D2620-01-04 CN5841 SEM320X User guide Page 1of 5

SEM320X USER GUIDE

ATEX / UKEX APPROVED HART HEAD MOUNT TEMPERATURE

TRANSMITTER AND DISPLAY WITH TWO WIRE (4 to 20) mA OUTPUT

Important - Please read this document before installing in particular the ATEX /

UKEX information when applicable to the application.

Every effort has been taken to ensure the accuracy of this document; however, we do

not accept responsibility for damage, injury, loss or expense resulting from errors and

omissions, and we reserve the right of amendment without notice.

IMPORTANT – CE, UKCA & SAFETY REQUIREMENTS.

Product must be mounted inside a suitable enclosure providing environmental

protection to IP64 or greater.

To maintain CE EMC requirements, input wires must be less than 3 metres.

The product contains no serviceable parts, or internal adjustments. No attempt must be

made to repair this product. Faulty devices must be returned to supplier for repair. This

product must be installed by a qualified person. All electrical wiring must be carried out

in accordance with the appropriate regulations for the place of installation. Before

attempting any electrical connection work, please ensure all supplies are switched off.

ABSOLUTE MAXIMUM CONDITIONS: To exceed may cause damage to the

device.

± 30 V dc (Protected for over-voltage and reverse connection)

Current with over-voltage

± 3 V between any terminals

Temperature (-40 to 85) °C, Humidity (10 to 95) % RH (Non-

condensing)

Important – Read this

document before installing.

2503 2776

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

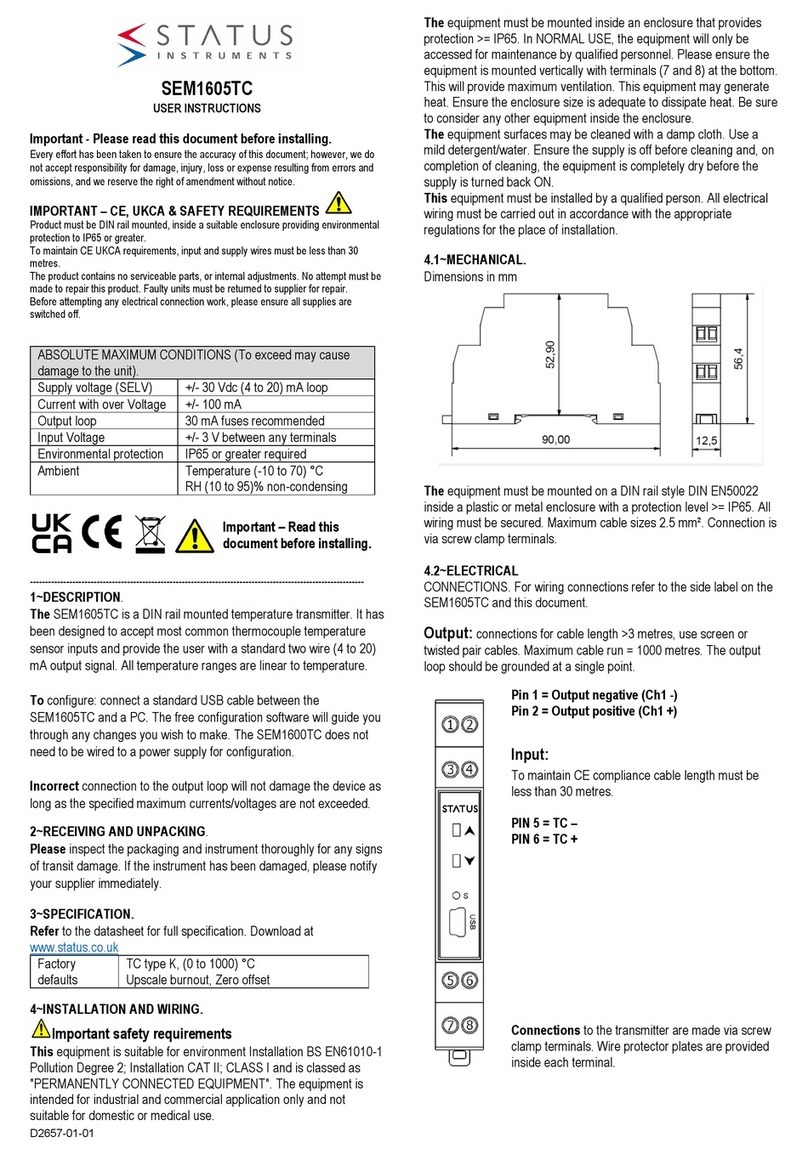

1~DESCRIPTION.

