StoneAge BJV-M User manual

ROTARY WATERBLAST NOZZLE

BJV-M

OPERATION AND MAINTENANCE

MANUAL

54 Girard St. Durango, Colorado 81303 (970) 259-2869 Phone (970) 259-2868 Fax

www.stoneagetools.com [email protected]

07/02

TABLE OF CONTENTS

1.0 INTRODUCTION

2.0 SAFETY WARNING

3.0 DESCRIPTION

4.0 PARTS LIST

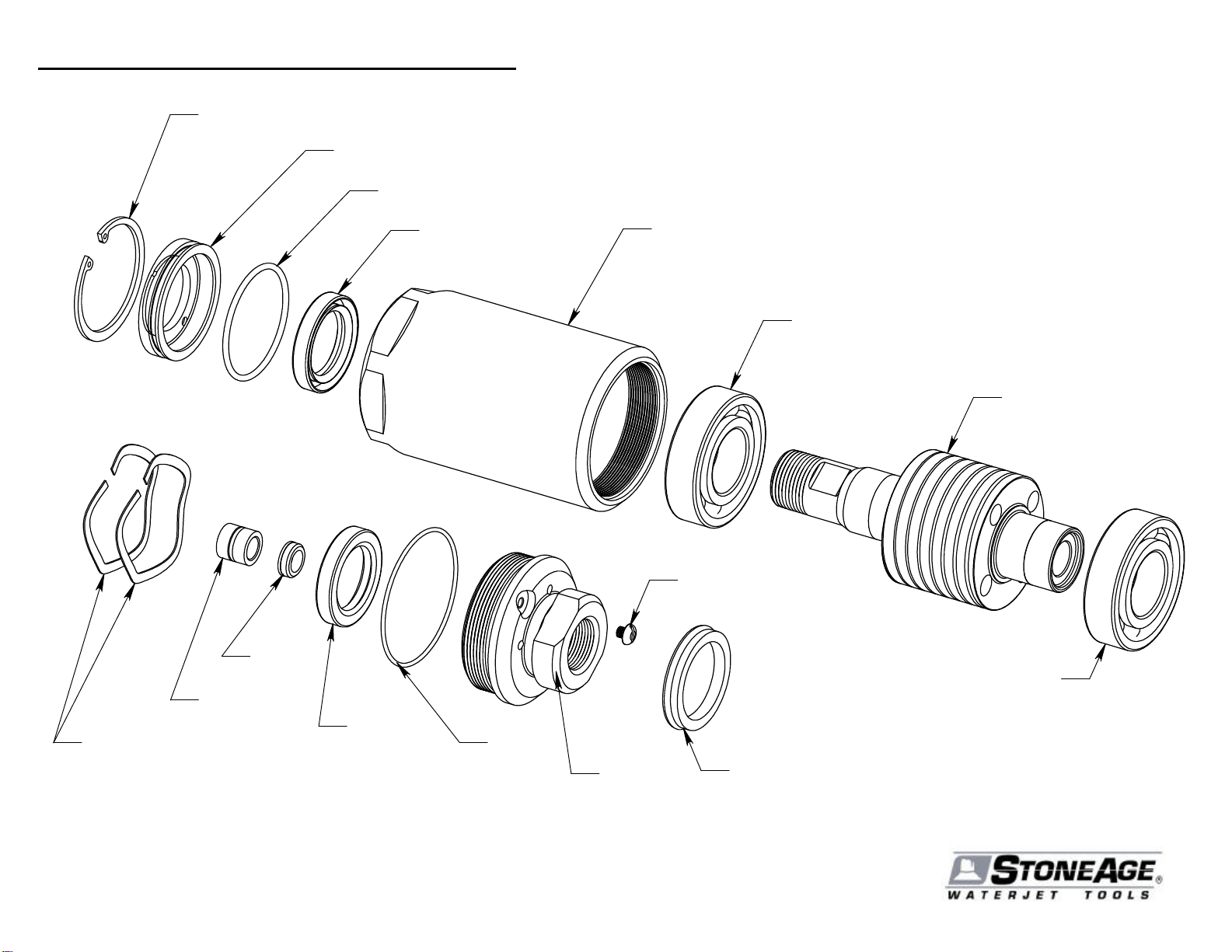

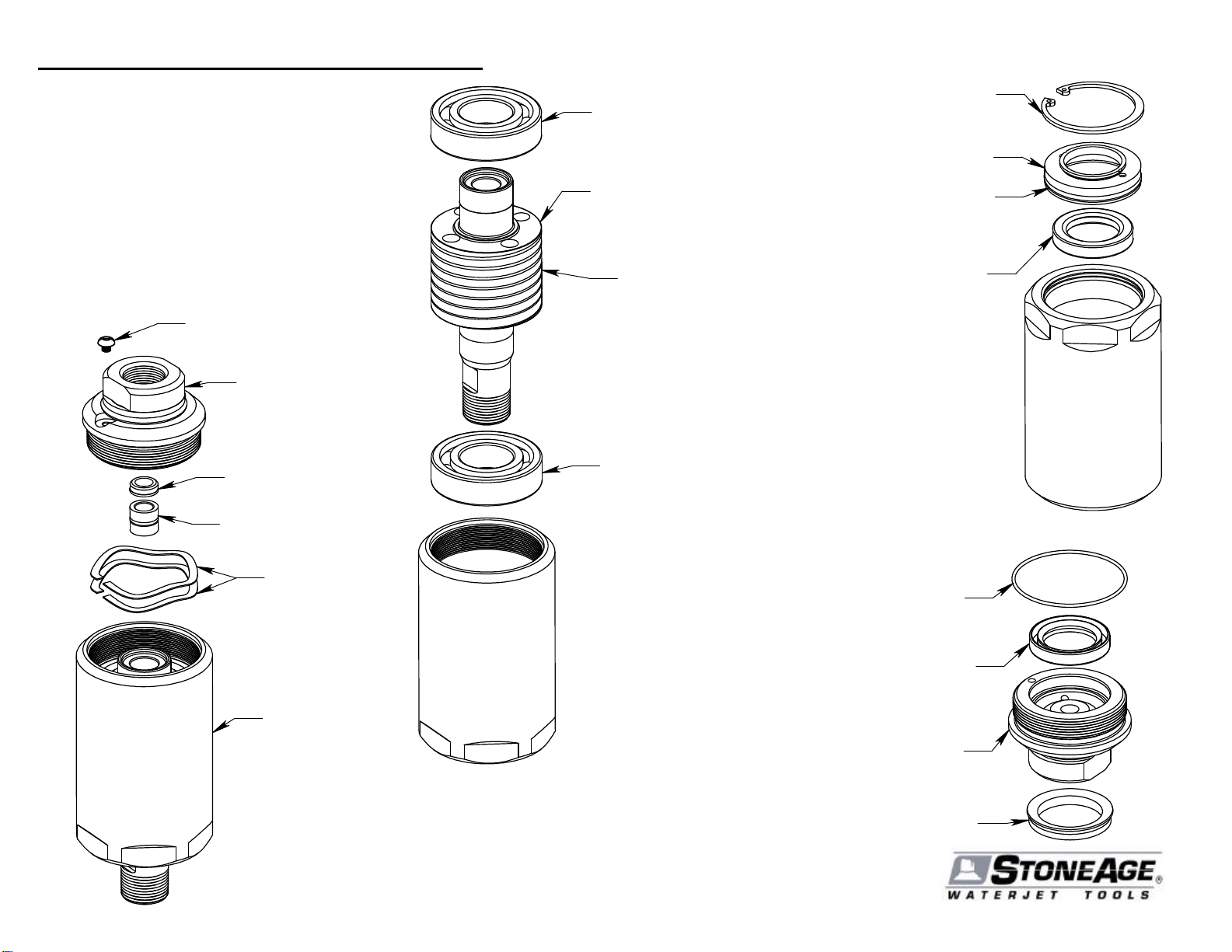

5.0 ASSEMBLY DRAWING

6.0 MAINTENANCE

7.0 WARRANTY

APPENDIX

A. Viscous Fluid Material Safety Data Sheet

1.0 INTRODUCTION

This manual was prepared to provide the operator with the basic information needed to operate and

service this equipment. The operating recommendations in the manual will ensure that you receive

satisfactory performance. All operating personnel responsible for the care of this equipment should be

familiar with the information in this manual.

If you have any questions or problems with this equipment, please contact the distributor you obtained the

product from, or the manufacturer:

StoneAge, Inc.

54 Girard St.

Durango, CO 81303

970-259-2869 Phone 970-259-2868 Fax

www.stoneagetools.com

2.0 SAFETY WARNING

Operations with this equipment can be potentially dangerous if caution is not exercised prior to and during

tool use. Please read and follow all of these instructions, in addition to the guidelines in the WJTA

Recommended Practices handbook.

2.1 Only competent and trained persons should operate this equipment.

2.2 The immediate work area should be marked off to keep out untrained persons.

2.3 All personnel in the area should wear appropriate personal protective equipment.

2.4 Inspect the equipment for visible signs of deterioration, damage, or improper assembly.

Do not operate until repaired. Make sure all threaded connections are tight and leak free.

2.5 Check nozzle orifices before use. If any are plugged, they must be cleaned or replaced.

2.6 This equipment should always be used with an operator controlled dump mechanism to

release the high pressure water. If it is necessary to have a person work near the

cleaning jets, then it is this person who should have control of the pressure dump.

2.7 Check that all control functions work properly before going to high pressure.

2.8 The tool should be securely supported. Strong thrust is created by waterjets and these

forces can become unbalanced if a nozzle should become plugged. The use of a backout

prevention device is recommended.

2.9 The length of the tool and end fitting on hose should be equal to or greater than the inside

diameter of the pipe to be cleaned. If not, use pipe between the hose end and the tool.

