StressTel PocketMIKE User manual

PocketMIKE

Operating Manual

021-002-279

©2004 GE Inspection Technologies, LP

50 Industrial Park Road

Lewistown, PA 17044

Phone: +1 (717) 242-0327

Fax: +1 (717) 242-2606

www.GEInspectionTechnologies.com

GE Inspection Technologies GmbH

Robert-Bosch-Straße 3

D – 50354 Hürth

Phone: +49 (0) 2233 60111

Fax.: +49 (0) 2233 601402

PocketMIKE

Operating Manual

021-002-279

©2004 GE Inspection Technologies, LP

50 Industrial Park Road

Lewistown, PA 17044

Phone: +1 (717) 242-0327

Fax: +1 (717) 242-2606

www.GEInspectionTechnologies.com

GE Inspection Technologies GmbH

Robert-Bosch-Straße 3

D – 50354 Hürth

Phone: +49 (0) 2233 601111

Fax.: +49 (0) 2233 601402

PocketMIKE

Operating Manual version 1.0

PocketMIKE

Operating Manual version 1.0

PocketMIKE Operating Manual Page i

Important Notice

The following information must be read and understood by any user of

a GE Inspection Technologies ultrasonic thickness gauge. Failure to

follow these instructions can lead to errors in thickness measurements

or other test results. Decisions based on erroneous results can, in turn,

lead to property damage, personal injury or death.

General Warnings

Proper use of ultrasonic test equipment requires three essential ele-

ments:

◆Selection of the correct test equipment.

◆Knowledge of the specific “test application requirements.”

◆Training on the part of the instrument operator.

This operating manual provides instruction in the basic set up and

operation of the GE Inspection Technologies thickness gauge.

There are, however, additional factors which affect the use of ultrasonic

test equipment. Specific information regarding these additional factors

is beyond the scope of this manual. The operator should refer to text-

books on the subject of ultrasonic testing for more detailed information.

Operator Training

Operators must receive adequate training before using ultrasonic test

equipment. Operators must be trained in general ultrasonic testing

procedures and in the set up and performance required by a particular

test. Operators must understand:

◆Soundwave propagation theory.

◆Effects of the sound velocity of the test material.

◆Behavior of the sound wave where two different materials

are in contact.

◆Areas covered by the sound beam.

PocketMIKE Operating Manual Page i

Important Notice

The following information must be read and understood by any user of

a GE Inspection Technologies ultrasonic thickness gauge. Failure to

follow these instructions can lead to errors in thickness measurements

or other test results. Decisions based on erroneous results can, in turn,

lead to property damage, personal injury or death.

General Warnings

Proper use of ultrasonic test equipment requires three essential ele-

ments:

◆Selection of the correct test equipment.

◆Knowledge of the specific “test application requirements.”

◆Training on the part of the instrument operator.

This operating manual provides instruction in the basic set up and

operation of the GE Inspection Technologies thickness gauge.

There are, however, additional factors which affect the use of ultrasonic

test equipment. Specific information regarding these additional factors

is beyond the scope of this manual. The operator should refer to text-

books on the subject of ultrasonic testing for more detailed information.

Operator Training

Operators must receive adequate training before using ultrasonic test

equipment. Operators must be trained in general ultrasonic testing

procedures and in the set up and performance required by a particular

test. Operators must understand:

◆Soundwave propagation theory.

◆Effects of the sound velocity of the test material.

◆Behavior of the sound wave where two different materials

are in contact.

◆Areas covered by the sound beam.

Page ii PocketMIKE Operating Manual

More specific information about operator training, qualification,

certification, and test specifications is available from various technical

societies, industry groups, and government agencies.

Testing Limitations

In ultrasonic testing, information is obtained only from within the limits

of the sound beam. Operators must exercise great caution in making

inferences about the test material outside the limits of the sound beam.

For example, when testing large materials it may be impossible or

impractical to inspect the entire test piece. When a less-than-complete

inspection is to be performed, the operator must be shown the specific

areas to inspect. Inferences about the condition of areas not inspected,

based on data from the evaluated areas, should only be attempted by

personnel fully qualified and trained in applicable standards of statisti-

cal evaluation. In particular, materials subject to erosion or corrosion, in

which conditions can vary significantly in any given area, should only

be evaluated by fully trained and experienced operators.

