STOLZENBERG TT 1200 User manual

TT 1200

htttp://www.stolzenberg.de

!

Service Manual

EN

2

1 CLEANING AND MAINTENANCE

The regular maintenance of the sweeper serves to preserve the

machine, its components and the sweeping result. If performed

regularly, the subsequently described maintenance work can

extend the lifetime of the equipment!

ATTENTION - Personal protective equipment in

the form of goggles, breathing protection and

gloves must be worn for interior and exterior

cleaning of the sweeper!

To clean the machine interior, the main cover must be opened and

secured by means of the main cover holder. Use a dry cloth for

cleaning and blow through the machine with compressed air.

Subsequently close the main cover properly once again.

For the exterior cleaning of the sweeper, use compressed air

and/or a cloth or a wash mitt moistened with warm water or a mild

detergent solution.

Safety instructions for cleaning and

maintenance

1.1

GENERAL CLEANING AND MAINTENANCE INSTRUCTIONS1.2

ATTENTION - For safety reasons, all cleaning and

maintenance work may only be carried out when

the machine is switched off! To do so, remove the

key from the device! Failure to do so may result in

serious injury!

For cleaning and maintenance intervals, please refer to the service

indicator

(§ see page 37 ) or the maintenance manual!

All service and maintenance work must be performed by a

qualified technician! If necessary, a Stolzenberg dealer can be

contacted at any time! You can find the relevant dealer or service

technician for your machine on the manufacturer website!

MAINTENANCE OF THE SWEEPING SYSTEM1.3

1.3.1 Maintenance of the sweeper roller drive

To maintain functioning, the sweeper roller should be inspected

regularly for wear on the drive chain and pinions. Furthermore, the

chain elongation must be measured regularly. For this purpose,

ten rolls are counted at an arbitrary position on the chain (ideally

in the pull strand) and the inner tangential distance between them

is measured with a calliper. If the value is between 79.3 mm and

81.8 mm, then the chain is still in order. A measured length of 81.9

mm or above indicates that the chain should be replaced, because

the wear of the pinions will be increased as of this value!

3

IMPORTANT - Do not use aggressive cleaning

agents!

ATTENTION - The sweeper may not be cleaned

using high-pressure or water jet, as these can

cause damage! There is a danger of short circuit

or other serious damage!

Contents

1 Cleaning and maintenance

1.1 Safety instructions for cleaning and maintenance

1.2 General cleaning and maintenance instructions

1.3 Maintenance of the sweeping system

1.3.1 Maintenance of the sweeper roller drive

1.3.2 Adjusting the sweeping pattern

1.3.3 Sweeper roller replacement

1.3.4 Maintenance of the side brush unit

1.3.5 Re-adjusting the side brush

1.3.6 Side brush replacement

1.4 Maintenance of the filter system

1.4.1 Maintenance of the fan

1.4.2 Filter replacement

1.4.3 Cleaning the filter

1.5 Battery setting & maintenance

1.5.1 Setting the battery type

1.5.2 Checking the battery status

1.6 Steering maintenance

1.6.1 Control and readjustment of the chain tension

1.6.2 Control of slide bearings

1.7 Maintenance of wheels

1.7.1 Rear wheel replacement

1.7.2 Front wheel replacement

1.8 Maintenance of the brake

1.8.1 Inspection of brake pads

1.8.2 Readjustment of the brake

1.9 Changing the machine settings

1.9.1 Setting options for end users

1.9.2 Setting options for service technicians

1.10 Resetting the service counter

2 Wiring diagrams

2.1 Wiring diagram basic version

2.2 Wiring diagram left side brush option

2.3 Wiring diagram light option

2.4 Wiring diagram on-board charger option

2.5 Wiring diagram backward signal

3 Accessories and spare parts

4 Warranty

5 Transport of the sweeper

6 Maintenance Plans

6.1 Maintenance work for machine owners

6.2 Maintenance work for service center

6.2.1 Service I

6.2.2 Service II

6.2.2 Service II

7 Maintenance Proof

8 Contact

..............................................................3

.............3

.................3

...................................3

.........................3

.........................................4

...............................................6

...................................8

.................................................9

.....................................................10

..........................................11

......................................................11

...............................................................11

................................................................16

.............................................17

.....................................................17

..............................................18

.............................................................19

...........19

...................................................22

...........................................................22

....................................................22

..................................................24

.......................................................26

...................................................26

................................................27

.............................................27

...........................................27

.........................28

................................................30

...............................................................................31

................................................31

................................32

...................................................33

...........................34

..........................................35

..........................................................36

.............................................................................................36

...............................................................36

..........................................................................38

..............................38

..................................38

.................................................................................38

................................................................................38

................................................................................38

...........................................................................39

...............................................................................................40

