STIER SPRO 0.75T-9T Manual

1

www.indef.com

STIER SPRO RATCHET LEVER HOIST

0.75T-9T

IMPORTANT – READ BEFORE USE!

OPERATING & MAINTENANCE

INSTRUCTION MANUAL

WITH SPARE PART LIST

(Guarantee will be void if not used as instructed in this manual)

2 3

Hercules Hoists Limited ©2020

Note :- Due to continuous development and improvement specification listed above may be changed without notice

Hercules Hoists Limited ©2020

Note :- Due to continuous development and improvement specification listed above may be changed without notice

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

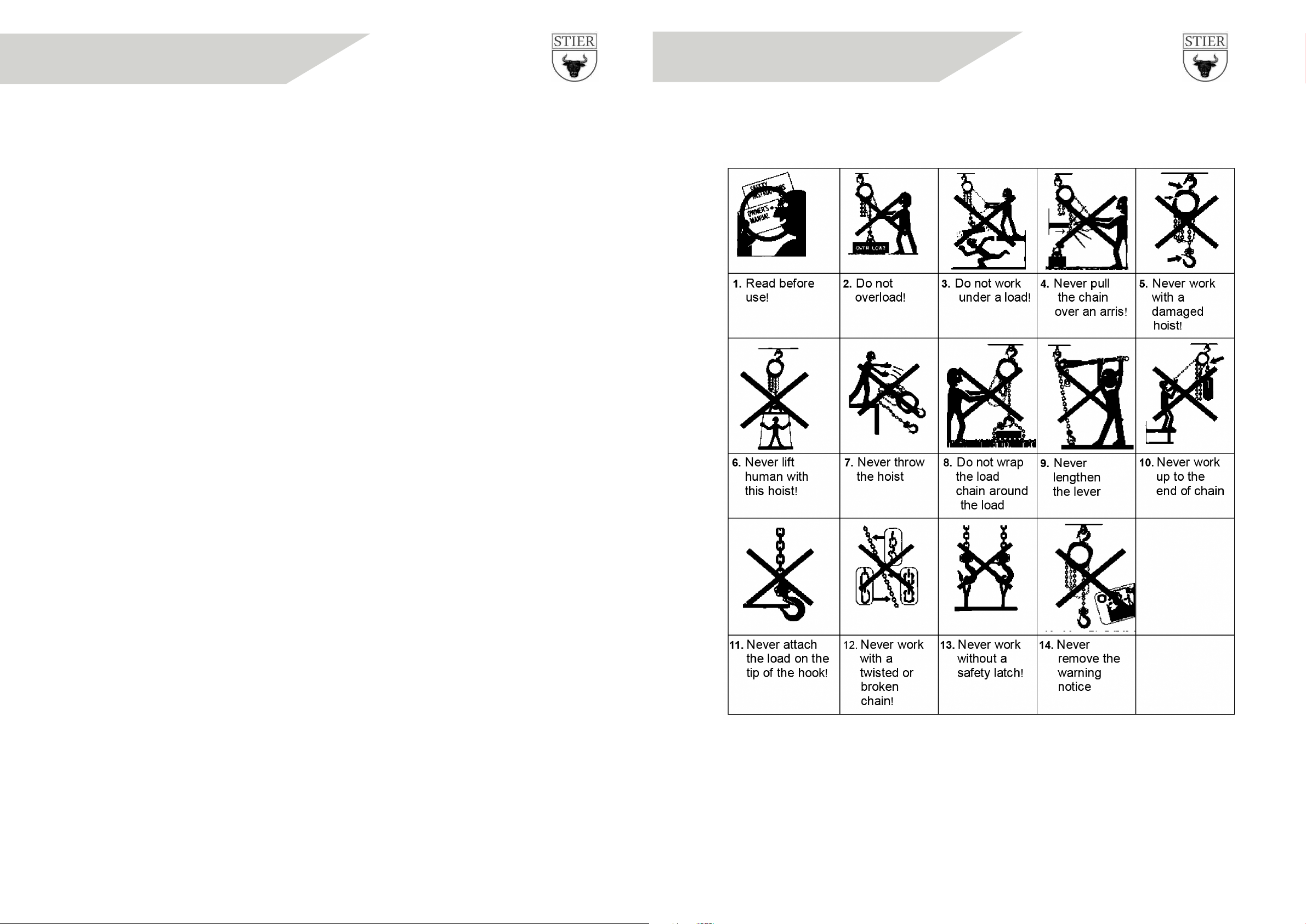

Security Warnings

INDEX

Safety

1. Generally 4

2. Name plate 4

3. Safety remark 5

4. General instructions about the safety 5

5. Operation 6

6. Installation 7

7. Operation Manual Lever Hoist SPRO 8

8. Periodic inspections, Repair and Maintenance 8

9. Service 10

10. Technical Data Manual Lever Hoist SPRO 11

11. Spare Parts For Manual Lever Hoist SPRO 12

12. Spare Parts Listing Manual Lever Hoist SPRO 13

4 5

Generally

Intellectual property

Hoist models, drawings and engineering are of our exclusive property. It is expressly forbidden

to copy, use or hand over to third parties such information without a specific written permission.

Warranty

HHL warrants to the original user its hoists to be free of defects in material and workmanship for

a period of one year from the date of purchase. HHL will repair, without cost, any product found

to be defective, including parts and labor charges, or at its option, will replace such products

or refund the purchase price less a reasonable allowance for depreciation, in exchange for the

product.

If any product proves defective within its original one year warranty period, it should be returned

to any authorized HHL dealer, transportation prepaid with proof of purchase or hoist data sheet /

test certificate.

This warranty does not apply to products which HHL has determined to have been misused or

abused, improperly maintained by the purchaser; or where the malfunction or defect can be

attributed to the use of no genuine HHL parts. HHL makes no other warranty, and all implied

warranties including any warranty of merchantability or fitness for a particular purpose are

limited to the duration of the expressed warranty period as set forth above. HHL´s maximum

liability is limited to the purchase price of the product and in no event shall HHL be liable for any

consequential, indirect, incidental, or special damages of any nature arising from the sale or use

of the product, whether based on contract, tort, or otherwise.

2. Name plate

There are, of course, some spare parts with wear which have to be replaced aer a longer operation

period. We recommend to fill in at once the following table to assure that you get the correct parts

in future. Mostly the liing hoist or trolley has passed later a tough job and you cannot read the

numbers or letters. Take the important data from the name plate or from your test certificate.