The SEM320X is a HART 5 upwards (generic device) compatible universal temperature

transmitter with display. It accepts RTD, Thermocouple, Potentiometer or millivolt input

signals and converts them to the industry standard (4 to 20) mA transmission signal.

Alternatively, HART multidrop mode can be selected, not for ATEX applications.

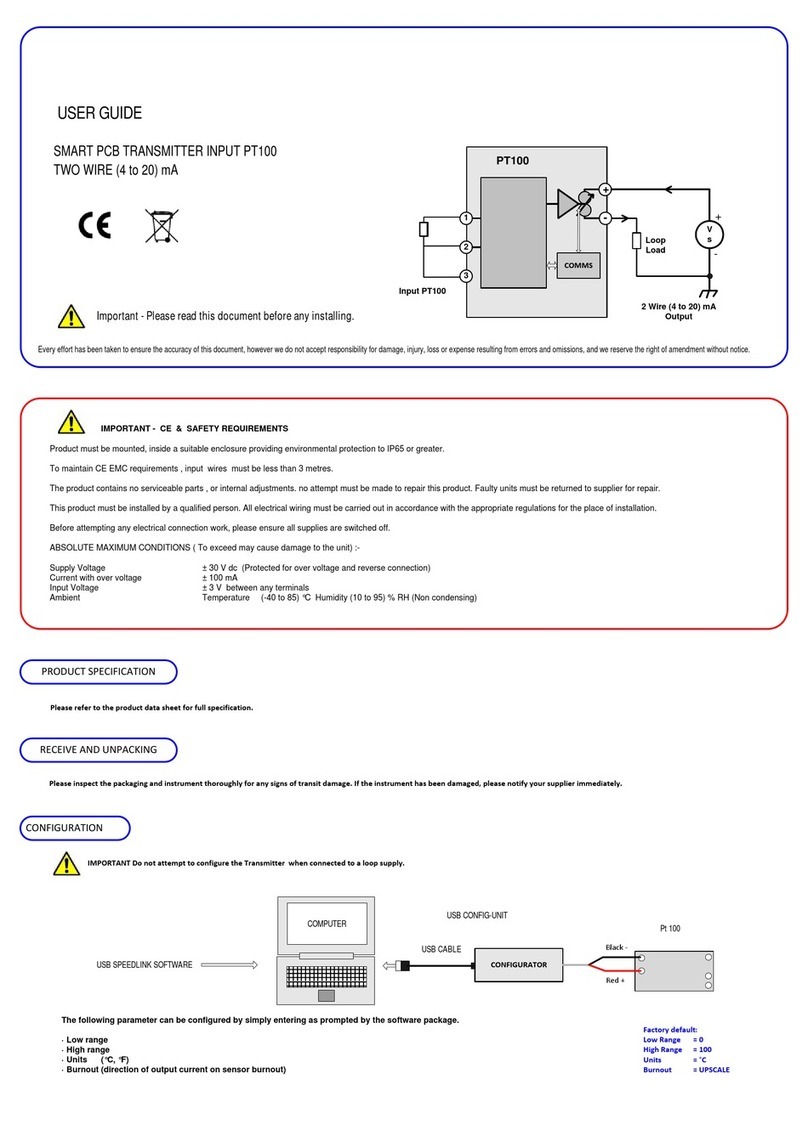

It is programmed using a communication lead (USBX Config) together with our free

configuration USBSpeedlink software. Standard HART features can also be

programmed using HART communication. The SEM320X has a rotational five-digit

display for the process value and a 5-digit display for messaging, in addition to a bar

graph for % of mA output.

The apparatus is intended for use mounted in a suitable ATEX or IEC Ex approved

enclosure which provides at least IP64 protection.