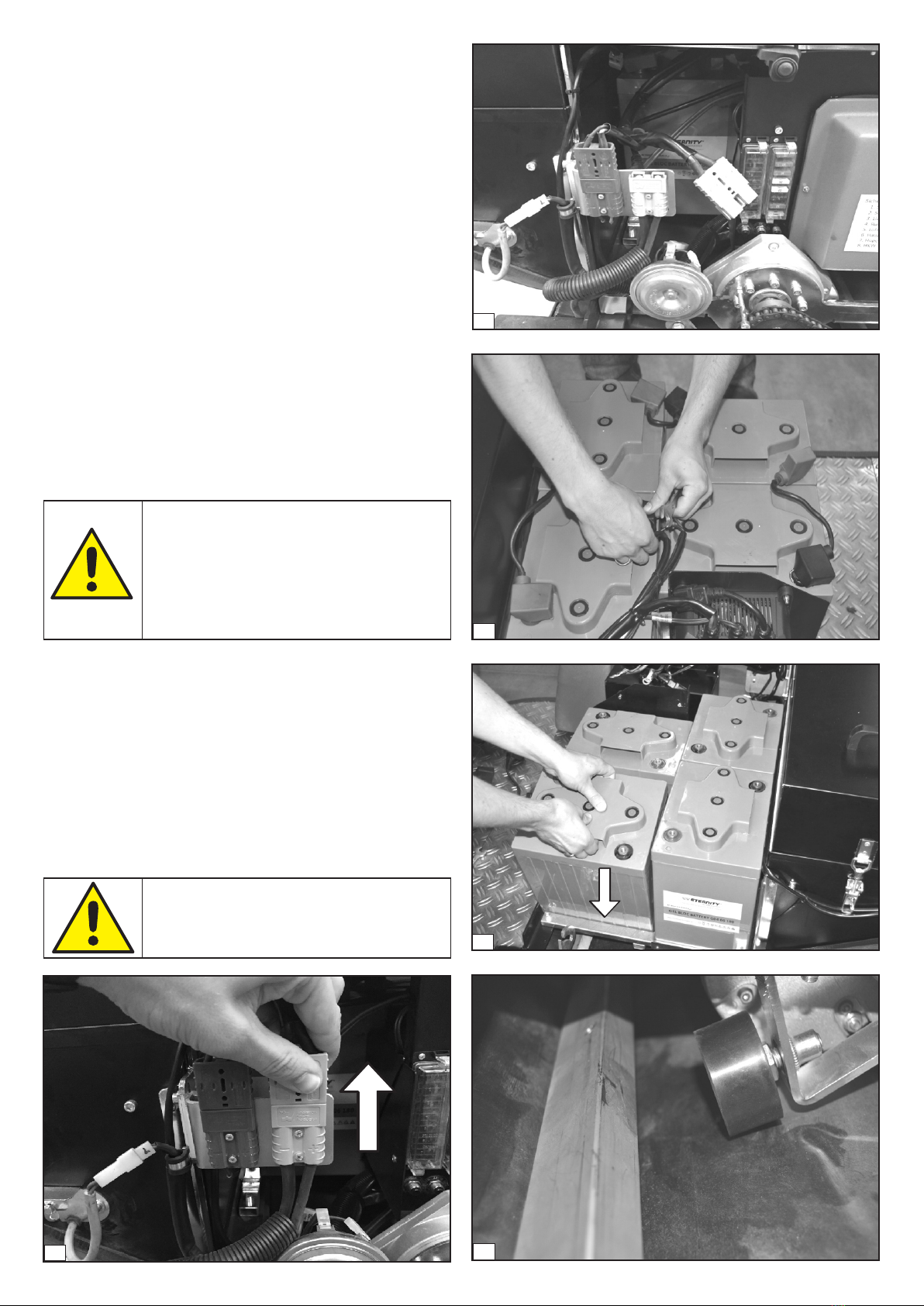

ATTENTION - Do not place any tools on the

batteries. This could short-circuit the batteries

and lead to the explosion of the batteries! It is

necessary to ensure that no connection can be

established between the battery terminals.

Special terminal protectors or electrical tape can

be used for this purpose.

NOTE - Since the position of the stop buffer must

be adjusted depending on the surface, it may be

necessary to repeat the steps described above

several times.

