- 12 - - 13 -

This is how it's done: Welding umpers

Drill a hole of approx. 5 mm in diameter at

both ends of the crack to visually mark the

crack ends and prevent further cracking.

Using an angle grinder/milling tool, remove

approx. 1 mm of material over a width of

approx. 20 mm on either side of the crack

to insert the stainless-steel mesh later on.

Using an orbital sander, now sand off the

paint across a width of approx. 40 mm all

the way round the crack.

Fit the heat guard, reduction nozzle and re-

pair nozzle to the hot-air outlet nozzle. Set the

hot air gun to 650 °C/air flow rate to speed 8

and save this setting to programme 4. The

gun is ready for use after approx. 3 mins.

While the gun is warming up, cut the stain-

less-steel mesh to size. Dimension: 10 mm

longer than the crack, extending by 20 mm

beyond the crack on either side. Round off

the corners.

Cracks with a length of up to 10 cm can

be repaired without removing the bumper.

If material has broken out of the bumper,

the damaged area should be repaired from

both sides.

Dear Customer

Thank you for purchasing the STEINE plastic

repair kit for motor vehicles. This brochure

describes a new method of repairing motor

vehicle plastics. From now on, the special

welding rod and specially developed vehicle

repair nozzle will make it easier and save time

welding a whole host of plastic components.

GB Plastic repair kit for motor vehicles

What's different a out this system?

The special welding rod can be used on all

thermoplastics. As a result, the painstaking

process of finding out the type of plastic you

want to work on now belongs to the past.

Important: the Multi-Thermoflexx welding rod

must always be used in conjunction with the

stainless steel wire mesh. It is highly flexible,

extremely resistant to stress cracking and

bonds well with all thermoplastics. Thermoplas-

tics can be worked and re-worked over long

periods.

Best results can only be achieved with the

Multiflexx welding rod by using the vehicle

repair nozzle (see "This is how it's done").

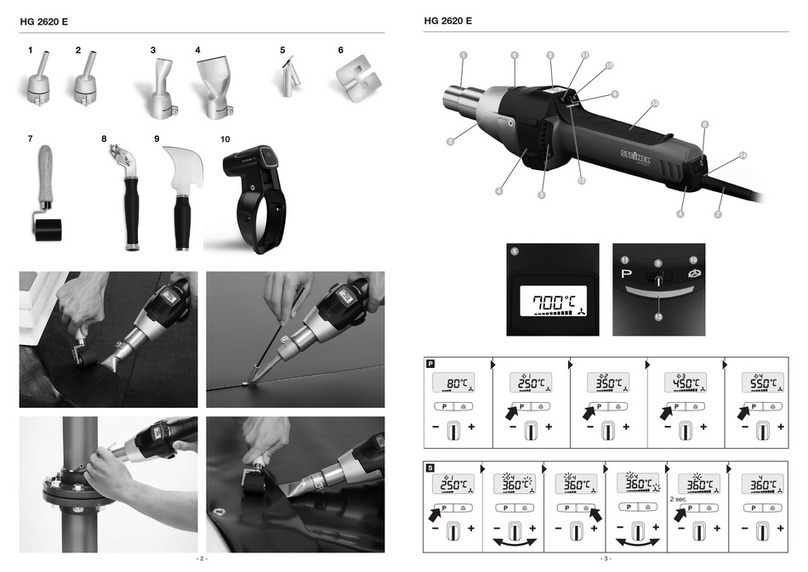

For further details on the tool and its applications, please refer to the

HG 2320 CD operating instructions.

Contents

Reduction nozzle, 9mm, Prod. No. 070601

Vehicle repair nozzle

Temperature guard, Prod. No. 076665

Multi-Thermoflexx welding rod,

Prod. No. 076467

Stainless steel wire mesh, Prod. No. 076566

HG 2320 CD

A

B

C

D

Not suitable for repairing:

– rubber parts

– pipes

– load-bearing parts

– film, foil or sheeting

Caution:

Unfamiliar plastics present a risk of

fire and poisoning. Carry out a

melting test on an inconspicuous

spot to identify the thermoplastic

material. Always ensure good ven-

tilation while working.

Do not inhale vapours.

Please note that when working

on the motor vehicle, its fuel may

increase the risk of explosion.

Always observe the safety warnings

in the operating instructions provid-

ed with the HG 2320 CD.

Additional safety notification

E

F

GB