Strand R21 User manual

O

The material in this manual is for information purposes only and is subject to change without notice. Vari-

Lite assumes no responsibility for any errors or omissions which may appear in this manual. For comments and

suggestions regarding corrections and/or updates to this manual, please contact your nearest Vari-Lite office.

El contenido de este manual es solamente para información y está sujeto a cambios sin previo aviso. Vari-

Lite no asume responsabilidad por errores o omisiones que puedan aparecer. Cualquier comentario, sugerencia

o corrección con respecto a este manual, favor de dirijirlo a la oficina de Vari-Lite más cercana.

Der Inhalt dieses Handbuches ist nur für Informationszwecke gedacht, Aenderungen sind vorbehalten. Vari-

Lite uebernimmt keine Verantwortung für Fehler oder Irrtuemer, die in diesem Handbuch auftreten. Für

Bemerkungen und Verbesserungsvorschlaege oder Vorschlaege in Bezug auf Korrekturen und/

oder Aktualisierungen in diesem Handbuch, moechten wir Sie bitten, Kontakt mit der naechsten Vari-Lite-

Niederlassung aufzunehmen.

Le matériel décrit dans ce manuel est pour information seulement et est sujet à changements sans préavis.

La compagnie Vari-Lite n'assume aucune responsibilité sur toute erreur ou ommission inscrite dans ce manuel.

Pour tous commentaires ou suggestions concernant des corrections et/ou les mises à jour de ce manuel, veuillez

s'll vous plait contacter le bureau de Vari-Lite le plus proche.

Information contained in this document may not be duplicated in full or in part by any person without prior

written approval of Vari-Lite. Its sole purpose is to provide the user with conceptual information on the

equipment mentioned. The use of this document for all other purposes is specifically prohibited.

Document Number: 2-450334-010 Rev. A

Version as of: 08 January 2014

R21 Powered Raceway Installation Guide

Website:

www.vari-lite.com

1

R21 Powered Raceway Installation Guide

IMPORTANT SAFEGUARDS

WARNING! The unit is to be stored and operated in and environment that is at or below the following conditions -

Ambient Temperature: 32 to 104oF / 0 to 40oC with a relative humidity of 5%-95% Non-Condensing. At no time

should the unit be stored, operated, or installed outdoors.

When using electrical equipment, basic safety precautions should always be followed including the following:

a. READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

b. Do not use outdoors.

c. Do not mount near gas or electric heaters.

d. Equipment should be mounted in locations and at heights where it will not readily be subjected to

tampering by unauthorized personnel.

e. The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

f. Do not use this equipment for other than intended use.

g. Refer service to qualified personnel.

SAVE THESE INSTRUCTIONS.

WARNING: You must have access to a main circuit breaker or other power disconnect device

before installing any wiring. Be sure that power is disconnected by removing fuses or turning the

main circuit breaker off before installation. Installing the device with power on may expose you to

dangerous voltage and damage the device. A qualified electrician must perform this installation.

WARNING: Refer to National Electrical Code® and local codes for cable specifications. Failure to

use proper cable can result in damage to equipment or danger to persons.

WARNING: This equipment is intended for installation in accordance with the National Electric

Code® and local regulations. It is also intended for permanent installation in indoor applications

only. Before any electrical work is performed, disconnect power at the circuit breaker or remove the

fuse to avoid shock or damage to the control. It is recommended that a qualified electrician perform

this installation.

CAUTION: Wire openings MUST have fittings or lining to protect wires/cables from damage. Use

90° C copper wire only! Aluminum wire may not be used.

Installation Guide R21 Powered Raceway

2Table of Contents

TABLE OF CONTENTS

Important Safeguards

Table of Contents

Preface

About This Guide........................................................................................................................................................................ 3

DMX Output Options ......................................................................................................................................................... 3

Mounting Hardware Options.............................................................................................................................................. 3

Additional Resources.................................................................................................................................................................. 3

Other Manuals..................................................................................................................................................................... 3

Additional Resources for DMX512.................................................................................................................................... 4

Overview

Installation and Checkout Sequence........................................................................................................................................... 4

Components

R21 Powered Raceway............................................................................................................................................................... 5

Raceway Control Module........................................................................................................................................................... 6

DMX Headend............................................................................................................................................................................ 6

Dimmer Modules........................................................................................................................................................................ 7

Overview............................................................................................................................................................................. 7

Dimmer Module - Focus Buttons ....................................................................................................................................... 7

Dimmer Modules - LED Indicators.................................................................................................................................... 7

Relay Modules............................................................................................................................................................................ 8

Overview............................................................................................................................................................................. 8

Relay Module - Focus Buttons ........................................................................................................................................... 8

Relay Modules - LED Indicators........................................................................................................................................ 8

DMX Single Output Plate........................................................................................................................................................... 9

Overview............................................................................................................................................................................. 9

Mechanical Considerations

Tools and Supplies.................................................................................................................................................................... 10

Installation Location ................................................................................................................................................................. 10

Wire Routing............................................................................................................................................................................. 11

Wiring Requirements................................................................................................................................................................ 11

Installation Procedure

Connecting Sections ................................................................................................................................................................. 12

Mounting the Unit..................................................................................................................................................................... 12

Single-Pipe Methods......................................................................................................................................................... 12

Double-Pipe Methods....................................................................................................................................................... 13

Threaded Rod and Wall Mount Methods ......................................................................................................................... 13

Connecting Power Wiring......................................................................................................................................................... 14

Overview........................................................................................................................................................................... 14

Line Power........................................................................................................................................................................ 15

Connecting Control Wiring....................................................................................................................................................... 16

Overview........................................................................................................................................................................... 16

DMX512........................................................................................................................................................................... 17

Vision.net Networks (SVN/485)....................................................................................................................................... 18

Termination of Shielded Cable......................................................................................................................................... 18

Termination of Ethernet Cable ......................................................................................................................................... 19

Master/Slave Wiring (DIM96).......................................................................................................................................... 20

Panic Input........................................................................................................................................................................ 20

Installing Cable Tray (if applicable)......................................................................................................................................... 21

Complete and Test .................................................................................................................................................................... 21

Technical & Accessories

Technical Information............................................................................................................................................................... 22

Mounting Hardware.................................................................................................................................................................. 22

Maintenance Procedures

Replacing a Dimmer or Relay Module..................................................................................................................................... 23

Appendix A.

R21 Powered Raceway Dimmer / Relay Module DIP Switch Settings ................................................................................... 24

About This Guide 3

R21 Powered Raceway Installation Guide

PREFACE

1. About This Guide

The document provides installation instructions for all configurations of the R21 Powered Raceway. Please read all

instructions before installing or using this product. Retain this guide for future reference.

• R21 Powered Raceway Configuration: 96350- aa-bb(bb)-cc(cc)-dd(dd)-e(e)-ff(ff)

Note: Each R21 Powered Raceway is a customer specific, built-to-order distributed dimming system. For specific

information on your system, please refer to Strand Lighting or contract drawings

DMX Output Options

Mounting Hardware Options

2. Additional Resources

Other Manuals

For additional operation, maintenance, and setup information, please see the following Strand manuals:

• R21 Powered Raceway Operation and Maintenance Guide

Note: R21 Powered Raceway information and manuals may be downloaded at www.vari-lite.com.