2

1

4

5

3

4

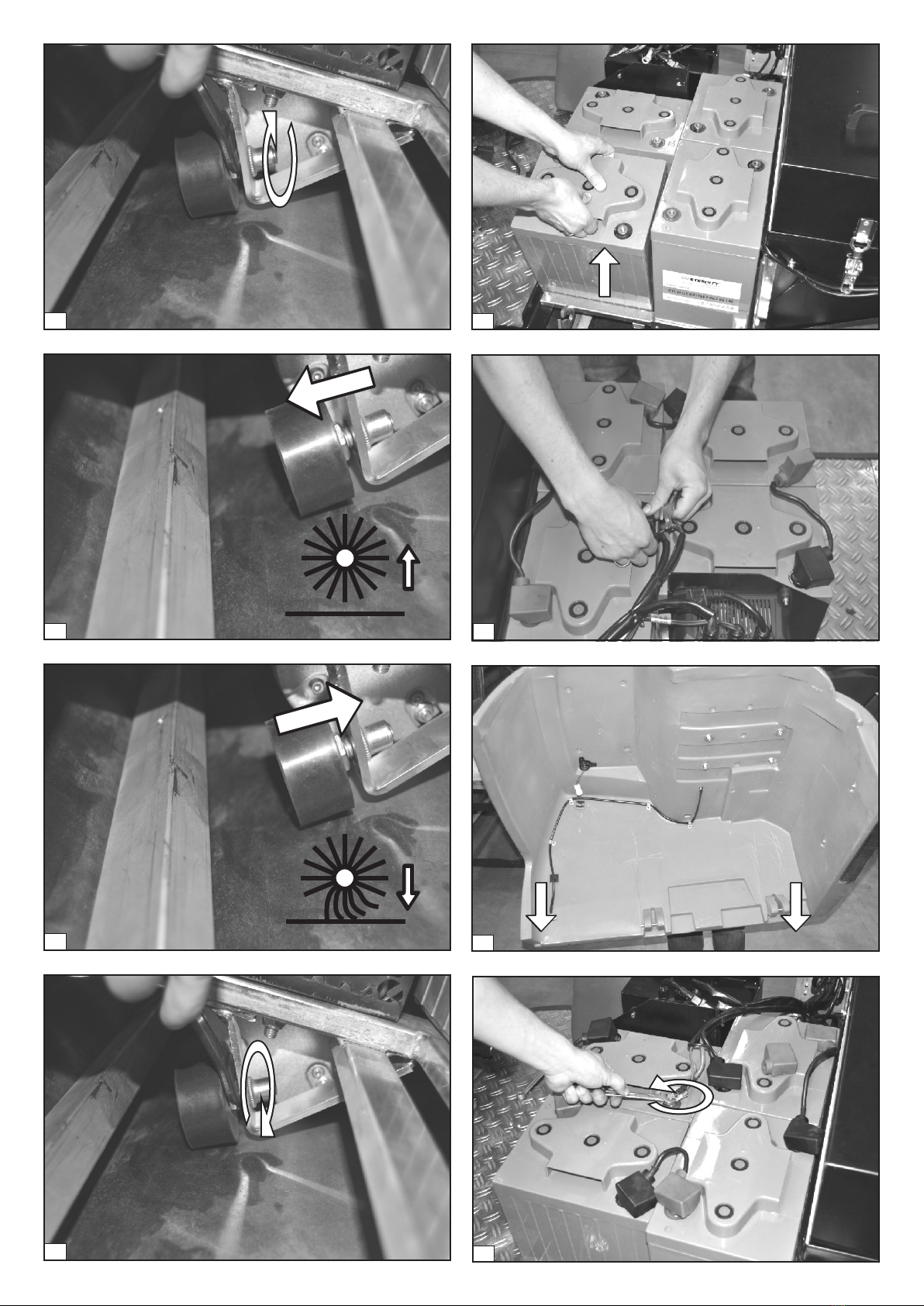

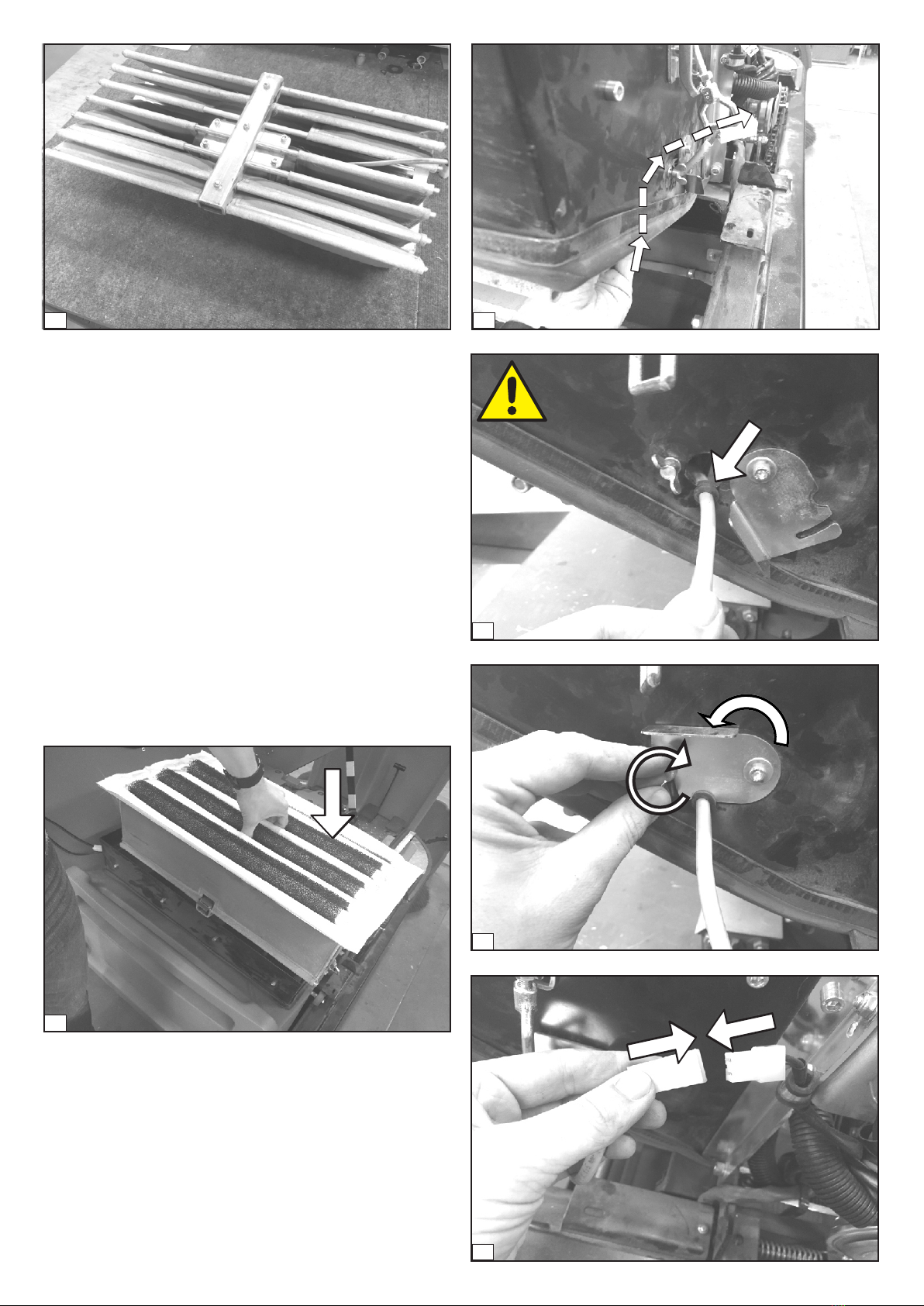

Now both batteries at the front (in driving direction) can be

removed from the machine (4) to allow access to the sweeper

roller's depth stop buffer (5). To be able to turn the stop buffer, it is

necessary to loosen the locknut (6). To reduce the sweeping

pattern, the stop buffer is rotated clockwise (7) and to enlarge the

pattern, it is rotated counterclockwise (8). After the adjustment,

the locknut must be tightened again (9). Now the batteries can be

inserted and connected to the wiring harness (10-11). The

assembly of the main cover and the connection of the battery

connector (12-13) are the final steps to make the machine ready

for use once again.

The sweeper roller driving chain should be treated regularly with a

non-adhesive, solvent-based lubricant (e.g. B. Innotech 105) to

remove dirt particles and to maintain the lubricating film between

the individual chain elements and between the chain and the

pinions.

1.3.2 Adjusting the sweeping pattern

The sweeping pattern does not need to be set manually for this

sweeper. When the main sweeper roller motor is started, the

automatic lowering mechanism lowers the rear sweeper roller to

the floor, until a certain contact pressure is reached. The automatic

lowering mechanism can thus also ensure wear re-adjustment, so

that a consistently good sweeping result is achieved. For certain

applications - on carpets in particular - the pre-set pressure may,

however, be too high. In this case, a depth limitation can be set for

the automatic lowering mechanism.

The stop buffer required for the depth limitation is located

beneath the batteries. To access it, you first have dismantle the

main cover § see chapter 4.5.2 at the Operating Manual

Subsequently, the battery plug must be removed (1-2) to break the

connection between the machine and the batteries. Now the

battery terminals of the batteries can be loosened (3).

