Table of Contents Page Nu ber

Warranty......................................................................................................................................................2

Warnings..................................................................................................................................................3-4

Table of Contents........................................................................................................................................5

Specifications...............................................................................................................................................5

Uncrating the Machine.................................................................................................................................6

Contents......................................................................................................................................................6

Machine Preparation and Setup............................................................................................................6-8

Control panel and magnetic starter..............................................................................................................7

V-Belts.........................................................................................................................................................7

Handwheels.................................................................................................................................................8

Dust Collection.............................................................................................................................................8

Electrical Connections.................................................................................................................................8

Blade guard.................................................................................................................................................8

Fence Operation........................................................................................................................................9

Fence Legend..............................................................................................................................................9

Adjustment of the 9 Degree Stop...............................................................................................................9

Fence Operation..........................................................................................................................................9

Knives.......................................................................................................................................................1

Knife Replacement.....................................................................................................................................1

Adjusting the Outfeed Table......................................................................................................................1

Operation..................................................................................................................................................11

Hand Safety and Placement......................................................................................................................11

Jointing......................................................................................................................................................11

Direction of the grain..................................................................................................................................11

Edging........................................................................................................................................................11

Facing........................................................................................................................................................12

Beveling.....................................................................................................................................................12

Rabbeting..................................................................................................................................................12

Adjusting the Infeed Table Height..............................................................................................................13

Maintenance.............................................................................................................................................13

V-Belts.......................................................................................................................................................13

Lubrication.................................................................................................................................................13

Knives........................................................................................................................................................13

Table Leveling...........................................................................................................................................13

Troubleshooting.......................................................................................................................................14