2.10 Do not exceed the maximum operating pressure specified for any component in a system.

2.11 Avoid operator/personnel positioning in possible path of out of control tool.

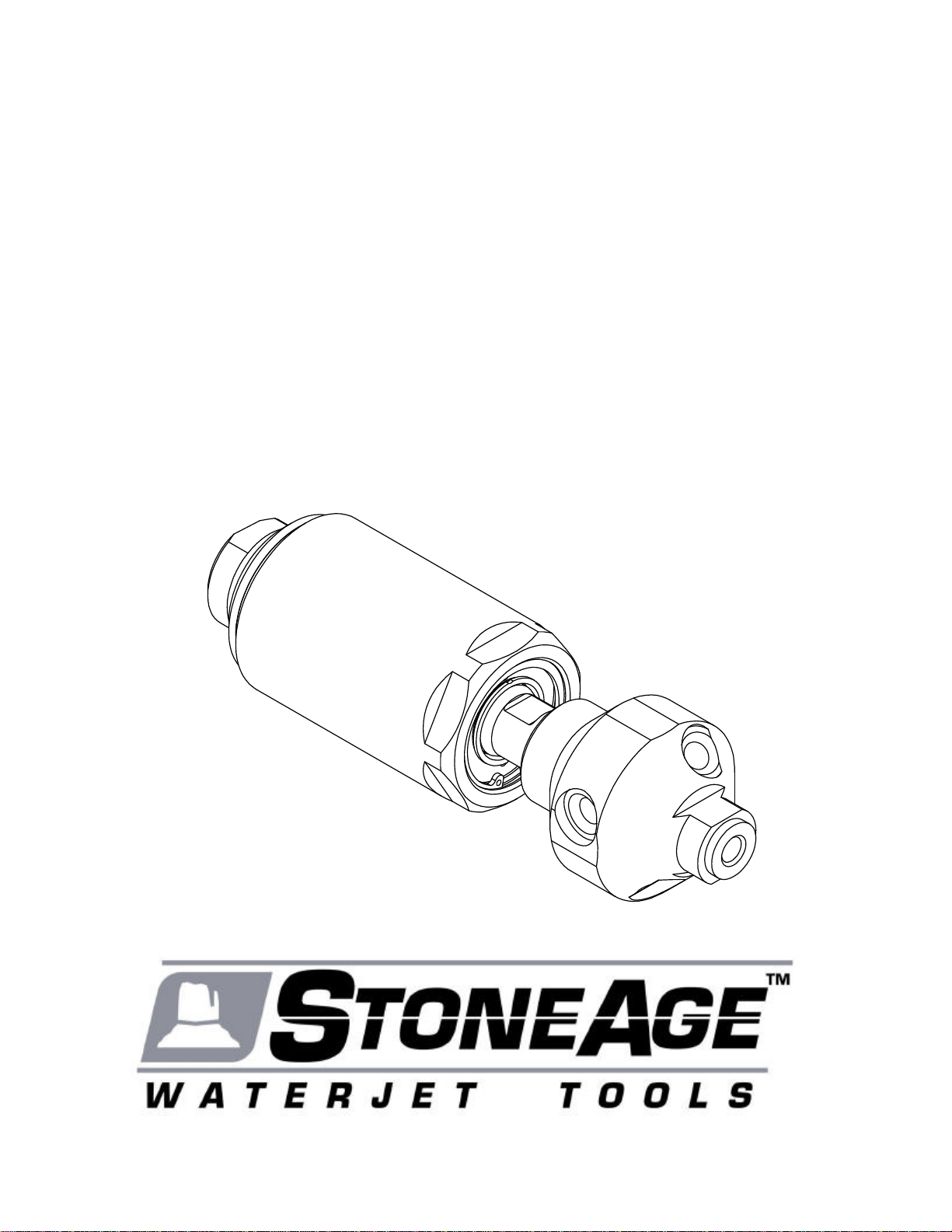

3.0 DESCRIPTION

The BJV-MRotary Waterblast Nozzle was designed for waterblast cleaning of pipes, tanks, vessels and

surfaces. Jet reaction force makes the tool rotate, and a built in viscous fluid governor controls the rotation

speed. The tool is constructed of stainless steel for corrosion resistance.

The swivel is a straight flow through design with a single high pressure seal. It has a 3/4 npt female inlet

connection. The BJV-M is capable of working pressures up to 15000 psi and flow rates of 10 to 100 gpm.

Two rotation speed ranges are available; a thick fluid is used for rotation speeds of 10 to 80 rpm, and a

thinner fluid is used for rotation speeds of 50 to 200 rpm. The fluid in the swivel can be changed to

provide either fast or slow rotation.

The correct nozzle head must be used to match the operating conditions of pressure and flow. If a nozzle

head with too little offset is used, the swivel will not rotate; if a head with too much offset is used, the tool

will rotate too fast and cause rapid seal wear and failure. See the chart below for head selection.

Head Offset Flow

.60 10 to 18 gpm

.35 18 to 32 gpm

.20 32 to 55 gpm

.12 55 to 100 gpm

4.0 PARTS LIST

Part # Description Qty

BJ 001-DM Shaft 1

BJ 002-MInlet Nut 1

BJ 003 Body 1

BJ 008 O-Ring 1

BJ 010-DShaft Seal 2

BJ 014-DWave Spring 2

BJ 021-SWeep Seal 1

BJ 026 Port Screw 1

BJ 028 Piston 1

BJ 030 O-Ring 1

BJ 032 Retaining Ring 1

HC 012-TO High Pressure Seal 1

MJ 011-CSeat, Carbide 1

SG 009 Bearing 2

Also available separately:

BJ 600 Service Kit (Includes items needed for maintenance)

BJ 602 Seal Kit (Includes parts needed for one seal change)

BJ 610 Overhaul Kit (Includes parts needed for tool rebuild)

BJ 612 Tool Kit (Includes tools to aid assembly)

BJ 032

Retaining Ring BJ 028

PistonBJ 030

O-Ring

BJ 010-D

Shaft Seal BJ 003

Body

SG 009

Bearing

BJ 001-DM

Shaft

SG 009

Bearing

BJ 021-S

Weep Seal

BJ 026

Port Screw

BJ 002-M

Inlet Nut

BJ 008

O-Ring

BJ 010-D

Shaft Seal

MJ 011-C

Seat

HC 012-TO

H.P. Seal

BJ 014-D

Wave Spring (2)