Item Description

aa Total Length in Feet

bb Number of 2400 Watt Dual-Dimmer Modules

(bb) Number of 20 Amp Dual-Relay Modules

cc Number of Dimmer Load Connectors

(cc) Number of Relay Load Connectors

dd Dimmer Load Connector Type (GP - Grounded Stage Pin / GTL - Twistlock / GR - Edison)

(dd) Relay Load Connector Type (GP - Grounded Stage Pin / GTL - Twistlock / GR - Edison)

e Dimmer Connector Style (F - Flush / P - Pigtail)

(e) Relay Connector Style (F - Flush / P - Pigtail)

ff If Pigtail, Specify Dimmer Pigtail Length in Inches (note, standard length is 18 inches)

(ff) If Pigtail, Specify Relay Pigtail Length in Inches (note, standard length is 18 inches)

Item Description

96350-DMXHE R21 Raceway Headend (one required per universe)

96350-DMX R21 Raceway DMX Single Plate (A5F panel connector)

Item Description

71440 Single-Pipe Rigged Hanger Bracket

71441 Double-Pipe Rigged Hanger Bracket

71442 Wall-Mount Hanger Bracket

71443 Double-Pipe Offset Hanger Bracket

71444 Single -Pipe Overhung Pipe Hanger Bracket

71445 Single-Pipe Threaded Rod Hanger Bracket

Installation Guide R21 Powered Raceway

4Overview

Additional Resources for DMX512

For more information on installing DMX512 control systems, the following publication is available for purchase

from the United States Institute for Theatre Technology (USITT), "Recommended Practice for DMX512: A Guide for

Users and Installers, 2nd edition" (ISBN: 9780955703522). USITT Contact Information:

USITT

315 South Crouse Avenue, Suite 200

Syracuse, NY 13210-1844 USA

1-800-938-7488 or 1-315-463-6463

www.usitt.org

OVERVIEW

1. Installation and Checkout Sequence

The R21 Powered Raceway is shipped from the factory in a ready-to-install configuration. The following steps will

be required to successfully install the unit(s) at your location:

1) Unpack and Inspect

Remove all components from shipping container(s) and inspect for damage. Compare the equipment you

received to the packing list. If these do not match, contact Vari-Lite Customer Service at: 1-214-647-7880

(international).

2) Review ALL Instructions

Read this entire installation guide before you start the installation.

3) Gather Tools

Obtain all tools and supplies listed in "Tools and Supplies" on page 10.

4) Choose Appropriate Installation Location

Ensure installation location meets the requirements listed in "Installation Location" on page 10.

5) Plan Wire Routing

Decide where line and control wiring will enter the unit.

6) Install Unit

Following the instructions provided in "Installation Procedure" on page 12, mount and wire the unit.

7) Checkout

Perform the steps listed in "Complete and Test" on page 21 to ensure that the unit has been properly installed.

8) Call For Approval

DO NOT ENERGIZE the R21 Powered Raceway until the wiring has been approved by an authorized

technician. Call Strand Lighting to schedule an Engineering Checkout.

R21 Powered Raceway 5

R21 Powered Raceway Installation Guide

COMPONENTS

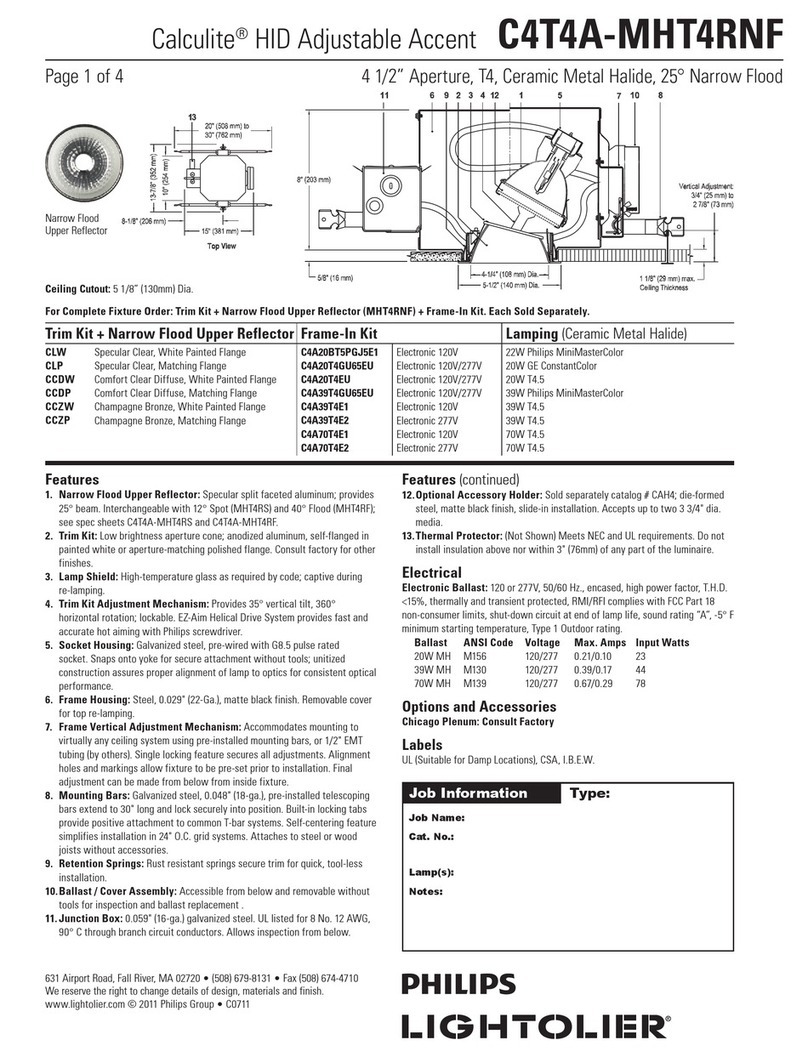

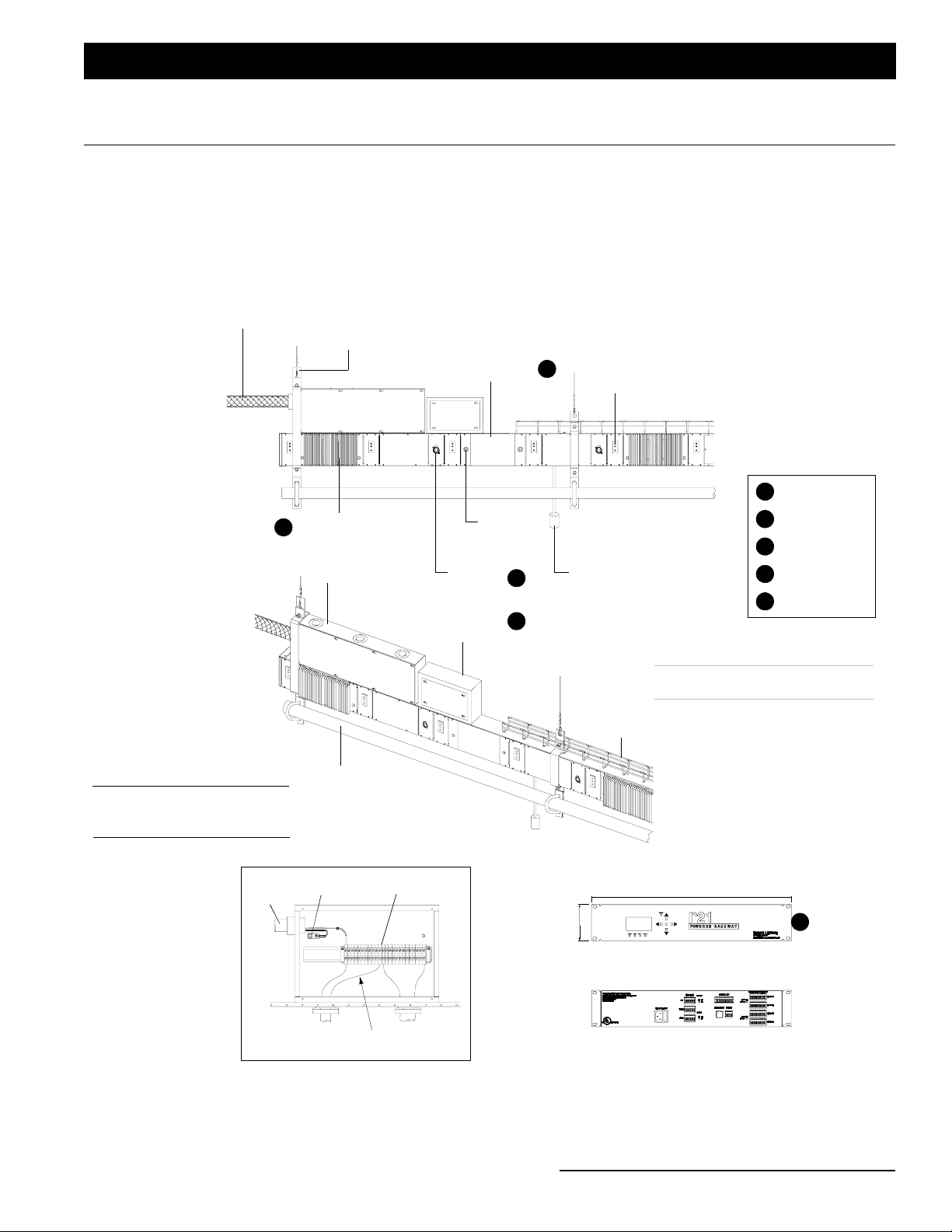

1. R21 Powered Raceway

The R21 Powered Raceway - up to 96 feet long - contains one DMX Headend (one required per universe), up to

forty-eight 20A Dual Dimmer and/or Relay Modules, and at least one Power Terminal Box (PTB). The number of

Power Terminal Boxes is determined by the location and the number of necessary power feeds.