Please use only our spare parts list to order parts and mention the correct spare part number.

Since the quality of the product is being continually improved and alterations or inventions

should be latest state of art, changes of design are reserved by us without prior information. If

this manual diers in unimportant points from the real version of your hoist, we kindly beg your

pardon. The next print will include this modification. But if you mention us the serial number, year

of manufacturing or other typical design details, we should be able to find out the proper part

which you require. For further information in English language please order our English manual.

3. Safety remarks

Some works and some way of operations are not allowed with the chain hoist and trolley of any

type because they may destroy the hoist or trolley or they can do invisible damage and a later

sudden accident. They also will bring danger for life and health of the operator. So remind:

Transportation of persons is strictly forbidden.

Do not drive loads hanging in trolley hooks above persons.

Do not pull attachedloadsunder angleoraside. Only verticalliingand lowering and horizontal

movements are allowed.

Do not try to force sticking loads.

Do not attach overload willingly..

Never leave a suspended load unattended.

Never run chains over sharp edges and around corners. Use a sheave!

Do not use liing chain as a sling.

Chain hoist with push or geared trolley has to be moved by hauling the hand chain or by

pushing against the load or the bottle hook. Never pull or tear simply the hand chain.

Don not drop a load into the slack chain or hook.

4. General instructions about the safety

We have pointed out already in the introduction how important it is to mind all points of this

instruction. You should especially be aware of the regulations and laws in connection with the

product liability and insurance requests.

The Operation and maintenance manual has to be always in the near of the place of

employment. It contains important and essential aspects and extracts from the relevant

standards and precautions. Any non-observance of the guide lines and hints out of this manual

may lead to injuries or even to the death of the user of hoist or other innocent persons.

In addition to this operation and maintenance manual there are National standards, laws and

common safety senses to mind and to follow. Have also pollution and accident prevention

regulations in mind! It could also be your obligation to wear special protection suits or to use

special tools and safety devices for handling of dangerous loads.

Any working with this hoist and trolley assumes and implies the observance of the local

accident prevention regulations and the consequently action according these regulations.

Even then, following up all of this, there could be more danger from untrained or not special

advised workers using this hoist/trolley not in the sense of its originated purpose. Please make

sure that only people with education and clear senses will use it.