Sound beams reflect from the first interior surface encountered. Be-

cause of part geometry and overlapped flaws or overlapped surfaces,

thickness gauges may measure the distance to an internal flaw rather

than to the back wall of the material. Operators must take steps to

ensure that the entire thickness of the test material is being examined.

Ultrasonic Thickness Measurement

Critical Operating Procedures

The following operating procedures must be observed by all users of

ultrasonic thickness gauges in order to minimize errors in test results.

1. Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness gauge is that the

instrument measures the time of flight of an ultrasonic pulse through

the test piece and multiplies this time by the sound velocity of the

material. Thickness measuring error is minimized by ensuring that the

sound velocity to which the instrument is calibrated is the sound

Page ii PocketMIKE Operating Manual

More specific information about operator training, qualification,

certification, and test specifications is available from various technical

societies, industry groups, and government agencies.

Testing Limitations

In ultrasonic testing, information is obtained only from within the limits

of the sound beam. Operators must exercise great caution in making

inferences about the test material outside the limits of the sound beam.

For example, when testing large materials it may be impossible or

impractical to inspect the entire test piece. When a less-than-complete

inspection is to be performed, the operator must be shown the specific

areas to inspect. Inferences about the condition of areas not inspected,

based on data from the evaluated areas, should only be attempted by

personnel fully qualified and trained in applicable standards of statisti-

cal evaluation. In particular, materials subject to erosion or corrosion, in

which conditions can vary significantly in any given area, should only

be evaluated by fully trained and experienced operators.

Sound beams reflect from the first interior surface encountered. Be-

cause of part geometry and overlapped flaws or overlapped surfaces,

thickness gauges may measure the distance to an internal flaw rather

than to the back wall of the material. Operators must take steps to

ensure that the entire thickness of the test material is being examined.

Ultrasonic Thickness Measurement

Critical Operating Procedures

The following operating procedures must be observed by all users of

ultrasonic thickness gauges in order to minimize errors in test results.

1. Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness gauge is that the

instrument measures the time of flight of an ultrasonic pulse through

the test piece and multiplies this time by the sound velocity of the

material. Thickness measuring error is minimized by ensuring that the

sound velocity to which the instrument is calibrated is the sound

PocketMIKE Operating Manual Page iii

velocity of the material being tested. Actual sound velocities in materi-

als often vary significantly from the values found in published tables.

In all cases, best results are obtained if the instrument is calibrated on a

velocity reference block made from the same material as the test piece;

this block should be flat and smooth and as thick as the maximum

thickness of the test piece.

Operators should also be aware that the sound velocity may not be

constant in the material being tested; heat treating, for example, can

cause significant changes in sound velocity. This must be considered

when evaluating the accuracy of the thickness provided by this instru-

ment. Instruments should always be calibrated before testing, and the

calibration should be checked after testing, to minimize testing errors.

2. Probe Zero Procedure

Probe zeroing is the process of measuring the time of flight of sound

through the transducer. The transducer time of flight is then automati-

cally removed from each measurement so that only the test piece time

of flight is used to calculate and display the thickness value. The probe

zeroing process is performed automatically while the probe is coupled.

3. Effects of Temperature on Calibration

Temperature variations change the sound velocity of materials and

transducer delay lines and, therefore, calibrations. All calibrations

should be performed on-site, and with test blocks at the same

temperature as the test piece, to minimize errors due to temperature

variations.

4. Transducer Selection

The transducer used in testing must be in good condition without

noticeable wear of the front surface. Badly worn transducers will have a

reduced effective measuring range. The specified range of the trans-

ducer must include the complete range of thicknesses to be tested. The

temperature of the material to be tested must be within the transducer’s

temperature range.

PocketMIKE Operating Manual Page iii

velocity of the material being tested. Actual sound velocities in materi-

als often vary significantly from the values found in published tables.

In all cases, best results are obtained if the instrument is calibrated on a

velocity reference block made from the same material as the test piece;

this block should be flat and smooth and as thick as the maximum

thickness of the test piece.