13

12

11

8

7

6

9

10

5

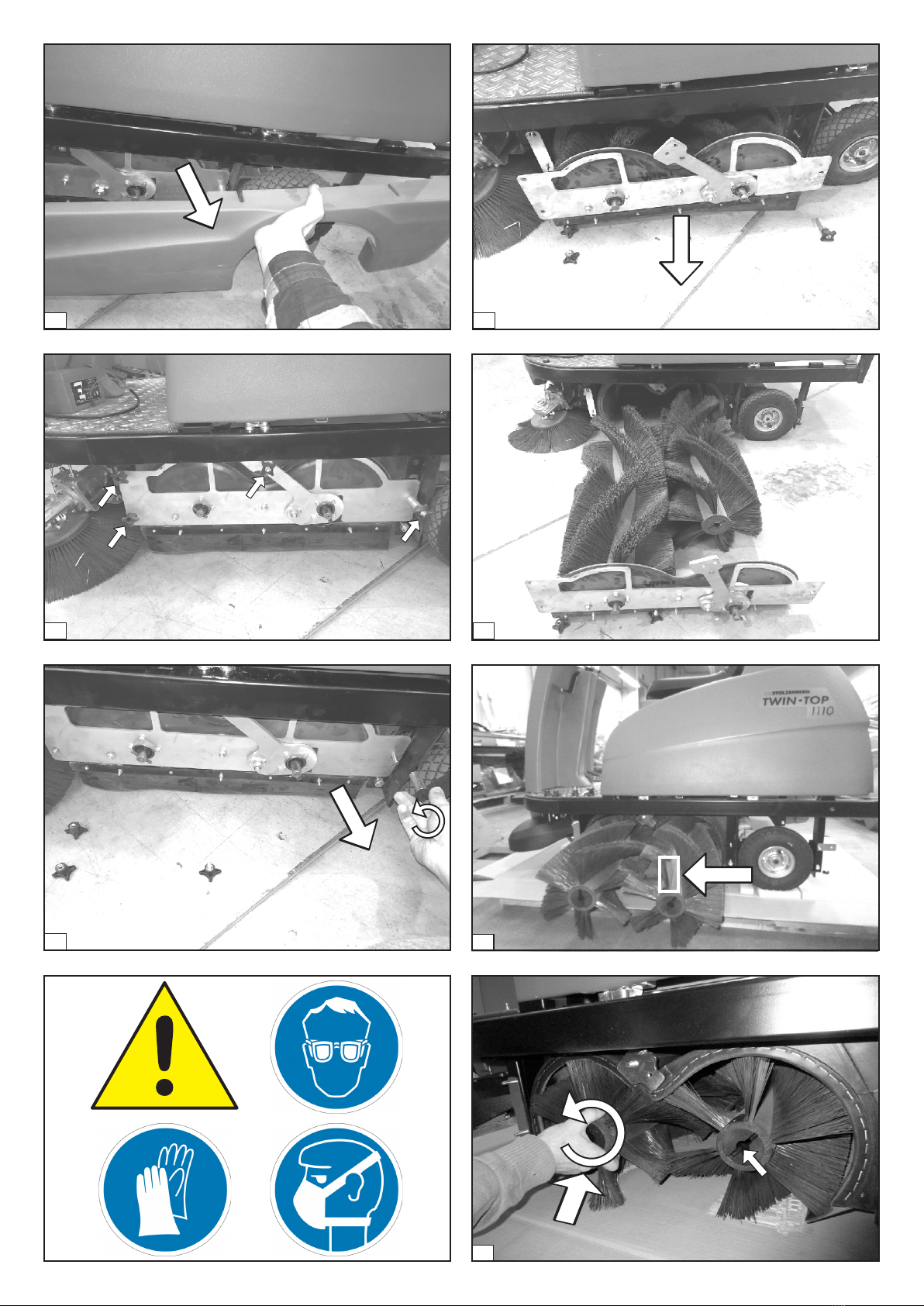

1.3.3 Sweeper roller replacement

For sweeper roller replacement, start by dismounting the left side

cover. For this purpose, start by removing the hopper (1). The

knurled nut to fasten the side cover on the machine frame is now

accessible (2) and must be removed (3). In the next step, the front

fixation of the side cover must be loosened (4-5). Now the side

cover can be removed (6). The lateral sweeper roller tunnel cover,

which is secured with four star grip nuts, is now accessible (7).

These nuts must now be loosened (8).

ATTENTION - Personal protective equipment in

the form of goggles, breathing protection and

gloves must be worn when removing the

sweeper rollers!

Then the lateral sweeper roller tunnel cover can be pulled off to

the side (9). The sweeper rollers are now freely accessible (10) and

can be replaced with new sweeper rollers. The correct mounting

orientation must be observed when inserting the new sweeper

rollers (11). The wear indicator (red bristles) must be visible on the

rear sweeper roller, i.e. it should point to the left in the driving

direction. For the front sweeper roller, the wear indicator must not

be visible, i.e. it should point to the right in the driving direction. It

is also important to ensure that the clamping pins at the engaging

elements (12) correctly engage the sweeper rollers. For this

purpose, the sweeper roller is inserted into the sweeper roller

tunnel and pushed on to the driving element with a slight twist

(13). The snapping of the sweeper roller into the clamping pin of

the driving element is ensured when the sweeper roller can no

longer be turned at all or only to a very limited extent. If the

sweeper roller is inserted correctly, the side sweeper roller tunnel

cover can be mounted again and secured with the corresponding

star grip nuts (14-15). Finally, the side cover is attached (16) and

fixed with the knurled nuts (17-18). After insertion and locking of

the dust box (19), the machine is once again ready for use.