Please add to this chapter the instructions given by your company, i.e. regarding daily

inspections, test procedures, working processes, records, and all instructions you think that

they are helpful to prevent accidents.

All sta who will work with this liing equipment must read this booklet prior the use of the

hoist, especially the chapter about the safety instructions. This is too late during the operation

of the hoist! This is valid especially for the use of hoists only through inspection periods or

when doing seldom maintenance work with the hoist.

Model: Serial-No.:

Capacity: t Year:

Li: m Chain: mm

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

6 7

Responsible personal shall check frequently whether the sta working with the hoist is doing

it in accordance with the safety instructions.

The owner of the hoist or of the company and his management are responsible for the good

condition and for completeness of all necessary safety devices at the hoist and that it is used

only in a safe manner. The Test booklet must be properly held and it has to contain the annual

inspection check. We recommend to sign a maintenance contract with HHL who can inspect,

maintain and repair your equipment periodically.

Please set any chain hoist or trolley out of order if a failure appears in function. Call for

designated help!

The personal who works with the hoist, shall not bear long open hair, loose suits or jewels

including rings. That could eect danger of injuries or that something can be pulled into the

hoist.

Safety tags, stickers and other attached instructions at the hoists like name plates are not

allowed to be replaced, removed or over painted. All written, printed or stamped letters and

safety instructions have to be held in good readable condition. Use grease or other protection

if necessary!

Important: If this hoist or this trolley was made for manual powered operation, you are not

allowed to power it by a motorized device without prior allowance of the manufacturer.

For example: the use of an electric hand drilling machine is not allowed to be used at a reel

chain wheel.

5. Operation

Test before use

Please check whether the supplied hoist is in accordance with your purchase order, check

completeness and tightness of all bolts and nuts.

Make sure that there occurred no damages during transportation.

Copy and write down the date from name plate into your operation manual aer inspection of

the hoist and trolley.

Take fully care that the maintenance and operation manual is in reach of the personal who

works with the hoist or make sure that the supervisor has it at hand to instruct the personal.

Check or recalculate whether the supporting construction (beam, clamp etc) in which the

trolley or hoist hangs is in full compliance with the necessary capacity. If you are in doubt,

please call for help of a construction engineer for statics.

Chain hoists hanging in a trolley or even incorporated in a trolley, are cranes.

They have to comply with special standards and safety regulations. They have to be checked

by a ”crane expert” prior use. We can help you with such an expert upon your request.

Installation hint

Do not use the hoist and trolley without corrosion protection (grease) under free sky or leave

it there.

If it is necessary that the unit has to be used outside, we recommend to construct a little ”hut”

or only a roof like a ”car port“ to protect the unit against rain and other environed aggressive

influences. A new HHL-hoist is not restricted in use outside or under the described conditions,

but during the operations while chains move and wheels drive, there will be wear on metal

parts where corrosion can take eect. This is not a warranty claim! Mainly high temperatures,

high air moisture, acid atmospheres, poison steams or high dust pollution are the major

reasons why a hoist can get wear and can get a shortened life time. Mechanical moving parts

are mostly aected. Watch these parts generally and keep them greased and maintained

whenever it seems to be necessary.

When your unit will be used daily and it is important that it functions absolutely for sure,

please buy a spare unit to have it at hand in case of trouble. This avoids down time in your

production.

Do not allow the unit and chain to be exposed to extremely cold whether. Do not apply loads

to a cold chain. Temperatures below -20 degr. C or above +60 may decrease the safe working

load. Call manufacturer if in doubt!

6. Installation

Prior delivery, all units have been lubricated, tested with full load and overload and they received

a test certificate.

Hang hoist with the clamp into the load carrying system and turn once.

Hand chain and load chain must hang free and be without breaks or twists.

Operate mechanism for liing and lowering and carry out load-free test run with liing and

lowering.

Inspection of load brake: Li up lightly the load and hold it. If load is safe, go on liing. When

lowering, the load shall not slide aer hand chain shutdown or stop of the lever movement at

the lever hoist respectively.

If everything is performed properly, operation can be started.

Important for devices of multiple lines: Lower block shall not be snapped

through the chain loop. This can be recognized by a twisted chain. Each

second chain link is in one row not steadily in alignment. If the welded

seams of the chain links are not in same direction the lower block must be

struck back through the chain loop.

The last chain link must be fastened on the cabinet

Indications for the lever hoist S PRO

The top load hook of the hoist must be secured fasten to the supporting part.