Operators should also be aware that the sound velocity may not be

constant in the material being tested; heat treating, for example, can

cause significant changes in sound velocity. This must be considered

when evaluating the accuracy of the thickness provided by this instru-

ment. Instruments should always be calibrated before testing, and the

calibration should be checked after testing, to minimize testing errors.

2. Probe Zero Procedure

Probe zeroing is the process of measuring the time of flight of sound

through the transducer. The transducer time of flight is then automati-

cally removed from each measurement so that only the test piece time

of flight is used to calculate and display the thickness value. The probe

zeroing process is performed automatically while the probe is coupled.

3. Effects of Temperature on Calibration

Temperature variations change the sound velocity of materials and

transducer delay lines and, therefore, calibrations. All calibrations

should be performed on-site, and with test blocks at the same

temperature as the test piece, to minimize errors due to temperature

variations.

4. Transducer Selection

The transducer used in testing must be in good condition without

noticeable wear of the front surface. Badly worn transducers will have a

reduced effective measuring range. The specified range of the trans-

ducer must include the complete range of thicknesses to be tested. The

temperature of the material to be tested must be within the transducer’s

temperature range.

Page iv PocketMIKE Operating Manual

5. Use of Couplants

Operators must be familiar with the use of ultrasonic couplants. Testing

skills must be developed so that couplant is used and applied in a

consistent manner to minimize variations in couplant layer thickness

and errors in test results. Calibration and actual testing should be

performed under similar coupling conditions, using a minimum amount

of couplant and applying consistent pressure on the transducer.

6. Doubling

Ultrasonic thickness gauges will, under certain conditions, display

readings which are twice (or, in some cases, three times) the actual

material thickness being measured. This effect, commonly known as

“doubling,” can occur below the minimum specified range of the

transducer. If the transducer being used is worn, doubling is possible at

a thickness greater than the minimum of the specified range.

When using a new transducer, any reading which is less than twice the

minimum specified range of the transducer may be a “doubled” read-

ing, and the thickness of the material being tested should be verified by

the use of other methods. If the transducer shows any sign of wear,

doubling may occur at a thickness greater than twice the minimum of

the specified range. This thickness should be determined by calibrating

the PocketMIKE on reference blocks that represent the complete range

of possible thicknesses that may be encountered in testing. This is

particularly important when the test piece is being ultrasonically

measured for the first time or in any case where the history of thickness

of the test specimen is unknown.

Physics of Ultrasound

These instruments operate on the ultrasonic pulse-echo principle,

similar to sonar. A short ultrasonic pulse is transmitted into the part by a

probe (transducer). The pulse travels through the material under test

until it encounters an interface, that is a material with substantially

different physical characteristics, such as air or liquid, at the back

surface of the part. At the interface, the pulse is reflected back to the

probe.

Page iv PocketMIKE Operating Manual

5. Use of Couplants

Operators must be familiar with the use of ultrasonic couplants. Testing

skills must be developed so that couplant is used and applied in a

consistent manner to minimize variations in couplant layer thickness

and errors in test results. Calibration and actual testing should be

performed under similar coupling conditions, using a minimum amount

of couplant and applying consistent pressure on the transducer.

6. Doubling

Ultrasonic thickness gauges will, under certain conditions, display

readings which are twice (or, in some cases, three times) the actual

material thickness being measured. This effect, commonly known as

“doubling,” can occur below the minimum specified range of the

transducer. If the transducer being used is worn, doubling is possible at

a thickness greater than the minimum of the specified range.

When using a new transducer, any reading which is less than twice the

minimum specified range of the transducer may be a “doubled” read-

ing, and the thickness of the material being tested should be verified by

the use of other methods. If the transducer shows any sign of wear,

doubling may occur at a thickness greater than twice the minimum of

the specified range. This thickness should be determined by calibrating

the PocketMIKE on reference blocks that represent the complete range

of possible thicknesses that may be encountered in testing. This is

particularly important when the test piece is being ultrasonically

measured for the first time or in any case where the history of thickness

of the test specimen is unknown.

Physics of Ultrasound

These instruments operate on the ultrasonic pulse-echo principle,

similar to sonar. A short ultrasonic pulse is transmitted into the part by a

probe (transducer). The pulse travels through the material under test

until it encounters an interface, that is a material with substantially

different physical characteristics, such as air or liquid, at the back

surface of the part. At the interface, the pulse is reflected back to the

probe.