1

3

4

2

5

6

6

7

8

9

10

12

11

7

14

15

16

17

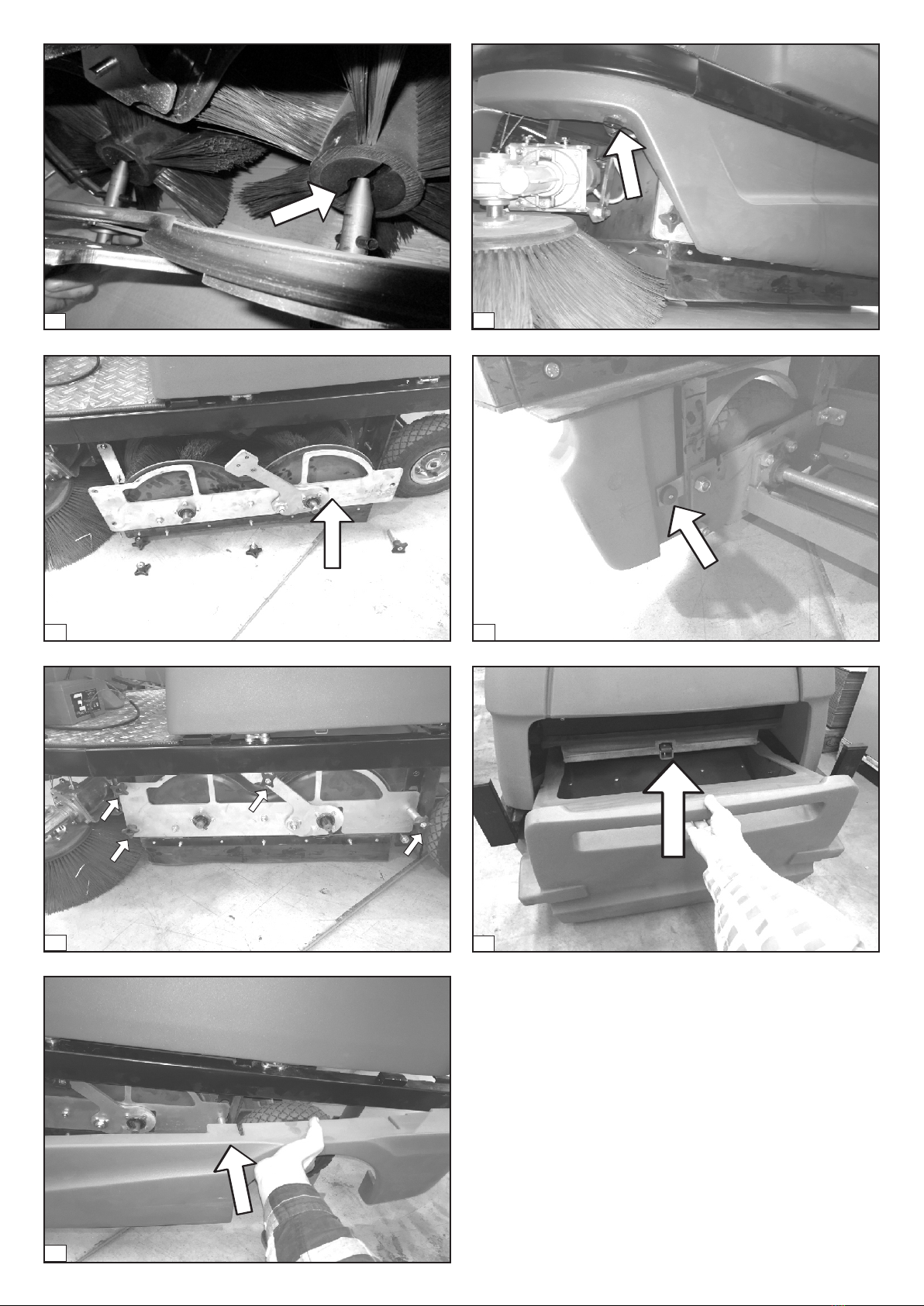

1.3.4 Maintenance of the side brush unit

The side brush driver unit is a direct drive, which can be

considered as free of wear. It should however be checked at

regular intervals, to confirm that the swivelling mechanisms of

the side brush arm is still functioning properly and smoothly.

For this purpose, the side brush must first be set to the working

position (arrow on the side brush adjustment lever pointing

downwards (1). Now the side brush arm on the side brush cover

is pressed completely towards the machine centre (2), after

which the cover must be completely immersed under the

machine frames (3-4). When the side brush arm is released, it

must fully swivel back to its original position (5). It may happen

that the complete spring-back only takes place after the side

brush is switched on, because the bristles create a slight

resistance on the floor.

18

19

13

8

1.3.5 Re-adjusting the side brush

To re-adjust the side brush in case of wear, it suffices to adjust a

screw that is attached to the side brush adjustment unit and which

forms the depth stop of the side brush. In order to access the

setting screw, the side brush adjustment lever must first be moved

to the upper position (with the arrow on the side brush adjustment

lever pointing upwards (1). The setting screw behind the side

brush adjustment lever is now accessible and visible from the

footwell (2). By turning the setting screw clockwise (3), the depth

stop of the side brush is lowered (4), by turning the setting screw

counter-clockwise (5), the depth stop of the side brush is raised

(6).

5

4

3

1

2

1

2

9

The adjustment of the correct contact zone is essential for the

sweeping result. If an insufficient number of bristles touch the

floor (A), then the sweepings are not directed to the machine

centre, but rather thrown forward obliquely. If the bristle bed of

the side brush is too large (C), then it is possible that sweepings are

passed in front of the main sweeper roller and ejected laterally.

The side brush is considered correctly adjusted if the bristles in

line with the side brush arm touch the floor in a sickle-shape of

approx. 120° (B).

1.3.6 Side brush replacementSeitenbesenwechsel

The side brush is fixed to the side brush motor with a screw. To

reach this easily, the side brush should be brought to the rest

position (1). The wing screw used for fixation is positioned

centrally on the underside of the side brush (2) and must now be

unscrewed (3) to remove the side brush from the motor (4).

When installing the new side brush, it is necessary to ensure that

the lug on the side brush engaging piece (5) engages in the feather

key groove of the motor shaft when mounting the side brush onto

the drive motor (6). The side brush must now only be fastened with

the wing screw (7) before it is ready for use.

