890383_b•en•01.05.2014We reserve the right to carry out improvements

2

Function of the Uniswitch ZL

Application example 1: galvanic isolation in case of long

control lines (Fig. 4)

An applied control command sets the floating output of

the Uniswitch ZL and triggers the move command in the

downstream device. The output remains set for the dura-

tion of the central command.

Application example 2: Formation of additional groups

in the control line system (Fig. 5)

This function is required, for example, if all sun shading

drives are centrally operated via a single push button in

one room. The Uniswitch ZL is simply inserted into the

control line and the push button is connected. The con-

nection and the mounting location of the existing motor

control units can be kept as they are, and group formation

within the downstream unit is retained as well.

Local operation

Actuation of the push button connected to the Uniswitch

ZL will set its floating outputs. The sun shading systems of

the unit that is switched downstream will travel into the cor-

responding direction and stop after 2 seconds. If the "Up/

Down" button continues to be pushed, the Uniswitch ZL

will switch to lock mode. The button may then be released.

The sun shading systems will then travel up or down to the

end position. If the movement is to be stopped during lock

mode, the button for the opposite direction of movement

must be briefly pushed. If the button is not pressed for a

duration of 3 minutes, the lock mode of Uniswitch ZL will

automatically be deactivated.

Central operation (applies to both applications):

Operation via the push buttons is blocked during a central

command. (This also applies to the push button con-

nected to the Uniswitch ZL). If lock mode is active, it is

deactivated and the central command is transmitted to the

downstream unit.

Maintenance

There are no parts within the device that require mainte-

nance.

Liability

Failure to comply with the product information in these

instructions and use of the device in a manner that con-

travenes its intended use and purpose may result in the

manufacturer refusing to honour warranty claims for prod-

uct damage. In this case, liability for consequential harm

to persons or damage to property will also be excluded.

Follow also the instructions in the operating manual of

your sun shading system. The automatic or manual opera-

tion of the sun shading system when iced over, and use of

the sun shading system during severe weather, may cause

damage and must be prevented by the user by taking suit-

able precautions.

Disposal

After its use, the device must be disposed of according to

legal regulations or brought to your local recycling centre.