Make sure that the safety latch is engaged.

Don’t use a hoist showing wear or damages.

Inspect the hoist periodically and replace worn and damaged parts.

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

8 9

Don’t support any load with the tip of the hook. The hoist is very dangerous if you over load it.

When you feel the operation hand force is obviously bigger than the eort under liing

permissible capacity, you should stop the operation immediately and ask the technical

personnel for checking. Because you could be in overloading or some parts have been

damaged.

Chain freewheel must be switched o before liing.

Never load the lever hoist with switched on free-wheel!

Do not li a load simultaneously with several lever hoists

Click sound of safety catch is normal when the load is lied.

The brake grabs permanently – independent from traction direction

(Liing or lowering)

Exception: In case of switched freewheel. – Never switch to freewheel under load!

Never hang on the rubber protection handhold!

7. Operation manual lever hoist PLH premium PRO

Fast Fast shortening of load chain:

Turn change lever in central position and hand wheel

clockwise; or set control lever to LOWER. The brake is

opened by fitful le-hand rotation of hand lever. Set

control lever to and pull through chain with little manual

force

Li/Pull/Clamp

For Liing/Pulling/Clamping tighten load chain and set

control lever to Li, for lowering (or loosening during

clamping) of load set control lever to LOWER.

Operation by settled, continuous pump movements of

device lever.

Brake closes independently when hanging on the minimal

load (appr. 10% of nominal load).

Warning: Do not attempt to select freewheel under load.

8. Inspections, Repair and Maintenance

When you detect during the disassembling of your hoist that some parts are worn or damaged,

please replace them by original new parts. The name of the spare parts are found in the spare

parts list and the spare parts drawings which are attached some pages later. Please mention the

correct spare part number, the description and the capacity of the hoist. If you are in doubt, send

defect part to us.

Chain and Hook Test

Demounting of the load chain (Item 44): Unload the device.

Disassemble the chain end link (pos. 71) and put it aside. Pull out the

chain by using the freewheel. Inspect the chain, the chain end link

and the hook.

Please check the chain regularly at short intervals. Pay attention to

wear, notches, sectional deviations, corrosion and other damage.

Check if the chain is running properly on the chain sprocket as follows:

The chains and clamps have to be inspected continuously!

Clean chain before inspection. Lubricate load chain from time to time a bit! Never lubricate or

grease the brake!

Retracted chain shall not click under load.

Check chain for tension! The internal length (t) of a worn chain link, smallest diameter of wire

(D) and length of 11 chain links (a) are measured by a slide gage where the chain must be

tightened firmly.

Dimensions: If the deviations of measurement exceed the values (a) in the following table

substitute chain immediately. Measure of diameter (D) shall not be under run and the splitting

(t) of the single link not be exceeded.

In case if the chain needs replacement it is assumed that the chain sprocket is also aected. This

must also be checked for wear.

Hook test (pos. 45 and 50): Hooks can get bent or extended due to heavy loading and wrong

handling of the equipment. The following table indicates when the hook needs replacement upon

exceeding dimension “G“. If this is the case, then the overloading has also damaged other parts

and the hoist needs to be checked thoroughly for deformations in all related components.

Because of the tolerances of the forged hooks, the actual dimension “G“ has to be measured

at the particular device by the operator and to be registered in the following list before

bringing it into service.

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

Max. Measurement of Min. chain link

Capacity 1 chain 11 chain diameter (D)

link (t) link (a)

800 kg 18.0 mm 193.7 mm 5.0 mm

1600 kg 22.4 mm 237.9 mm 6.4 mm

3200 kg,

6400 kg, 29.4 mm 317.2 mm 9.0 mm

9600 kg

10 11

Exception: All parts of the brake system are not allowed to be greased!

When not in use hang the lever hoist at a dry place.

Please note that a faultless and safe use is only warranted with the use of original spare parts. If

you want your device to be inspected or maintained within the warranty, please send it back in an

assembled state.

Returns of devices in a disabled state void all warranty claims.

Expert inspection:

All STIER lever hoists are subject to the Regulations of the UVV/BGV D 8 and have to be inspected

once a year by an expert. The entrepreneur has to proof the inspection.

Measurement must be carried out as follows:

Measure “G“ from metal to metal in the hook opening, not including the hook safety latch.

The abrasion of the hook surface should not exceed 10 % of the actual value.

