Jet BD-920N User manual

Other Jet Lathe manuals

Jet

Jet JWL-1015 User manual

Jet

Jet JWL-1440VS Service manual

Jet

Jet JWL-1440VS User manual

Jet

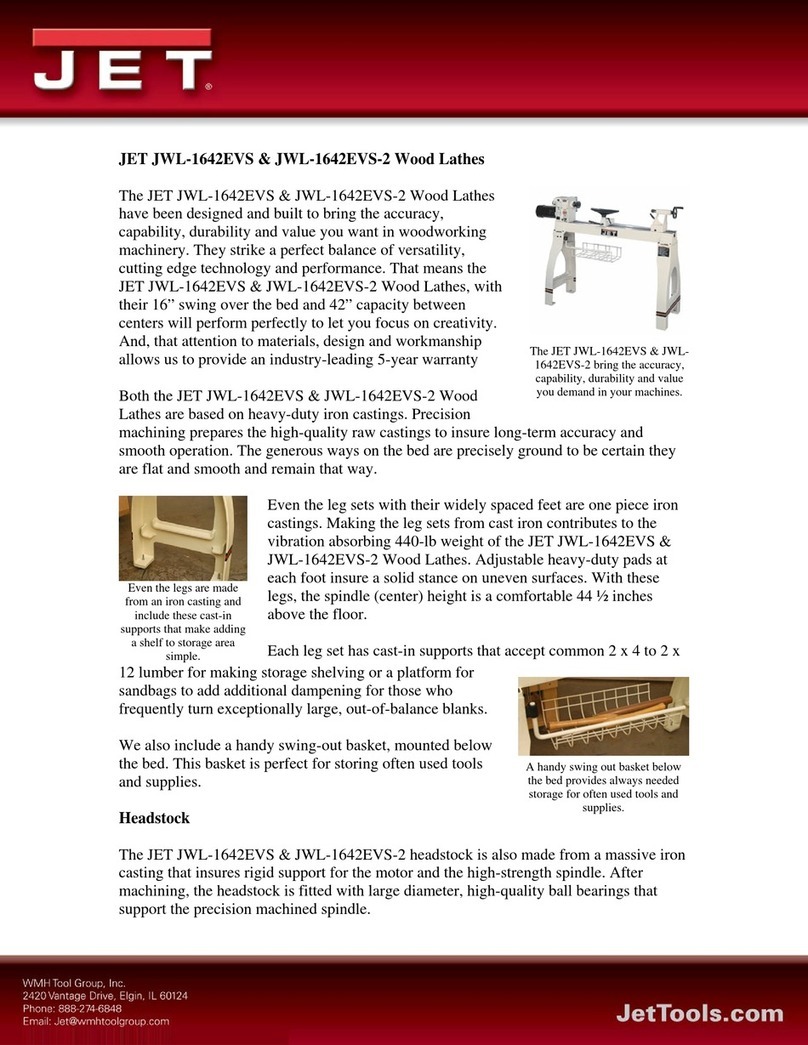

Jet JWL-1642EVS User manual

Jet

Jet BD-920N User manual

Jet

Jet GH-1440ZX User manual

Jet