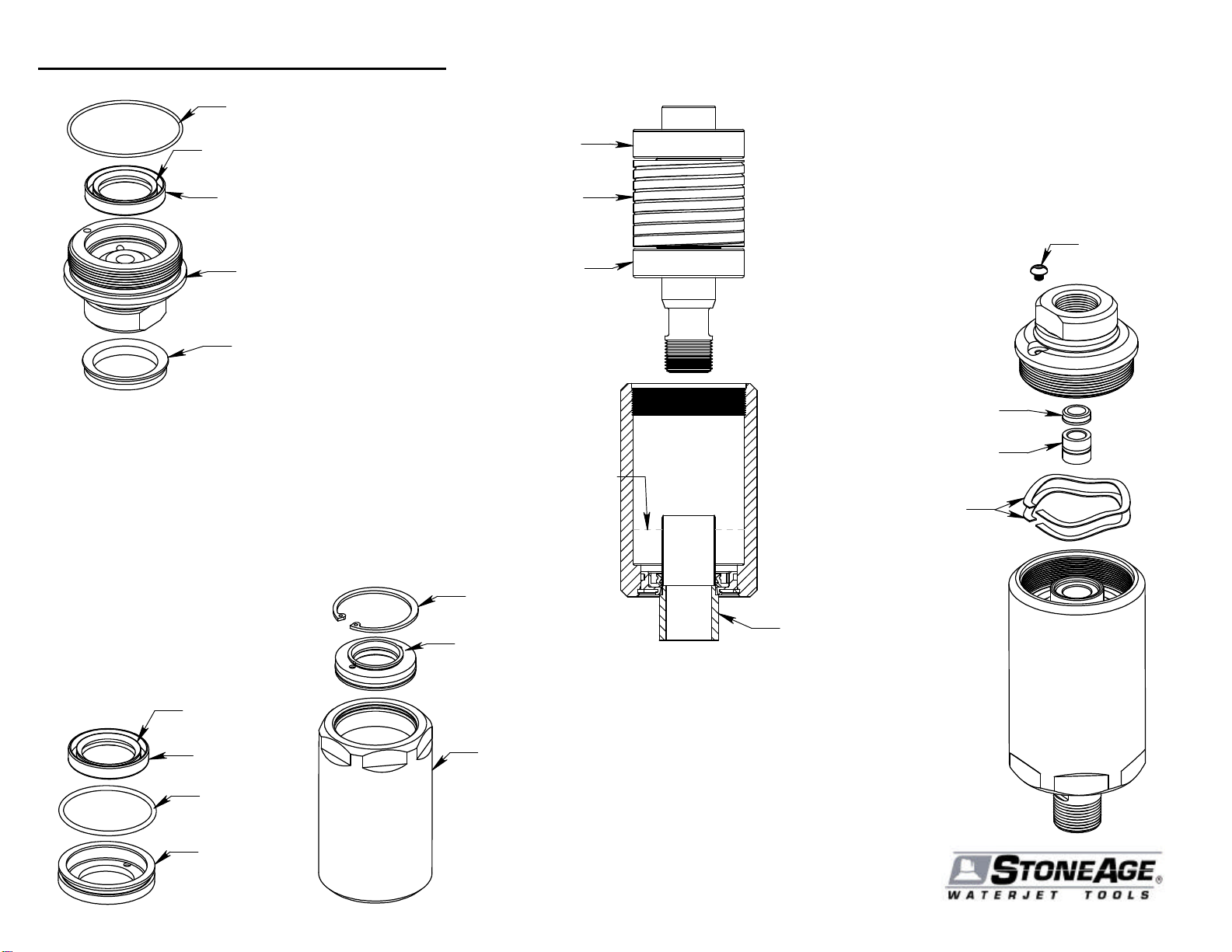

5.0 BJV-M EXPLODED ASSEMBLY DRAWING

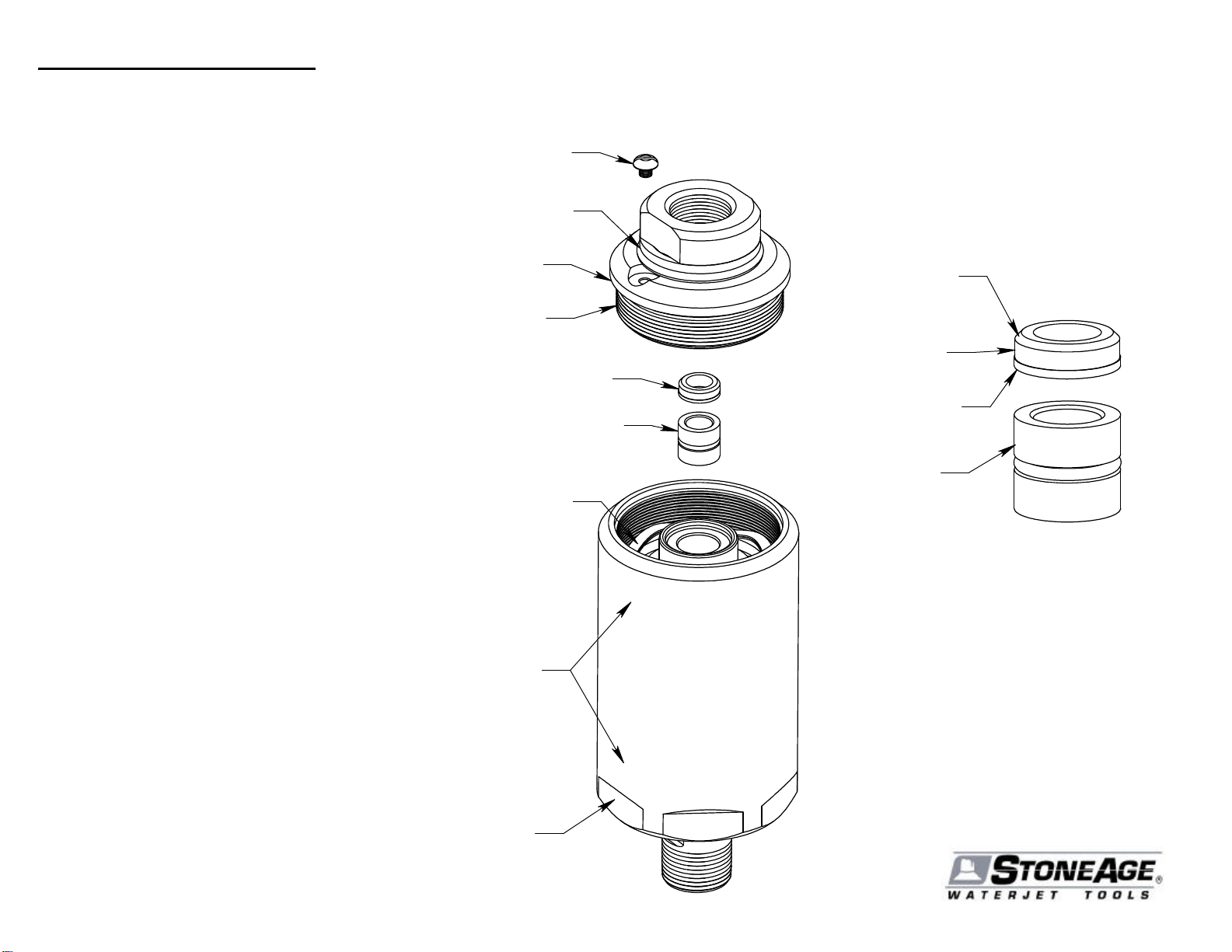

07/02

hold body by

flats only

Never clamp or strike

the round portion of Body

HC 012-TO

H.P. Seal

MJ 011-C

Seat

BJ 002-M

Inlet Nut

BJ 026

Port Screw

The high pressure seal will need to be replaced

when water is leaking continuously out of the

weep ports (under the Weep Seal) at or near

operating pressure. The viscous fluid should

also be checked and filled or replaced during

seal maintenance. BJ 021-S

Weep Seal

Viscous fluid level should

cover the wave springs.