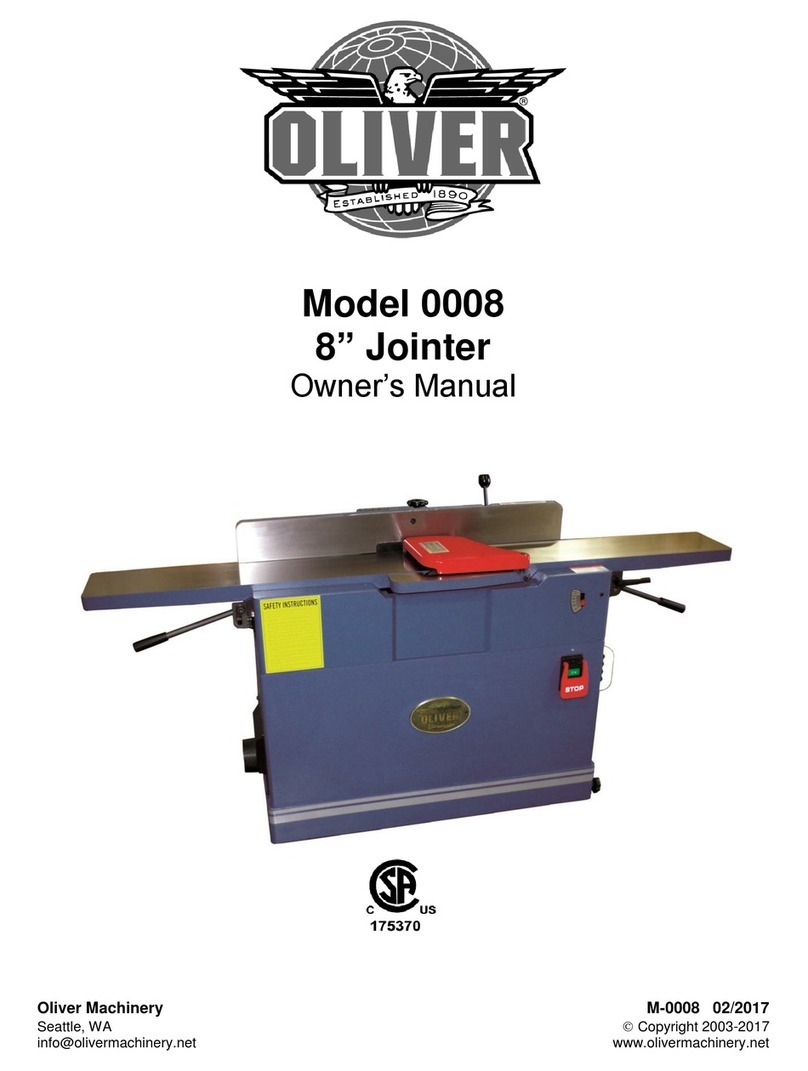

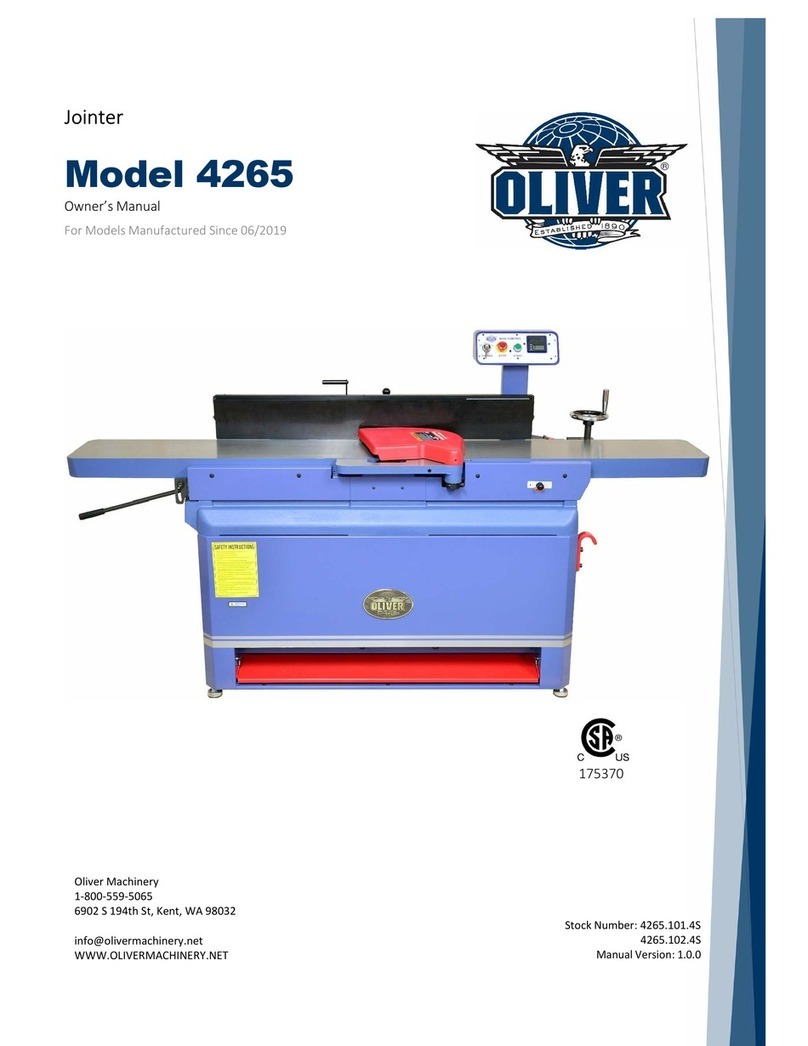

Specifications

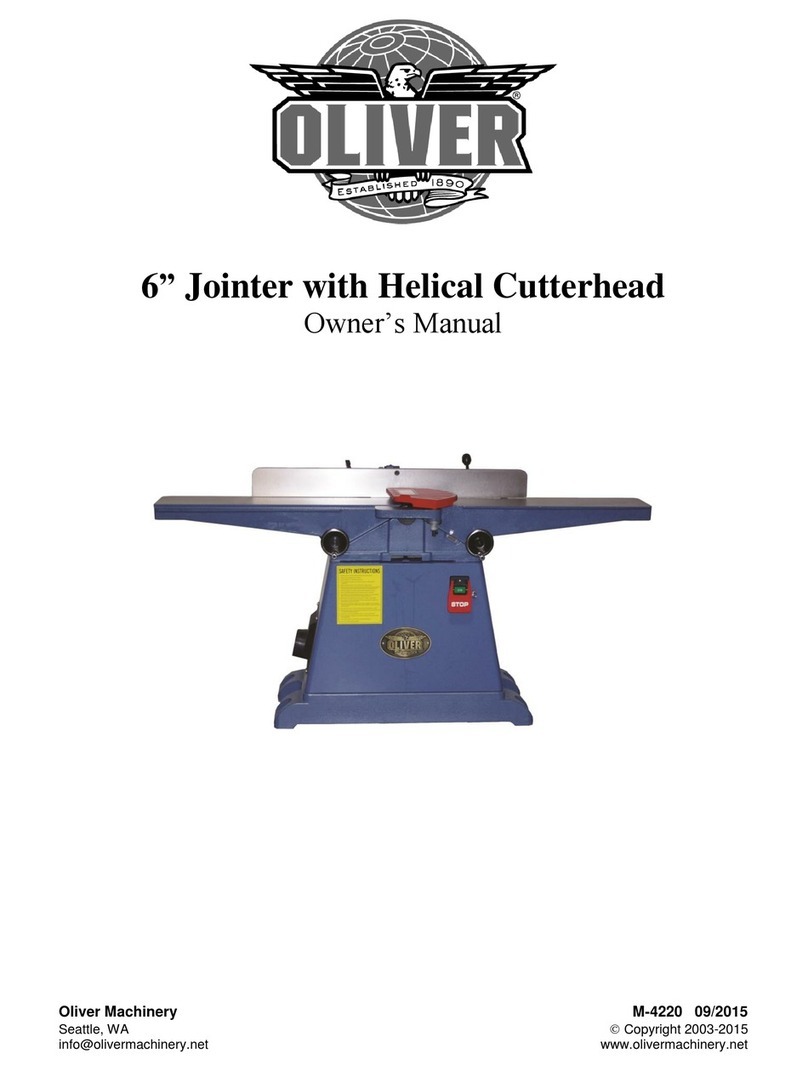

Model No...............................................................................................................................................423

Motor...............................................................................................................................2HP, 1PH, 22 Volt

Full load amps...........................................................................................................................................12

Infeed Table Travel (in.)............................................................................................................................1/2

Cutterhead speed (RPM).......................................................................................................................55

Number of Knives......................................................................................................................................54

Rabbeting Capacity (in.)...........................................................................................................................1/2

Dust Port Diameter (in.)...............................................................................................................................4

Table Dimensions (L x W/in.)...................................................................................................74-7/8 x 9-1/4

Table Height (In.).................................................................................................................................3 -1/2

Fence Dimensions (L x H/in.)...............................................................................................................38 x 4

Fence Tilts (deg.)................................................................................................................................9 - 45

Positive Stops (deg.)......................................................................................................................9 and 45

Overall Dimensions....................................................................................................................75 x 25 x 4

Gross Weight (lbs.)..................................................................................................................................572

CFM...........................................................................................................44 CFM at 45 FPM air velocity

5