PocketMIKE Operating Manual Page v

The time needed for the pulse to make this round trip is divided by two

and multiplied by the sound velocity of the material under test. The

result is the thickness of the material.

The figure below illustrates the pulse-echo principle of ultrasonic

thickness measurement.

Dual Element Thickness Measurement

Dual

Probe

Backwall Echo

Acoustic

Zero

V-Path of

Pulse

PocketMIKE Operating Manual Page v

The time needed for the pulse to make this round trip is divided by two

and multiplied by the sound velocity of the material under test. The

result is the thickness of the material.

The figure below illustrates the pulse-echo principle of ultrasonic

thickness measurement.

Dual Element Thickness Measurement

Dual

Probe

Backwall Echo

Acoustic

Zero

V-Path of

Pulse

Page vi PocketMIKE Operating Manual

Page vi PocketMIKE Operating Manual

PocketMIKE Operating Manual Page vii

Contents

Chapter 1: Getting Started ................................................................... 1

1.1 Installing the Battery ...................................................................................... 1

1.2 Powering On the Instrument ......................................................................... 2

Chapter 2: Quick Help for Interpreting the Keypad and

Display Screen ..................................................................................... 3

2.1 Keypad Operations ......................................................................................... 4

2.2 Display Indicators ........................................................................................... 5

2.3 Types of Display Screens ................................................................................ 6

Chapter 3: Setting Up the Instrument ................................................. 9

3.1 Adjusting the Display’s Brightness (Backlight) .......................................... 10

3.2 Thickness Calibration ................................................................................... 11

3.3 Velocity Calibration ...................................................................................... 12

3.4 Setting the Measurement Units and Resolution ......................................... 13

3.5 Reversing the Display’s Orientation ........................................................... 13

3.6 Replacing the Probe ...................................................................................... 14

3.7 Disabling Instrument Adjustment Controls ............................................... 15

3.8 Rotating the Display ..................................................................................... 15

Chapter 4: Measuring Thickness ...................................................... 17

Chapter 5: Specifications and Declaration ....................................... 19

5.1 Specifications ................................................................................................. 19

5.2 EC Declaration of Conformity ..................................................................... 20

Chapter 6: Application Considerations ............................................. 21

6.1 Material Consistency in Test Specimen ...................................................... 21

6.2 Flaws in the Specimen Being Tested ............................................................ 22

6.3 Condition of the Test Specimen’s Surface ................................................... 22

6.4 Test Specimens with Curved Surfaces ........................................................ 22

Chapter 7: Troubleshooting Guide ................................................... 25

Chapter 8: Warranty and Repair ....................................................... 27

8.1 Warranty ........................................................................................................ 27

8.2 Service ............................................................................................................ 29

Chapter 9: Appendix .......................................................................... 31

Index ................................................................................................... 33

PocketMIKE Operating Manual Page vii

Contents

Chapter 1: Getting Started ................................................................... 1

1.1 Installing the Battery ...................................................................................... 1

1.2 Powering On the Instrument ......................................................................... 2

Chapter 2: Quick Help for Interpreting the Keypad and

Display Screen ..................................................................................... 3

2.1 Keypad Operations ......................................................................................... 4

2.2 Display Indicators ........................................................................................... 5

2.3 Types of Display Screens ................................................................................ 6

Chapter 3: Setting Up the Instrument ................................................. 9

3.1 Adjusting the Display’s Brightness (Backlight) .......................................... 10

3.2 Thickness Calibration ................................................................................... 11

3.3 Velocity Calibration ...................................................................................... 12

3.4 Setting the Measurement Units and Resolution ......................................... 13

3.5 Reversing the Display’s Orientation ........................................................... 13

3.6 Replacing the Probe ...................................................................................... 14

3.7 Disabling Instrument Adjustment Controls ............................................... 15

3.8 Rotating the Display ..................................................................................... 15

Chapter 4: Measuring Thickness ...................................................... 17

Chapter 5: Specifications and Declaration ....................................... 19

5.1 Specifications ................................................................................................. 19

5.2 EC Declaration of Conformity ..................................................................... 20

Chapter 6: Application Considerations ............................................. 21