Determine the lateral torsion of the hook! In case of torsion exceeding 10 degrees beyond

plane level, the hook must be replaced.

Check the hook security catch for tight closure and smooth operation! If negative, replace!

Excessive damage due to chemical or corrosive influences require replacement of the hooks.

Do not repair a hook by welding or grinding!

To check the hook for freedom from cracks, a fluorescent medium test is carried out. Cracked

hooks need to be replaced.

These tests are to be carried out specialists for hoisting equipment only. In case of unavailability

please contact your supplier. We perform such regular tests, also within the framework of

Maintenance Agreement.

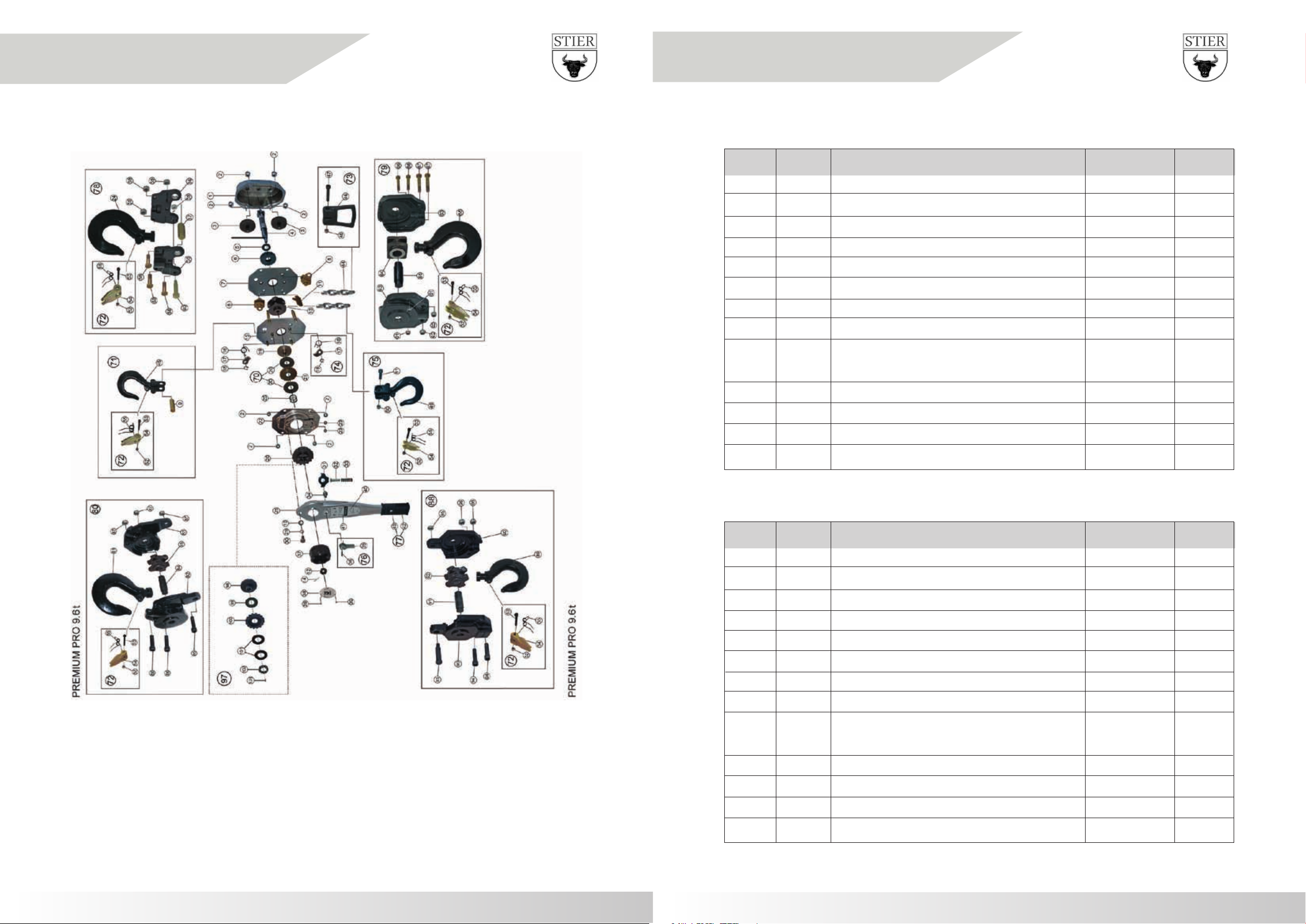

Disassembly of the brake: Please make use of the Spare Parts List!