Replace fluid if it has water

or other contamination.

apply anti-seize to

threads of Inlet Nut

1. Remove the Port Screw (BJ 026).

2. Hold Body by flats; unscrew the

Inlet Nut (BJ 002-M).

3. Remove the Seat (MJ 011-C) and

H.P. Seal (HC 012-TO) from the bore

of the Shaft.

4. Inspect the Seat for chips on the

edges and erosion pits on the face.

Replace if damaged.

5. Inspect the face of the Inlet Nut where

the Seat makes contact for dings, dents

or erosion; these must be faced off to

stop all leaking.

6. Check the viscous fluid level and

condition; if the fluid appears badly

contaminated it should be replaced.

Otherwise, add fluid to cover the

wave springs.

7. Apply grease to a new H.P. Seal

and install into bore of shaft. Do not

push it all the way in.

8. Install the Seat with the flat side

against the Seal (see detail drawing).

Push it in just far enough that it will stay

in the bore.

9. Apply anti-seize to the threads of

the Inlet nut; thread into Body, checking

that the Seat stays centered in bore of

shaft. Tighten to 60 ft-lb.

10. Install the Port Screw.

HC 012-TO

H.P. Seal

MJ 011-C

Seat

flat face

against seal

chamfered end

6.0 BJV-M MAINTENANCE

07/02

BJ 026

Port Screw

BJ 002-M

Inlet Nut

MJ 011-C

Seat

HC 012-TO

H.P. Seal

BJ 014-D

Wave Springs

BJ 003

Body

1. Remove the Port Screw (BJ 026) from the

Inlet Nut (BJ 002-M); unscrew the Inlet Nut from

the Body (BJ 003).

2. Remove the Seat (MJ 011-C) and H.P. Seal

(HC 012-TO) from the bore of the Shaft.

3. Remove the Wave Springs (BJ 014-D).

4. Push the Shaft (BJ 001-DM) with bearings out

of the Body.

5. Carefully remove the Bearings (SG 009) from

the Shaft.

SG 009

Bearing

BJ 001-DM

Shaft

SG 009

Bearing

Be careful not to raise

any dings or burrs on the

large portion of the shaft

when removing bearings

6. Remove the Retaining Ring

(BJ 032) from the Body. Push out

the Piston (BJ 028).

7. Inspect the O-Ring (BJ 030) and

the Shaft Seal (BJ 010-D); replace

if damaged.

8. Inspect the O-Ring (BJ 008),

Shaft Seal (BJ 010-D) and Weep

Seal (BJ 021-S) on the Inlet Nut;

replace if damaged.