6.1 Material Consistency in Test Specimen ...................................................... 21

6.2 Flaws in the Specimen Being Tested ............................................................ 22

6.3 Condition of the Test Specimen’s Surface ................................................... 22

6.4 Test Specimens with Curved Surfaces ........................................................ 22

Chapter 7: Troubleshooting Guide ................................................... 25

Chapter 8: Warranty and Repair ....................................................... 27

8.1 Warranty ........................................................................................................ 27

8.2 Service ............................................................................................................ 29

Chapter 9: Appendix .......................................................................... 31

Index ................................................................................................... 33

Page viii PocketMIKE Operating Manual

Page viii PocketMIKE Operating Manual

PocketMIKE Operating Manual Page 1

Getting Started

To begin using your PocketMIKE, you need only install a battery in

the instrument and power it on.

1.1 Installing the Battery

◆The instrument is powered by one “AA” size Alkaline

battery.

◆An alkaline battery will provide approximately 80 hours of

service life.

◆Replace the battery as soon as possible after the low battery

indicator ( ) appears on the instrument’s display.

To install the battery, refer to Figure 1-1 and follow these steps:

Step 1—Unscrew the probe locking ring and remove the probe from its

sealed position.

Step 2—Insert one “AA” battery in the instrument. Make sure the

battery poles are oriented as shown in Figure 1-1. The instrument will

not function if the battery is inserted incorrectly.

Step 3—Reinstall and finger tighten the probe locking ring until the

ring is seated against the instrument body.

PocketMIKE Operating Manual Page 1

Getting Started

To begin using your PocketMIKE, you need only install a battery in

the instrument and power it on.

1.1 Installing the Battery

◆The instrument is powered by one “AA” size Alkaline

battery.

◆An alkaline battery will provide approximately 80 hours of

service life.

◆Replace the battery as soon as possible after the low battery

indicator ( ) appears on the instrument’s display.

To install the battery, refer to Figure 1-1 and follow these steps:

Step 1—Unscrew the probe locking ring and remove the probe from its

sealed position.

Step 2—Insert one “AA” battery in the instrument. Make sure the

battery poles are oriented as shown in Figure 1-1. The instrument will

not function if the battery is inserted incorrectly.

Step 3—Reinstall and finger tighten the probe locking ring until the

ring is seated against the instrument body.

Page 2 PocketMIKE Operating Manual

Figure 1-1—Battery Replacement

NOTE: Avoid using tools which may over-tighten the probe locking

ring.

NOTE: When the low battery indicator ( ) lights, replace the battery

as soon as possible. When the battery is too weak for reliable operation,

the instrument automatically powers off. Instrument settings are saved

and restored when batteries are replaced and the instrument is again pow-

ered on.

1.2 Powering On the Instrument

To power on the instrument, simply press . Pressing and holding

this key for more than three seconds, when the instrument is on, will

cause it to power off. If the instrument is uncoupled and no keys are

pressed for three minutes, the instrument will automatically power off.

Page 2 PocketMIKE Operating Manual

Figure 1-1—Battery Replacement

NOTE: Avoid using tools which may over-tighten the probe locking

ring.

NOTE: When the low battery indicator ( ) lights, replace the battery

as soon as possible. When the battery is too weak for reliable operation,

the instrument automatically powers off. Instrument settings are saved

and restored when batteries are replaced and the instrument is again pow-

ered on.

1.2 Powering On the Instrument

To power on the instrument, simply press . Pressing and holding

this key for more than three seconds, when the instrument is on, will

cause it to power off. If the instrument is uncoupled and no keys are

pressed for three minutes, the instrument will automatically power off.