Follow the sequence in the explosion representation and dismantle it from right to le. Check

lever handle, free knob, hand wheel, pawl, select lever, brake disks, ratchet wheel and feathers for

deformation and wear as previously described under disassembly.

9. Service

Aer using the device please consider:

Switch the selector lever to its middle position.

Wipe o dust and water, grease chain and all rotating parts of the hook a little.

Check for functional capability of the safety latch.

From time to time – dependent on the frequency of use – the lubrication of the gear wheels has

to be checked.

Grease Directive:

Lubricate all movable parts (gear wheels etc.) with a thin layer of Molykote grease.

Capacity Clamp mouth opening

800 kg 31 mm – 34 mm

1600 kg 35 mm – 39 mm

3200 kg 45 mm – 50 mm

6400 kg 50 mm – 55 mm

9600 kg 50 mm – 55 mm

10. Technical data manual Lever hoist PREMIUM PRO

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

12 13

11. SPARE PARTS FOR MANUAL LEVER HOIST S PRO 1600 KG - 9000 KG 12. SPARE PARTS LISTING MANUAL LEVER HOIST SPRO 1600 kg

COMPONENT PARTS LEVER HOIST S PRO 3200 KG

Item Qty. Description HHL CODE

70 1 Friction plates assy., Item. 20 (2x) HZ0100570 Set

71 1 Top load hook assy., Item. 9, 45, 72 HZ0100571 Set

72 1 Safety latch assy., Item 52, 53, 54, 55 HZ0100572 Set

73 1 Chain end link assy., Item 46, 47, 48 HZ0100573 Set

74 2 Pawls assembly, Item 16, 17, 18 HZ0100574 Set

75 1 Load hook assy., Item 49, 50, 51, 72 HZ0100575 Set

76 1 Selector lever assy., Item 35, 36 HZ0100576 Set

77 1 Rubber grip assy., Item 42, 43 HZ0100577 Set

97 1 Overload protection assy., Item

98, 99, 100, 101 (2x), 102, 103 HZ0100597 Set

86 1 Draven Sha Assembly, Item 3,4,5,6 HZ0100586 Set

82 1 Side Plate Assembly, Item 16,17,18 HZ0100582 Set

84 1 Gear Assembly, Item 26,37 HZ0100584 Set

80 1 Load Assembly, Item 8,11,13 HZ0100580 Set

Item Qty. Description HHL CODE

70 1 Friction plates assy., Item. 20 (2x) HZ0100470 Set

71 1 Top load hook assy., Item. 9, 45, 72 HZ0100471 Set

72 1 Safety latch assy., Item 52, 53, 54, 55 HZ0100472 Set

73 1 Chain end link assy., Item 46, 47, 48 HZ0100473 Set

74 2 Pawls assembly, Item 16, 17, 18 HZ0100474 Set

75 1 Load hook assy., Item 49, 50, 51, 72 HZ0100475 Set

76 1 Selector lever assy., Item 35, 36 HZ0100476 Set

77 1 Rubber grip assy., Item 42, 43 HZ0100477 Set

97 1 Overload protection assy., Item

98, 99, 100, 101 (2x), 102, 103 HZ0100497 Set

86 1 Draven Sha Assembly, Item 3,4,5,6 HZ0100486 Set

82 1 Side Plate Assembly, Item 16,17,18 HZ0100482 Set

84 1 Gear Assembly, Item 26,37 HZ0100484 Set

80 1 Load Assembly, Item 8,11,13 HZ0100480 Set

STIER S PRO RATCHET LEVER HOISTSTIER S PRO RATCHET LEVER HOIST

14 15

COMPONENT PARTS LEVER HOIST S PRO 6000 KG

COMPONENT PARTS LEVER HOIST S PRO 9000 KG

Item Qty. Description HHL CODE

70 1 Friction plates assy., Item. 20 (2x) HZ0100870 Set

72 1 Safety latch assy., Item 52, 53, 54, 55 HZ0100872 Set

73 1 Chain end link assy., Item 46, 47, 48 HZ0100873 Set

74 2 Pawls assembly, Item 16, 17, 18 HZ0100874 Set

76 1 Selector lever assy., Item 35, 36 HZ0100876 Set

77 1 Rubber grip assy., Item 42, 43 HZ0100877 Set