3

4

5

6 1

2

10

BA C

~120°

3

4

6

5

7

8

MAINTENANCE OF THE FILTER SYSTEM1.4

1.4.1 Maintenance of the fan

The fan of this sweeper is a maintenance-free component. It only

needs to be checked regularly to see if any foreign objects are

inside the fan or whether the fan generates amplified or unusual

noise.

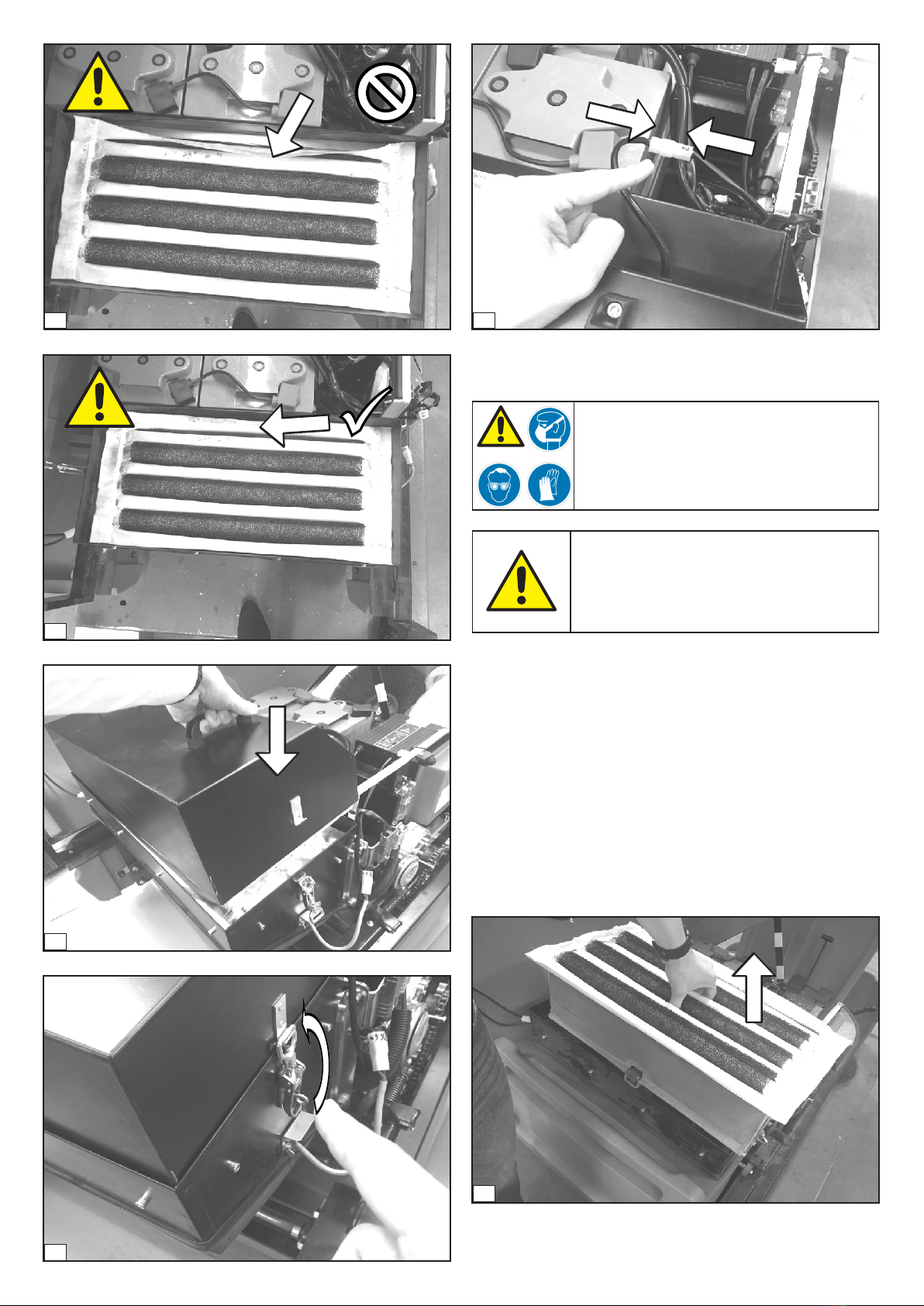

ATTENTION - Personal protective equipment in

the form of goggles, breathing protection and

gloves must be worn when removing and

replacing the filter!