PocketMIKE Operating Manual Page 3

Quick Help for

Interpreting the Keypad

and Display Screen

PocketMIKE controls and settings are displayed in the instrument’s

screen and adjusted using various combinations of key presses. This

chapter identifies the display screen’s features, the keypad functions,

and the general display structure. Topics covered include:

◆Keypad Operations (section 2.1)

◆Display Indicators (section 2.2)

◆On-Screen Menu Structure (section 2.3)

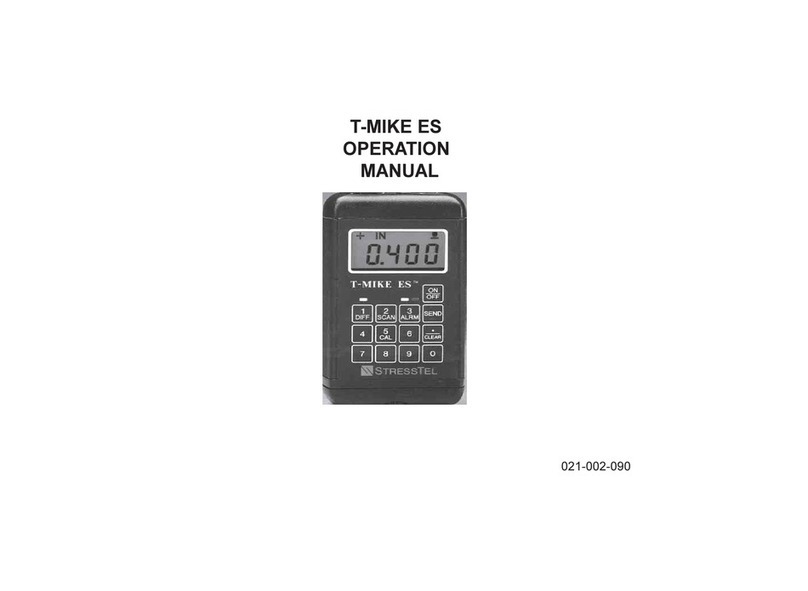

FIGURE 2-1—PocketMIKE

PocketMIKE Operating Manual Page 3

Quick Help for

Interpreting the Keypad

and Display Screen

PocketMIKE controls and settings are displayed in the instrument’s

screen and adjusted using various combinations of key presses. This

chapter identifies the display screen’s features, the keypad functions,

and the general display structure. Topics covered include:

◆Keypad Operations (section 2.1)

◆Display Indicators (section 2.2)

◆On-Screen Menu Structure (section 2.3)

FIGURE 2-1—PocketMIKE

Page 4 PocketMIKE Operating Manual

2.1 Keypad Operations

The following is a brief summary of each key’s function. For more

complete information, refer to the referenced manual section.

Powers the instrument on and off (section 1.2)

Launches and ends the thickness calibration

process (section 3.2)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

and Simultaneous pressing of these keys selects

measurement units and resolution (section 3.4)

Simultaneous pressing and HOLDING these keys

activates and deactivates SAFE mode in which most

instrument controls are disabled (section 3.7)

Launches and ends the Velocity Calibration process

and activates Backlight Adjustment mode

(sections 3.3 and 3.1)

Page 4 PocketMIKE Operating Manual

2.1 Keypad Operations

The following is a brief summary of each key’s function. For more

complete information, refer to the referenced manual section.

Powers the instrument on and off (section 1.2)

Launches and ends the thickness calibration

process (section 3.2)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

and Simultaneous pressing of these keys selects

measurement units and resolution (section 3.4)

Simultaneous pressing and HOLDING these keys

activates and deactivates SAFE mode in which most

instrument controls are disabled (section 3.7)

Launches and ends the Velocity Calibration process

and activates Backlight Adjustment mode

(sections 3.3 and 3.1)

PocketMIKE Operating Manual Page 5

2.2 Display Indicators

The PocketMIKE display (Figure 2-2) includes indicators (icons)

around its perimeter and text or numerical values in its center. Indica-

tors and other display contents vary in response to instrument settings,

key presses, and measurement status. The following is a summary of

display indicators. For more complete information, refer to the

referenced manual section.

FIGURE 2-2—Each of these screen

indicators are displayed only under

certain conditions.

Indicates instrument is in Thickness Measurement

mode when display is not inverted (chapter 4).

Thickness Calibration mode is in process

(section 3.2).

Velocity Calibration mode is in process

(section 3.3).

Indicates instrument is in Backlight Adjustment

mode (section 3.1).

Indicates a low battery condition (section 1.1).

Displayed when probe is coupled (chapter 4).

Unit of measurement set to inches (Imperial Units)

(section 3.4).

Unit of measurement set to millimeters (Metric

Units) (section 3.4).

