3

SECTION 2

INSTALLATION INSTRUCTIONS

2.1SAFETYPRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Takenoticeofallwarninglabelsonthemachine.Thelabels

have been put there to help maintain a safe working

environment.Thelabelshavebeendesignedtowithstand

washing and cleaning. All labels must remain legible for

thelifeofthemachine.Labelsshouldbecheckedperiodi-

callytobesuretheycanberecognizedaswarninglabels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantityrequired along with your addressand mail to:

STOELTING

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 SHIPMENT AND TRANSIT

Themachinehasbeenassembled,operatedandinspected

at the factory. Upon arrival at the final destination, the

entire machine must be checked for any damage which

mayhaveoccurredduringtransit.

With the method of packaging used, the machine should

arriveinexcellentcondition.THECARRIERISRESPON-

SIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLEORCONCEALED.Donotpaythefreightbilluntil

the machine has been checked for damage. Have the

carrier note any visible damage on the freight bill. If

concealeddamageand/orshortageisfound later, advise

the carrier within 10 days and request inspection. The

customermustplaceclaimfordamagesand/orshortages

in shipment with the carrier. Stoelting, Inc. cannot make

any claims against the carrier.

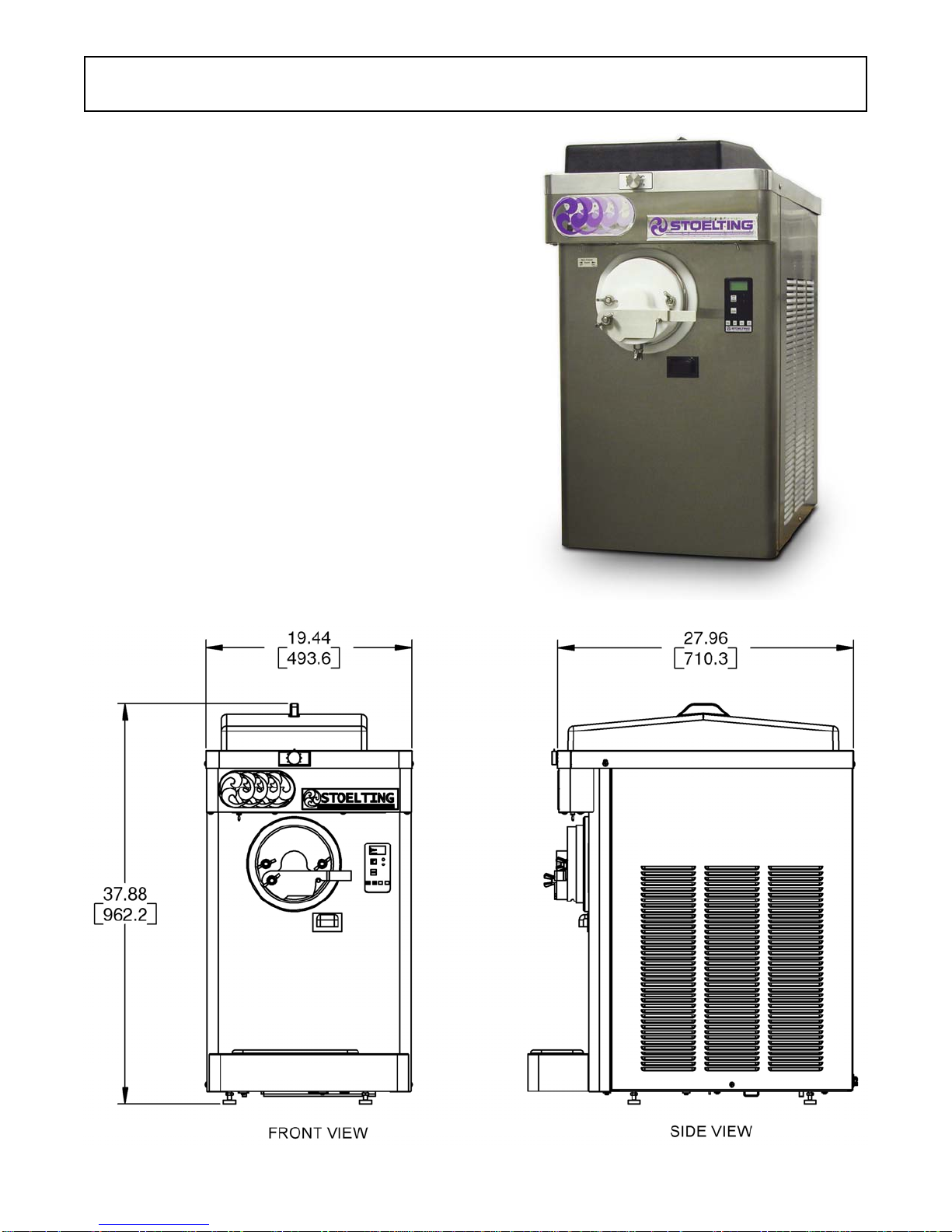

2.3MACHINEINSTALLATION

Installation of the machine involves moving the machine

close to its permanent location, removing all crating,

setting in place, assembling parts, and cleaning.