Figure 1: R21 Powered Raceway Component Overview

FRONT VIEW

SIDE VIEW

1-1/2" Schedule 40 Pipe

(not provided, available by others)

Control Cable

Tray (optional)

Power Feed Multi-conductor Cable

w

ith Strain Relief (optional) Hanger Bracket

- six types available

Pigtail Receptacle - Standard Length 18"

(choice of stagepin, twistlock, or Edison

connectors)

Dual Dimmer Modules

(2400 Watts total) Focus Button /

LED Indicator

Flush Receptacle (choice of stage pin,

twistlock, or Edison connectors)

Rack Mount Processor

Rear View

Relay Modules

(2 Relays, 20 Amps total)

Power Terminal

Box (PTB)

Rack Mount Processor

Front View

19.0"

3.469"

DMX Single

Plate (output)

DMX Headend

(one required per universe)

Power TerminalBox Interior View (Typical)

Ground Terminal

Input

Output Power Wiring

(pre-wired at factory)

Input Power Terminals

Power

Feed

EXAMPLE CONFIGURATION

Raceway Components May Vary

B

C

A

BSee next pages

for detail

D

C

Note: All components are pre-wired

at the factory except terminal box

line input connections.

E

A

illustrations.

D

E

Installation Guide R21 Powered Raceway

6Components

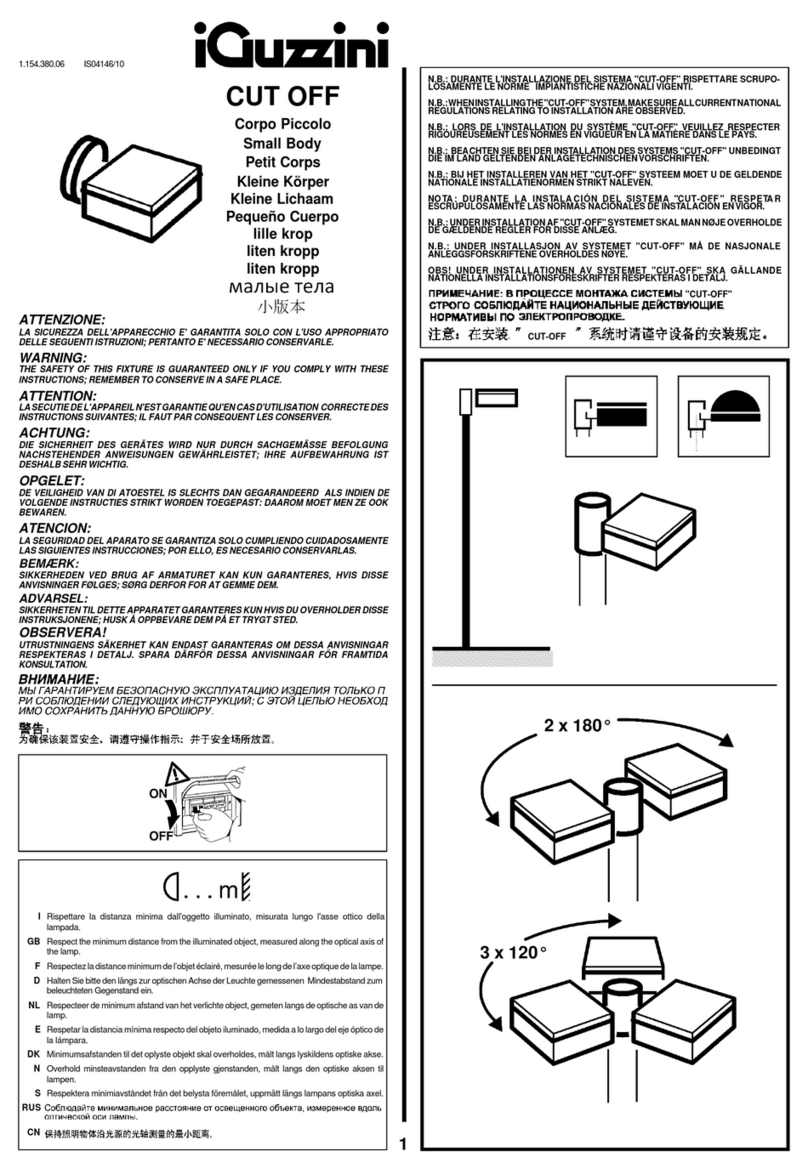

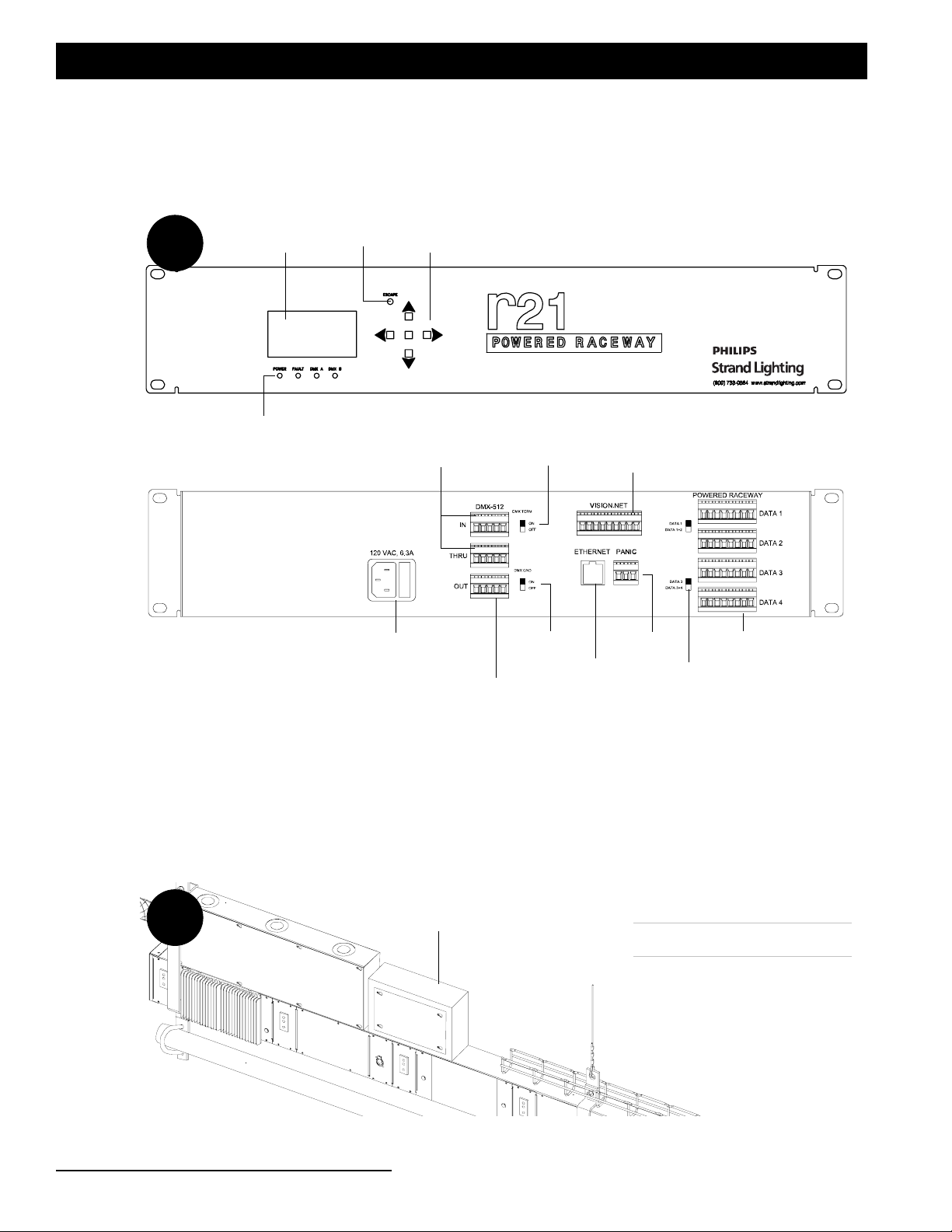

2. Raceway Control Module

The Raceway Control Module (RCM) is used to configure the R21 Powered Raceway. The RCM comes in a 19-inch

"rack mount" configuration for local applications.

