SECTION DESCRIPTION PAGE

1. INTRODUCTION

1.1 Remote Possibilities.......................................................................................... 1

1.2 Features ............................................................................................................ 1

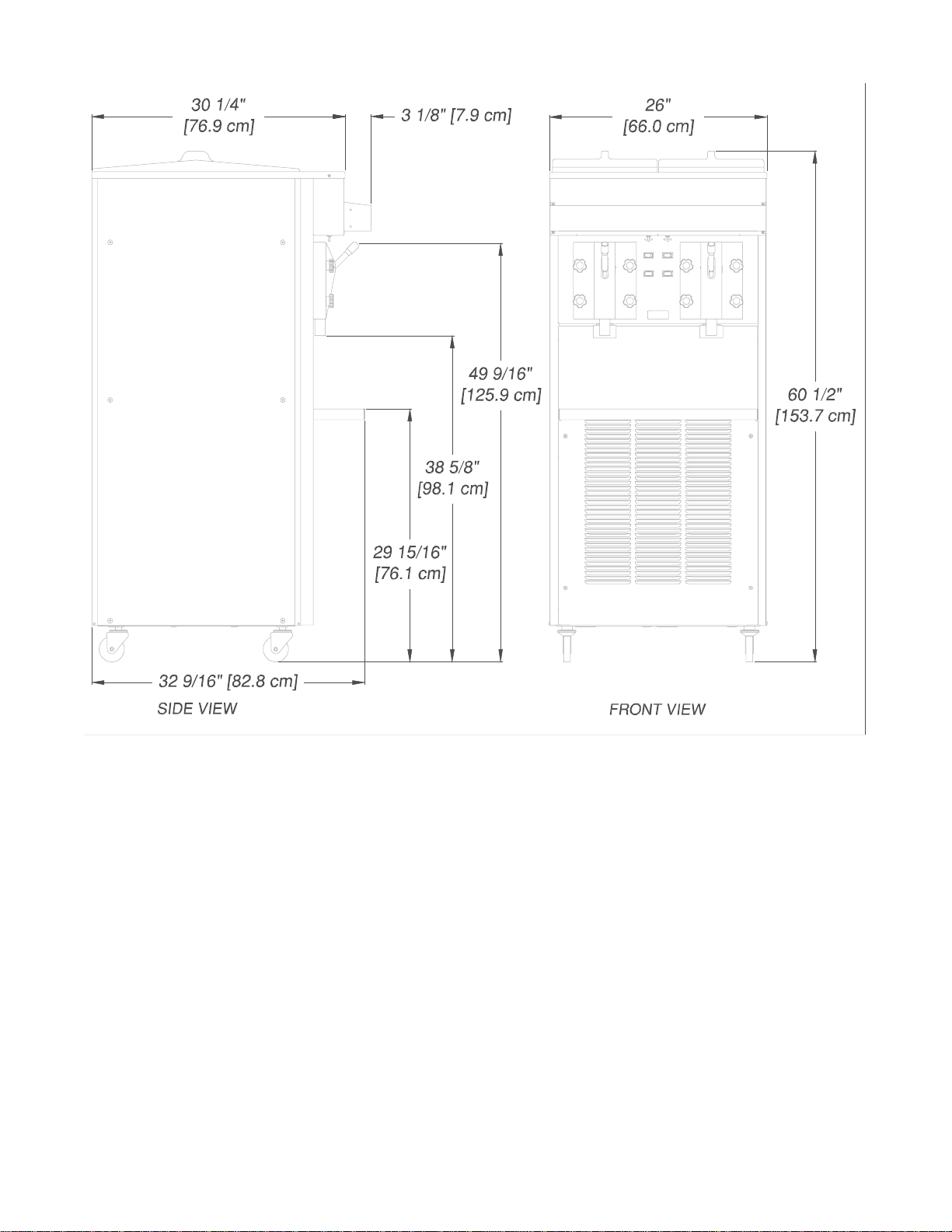

1.3 FreezerSpecifications....................................................................................... 2

2. INSTALLATION INSTRUCTIONS

2.1 SafetyPrecautions............................................................................................. 3

2.2 ShipmentandTransit ......................................................................................... 3

2.3 FreezerInstallation ............................................................................................. 3

2.4 InstallingPermanentWiring ................................................................................ 4

3. INITIAL SET-UP AND OPERATION

3.1 Operator'sSafetyPrecautions............................................................................ 5

3.2 OperatingControlsandIndicators ...................................................................... 5

3.3 DisassemblyofFreezerParts ............................................................................ 5

3.4 CleaningtheFreezerParts ................................................................................ 6

3.5 SanitizeFreezerandFreezerParts.................................................................... 6

3.6 AssemblyofFreezer .......................................................................................... 6

3.7 Sanitizing ........................................................................................................... 7

3.8 Cleaning&SanitizingofSO328withFill-o-maticIIandFill-o-maticIII.................. 8

3.9 InitialFreezeDownandOperation ..................................................................... 8

3.10 RemovingProduct ............................................................................................. 8

3.11 SO328Operation............................................................................................... 8

4. PREVENTATIVE MAINTENANCE

4.1 RoutineCleaning ............................................................................................... 11

4.2 PreventativeMaintenance .................................................................................. 11

4.3 ExtendedStorage.............................................................................................. 11

4.4 ConsistencyAdjustment..................................................................................... 11

5. REPLACEMENT PARTS INFORMATION

5.1 OrderingParts ................................................................................................... 13

5.2 ReferenceDrawing ............................................................................................ 13

6. ACCESSORIES

6.1 Fill-o-maticII....................................................................................................... 15

6.2 Fill-o-maticIII ...................................................................................................... 17

6.3 Fill-o-maticConnections .................................................................................... 19

TABLE OF CONTENTS