- 6 - - 7 -

for choosing a STEINEL hot air tool.

This tool can be used for completing

a wide range of jobs safely and reli-

ably, such as soldering, de-soldering,

shrink-fitting, stripping paint etc. All

STEINEL tools are manufactured to

the highest standards and undergo a

strict process of quality control.

Used properly (please refer to the

safety precautions provided below),

the tool will give you prolonged service

and lasting satisfaction.

Thank you

Safety precautions

!

Read and observe this information

before using the tool. Failure to ob-

serve the operating instructions

may result in the tool becoming a

source of danger.

When using electric power tools, ob-

serve the following basic safety pre-

cautions to protect yourself from elec-

tric shock, the risk of injury and fire

hazards. Used carelessly, the tool can

start a fire or cause injury.

Check the tool for any damage (mains

connection lead, housing etc.) before

putting it into operation and do not

use the tool if it is damaged.

Children should be supervised to

make sure they do not play with the

tool.

Take the ambient

conditions into account.

Do not expose electric power tools to

rain. Do not use electric power tools

when they are damp or in a damp or

wet environment. Exercise care when

using the tool in the proximity of com-

bustible materials. Do not direct hot air

onto the same spot for any prolonged

period. Do not use in the presence of

an explosive atmosphere. Heat may

be conducted to combustible materi-

als that are out of sight.

Protect yourself from

electric shock

Avoid touching earthed installations and

appliances, such as pipework, radiators,

cookers, refrigerators. Do not leave the

tool unattended while in operation.

Keep your tools

in a safe place.

Place tool on stand after use and allow

to cool before putting it away.

When not in use, tools should be stored

in a dry, locked room out of the reach of

children. This tool is not intended for use

by persons (adults and children) with

physical, sensory or mental impairments

or lacking experience and/or knowledge

of use unless they are supervised by a

person responsible for their safety or

have received instructions from that per-

son on how to use the tool.

Do not overload

your tools.

Your work results and safety will be en-

hanced if you operate the tool within

the specified output range. After using

the tool for a prolonged period at max-

imum temperature, you should reduce

the temperature before switching the

tool off. This will prolong the heating

element's useful life.Do not carry the

tool by the power cord and do not pull

the power cord to pull the plug out of

the power socket. Protect the power

cord from heat, oil and sharp edges.

Pay attention to toxic gases

and ignition hazard.

Toxic gases may occur when working

on plastics, paints, varnishes or simi-

lar materials.

Beware of fire and ignition hazards.

For your own safety, only use acces-

sories and attachments that are spec-

ified in the operating instructions or

recommended or specified by the tool

manufacturer. Using attachments or

accessories other than those recom-

mended in the operating instructions

or catalogue may result in personal

injury.

Repairs must only

be carried out by a

qualified electrician.

This electric power tool complies with

the relevant safety regulations. Re-

pairs must only be performed by a

qualified electrician, otherwise the

user may run the risk of accidents.

If this tool's main power cord is

damaged, it must be replaced by the

manufacturer or its customer service

department or a similarly qualified

person so as to avoid hazards.

Keep these safety precautions with

the tool so they are always to hand.

Proper use

The STEINEL HG 350 S power tool is designed for shaping and welding plastic as well as for heating shrink-fit tubing.

It is also suitable for soldering, tin-plating and ungluing bonded joints.

For your safety

The thermal cut-out shuts the tool down if it is overloaded.

Technical specifications

Voltage

Output

Temperatures

Airflow rate

Mains power cord

Protection class

230-240 V/50 Hz

350 W

400 °C without nozzle

500 °C with reduction nozzle 7 mm (included)

100 l / min. max.

H05

I (with protective earth terminal)

The LED light 7is lit when the tool is switched on. In addition to illuminating the area you are working on, it also serves as

a telltale lamp indicating "tool ON".

LED light

Setting 1 is the cold-air stage, delivering a temperature of approx. 40 °C.

Use the cold-air function to cool workpieces or the nozzle for changing an attachment.

Setting 2 without nozzle delivers a temperature of 400 °C. A temperature of 500 °C is reached with the 7 mm reduction nozzle

attached.