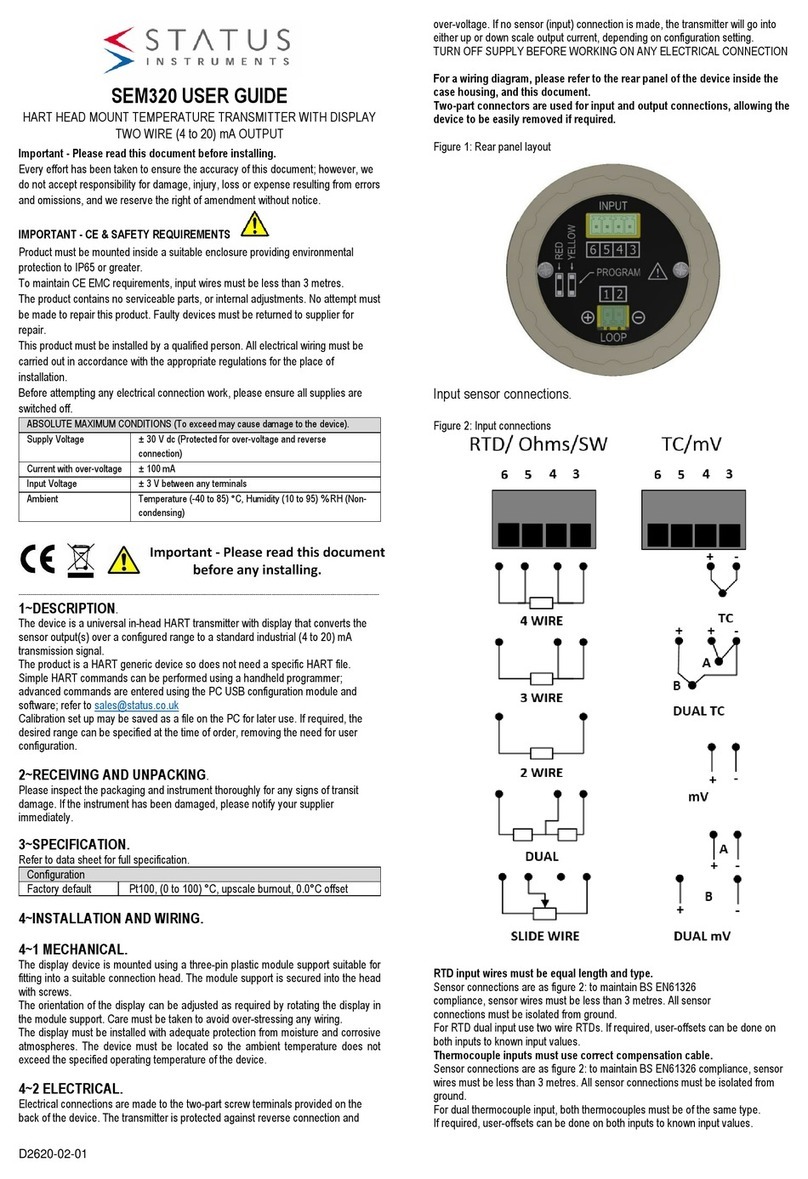

Sensor types RTD, Thermocouple, Slide wire (resistance). Output two wire (4 to 20) mA

loop, with HART interface.

2~RECEIVING AND UNPACKING.

Please inspect the packaging and instrument thoroughly for any signs of transit

damage. If the instrument has been damaged, please notify your supplier immediately.

3~SPECIFICATION.

Refer to data sheet for full specification.

Pt100, (0 to 100) °C, upscale burnout, 0.0°C offset

4~SPECIAL CONDITIONS.

4~1 For use to comply with CE, UKCA and safety.

The equipment must be installed correctly, providing enviromental

protection of IP64 or greater. Steps must be taken to ensure the

maximum ambient operating range is not exceeded. In particular the

temperature probe surface temperature at the point of entry into the

The maximum recommended sensor wire length is 10 metres. To

maintain full CE EMC requirements for industrial applications, max length

The device contains no serviceable parts. No attempt must be made to

repair this product. Please return faulty devices to the supplier or

This equipment must be installed by a qualified person. All electrical

wiring must be carried out in accordance with the appropriate regulations

for the place of installation.