BJ 032

Retaining Ring

BJ 028

Piston

BJ 030

O-Ring

BJ 010-D

Shaft Seal

BJ 008

O-Ring

BJ 010-D

Shaft Seal

BJ 002-M

Inlet Nut

BJ 021-S

Weep Seal

6.1 BJV-M DISASSEMBLY INSTRUCTIONS

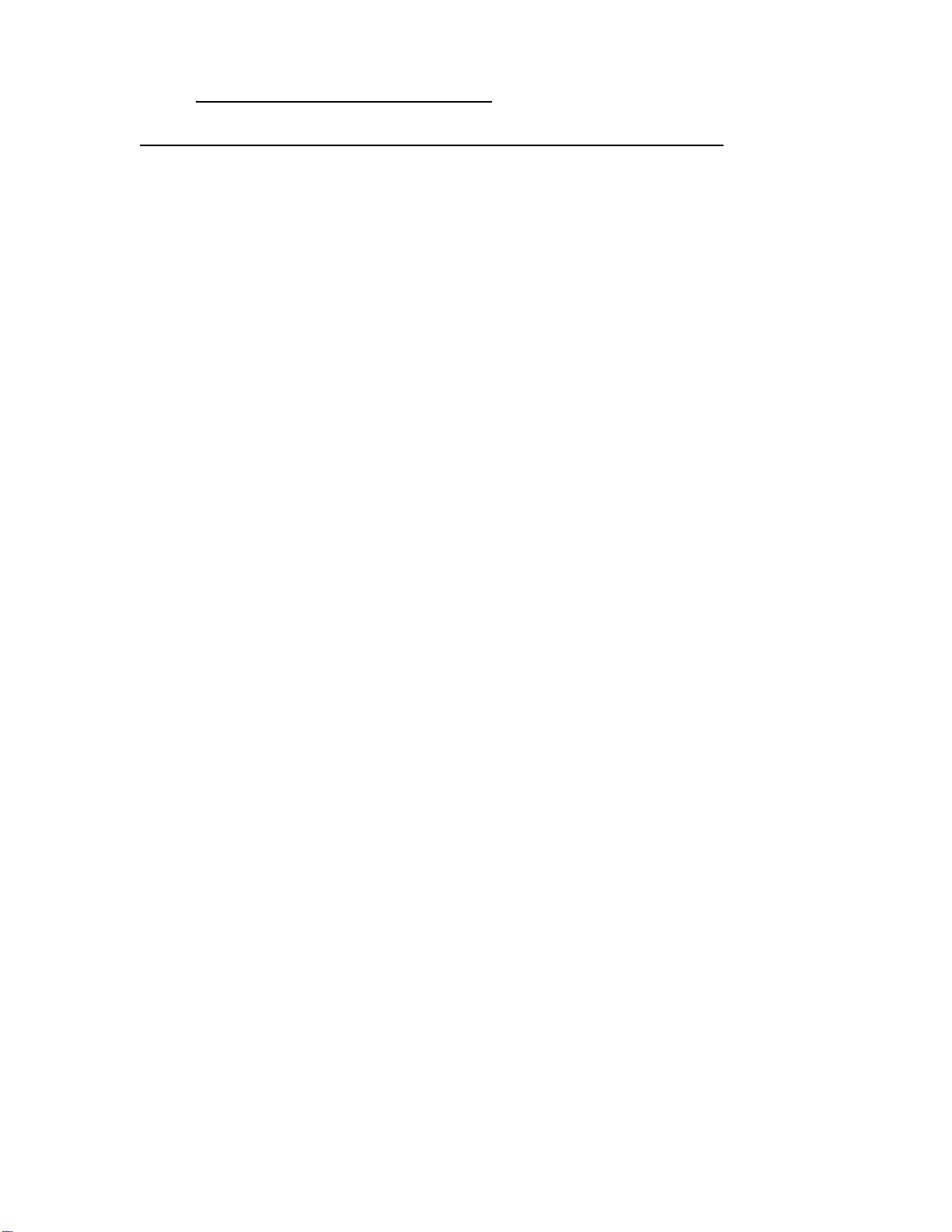

07/02

BJ 026

Port Screw

MJ 011-C

Seat

HC 012-TO

H.P. Seal

BJ 014-D

Wave Springs

BJ 008

O-Ring

BJ 010-D

Shaft Seal

BJ 002-M

Inlet Nut

BJ 021-S

Weep Seal

lip with spring

facing up

1. Install Shaft Seal (BJ 010-D)

in Inlet Nut (BJ 002-M) as shown.

2. Place O-Ring (BJ 008) over

threads of Inlet Nut.

3. Install Weep Seal (BJ 021-S).

4. Install Shaft Seal (BJ 010-D)

in Piston (BJ 028) as shown.

5. Place O-Ring (BJ 030) in

groove around Piston.

6. Push Piston into Body (BJ 003),

install Retaining Ring (BJ 032). 7. Press Bearings (SG 009) onto Shaft (BJ 001-DM).

8. Insert Fill Tube (HC 064) thru shaft seal in Piston up

to shoulder.

9. Pour viscous fluid into Body, until about 3/4" deep.

10. Slide Shaft into Body, allowing Shaft to push

out the fill tube. Fluid should come up around shaft.

lip with spring

facing up

BJ 010-D

Shaft Seal

BJ 030

O-Ring

BJ 028

Piston

BJ 032

Retaining Ring

BJ 028

Piston

BJ 003

Body

HC 064

Fill Tube

pour in viscous fluid,

about 3/4" deep

SG 009

Bearing

SG 009

Bearing

BJ 001-DM

Shaft

10. Place the two Wave Springs (BJ 014-D)

on top of bearing. Add viscous fluid until the

Wave Springs are covered.

11. Apply grease to the H.P. Seal (HC 012-TO)

and install in bore of shaft. Install Seat (MJ 011-C)

on top of Seal, as shown in Section 6.0.

12. Apply anti-seize to threads of Inlet Nut

and thread into Body. Tighten to 60 ft-lb.

13. Install Port Screw (BJ 026).

6.2 BJV-M ASSEMBLY INSTRUCTIONS

07/02

6.3 TROUBLESHOOTING GUIDE

SYMPTOM PROBLEM SOLUTION

Leaks around weep seal Worn H.P. seal Replace H.P. Seal (HC 012-TO)

Damaged seat Replace Seat (MJ 011-C)

Damaged Inlet Nut Face or replace Inlet Nut

Seals wear out quickly Chipped seat Replace Seat (MJ 011-C)

Worn Shaft bore Replace Shaft if bore >.635”

Will not rotate Not enough jet torque Check nozzles for plugging

or wear.

Check that head offset correctly

matches pressure and flow.

Internal damage Rotate head by hand, if rough to

turn, check bearings; check

grooved section of shaft for

contact with body.

Water inside tool Bad H.P. Seal leak Replace H.P. Seal

Worn shaft seals Replace shaft seals

Spins too fast Low or empty viscous fluid Refill with viscous fluid.

Water in viscous fluid Clean and refill viscous fluid.

Too much jet torque Check that head offset matches

pressure and flow.

Wrong viscous fluid Replace with slow fluid.

7.0 LIMITED WARRANTY

StoneAge, Inc. warrants to the extent herein provided the products of its own manufacture against defects

in material and workmanship under normal use and service for which the products were designed for a