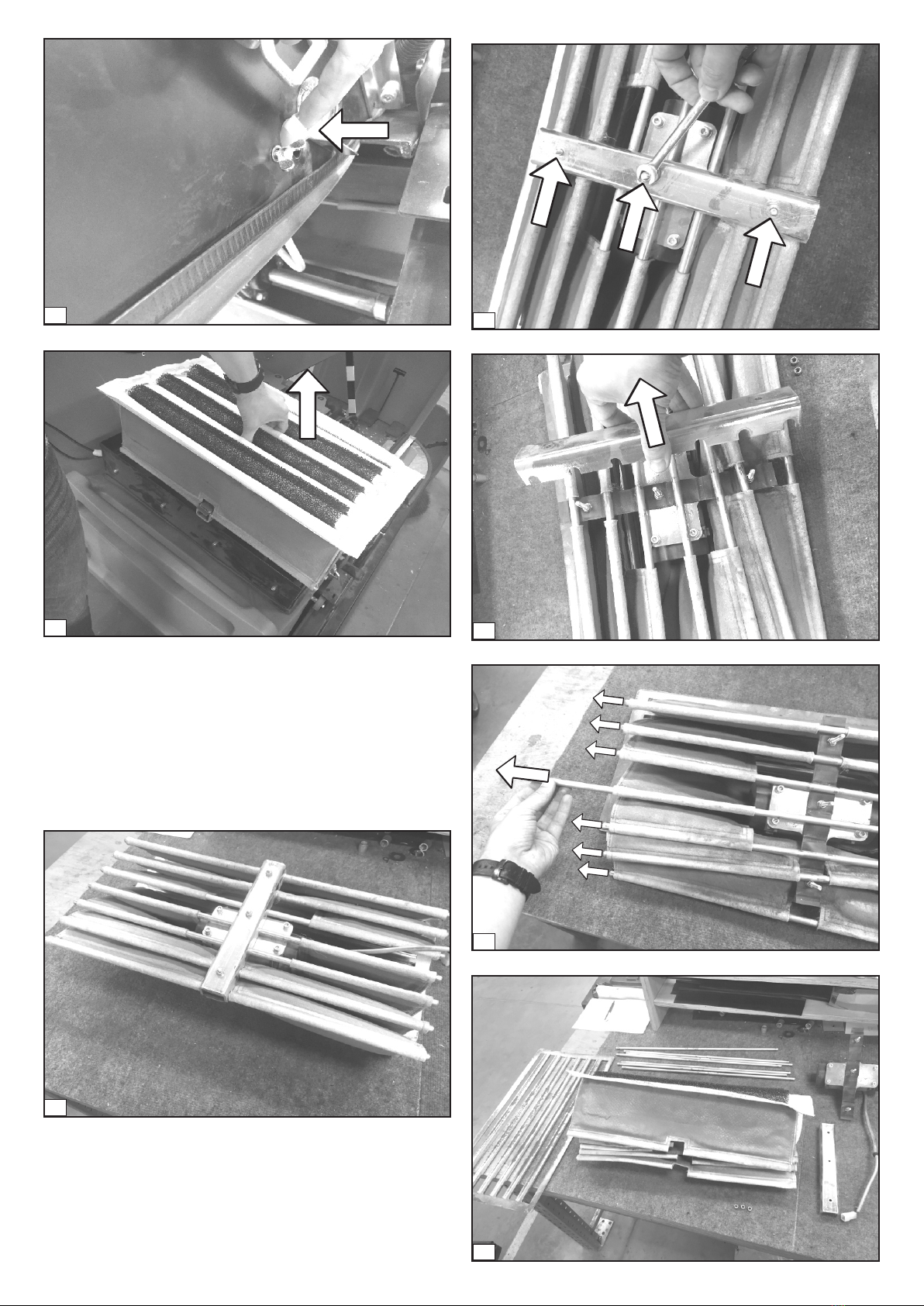

1.4.2 Filter replacement

1.4.2.1 Removing the filter unit

In order to remove the filter unit, it is initially necessary to open

the main cover and to secure it with the main cover bracket (1). In

the next step, the filter chamber cover must be removed. For this

purpose, the power supply of the fan is disconnected (2), the

clamps of the filter chamber cover attachment are loosened (3)

and the filter chamber cover is removed upwards (4). The filter unit

is now freely accessible (5). In order to remove it, the power

connector of the filter vibrator must be disconnected (6), the plug

feedthrough must be opened (7-8) and the plug must be pushed

inside the filter chamber (9). The entire filter unit can now be

removed upwards from the filter chamber (10).

11

4

5

6

7

8

3

1

2

12

9

10

1.4.2.2 Disassembling the filter unit

Place the filter unit upside down on a workbench/table for

disassembly (1). Then start by unscrewing the three screws of the

clamping plate (2). Remove the clamping plate (3) and laterally

pull out the seven vibrating rods from the filter bags (4). The entire

filter unit is now disassembled (5).