Figure 2: Rack Mount RCM Components

3. DMX Headend

The DMX Headend is a central connection point for the R21 Powered Raceway dimming system. One DMX

Headend is required for each universe. The incoming DMX universe is wired inside the DMX Headend and the

headend distributes its connected DMX universe to all dimmers, relay modules, and DMX outlets (as applicable)

within the R21 Powered Raceway chassis.

Figure 3: Rack Mount RCM Components

FRONT VIEW

REAR VIEW

Menu

Status

Menu Navigation

Escape

Button

Display

LEDs

and Enter Buttons

Ethernet

Vision.net Port

A/C Input

DMX512

Termination

Port

DMX512

Ground

DMX512-Over-Ethernet

Output (Ethernet-Enabled Units)

DMX512 In & Thru

(DMX Only Units)

Data Ports

Panic

Input

Data Port

Enable Switches

A

DMX Headend

(one required per universe)

BEXAMPLE CONFIGURATION

Raceway Components May Vary

Dimmer Modules 7

R21 Powered Raceway Installation Guide

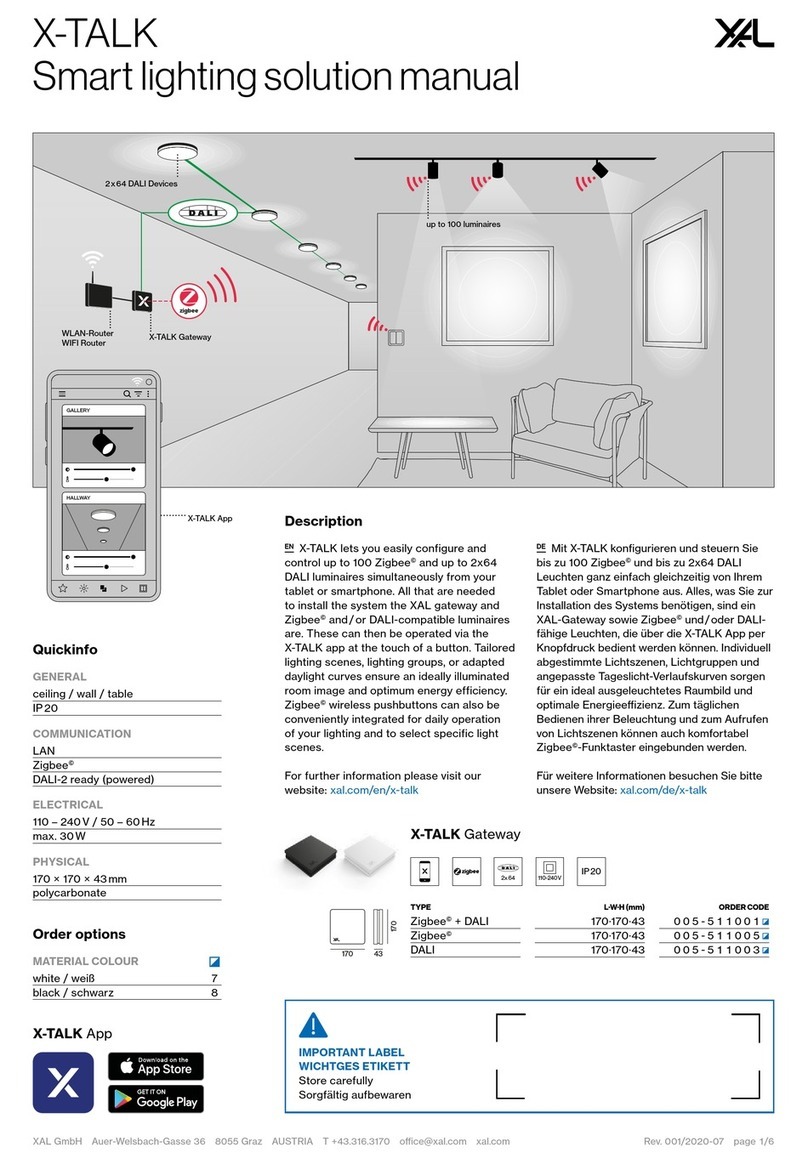

4. Dimmer Modules

Overview

R21 Powered Raceway Dimmer Modules contain one 20A dual dimmer with 20A (2400W) power shared between

the two dimmers. Each dual dimmer module includes two Focus/LED Indicator buttons, which function as both focus

adjustment controls and status indicators.

Figure 4: Dimmer Module Detail

Dimmer Module - Focus Buttons

The Focus Buttons can be used to quickly set the output level or test the module as follows:

• If the module is Off, a tap on the button will take it to full on.

• If the module is On, a tap will turn it off.

• Whether On or Off, pressing and holding the button will ramp up the intensity level. Releasing the button will hold

the setting at an intermediate level.

Note: Fixtures turned on by the Focus Button will remain on until a control console sets a non-zero DMX512 level

for the module. The module’s level setting will be cancelled and it will now follow console control. If the module is

already set to a non-zero DMX512 level by the console, the button becomes a “Flash-to-Full” control, overriding the

level only while the button is pressed.

Dimmer Modules - LED Indicators

Each focus button contains two LEDs associated that are associated with each dimmer and report various operating

conditions. The Red LED turns on for approximately 4 seconds on power-up, and after that the indications are as

follows:

Red LED Green LED Condition

Off Off Normal Operation

Off Flashing No Load

Off On Focus mode (controlled at dimmer)

Flashing

(1.5 sec On, 0.5 sec Off) Off Oversized Load or Overload

Flashing

(0.5 sec On, 0.5 sec Off) Off Over Operational Temperature

On Off No Communications with Head-end Processor

Flashing Flashing Over Voltage

Dimmer A Focus

Button / LED Indicator Dimmer B Focus

Button / LED Indicator

C

Installation Guide R21 Powered Raceway

8Components

5. Relay Modules

Overview

R21 Powered Raceway Relay Modules contain one 20A dual relay with 20A (2400W) power shared between the two

relays. Each dual relay module includes two Focus/LED Indicator buttons, which function as both focus adjustment

controls and status indicators.

Figure 5: Relay Module Detail

Relay Module - Focus Buttons

The Focus Buttons can be used to quickly set the relay operation or test the module as follows:

• If the module is Off, a tap on the button will turn on the relay.

• If the module is On, a tap will turn it off.

Note: Fixtures turned on by the Focus Button will remain on until a control console sets a non-zero DMX512 level

for the module. The module’s level setting will be cancelled and it will now follow console control. If the module is

already set to a non-zero DMX512 level by the console, the button becomes a “Flash-to-Full” control, overriding the

level only while the button is pressed.