period of six months after shipment from the factory. If such products should fail through defect in

workmanship or material and specific written notice of failure is made within six months after date of

shipment from factory, StoneAge, Inc. will either repair or replace any such items, F.O.B. its factory without

charge. StoneAge, Inc. shall not be liable for expense incurred in repairs or alterations made outside the

factory without the proper and prior authorization. StoneAge, Inc. shall have the option of requiring the

return of the defective products to its factory, with transportation charges prepaid, to establish the claim.

StoneAge, Inc. shall in no event be held liable for damages or delay resulting from or arising out of

defective products nor for consequential damages or otherwise except for repair or replacement of items

of defective material or workmanship aforesaid.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE AND NEITHER

ASSUMES, NOR AUTHORIZES ANY PERSON TO ASSUME FOR STONEAGE, INC. ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF ITS PRODUCTS. THIS WARRANTY SHALL NOT

APPLY TO PRODUCTS OR ANY PARTS THEREOF WHICH HAVE BEEN SUBJECT TO ACCIDENT,

NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. STONEAGE, INC. MAKES NO WARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES, PARTS OR PRODUCTS NOT MANUFACTURED BY

STONEAGE, INC.

APPENDIX BJ 048-S VISCOUS FLUID

OSI SPECIALTIES INC —POLYDIMETHYLSILOXANE L-405-12500

MATERIAL SAFETY DATA SHEET Revision: 1.0 9/27/2000

=======================================================

MSDS Safety Information

=======================================================

MSDS Date: 9/27/2000

MSDS Num: 910000000791

Product ID: L-405-12500

Chemical Name: Polydimethylsiloxane(inhibited)

Responsible Party: Mr. Dana Dalrymple

Name: OSI SPECIALTIES INC

Address: ONE AMERICAN LANE

City: GREENWICH CT 06831-2559

Info Phone Number: 304-652-8446

Emergency Phone Number: 800-809-9998; 800-424-9300(CHEMTREC)

Published: Y

=======================================================

Ingredients

=======================================================

Proprietary: NO

Ingredient: POLYDIMETHYLSILOXANE

Ingredient Sequence Number: 01

Percent: <100%

CAS Number: 63148-62-9

Other Recommended Limit: NONE SPECIFIED

———————————————————————————

Proprietary: NO

Ingredient: PROPRIETARY inhibitors

Ingredient Sequence Number: 02

Percent: <1%

Trade secret

=======================================================

Health Hazards Data

=======================================================

LD50-LC50 Mixture: LD50 (ORAL RAT) IS UNKNOWN

Route Of Entry -Inhalation: NO

Route Of Entry -Skin: NO

Route Of Entry -Ingestion: NO

Health Haz Acute And Chronic: ACUTE & CHRONIC: NO EVIDENCE OF ADVERSE

FROM AVAILABLE INFORMATION.

