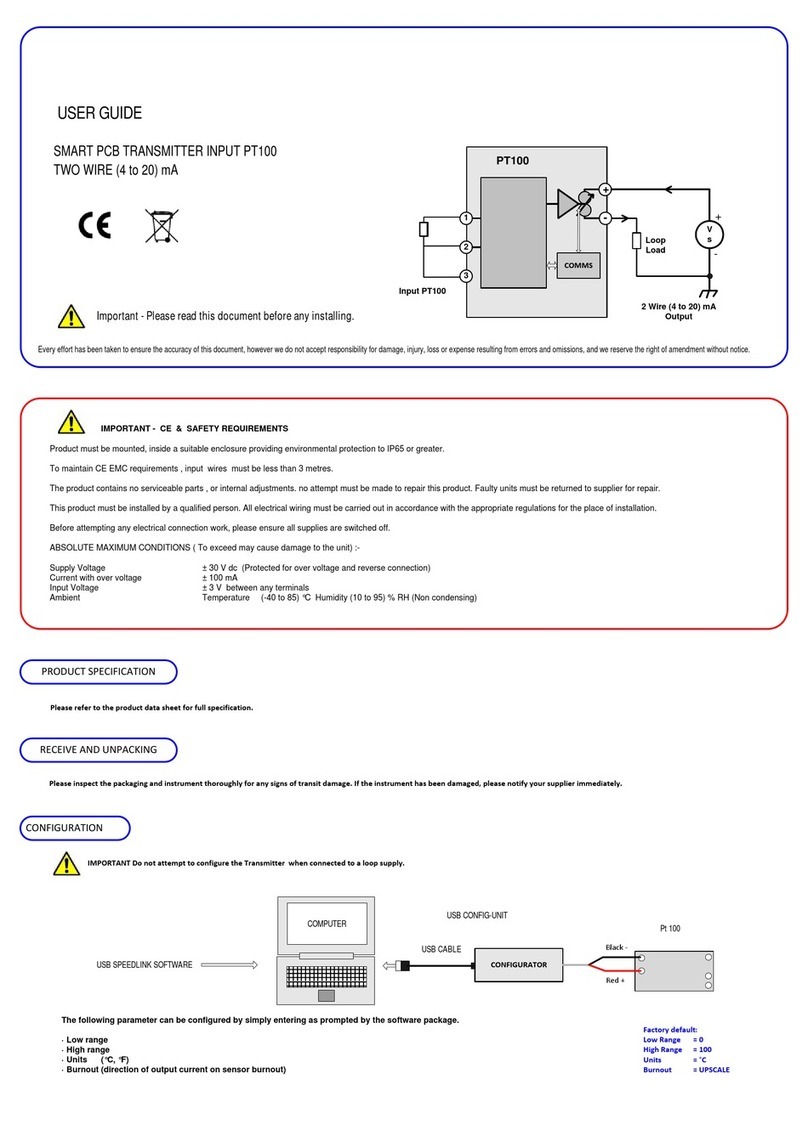

5~1 USBSpeedLink USER CONFIGURATION

A USB configuration module is required for connecting the device to the PC. Refer

to your supplier for details.

The device can be configured whilst connected and powered but a portable battery

powered computer must be used to avoid the effects of ground loops if the (4 to20)

mA loop is grounded. This may cause damage to the display device.

Figure 4: Configuration connection.

Install the software and connect the USB configuration module