Relay Modules - LED Indicators

Each focus button contains two LEDs associated that are associated with each relay and report various operating

conditions. The Red LED turns on for approximately 4 seconds on power-up, and after that the indications are as

follows:

Red LED Green LED Condition

Off Off Normal Operation

Off Flashing No Load

Off On Focus mode (controlled at relay)

Flashing

(1.5 sec On, 0.5 sec Off) Off Oversized Load or Overload

Flashing

(0.5 sec On, 0.5 sec Off) Off Over Operational Temperature

On Off No Communications with Head-end Processor

Flashing Flashing Over Voltage

Relay A Focus

Button / LED Indicator Relay B Focus

Button / LED Indicator

D

DMX Single Output Plate 9

R21 Powered Raceway Installation Guide

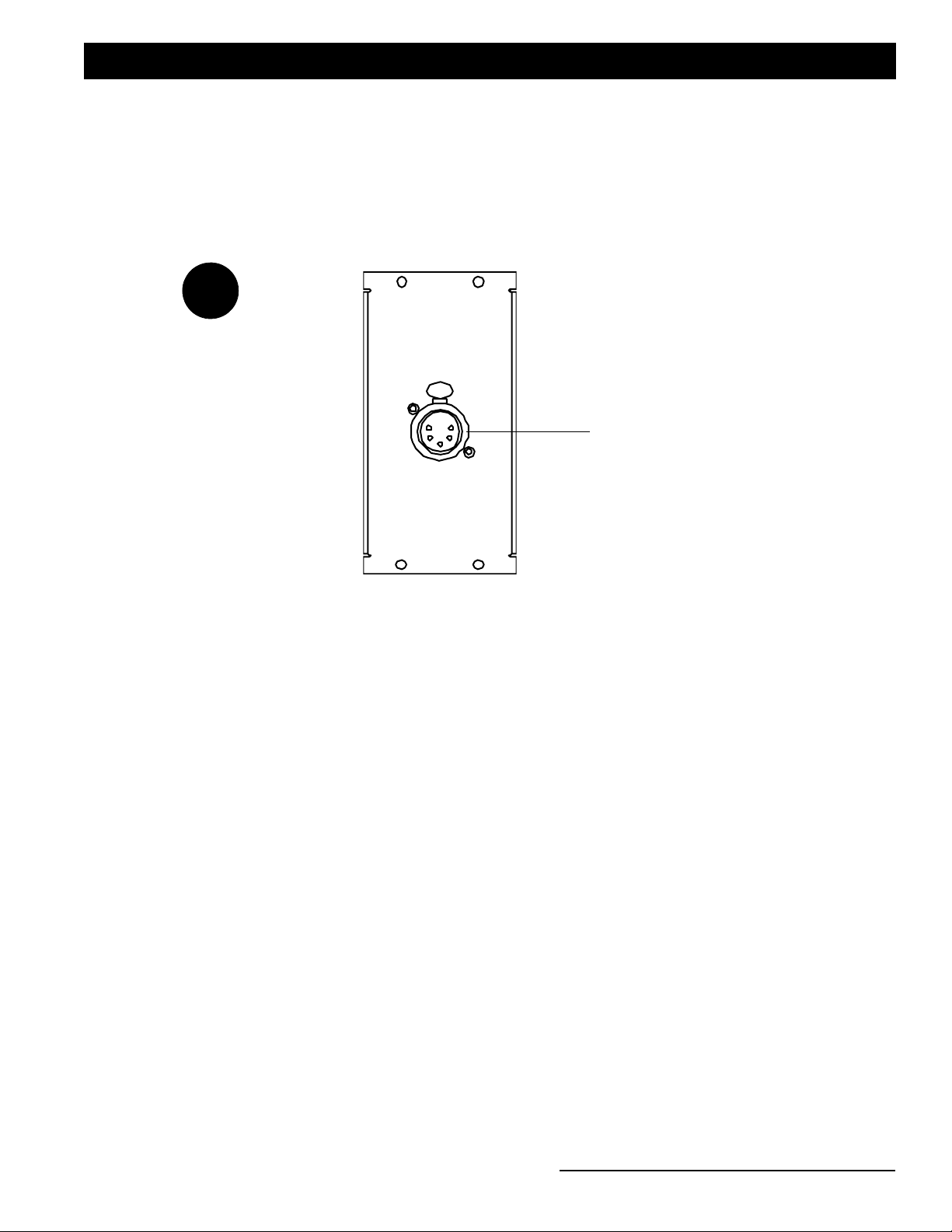

6. DMX Single Output Plate

Overview

As an option, the R21 Powered Raceway can be configured to include single DMX output plates to connect DMX

controlled equipment that may be hung with the R21 Powered Raceway, but not controlled by a dimmer or relay

module. The DMX Single Output Plate is wired directly into the R21 Powered Raceway, so additional wiring is not

required.

Figure 6: DMX Single Output Plate Detail

5-Pin DMX Output

Connector

E

Installation Guide R21 Powered Raceway

10 Mechanical Considerations

MECHANICAL CONSIDERATIONS

1. Tools and Supplies

The following tools and supplies will be required:

• Phillips and slotted screwdrivers

• Adjustable open-ended wrench

• Ratchet and assorted socket set

• Wire cutter and stripper

• Cable/box connectors and fittings

• Digital voltmeter / RMS

• Hammer (for terminal box knock-out holes)

Note: This is a basic list. Depending on your specific installation, additional tools may be required.

2. Installation Location

The location planned for installation MUST meet the following requirements:

•Weight Load Capacity - The R21 Powered Raceway should be installed using mounting brackets with sufficient

load capacity to support it. Choose one of six approved mounting configurations. Refer to "Mounting the Unit" on

page 12.

•Ventilation Allowance - The room must have sufficient space to allow air to circulate and cool. The R21 Powered

Raceway must have a minimum of 12 inches of clear space above it to allow for proper convection cooling.

•Indoor Use Only - The R21 Powered Raceway is rated for indoor use only.

WARNING! The unit is to be stored and operated in and environment that is at or below the following conditions -

Ambient Temperature: 32 to 104oF / 0 to 40oC with a relative humidity of 5%-95% Non-Condensing. At no time

should the unit be stored, operated, or installed outdoors.

•Dry Locations Only - The R21 Powered Raceway can only be installed in an "office clean" area that is never

exposed to moisture of any kind. Vari-Lite is not responsible for damage to equipment caused by paint, dust,

solvents, cleaning supplies, improper storage or abuse.

CAUTION: Refer to National Electrical Code® and local codes to determine whether additional requirements must

be met.

Wire Routing 11

R21 Powered Raceway Installation Guide

3. Wire Routing

Before deciding a final mounting position, consider all wire routing as follows:

• Line power wiring may enter the unit through the top or side of the Power Terminal Box. See Figure 12 under

"Line Power" on page 15.

Note: The RCM does not contain any field serviceable components.

WARNING! You must have access to a main circuit breaker or other power disconnect devices in order to install any

wiring. Failure to disconnect power before installing or servicing the unit may result in injury.

4. Wiring Requirements

• For control wire-type requirements, refer to your job drawings as prepared by Strand Lighting.

• For power wire-type requirements, refer to Strand Lighting drawings, contract drawings, and applicable codes.

Note: For assistance or questions regarding installing or connecting power to the R21 Powered Raceway,

please contact your Authorized Strand Dealer or Vari-Lite technical support at 1-214-647-7880.