Carcinogenicity -NTP: NO

Carcinogenicity -IARC: NO

Carcinogenicity -OSHA: NO

Signs/Symptoms Of Overexp: No Adverse Effects.

Med Cond Aggravated By Exp: None Specified By Manufacturer.

Emergency/First Aid Proc:

INGESTION: NO EMERGENCY CARE ANTICIPATED.

SKIN:WASH WITH SOAP AND WATER.

INHALATION: NO EMERGENCY CARE ANTICIPATED.

EYES: FLUSH THOROUGHLY WITH WATER FOR SEVERAL MINUTES.

NOTES TO PHYSICIAN: THERE IS NO SPECIFIC ANTIDOTE. TREATMENT OF

OVEREXPOSURE SHOULD BE DIRECTED AT THE CONTROL OF SYMPTOMS AND THE

CLINICAL CONDITION OF THE PATIENT

=======================================================

Handling and Disposal

=======================================================

=======================================================

Fire and Explosion Hazard Information

=======================================================

Flash Point: 254°C/(490°F)

Extinguishing Media: DO NOT SPRAY A SOLID STREAM OF WATER DIRECTLY INTO

BURNING LIQUID.

USE CARBON DIOXIDE, ALCOHOL FOAM, OR DRY CHEMICAL.

Special Fire Fighting Proc: WEAR SELF CONTAINED BREATHING APPARATUS.

CONTAIN RUNOFF.

Unusual Fire And Expl Hazrds: MAY CAUSE FLOATING FIRE HAZARD

=======================================================

Control Measures

=======================================================

Respiratory Protection: NONE EXPECTED TO BE REQUIRED.

Protective Gloves: 4H, BUTYL, NEOPRENE, NITRILE(NBR), PVC COATED

Eye Protection: SAFETY GLASSES

Work Hygienic Practices: OBSERVE GOOD PERSONAL HYGIENE PRACTICES AND

RECOMMENDED PROCEDURES. DO NOT WEAR CONTAMINATED CLOTHING OR

FOOTWEAR.

Other Protective Equipment: SAFETY SHOWER, EYE BATH

=======================================================

Physical/Chemical Properties

=======================================================

Appearance:

Physical state: Clear to Hazy Liquid

Color: Yellow

Odor: Mild

Other Properties:

Boiling Point: >250°C @STP unless specified below

Melting Point: <-50°C @ STP unless specified below

pH: N/A

Spec Gravity: 0.9738@25°C

Vapor Pres: <1.33hPa (1.00mmHg) @20°C

Vapor Density: Heavier Than Air

Solubility in Water: Insoluble

Evaporation Rate: <1

Flash Point: >254°C / >490°F

Upper Explosion Limit: N/A

Lower Explosion Limit: N/A

Percent Volatile: Not Determined

Molecular Weight: Polymer

=======================================================

Reactivity Data

=======================================================

Stability: Stable

Stability Condition To Avoid: None Known.

Materials To Avoid: Strong oxidizing agents

Hazardous Combustion Products:

Burning Can Produce The Following Combustion Products:

OXIDES OF CARBON, OXIDES OF SILICON, FORMALDEHYDE, CARBON MONOXIDE IS

HIGHLY TOXIC IF INHALED;CARBON DIOXIDE IN SUFFICIENT CONCENTRATIONS CAN

ACT AS AN ASPHYXIANT.

ACUTE OVEREXPOSURE TO THE PRODUCTS OF COMBUSTION MAY RESULT IN

IRRITATION OF THE RESPIRATORY TRACT.

Hazardous Polymerization: Will Not Occur.

Conditions To Avoid Polymerization: None Known.

=======================================================

Toxicological Information

=======================================================

No information relevant to human health hazard evaluation is currently available

=======================================================

Ecological Information

=======================================================

Prevent Runoff

Use Absorbent To Clean Up

=======================================================

MSDS Transport Information

=======================================================

This product is not regulated by the DOT, IMDG, ICAO.

Freight description road: OIL, O/T PETROLEUM, LUBRICATING, NOIBN

=======================================================

Regulatory Information

=======================================================

CERCLA; None

SARA; None

MSL; None

EPA; None

California Prop 65; None

California SCAQMD; VOC=>0.5mmHg@ 104°C / 219.2°F **Not determined**

=======================================================

Other Information

=======================================================

Chemical Inventory

Europe: The ingredients of this mixture are on the EINECS inventory.

United States: The ingredients of this product are listed on the TSCA

inventory or are exempt.

=======================================================

HAZCOM Label

=======================================================

Product ID: POLYDIMETHYLSILOXANE L-45-12500

Supplier: Crompton Corporation

Street: One American Lane

City: Greenwich, CT

Zipcode: 06831-2559, USA

Health Emergency Phone: 800-809-9998;800-424-9300(CHEMTREC)

Label Required: Yes

Health Hazard: 0

Flammability: 1

Reactivity: 0

PPE: X

=======================================================

APPENDIX BJ O48-F VISCOUS FLUID

OSI SPECIALTIES INC —POLYDIMETHYLSILOXANE L-405-2000

MATERIAL SAFETY DATA SHEET Revision: 1.0 9/27/2000

=======================================================

MSDS Safety Information

=======================================================

MSDS Date: 9/27/2000

MSDS Num: 491

Product ID: L-405-2000

Chemical Name: Polydimethylsiloxane(inhibited)