80 1 Top load hook assy., Item 72, 81, 82,

83, 84, 85, 86 (3x), 87 (3x) HZ0100880 Set

88 1 Load hook assy., Item 72, 89, 90 (2x),

91, 92, 93, 94 (2x), 95, 96 (2x) HZ0100888 Set

97 1 Overload protection assy., Item

98, 99, 100, 101 (2x), 102, 103 HZ0100897 Set

86 1 Draven Sha Assembly, Item 3,4,5,6 HZ0100886 Set

82 1 Side Plate Assembly, Item 16,17,18 HZ0100882 Set

84 1 Gear Assembly, Item 26,37 HZ0100884 Set

80 1 Load Assembly, Item 8,11,13 HZ0100887 Set

Item Qty. Description HHL CODE

70 1 Friction plates assy., Item. 20 (2x) HZ0100770 Set

72 1 Safety latch assy., Item 52, 53, 54, 55 HZ0100772 Set

73 1 Chain end link assy., Item 46, 47, 48 HZ0100773 Set

74 2 Pawls assembly, Item 16, 17, 18 HZ0100774 Set

76 1 Selector lever assy., Item 35, 36 HZ0100776 Set

77 1 Rubber grip assy., Item 42, 43 HZ0100777 Set

78 1 Top load hook assy., Item 24, 56 (2x),

57, 58 (3x), 59 (4x), 60, 72 HZ0100778 Set

79 1 Load hook assy., Item 61 (2x), 62 (2x),

63 (2x), 64, 65, 66 (2x), 67 (2x), 68, 72 HZ0100779 Set

97 1 Overload protection assy., Item

98, 99, 100, 101 (2x), 102, 103 HZ0100797 Set

86 1 Draven Sha Assembly, Item 3,4,5,6 HZ0100786 Set

82 1 Side Plate Assembly, Item 16,17,18 HZ0100782 Set

84 1 Gear Assembly, Item 26,37 HZ0100784 Set

80 1 Load Assembly, Item 8,11,13 HZ0100780 Set

STIER S PRO RATCHET LEVER HOIST

16

HERCULES HOISTS LIMITED

C.T.S. No.43/2B, 43/5, 45/2, Near Naik Navre Chemicals

At Village - Dhamani, Tal. - Khalapur, Dist. - Raigad, Khopoli - 410202 (M.S.)

E-mail : csga@indef.com

Tel. 02192-662502/503/555 Fax : 02192-662504

501-504, 5th Floor , Shelton Cubix, Plot No. 87, CBD Belapur,

Navi Mumbai 400 614. Maharashtra, INDIA

P: +91 22-45417300

www.indef.com

SERVICE HOTLINE / CONTACT:

020 - 68115000 - 10 AM TO 6 PM (Monday - Friday)

service@indef.com - ANYTIME

www.indef.com/service - ANYTIME

HERCULES HOIST S LI MITE D

Issue OOO Revision R0 Revision

summary

Issue 05.09.2020 Revision Date

Date

WARRANTY VALID ONLY IF INSTALLATION CERTIFIED BY HHL AUTHORISED

PERSONNEL

PLEASE CALL - 020 68115000 TO REQUEST CERTIFICATION

OR DOWNLOAD genulne Indef APP TO REGISTER YOUR HOISTS & CERTIFICATION REQUEST

Please ask for a copy of our on-line certification report to ensure your warranty

Register your Company & you purchased Product on our App and get 3 (three month additional warranty)

CAUTION

HERCULES HOIST S LI MITE D

Table of contents

Popular Chain Hoist manuals by other brands

R&M

R&M STAGEMAKER SM5 Installation, operation and maintenance instructions

Harrington

Harrington TCS Series owner's manual

Powerfix Profi

Powerfix Profi 306852 Operating and Safety Instructions, Translation of Original Operating Manual

POWERTEX

POWERTEX Lashing Chain PLC Instructions for use

Tractel

Tractel supertirfor TU16A Operating and maintenance instruction

TMG

TMG TMG-AHL6 product manual

Bosch

Bosch 0 607 950 938 Original operating instructions

Planeta

Planeta PTM Series user manual

Verlinde

Verlinde Stagemaker SR25 2508 M1 B owner's manual

Thiele

Thiele OCTA STAR Mounting instructions

Austlift

Austlift W-4 Series user manual

Southwire

Southwire Sumner LH025 Operating instructions and parts manual