Installation Guide R21 Powered Raceway

12 Installation Procedure

INSTALLATION PROCEDURE

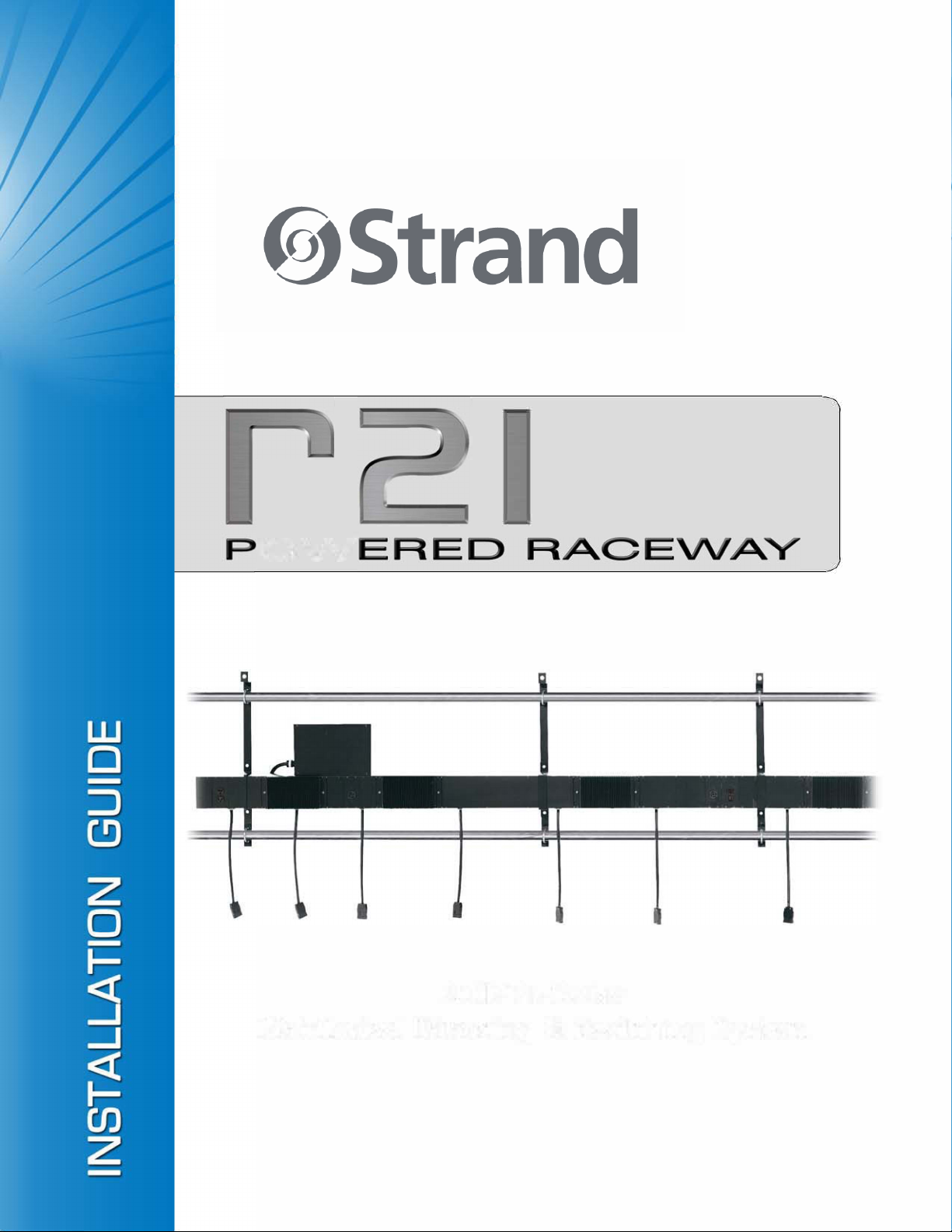

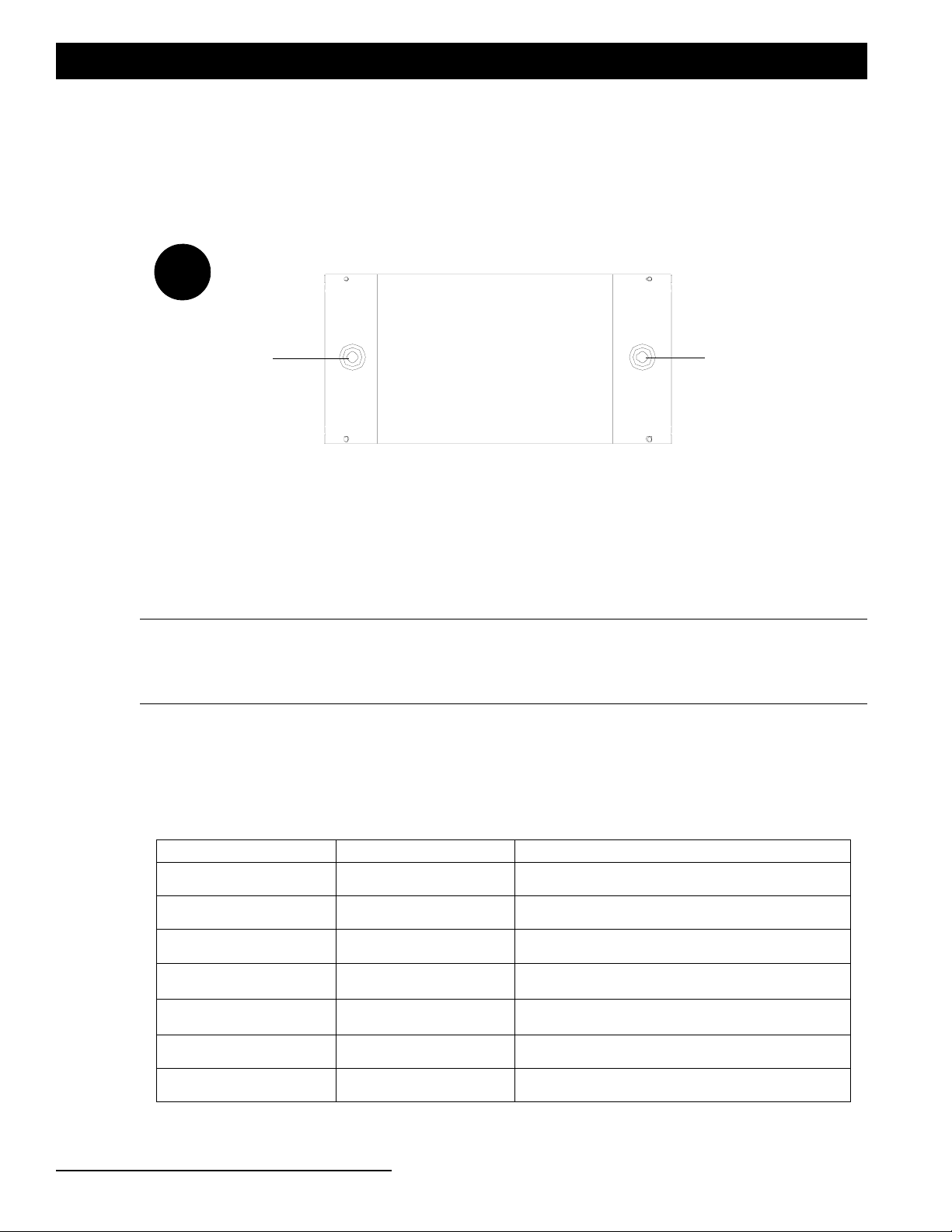

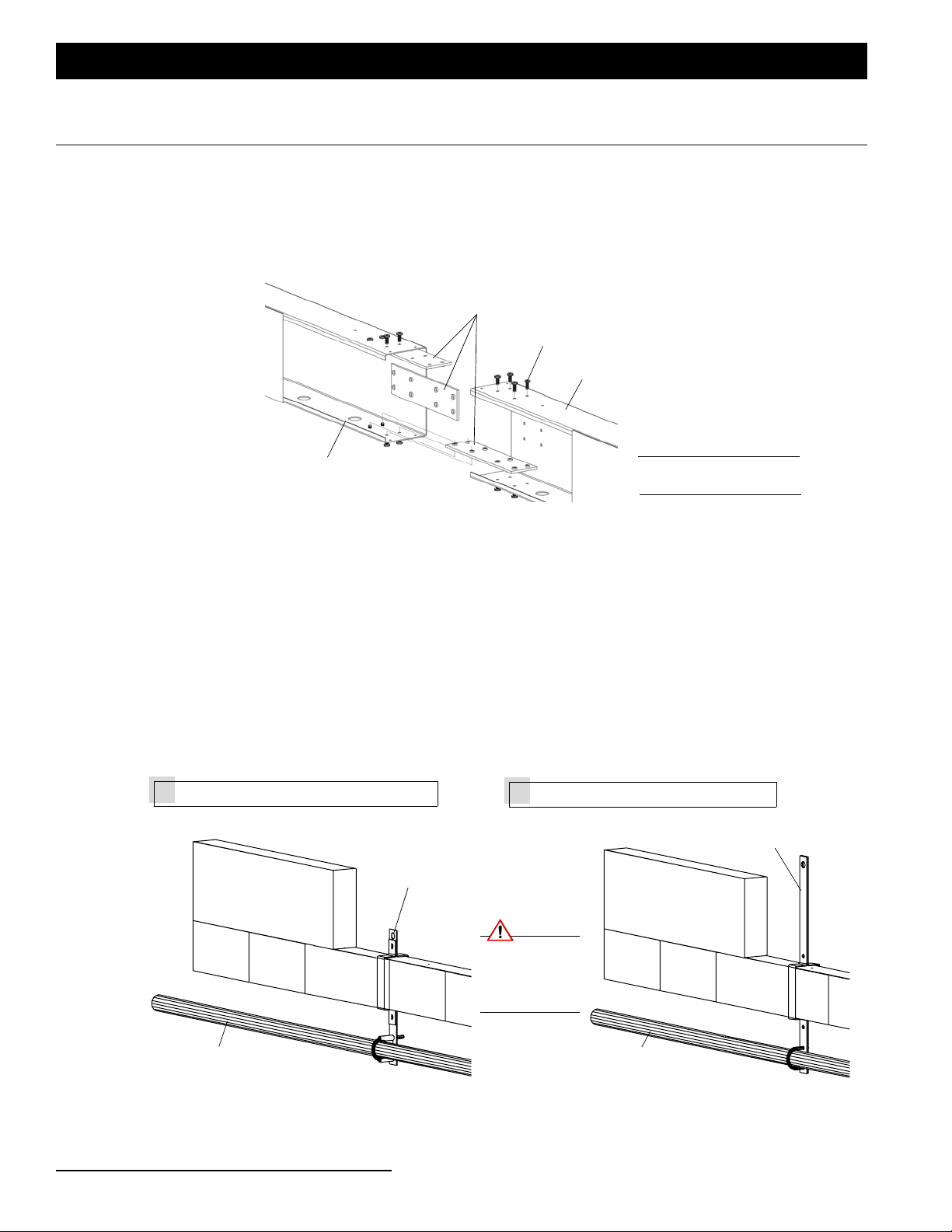

1. Connecting Sections

Before mounting the R21 Powered Raceway, it will be necessary to connect all modular sections. Sections are

connected using three metal connector plates and screws (provided). Refer to Figure 7 below.

Figure 7: Connecting Modular Sections

2. Mounting the Unit

The R21 Powered Raceway can be mounted in one of six configurations depending on your specific requirements.

Regardless of type, brackets cannot be spaced more than 5 feet apart per National Electrical Code®.

Single-Pipe Methods

The 71444 Single-Pipe Overhung Hanger Bracket is used to attach an R21 Powered Raceway to a single 1-1/2"

schedule 40 pipe with no additional overhead support.

The 71440 Single-Pipe Rigged Hanger Bracket is used to suspend a single 1-1/2" schedule 40 pipe and an R21

Powered Raceway from a rigging system or a ceiling.

Figure 8: Single-Pipe Methods

10-32 Screw (eight per plate)

Connector Plates

R21 Powered Raceway Section

R21 Powered Raceway Section

Note: Some components and

wiring not shown for clarity.

1-1/2" Schedule 40

Single-Pipe Overhung

Pipe (not provided)

Hanger Bracket (71444)

CAUTION:

Brackets must be

spaced every five

feet or less per

NEC® requirements.

Single-Pipe Overhung Hanger Bracket

1Single-Pipe Rigged Hanger Bracket

2Single-Pipe Rigged

Hanger Bracket (71440)

1-1/2" Schedule 40

Pipe (not provided)

Mounting the Unit 13

R21 Powered Raceway Installation Guide

Double-Pipe Methods

The 71443 Double-Pipe Offset Hanger Bracket is used to attach an R21 Powered Raceway to two 1-1/2" schedule 40