PocketMIKE Operating Manual Page 5

2.2 Display Indicators

The PocketMIKE display (Figure 2-2) includes indicators (icons)

around its perimeter and text or numerical values in its center. Indica-

tors and other display contents vary in response to instrument settings,

key presses, and measurement status. The following is a summary of

display indicators. For more complete information, refer to the

referenced manual section.

FIGURE 2-2—Each of these screen

indicators are displayed only under

certain conditions.

Indicates instrument is in Thickness Measurement

mode when display is not inverted (chapter 4).

Thickness Calibration mode is in process

(section 3.2).

Velocity Calibration mode is in process

(section 3.3).

Indicates instrument is in Backlight Adjustment

mode (section 3.1).

Indicates a low battery condition (section 1.1).

Displayed when probe is coupled (chapter 4).

Unit of measurement set to inches (Imperial Units)

(section 3.4).

Unit of measurement set to millimeters (Metric

Units) (section 3.4).

Page 6 PocketMIKE Operating Manual

SAFE Control lockout is activated, instrument controls are locked

out (section 3.7).

donE Displayed when lockout mode has been disabled (section 3.7).

HOT Instrument’s internal temperature has exceeded defined

limits (chapter 4)

FAIL (Diagnostic Message displayed after power-up)

Instrument memory is corrupted. Return for service.

CAL Calibration mode for sound velocity is active. Thickness

may be calibrated.

2.3 Types of Display Screens

The PocketMike offers three general display screen modes, similar to

the three shown below:

◆Thickness Measurement Display (Figure 2-3)

◆Calibration Mode (Figure 2-4)

◆Backlight Adjustment Mode (Figure 2-5)

FIGURE 2-3—In thickness measurement

mode, appears along the display’s

upper edge. Other on-screen indicators

are shown here. See Chapter 4 for more

details related to Thickness Measurement

mode and related display indicators.

Page 6 PocketMIKE Operating Manual

SAFE Control lockout is activated, instrument controls are locked

out (section 3.7).

donE Displayed when lockout mode has been disabled (section 3.7).

HOT Instrument’s internal temperature has exceeded defined

limits (chapter 4)

FAIL (Diagnostic Message displayed after power-up)

Instrument memory is corrupted. Return for service.

CAL Calibration mode for sound velocity is active. Thickness

may be calibrated.

2.3 Types of Display Screens

The PocketMike offers three general display screen modes, similar to

the three shown below:

◆Thickness Measurement Display (Figure 2-3)

◆Calibration Mode (Figure 2-4)

◆Backlight Adjustment Mode (Figure 2-5)

FIGURE 2-3—In thickness measurement

mode, appears along the display’s

upper edge. Other on-screen indicators

are shown here. See Chapter 4 for more

details related to Thickness Measurement

mode and related display indicators.

PocketMIKE Operating Manual Page 7

FIGURE 2-4—While the calibration process is underway,

appears (and flashes) along the display’s edge. The calibration

display varies depending on whether velocity or thickness

calibration mode is indicated. See sections 3.2 and 3.3 for more

details related to instrument calibration.

FIGURE 2-5—Pressing twice (when operating in Thickness

Measurement mode) launches the Backlight Adjustment mode.

Pressing or sets backlight to On, OFF, or Auto (section 3.1).

PocketMIKE Operating Manual Page 7

FIGURE 2-4—While the calibration process is underway,

appears (and flashes) along the display’s edge. The calibration

display varies depending on whether velocity or thickness

calibration mode is indicated. See sections 3.2 and 3.3 for more

details related to instrument calibration.

FIGURE 2-5—Pressing twice (when operating in Thickness

Measurement mode) launches the Backlight Adjustment mode.

Pressing or sets backlight to On, OFF, or Auto (section 3.1).