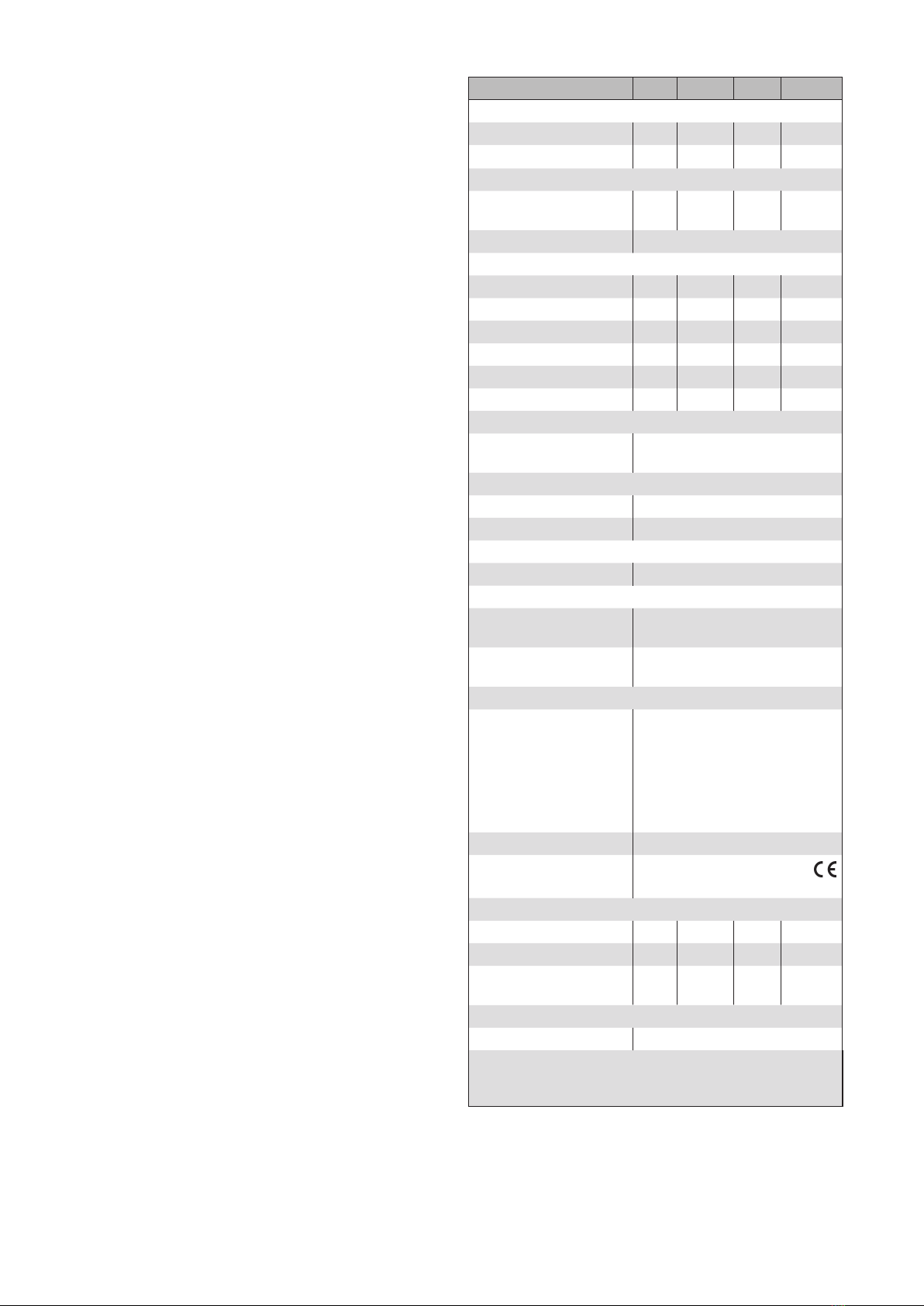

Technical data

Uniswitch ZL Min. Typ. Max. Unit

Supply 24V DC SELV

Supply voltage 18 24 30 V DC

Current consumption 13 18 23 mA

Floating output

Switching capacity at

24 V DC

72 W

Minimum load 10 mA with 5 V DC

Input control

Central voltage active 8 24 36 V DC

Central current active 0.5 1 1.5 mA

Central voltage inactive -0.5 0 3 V DC

Local voltage active 8 24 36 V DC

Local current active 0.5 1 1.5 mA

Local voltage inactive -0.5 0 3 V DC

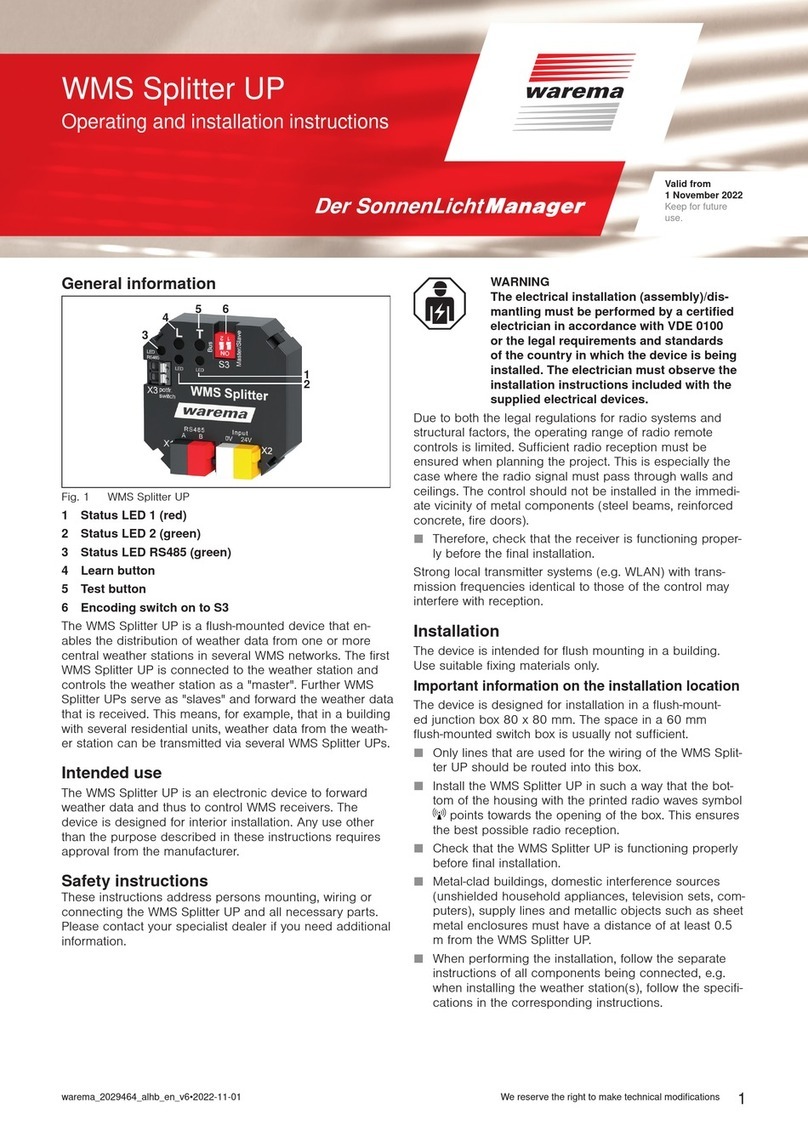

Enclosure

Dimensions Installation in flush-mounting

box, see Fig. 3

Degree of protection/safety class

In flush-mounting box IP 20

Safety class III

Connection

All connections Spring terminals

Terminals

Input,

output

0.5...1.5 mm2

Control line,

Push button line

0.2...0.5 mm2

Other

Test standards: EN 61000-6-2:2005

EN 61000-6-3:2007 + A1:2011

EN 60669-1:1999 + A1:2002 +

Corrigendum:2007 + A2:2008

EN 60669-2-1:2004 + A1:2009

EN 60669-2-1:2004/A12:2010

EN 62233:200

Location of use Clean ambient conditions

Conformity

Available at www.warema.de

Ambient conditions

Operating temperature 0 20 40 °C

Storage temperature 0 20 50 °C

Rel. humidity

(non-condensing)

10 40 85 %RH

Article numbers

Uniswitch ZL UP 1002 473

WAREMA Renkhoff SE

Hans-Wilhelm-Renkhoff-Strasse 2

97828 Marktheidenfeld