pipes with no additional overhead support. Components are supported in an offset position in front of the two battens.

The 71441 Double-Pipe Rigged Hanger Bracket is used to suspend two 1-1/2" schedule 40 pipes and an R21 Powered

Raceway from a rigging system. Components are supported midway between the two battens.

Figure 9: Double-Pipe Methods

Threaded Rod and Wall Mount Methods

The 71445 Threaded Rod Bracket is used to suspend one 1-1/2" schedule 40 pipe and an R21 Powered Raceway from

a rigging system using threaded rod support.

The 71442 Wall Mount Hanger Bracket is used to permanently mount an R21 Powered Raceway to a wall.

Figure 10: Threaded Rod and Wall Mount Methods

1-1/2" Schedule 40

Double-Pipe Offset

Pipe (not provided)

Hanger Bracket (71443)

CAUTION:

Brackets must be

spaced every five

feet or less per

NEC® requirements.

Double-Pipe Offset Hanger Bracket

3Double-Pipe Rigged Hanger Bracket

4Double-Pipe Rigged

Hanger Bracket (71441)

1-1/2" Schedule 40

Pipe (not provided)

1-1/2" Schedule 40

Pipe (not provided)

CAUTION:

Brackets must be

spaced every five

feet or less per

NEC® requirements.

Threaded Rod Bracket

5Wall Mount Hanger Bracket

6

Wall Mount

Hanger Bracket

Threaded Rod Bracket

(71445)

(71442)

Installation Guide R21 Powered Raceway

14 Installation Procedure

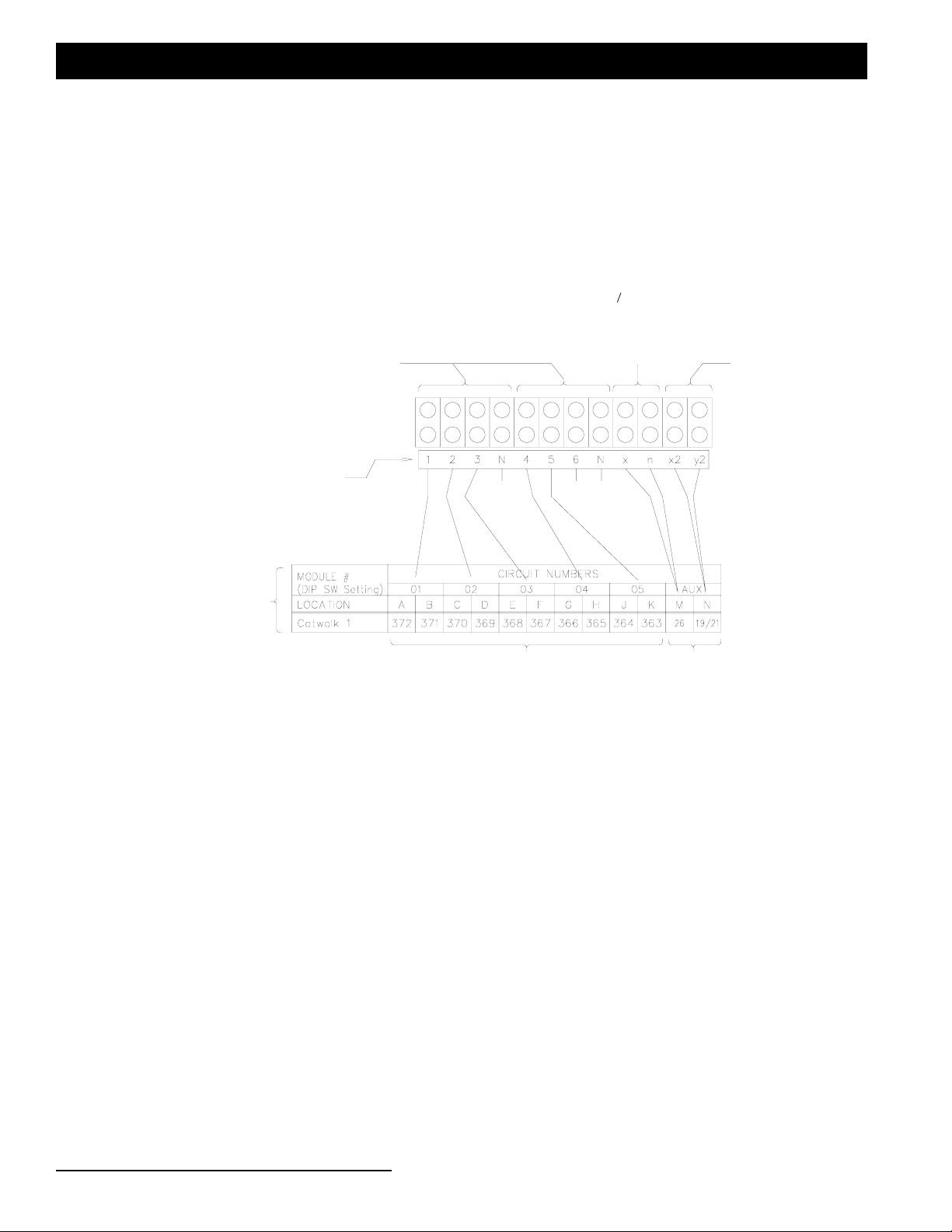

3. Connecting Power Wiring

Overview

The R21 Powered Raceway is designed to be wired from the top or side of the Power Terminal Box (see

Figure 12 on next page). Eight knock-out holes are provided (four on top, two on each side) for this purpose. We

recommend connecting the Line Power wiring and Grounds (if applicable) first, and the Load Neutral and Load Hot

wires last. Refer to Figure 11 below for wiring key.