Page 8 PocketMIKE Operating Manual

Page 8 PocketMIKE Operating Manual

Table of contents

Other StressTel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kirchner und Tochter

Kirchner und Tochter KLA Assembly and operating instructions

Mag-ic Probe

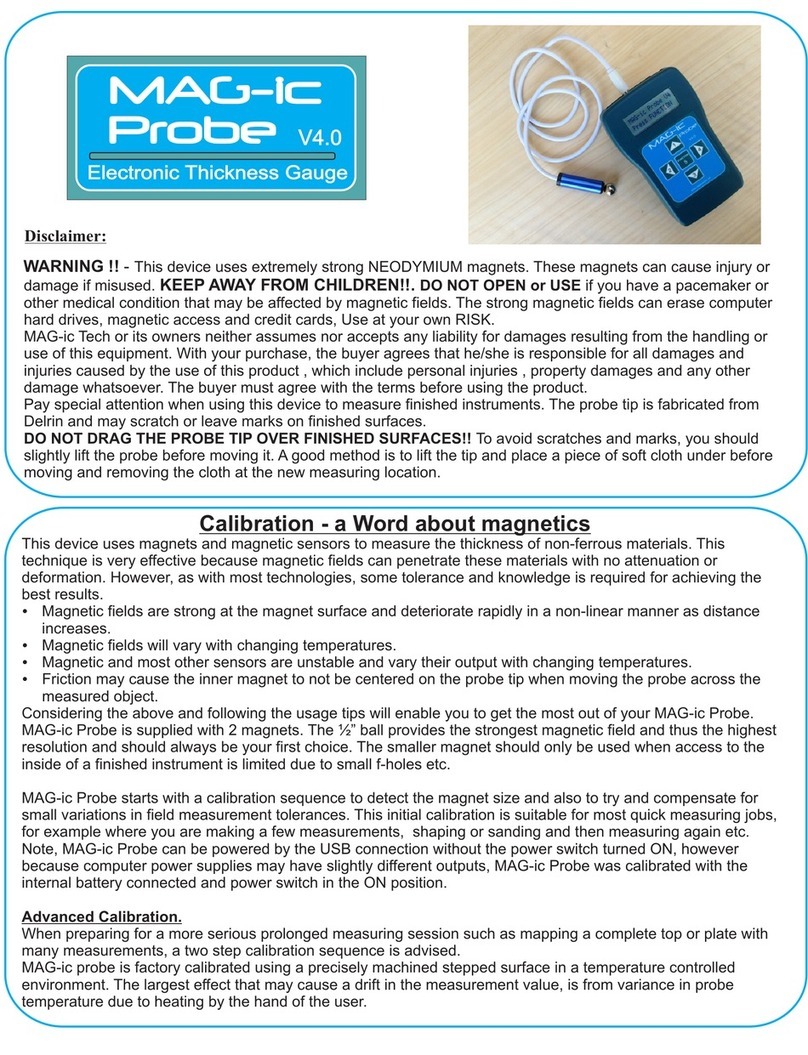

Mag-ic Probe V4.0 user guide

Brantz

Brantz International 2S Pro operating instructions

HP

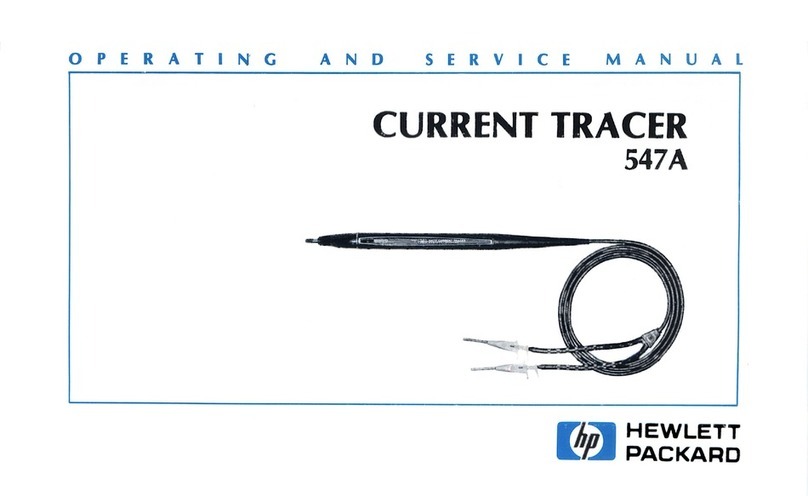

HP 547A Operating and service manual

Minolta

Minolta SPOTMETER F - IR REMOTE CONTRO LRC-3 manual

Sper scientific

Sper scientific 840018 instruction manual