A. Uncratethemachine.

B. Accuratelevelingisnecessaryforcorrectdrainage

of machine barrel and to insure correct overrun.

Placeabubblelevelontopofthemachineateach

corner to check for level condition. If adjustment

is necessary, level the machine by turning the

bottom part of each leg in or out. Then separate

machinebasegasketandinstallwithseamtothe

back and angle to the top.

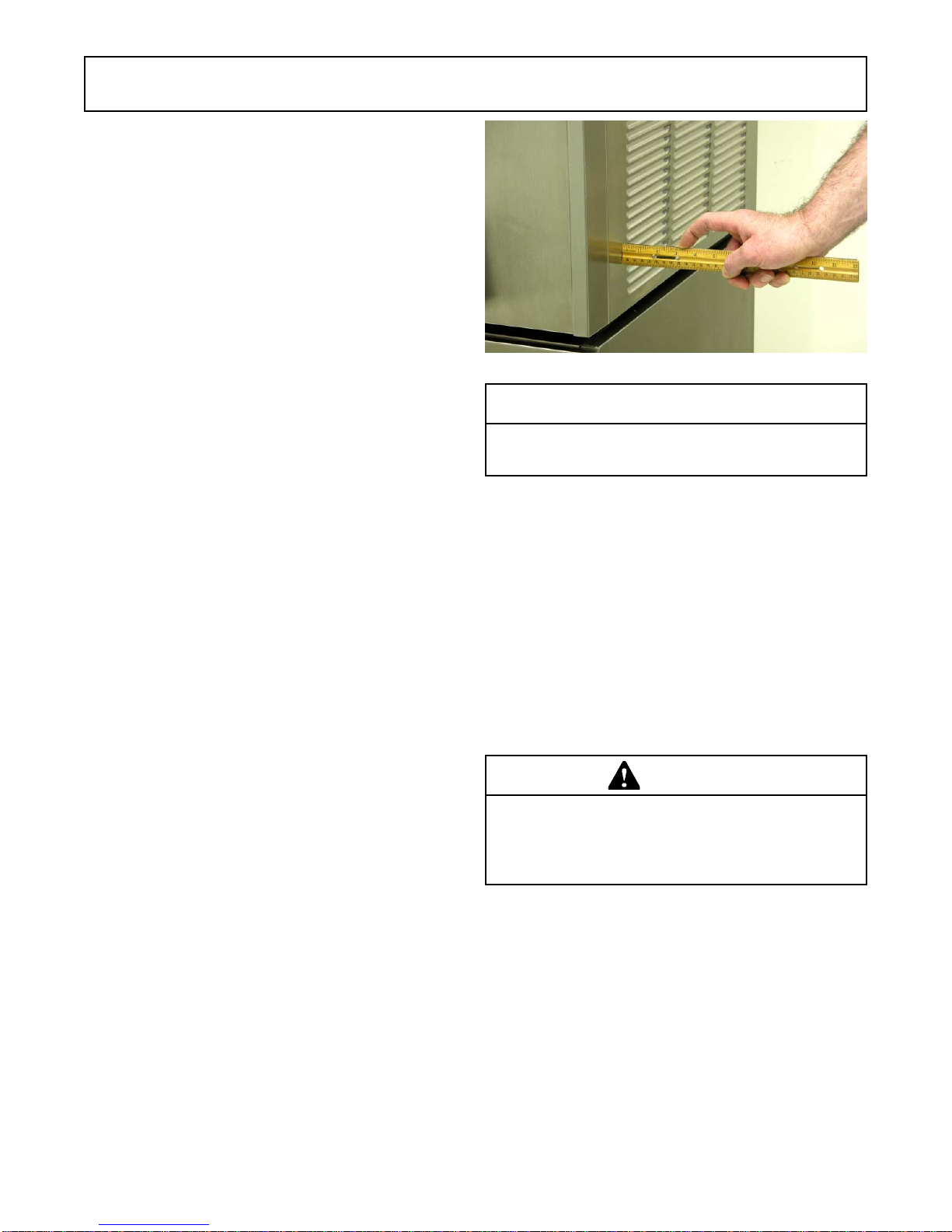

C. Correctventilationisrequired.TheCF101requires

a minimum of 6" (15,2 cm) air space at left and

right sides and 10" (25,4) air space above the

machine.

CAUTION

Failuretoprovide adequate ventilationwillvoid war-

ranty.

D. Place the Main Freezer Power Off/On switch in

the OFF position.

E. Connect the power cord to the proper power

supply. The plug is designed for 208-240 volt/20

ampduty.Checkthenameplateonyourmachine

for proper supply. The unit must be connected to

a properly grounded receptacle. The electrical

cordfurnishedaspartofthemachinehasa three

pronggroundingtypeplug.Theuseofanextension

cord is not recommended, if necessary use one

witha size 12gauge orheavier withground wire.

Do not use an adapter to get around grounding

requirement.

WARNING

Do not alter or deform electrical plug in any way.

Altering the plug to fit into an outlet of different con-

figuration may cause fire, risk of electrical shock,

product damage and will void warranty.

Figure 2-2 Space and Ventilation Requirements