Jet Elite 1700 Series Service manual

Jet

Jet GH-1640ZK Troubleshooting guide

Jet

Jet GH-1640ZX User manual

Jet

Jet JWL-1642EVS Service manual

Jet

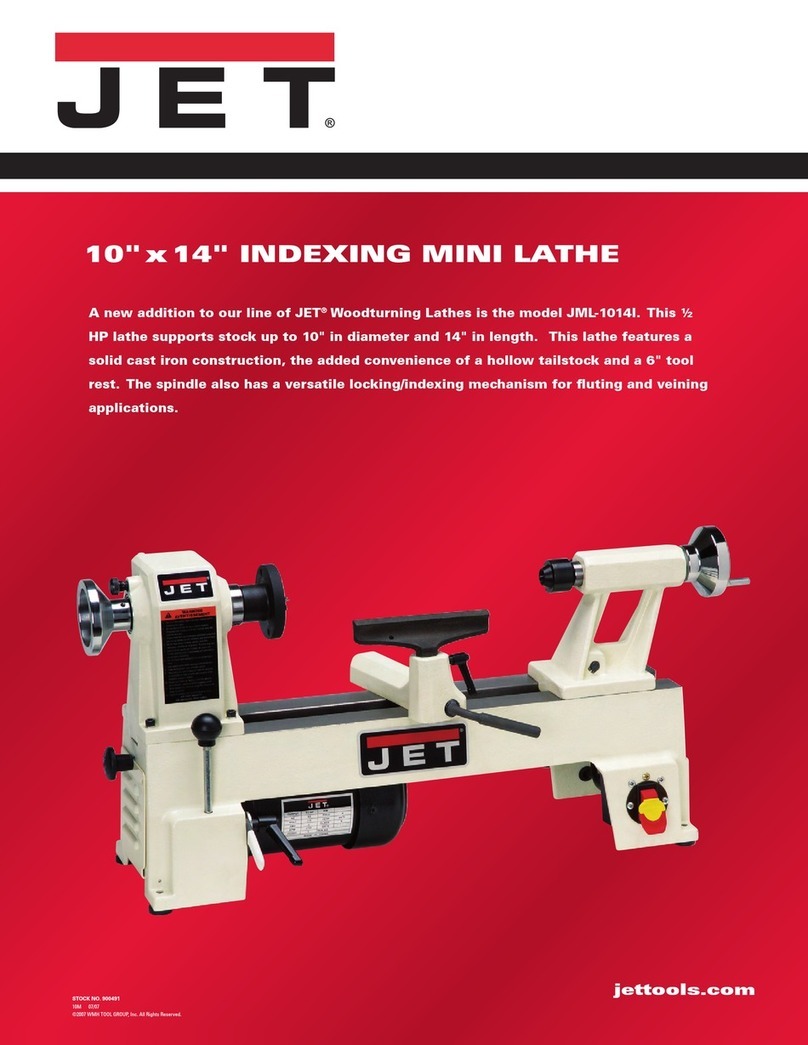

Jet JML-1014I User manual

Jet

Jet GH-1640ZX User manual

Jet

Jet EVS-1440B Service manual

Jet

Jet GH-20 ZH Series User manual