4~2 ATEX / UKEX SPECIAL CONDITIONS FOR SAFE USE.

a) For gas applications, the SEM320X temperature transmitters must be

mounted in an ATEX/IECEx approved enclosure rated for IP64 and

located in an area where the enclosure will not be subject to impact or

friction

b) For dust applications, the SEM320X temperature transmitters must be

mounted in a suitably ATEX or IECEx certified enclosure appropriate for

Equipment shall only be configured by means of the USBX configurator

(certificate references ATEX EMT16ATEX0024X, IECEx EMT16.0013X &

CML21UKEX2526X) Connection outside the hazardous area.However, it

can it be config by HART in hazardous area via HART communication.

The equipment is mounted in an enclosure with separate IS circuits,

appropriate segregation shall be provided in accordance with

IEC 60079-11 Clause 6.2.1.

Only suitable for connection to Thermocouple(s), RTD temperature

sensor(s) or slide wire resistance devices or a simple apparatus. They

shall conform to the requirements for simple apparatus as defined in IEC

60079-11 clause 5.7 and shall meet the dielectric withstanding

requirements of IEC 60079-11 clause 6.3.13.

The insulation must be capable of withstanding an r.m.s a.c. test voltage

of 2U + 1000V, with a minimum of 1500V r.m.s., where U is the sum of

the voltages of the intrinsically safe and the non-intrinsically safe circuit.

The ambient temperature range of the enclosure will limit the permitted

ambient range of the overall equipment. Refer to enclosure certification.

5~ATEX / UKEX INSTRUCTIONS.

User instruction for SEM320X electrical apparatus when used in a

hazardous area. Important: Read and understand this section before any

installation.

For safe installation of the SEM320X in hazardous areas the following instructions must

be observed. The device must be installed by competent personnel, who are familiar

with national and international laws, directives and standards that apply to their region.

For installation in European Economic Area (EEA) users in member countries must

follow requirements for electrical equipment for use in potentially explosive

atmospheres, e.g. EN60079-11 & EN IEC60079-0. This instruction sheet describes

installation, which conforms with BS EN60079-14 & BS EN60079-17. Important -

Attention must be paid to the section titled, ATEX / UKEX SPECIAL CONDITIONS FOR

SAFE USE. Failure to comply to this requirement will result in an unsafe system. The

SEM320X has been issued with a certificate, confirming compliance with European

ATEX directive 2014/34/EU, and SI2016 No.1107 for the following specification:

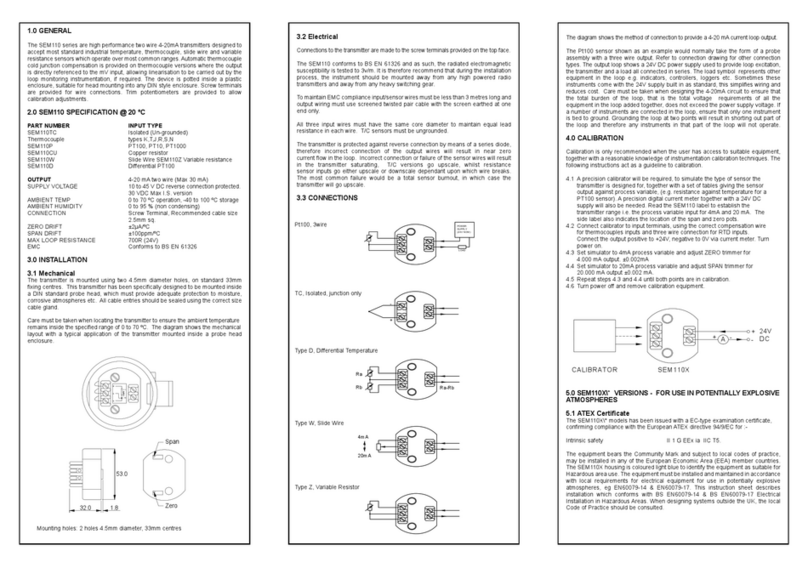

Product Information.

Area Classification

Gases Dusts Zone Criteria for Application Atmosphere

Zone 0

Zone 20

Present continuously or for long periods

(> 1000 hours per annum)

Zone 1

Zone 21

Likely to occur in normal operation occasionally

(> 10 to < 1000 hours per annum)

Zone 2

Zone 22

Unlikely to occur in normal operation

(< 10 hours per annum)

Product label.

Certificate Label.

Terminals + / -