Temperature setting

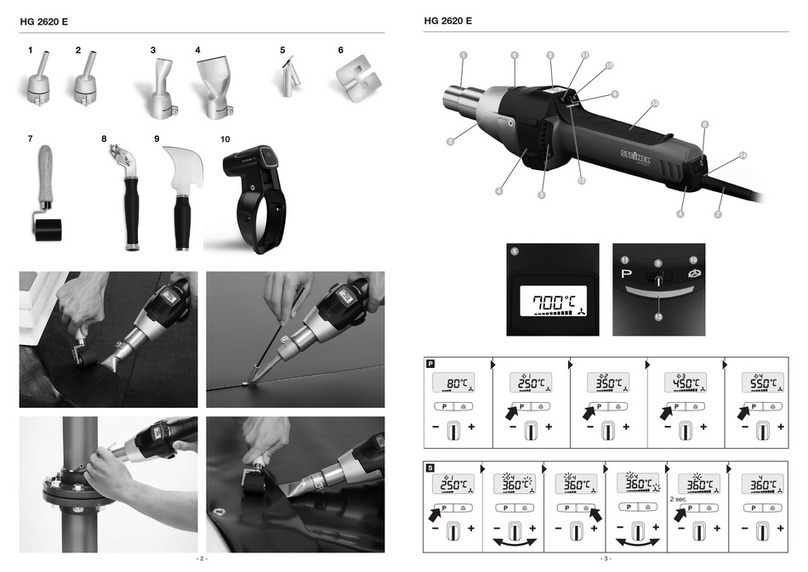

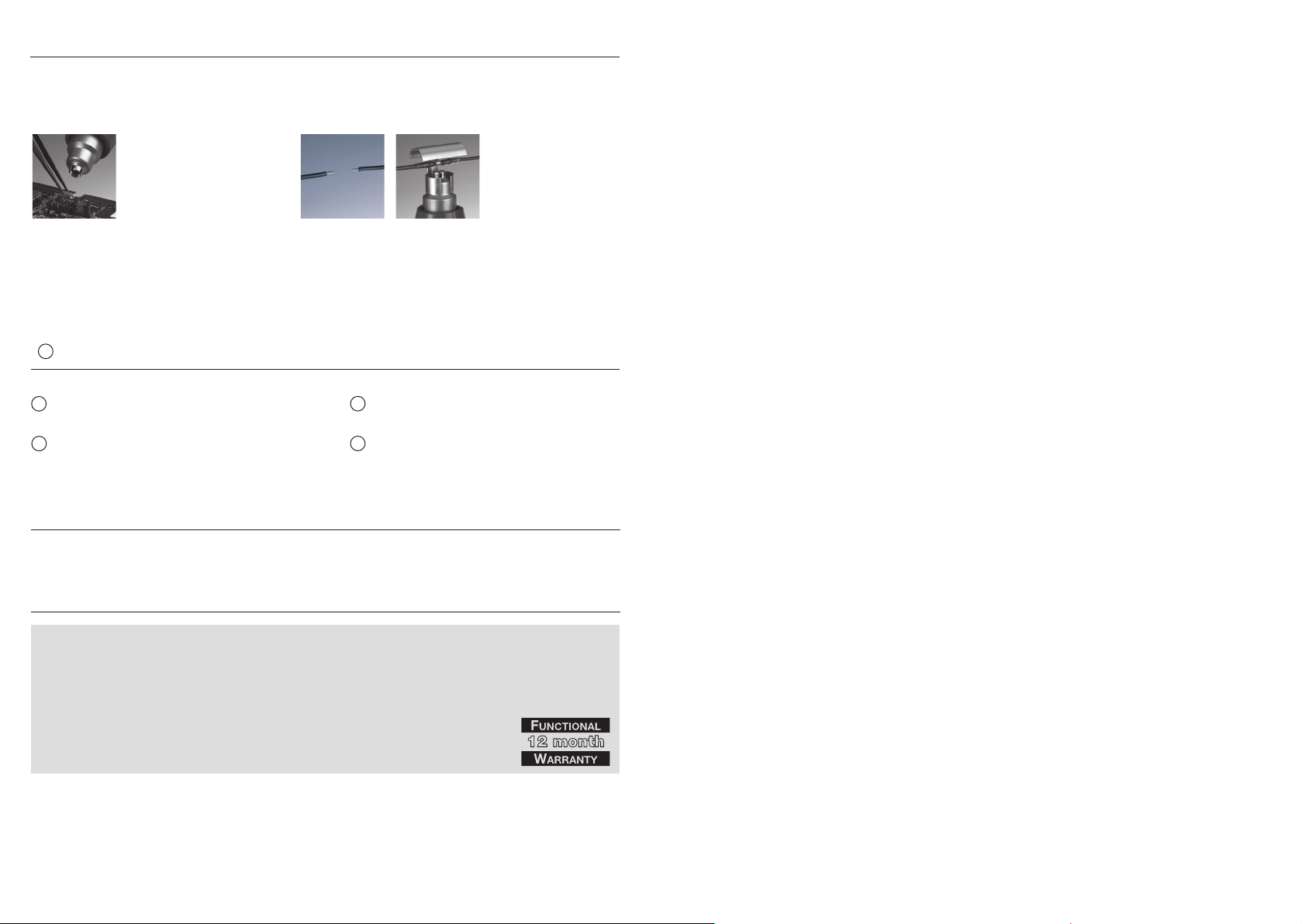

Tool description - Operation

The tool is switched ON and OFF at the 3-stage switch on the front of the grip. The distance from the object you are

working on depends on material and intended method of working. Always try out airflow and temperature on a test piece

first. Using the attachable accessory nozzles (see accessories page on the cover) the flow of hot air can be controlled

with maximum precision.

A small quantity of smoke may occur the first time the tool is used. Switch the tool OFF by setting the switch 4to the "0"

position.

Exercise care when changing hot nozzles. When using the hot air tool in the self-resting position, make sure it is standing

on a stable, non-slip and clean surface.

Operation

The integrated ring allows you to hang the tool.

Attention: max. pulling force = 150 N

Hanging ring

5

Stainless steel outlet nozzle

Air inlet with lattice guard keeps

out foreign matter

Ergonomic soft grip handle

3-stage switch

OFF/COLD/HOT

Hanging ring

Rubber sheathed cord

LED light for illuminating the area

you are working on

Temperature indicator.

Turns red as soon as the outlet

nozzle reaches a temperature

of approx. 50 °C

Reduction nozzle 7 mm

Tool features

4

1

2

3

5

6

7

9

8