Jet

Jet Revelation Reverb V2.0 User manual

Jet

Jet JWL-1220 User manual

Jet

Jet JWL-1642EVS User manual

Jet

Jet GH-1440ZX User manual

Jet

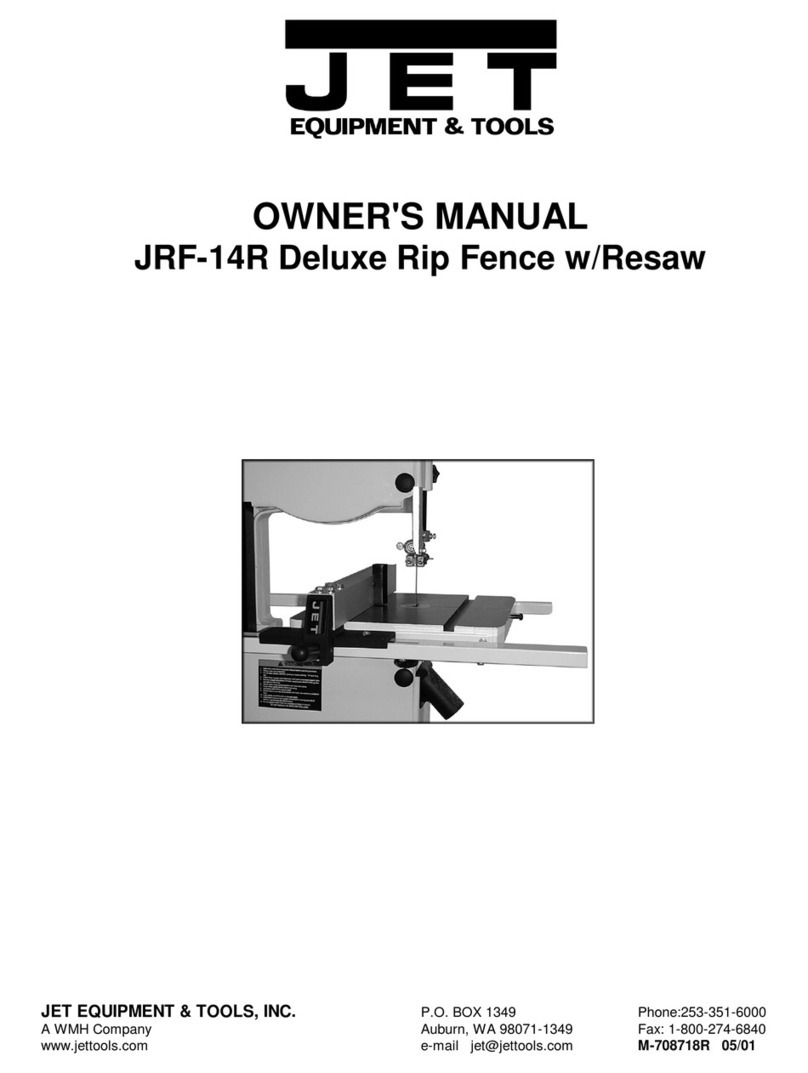

Jet JRF-14R User manual

Jet

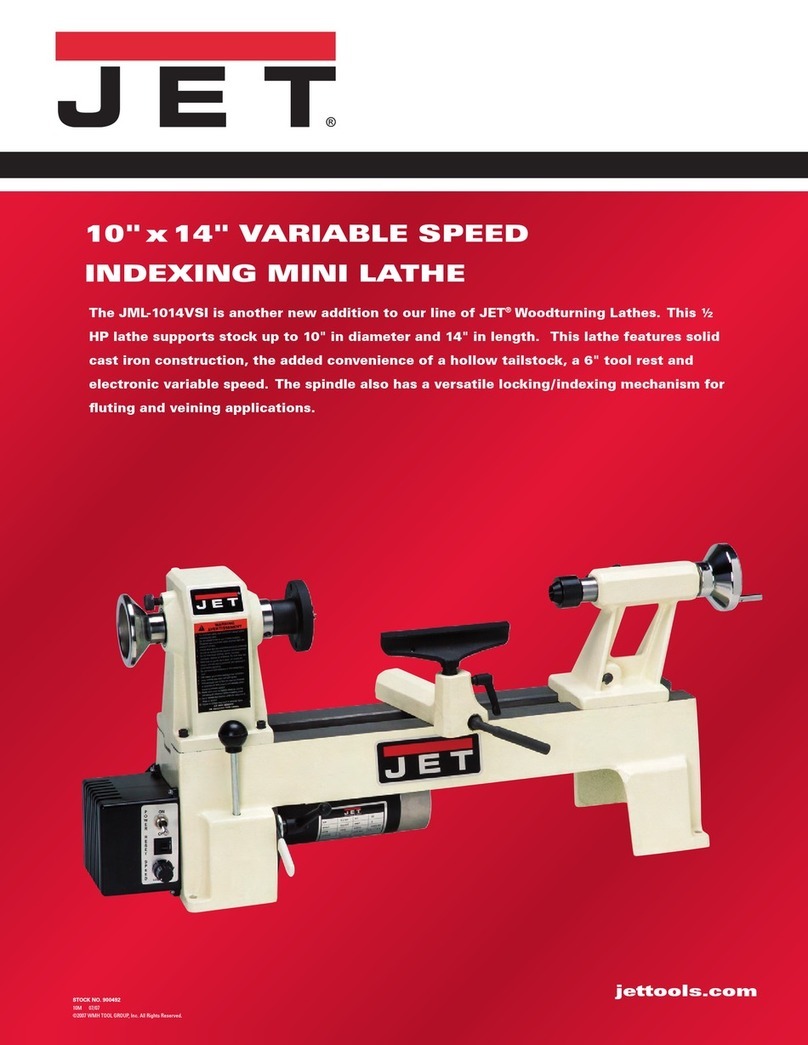

Jet JML-1014VS User manual