5

1

2

3

4

13

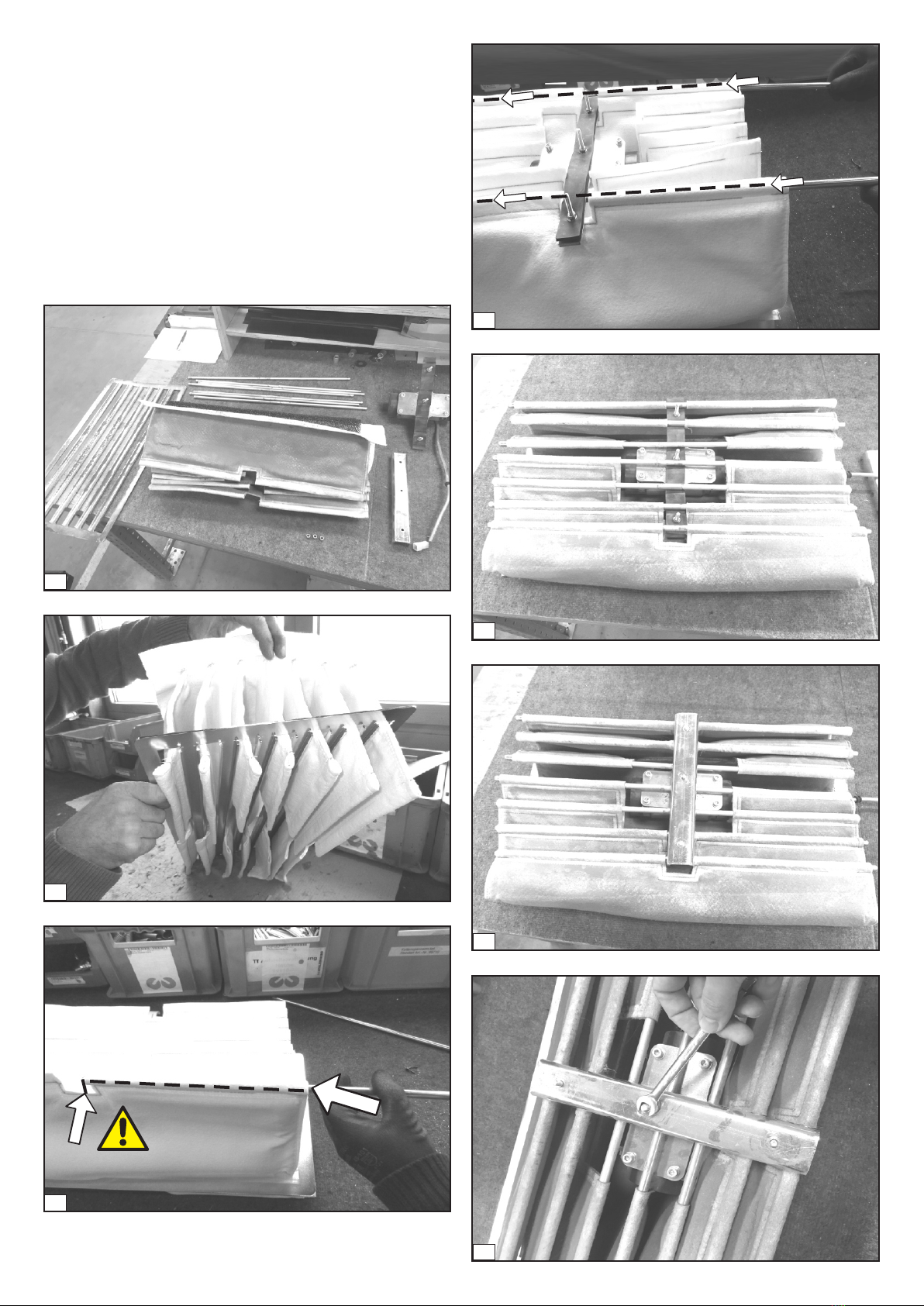

1.4.2.3 Mounting the filter unit

To assemble the filter unit, the filter bags must first be threaded

through the filter grid. It is important to make sure that the folds of

the filter grid point downward (2) in the installed state (inside the

machine)! In the next step the vibrating rods are threaded through

the filter loops laterally until the mark (3). The vibrator motor is

now positioned centrally on the pre-assembled filter unit (4). Now

the vibrating rods are pushed through the filter loops completely

(5). The vibrating rods are now placed on the rubber at the filter

vibrator (6), the clamping plate is mounted (7) and fixed with the

nuts (8). The filter unit is now ready for installation in the sweeper

(9).

1

2

5

7

6

14

3

4

1.4.2.4 Installing the filter unit

The pre-assembled filter unit is inserted into the filter chamber

from above (1) and the filter vibrator cable is pushed through the

cable feedthrough from the inside (2). It is important that the

cable grommet is mounted correctly on the filter vibrator cable at

the designated position on the cable feedthrough (3). Then close

and fasten the cable feedthrough (4) and restore the power

connection to the filter vibrator (5). Before the filter chamber

cover is put back in place, it must be ensured that the filter rests

properly and smoothly on the filter grid (6-7). If this is not the case,

dust can be suctioned past the filter, which has a strong negative

effect on the filtration result! If it is ensured, place the filter

chamber lid with the ventilation openings facing backwards in the

driving direction onto the filter from above (8), lock it with the

side-mounted turnbuckles (9). The turnbuckles are mounted

asymmetrically to prevent incorrect installation of the filter

chamber lid. Finally, the power supply of the fan needs to be

restored (10).

1

3

4

5

8 2

15

10

7

8

9

1.4.3 Cleaning the filter

ATTENTION! RISK OF INJURY! - Always wear

your personal protective equipment in the form

of protective goggles, gloves and breathing

protection when cleaning the filter!

NOTE! Never clean the filter with water or other

(chemical-containing) liquids. This would

damage the filter beyond repair!

To clean the filter, it should be removed from the machine as

described in section (1). Filter carrier, vibrating rods and vibrator

motor must not be disassembled for cleaning.

The filter can now be cleaned, ideally by means of compressed air

from the clean side (2). Never clean the filter from the dust side (3),

since the dust present on the filter would be pressed into the filter

pores and the filter performance would be fundamentally

reduced! Now mount the filter unit once again into the sweeper as

described in section .

The cleaning interval to be observed is strongly dependent on the

environment to be swept. For moderate dust concentrations,

cleaning with compressed air is recommended every 10 hours.

1

6

16

3

4

BATTERY SETTING & MAINTENANCE1.5

1.5.1 Setting the battery type

A distinction is made essentially between gel and acid batteries,

which have different discharge curves and shutdown thresholds.

To ensure proper battery indication and proper discharge

protection, it is thus necessary to select the right type of battery in

the settings menu of the control system. To do this, select the

menu item "Settings" in the main menu of the control system (1)

and sign-in with your access code (2). You have now entered the

settings menu (3). Now switch to the menu item "Battery type" (4)

and select the installed battery type from the sub-menu (5-6).

After selecting the battery type, you switch to the menu item "Exit

settings" (7). Now select "Save and Exit" (8). You have now

returned to the main menu of the control system.

1

4

3

2

2

17

8

6

7

1.5.2 Checking the battery status

AT TE N T IO N ! - O n ly u se t h e c h arge r s

recommended by the manufacturer of this

sweeper to charge this machine! Using the

wrong charger or the wrong setting can damage

the batteries!

The best way to determine the battery state is by measuring the

battery voltage in the charged state. For this purpose, the batteries

must first be fully charged (1-2). Subsequently, a voltmeter is

connected (3-4) between the positive pole of the first battery and

the negative pole of the last battery. For identification: The poles

to be measured are those that are connected to the main cable

strand of the machine (3). If the voltmeter displays a voltage

between 25.5 V and 24.5 V, the battery is still in good condition. If

the indicated voltage lies between 24.5 V and 23.5 V, the battery is

in a sufficient condition, however, the machine running time is

already reduced. For a reading below 23.5 V, new batteries should

be inserted!

2

100%

5

18

1

4

25,5V – 24,5V

24,5V – 23,5V

< 23,5V

STEERING MAINTENANCE1.6

1.6.1 Control and readjustment of the chain tension

If the steering clearance on the steering wheel is too large, then

this indicates that the chain tension is too low. Typically, a steering

clearance up to 1 cm is acceptable in each direction. Greater

steering clearance must be reduced by adjusting the chain

tension.

NOTE! - A certain steering clearance is common.

A too high chain tension can cause steering noise

and increase wear on the chain and the pinions!

1

2

The chain tension is being increased by adjusting the sprocket.

Therefore the screws of the adjustment plate and excenter plate

will be loosened. Then the adjuster plate can be moved backwards

by turning the excenter plate. Move the adjuster bracket as long as

the chain is tensioned properly and fasten the screws.

3

1cm =

> 1cm =

19

6

5

8

7

9

10

4

3

20

Other manuals for TT 1200

1

Table of contents

Other STOLZENBERG Scrubber manuals