Responsible Party: Mr. Dana Dalrymple

Name: OSI SPECIALTIES INC

Address: ONE AMERICAN LANE

City: GREENWICH CT 06831-2559

Info Phone Number: 304-652-8446

Emergency Phone Number: 800-809-9998; 800-424-9300(CHEMTREC)

Published: Y

=======================================================

Ingredients

=======================================================

Proprietary: NO

Ingredient: POLYDIMETHYLSILOXANE

Ingredient Sequence Number: 01

Percent: <100%

CAS Number: 63148-62-9

Other Recommended Limit: NONE SPECIFIED

———————————————————————————

Proprietary: NO

Ingredient: PROPRIETARY inhibitors

Ingredient Sequence Number: 02

Percent: <1%

Trade secret

=======================================================

Health Hazards Data

=======================================================

LD50-LC50 Mixture: LD50 (ORAL RAT) IS UNKNOWN

Route Of Entry -Inhalation: NO

Route Of Entry -Skin: NO

Route Of Entry -Ingestion: NO

Health Haz Acute And Chronic: ACUTE & CHRONIC: NO EVIDENCE OF ADVERSE

FROM AVAILABLE INFORMATION.

Carcinogenicity -NTP: NO

Carcinogenicity -IARC: NO

Carcinogenicity -OSHA: NO

Signs/Symptoms Of Overexp: No Adverse Effects.

Med Cond Aggravated By Exp: None Specified By Manufacturer.

Emergency/First Aid Proc:

INGESTION: NO EMERGENCY CARE ANTICIPATED.

SKIN:WASH WITH SOAP AND WATER.

INHALATION: NO EMERGENCY CARE ANTICIPATED.

EYES: FLUSH THOROUGHLY WITH WATER FOR SEVERAL MINUTES.

NOTES TO PHYSICIAN: THERE IS NO SPECIFIC ANTIDOTE. TREATMENT OF

OVEREXPOSURE SHOULD BE DIRECTED AT THE CONTROL OF SYMPTOMS AND THE

CLINICAL CONDITION OF THE PATIENT

=======================================================

Handling and Disposal

=======================================================

=======================================================

Fire and Explosion Hazard Information

=======================================================

Flash Point: 254°C/(490°F)

Extinguishing Media: DO NOT SPRAY A SOLID STREAM OF WATER DIRECTLY INTO

BURNING LIQUID.

USE CARBON DIOXIDE, ALCOHOL FOAM, OR DRY CHEMICAL.

Special Fire Fighting Proc: WEAR SELF CONTAINED BREATHING APPARATUS.

CONTAIN RUNOFF.

Unusual Fire And Expl Hazrds: MAY CAUSE FLOATING FIRE HAZARD

=======================================================

Control Measures

=======================================================

Respiratory Protection: NONE EXPECTED TO BE REQUIRED.

Protective Gloves: 4H, BUTYL, NEOPRENE, NITRILE(NBR), PVC COATED

Eye Protection: SAFETY GLASSES

Work Hygienic Practices: OBSERVE GOOD PERSONAL HYGIENE PRACTICES AND

RECOMMENDED PROCEDURES. DO NOT WEAR CONTAMINATED CLOTHING OR

FOOTWEAR.

Other Protective Equipment: SAFETY SHOWER, EYE BATH

=======================================================

Physical/Chemical Properties

=======================================================

Appearance:

Physical state: Clear to Hazy Liquid

Color: Yellow

Odor: Mild

Other Properties:

Boiling Point: >250°C @STP unless specified below

Melting Point: <-50°C @ STP unless specified below

pH: N/A

Spec Gravity: 0.9729@25°C

Vapor Pres: <1.33hPa (1.00mmHg) @20°C

Vapor Density: Heavier Than Air

Solubility in Water: Insoluble

Evaporation Rate: <1

Flash Point: >254°C / >490°F

Upper Explosion Limit: N/A

Lower Explosion Limit: N/A

Percent Volatile: Not Determined

Molecular Weight: Polymer

=======================================================

Reactivity Data

=======================================================

Stability: Stable

Stability Condition To Avoid: None Known.

Materials To Avoid: Strong oxidizing agents

Hazardous Combustion Products:

Burning Can Produce The Following Combustion Products:

OXIDES OF CARBON, OXIDES OF SILICON, FORMALDEHYDE, CARBON MONOXIDE IS

HIGHLY TOXIC IF INHALED;CARBON DIOXIDE IN SUFFICIENT CONCENTRATIONS CAN

ACT AS AN ASPHYXIANT.

ACUTE OVEREXPOSURE TO THE PRODUCTS OF COMBUSTION MAY RESULT IN

IRRITATION OF THE RESPIRATORY TRACT.

Hazardous Polymerization: Will Not Occur.

Conditions To Avoid Polymerization: None Known.

=======================================================

Toxicological Information

=======================================================

No information relevant to human health hazard evaluation is currently available

=======================================================

Ecological Information

=======================================================

Prevent Runoff

Use Absorbent To Clean Up

=======================================================

MSDS Transport Information

=======================================================

This product is not regulated by the DOT, IMDG, ICAO.

Freight description road: OIL, O/T PETROLEUM, LUBRICATING, NOIBN

=======================================================

Regulatory Information

=======================================================

CERCLA; None

SARA; None

MSL; None

EPA; None

California Prop 65; None

California SCAQMD; VOC=>0.5mmHg@ 104°C / 219.2°F **Not determined**

=======================================================

Other Information

=======================================================

Chemical Inventory

Europe: The ingredients of this mixture are on the EINECS inventory.

United States: The ingredients of this product are listed on the TSCA

inventory or are exempt.

=======================================================

HAZCOM Label

=======================================================

Product ID: POLYDIMETHYLSILOXANE L-45-2000

Supplier: Crompton Corporation

Street: One American Lane

City: Greenwich, CT

Zipcode: 06831-2559, USA

Health Emergency Phone: 800-809-9998;800-424-9300(CHEMTREC)

Label Required: Yes

Health Hazard: 0

Flammability: 1

Reactivity: 0

PPE: X

=======================================================

Table of contents

Other StoneAge Industrial Equipment manuals