Figure 11: Terminal Box Wiring Key

3-Phase, 4 Wire Blocks

120/208 VAC

20 Amp Circuits

(Sixth module not used in this

example - terminals always

provided in 3-Phase, 4 Wire

blocks.)

Single-Phase, 2 Wire Blocks

120 VAC

20 Amp Aux Circuit

(if applicable)

Label on Terminal Strip -

#’s correspond to module ID

Circuit schedule

from project

drawings

Dimmer / Relay (Non-Dim) Numbers

Neutral

for

4, 5, 6

Neutral

for

1, 2, 3

208 VAC

20 Amp

Aux Circuit

(if applicable)

Aux Ckt Numbers from

Panelboard (this shows 1:

1-Pole and 1: 2-Pole)

Connecting Power Wiring 15

R21 Powered Raceway Installation Guide

Line Power

WARNING! You must have access to a main circuit breaker or other power disconnect devices in order to install any

wiring. Failure to disconnect power before installing or servicing the unit may result in injury.

WARNING! Refer to National Electrical Code® and local codes for cable specifications. Failure to use proper cable

can result in damage to equipment or danger to persons.

CAUTION: Wire openings MUST have fittings or lining to protect wires/cables from damage.

CAUTION: Use 90° C copper wire only!

To connect Line Power:

Step 1. Turn off all power at main breaker

or disconnect device.

Step 2. Route line power wiring from

power source to top or side of

terminal box (Figure 12).

Step 3. Remove terminal box cover.

Step 4. Punch holes as required and install

conduit fittings or lining materials

into opening.

Step 5. Feed line power cables through

prepared openings.

Step 6. At end of each cable, strip

insulation as appropriate.

Step 7. Dress all wires to back of box.

Step 8. At appropriate lugs, terminate

Phase, Neutral and Ground wires.

Line connections are color coded

as follows:

CAUTION: Failure to use proper torque setting will cause premature equipment failure.

Step 9. Tighten lug set screws to proper torque settings as provided by label inside terminal box.

Wire Color

Phase A Black

Phase B Red

Phase C Blue

Screw

Terminal Box

Terminal Box Cover

Input Hole

F

igure 12: Connecting Line Power - Removing Terminal Box Cover

Installation Guide R21 Powered Raceway

16 Installation Procedure

4. Connecting Control Wiring

Overview

For details regarding the specific low-voltage control cable wiring for your project, refer to your project drawings as

prepared by Strand Lighting. The low-voltage control cable will connect to the R21 Raceway Control Module

(RCM). The RCM comes in a 19-inch "rack mount" configuration for remote applications.

Note: These generic details are for reference only, you must consult your specific project drawings for final

connection details.

Figure 13: Example Control Connections

Multiple R21 Powered Raceways - Rack Model

Ethernet In

DMX512 In Termination

Single R21 Powered Raceway - Rack Model

Ethernet In

Termination

DMX512 In

DMX512 Thru DMX512 Thru

Ethernet In

Ethernet In

Connecting Control Wiring 17

R21 Powered Raceway Installation Guide

DMX512

Contractor is Responsible for All Terminations

1) Only approved EIA-485 cable types may be used.

Approved types are:

Belden #9829 and TMB Proplex #PC224T

An acceptable plenum rated cable is: Belden

#89729.

2) Category 5e cable may be used for DMX512.

Approved types are: Belden #1583A and Belden

#1585A (Plenum).

3) Cable MUST be terminated exactly as shown here.

4) DMX512 cable runs MUST be routed in a "Daisy-

Chain" configuration as shown in your drawing

set, if provided. DO NOT convert these cables to

home runs.

5) DMX512 cable runs should all be in metal conduit.

Runs in exposed areas must be in metal conduit.

Maximum cable run should not exceed 1000 feet.

Additional Resources for DMX512

For more information on installing DMX512 control systems, the following publication is available for purchase

from the United States Institute for Theatre Technology (USITT)*:

• Recommended Practice for DMX512: A Guide for Users and Installers, 2nd edition (ISBN: 9780955703522)

Note: *See "Additional Resources" on page 3 for USITT contact information.

DMX512

Terminal XLR Pin

Name WE Color Code

(e.g., Belden #8132) IECA Color

Code Belden Standard

Color Code CAT5e

Color Code

GND 1 Drain Wire (Shield) Drain (Shield) Drain (Shield) Brown (8)

White/Brown (7)

DMX - 2 White w/ Blue Black Black

(of Red pair) Orange (2)

DMX + 3 Blue w/ White White Red White/Orange (1)

AUX - 4 White w/ Orange Red Black

(of White pair) Green (6)

AUX + 5 Orange w/ White Green White Green/White (3)

BELDEN #9829

or EQUAL

(NOT BY STRAND)

Female Male

Installation Guide R21 Powered Raceway

18 Installation Procedure

Vision.net Networks (SVN/485)

Contractor is Responsible for All Terminations

1) Only approved cable types may be used. Approved types are: Belden #1583A and Belden #1585A

2) Cable MUST be terminated exactly as shown here. Total length of cable in Vision.net Network Wiring must

NOT exceed 1000 feet.

3) Cable runs should be routed in a "Daisy-Chain" configuration as shown in your drawing set, if provided.

DO NOTconvert these cables to home runs.

4) Maximum station quantity subject to power supply and system requirements. Please consult factory for

specific information.

Termination of Shielded Cable

To terminate shielded cable:

Step 1. Strip off specified

length of outer jacket.

Step 2. Cut shield (foil or

braid) flush to outer

jacket. DO NOT cut

drain wire.

Step 3. Fit specified length of

1/16" heat shrink

tubing over the drain

wire.

Step 4. For solder connections, fit a 1/2" length of 1/16" heat shrink tubing over each conductor.

Step 5. Fit a 1" length of 3/8" heat shrink tubing over the entire cable. Position it so that 3/4" of its length is over the

cable jacketing, and 1/4" of its length is over the loose conductors.

Step 6. Strip 1/8" inch of the insulation from each of the conductors.

Step 7. Terminate the conductors on the terminal block, or solder the terminals as specified.

Step 8. For solder connections, shrink the individual 1/2" lengths of heat shrink tubing over the solder terminals.

Step 9. Shrink the remaining heat shrink tubing.

Step 10. Apply the appropriate ID label to the cable at the end of the outer heat shrink tubing.

Pin Number Signal Name CAT5e Wire Color

1 Data + White w/ Orange

2 Data - Orange

3SHIELD Shield

4 +24 VDC White w/ Green

5 Signal GND Green

6 +24 VDC White w/ Blue

7 Signal GND Blue

8 +24 VDC White w/ Brown

9 Signal GND Brown

Dimension Name Minimum Maximumfor

Terminal Maximum for

LXR (In-Line)

A Remove Cable Jacket 1" (25.4mm) 2-1/4" (60mm) 1-1/4" (31.8mm)

B Drain Wire Heatshrink Dim 'A' - 1/8" (3.2mm) - -

Table of contents

Other Strand Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

LEGRAND

LEGRAND KENALL MILLENIUM METREX METSW Series installation instructions

ETC

ETC Source Four Mini LED user manual

Hella

Hella BSN-LED Mounting instructions

wofi

wofi 226 Series installation instructions

Outside Living Industries

Outside Living Industries Hiver Pool UBBINK Series operating manual

Moree

Moree CUBE LED PRO ACCU instruction manual