2 3

Contents

Important information

This product must be installed professionally and in accordance with the pre-

scribed assembly guidelines and may therefore only be installed by qualied

and trained experts.

Application according to specication

The heat meter is used for the centralised recording of the consumption of

heating energy. The heat meter must be used exclusively for this purpose. The

medium is made up exclusively of water without chemical additives.

Use not according to specication

Any use other than the use described previously and any changes made to the

device constitute improper use. Uses and changes must be queried in writing

beforehand and are subject to special approval.

Warranty and guarantee

Warranty and guarantee claims are only valid if the parts in question have been

used in accordance with their intended use and if the technical requirements

and any applicable technical regulations have been observed.

Safety notes

Improper handling and excessively forceful tightening of screwed connections

can cause leaks. Observe the maximum torque stated in the manual. The

dimensions and thermal loads of seals must be appropriate for their application.

You should therefore only use the seals delivered with the device. Only use

water without chemical additives as the medium for this device.

The installed meter is a pressurized component.

There is a risk of persons suffering scolds from hot water.

Safety and warranty

Safety and warranty ...................................................................................... 3

Safety of lithium batteries............................................................................. 4

Safety notes for lithium batteries .................................................................. 4

Technical data................................................................................................ 5

Norms and standards ................................................................................... 5

Calculator unit............................................................................................... 5

Technical data................................................................................................ 6

Flow sensor .................................................................................................. 6

Temperature sensor...................................................................................... 6

Device elements ............................................................................................ 7

Device elements ........................................................................................... 7

Key assignment in standard mode ............................................................... 7

Status displays ............................................................................................. 7

Display............................................................................................................ 8

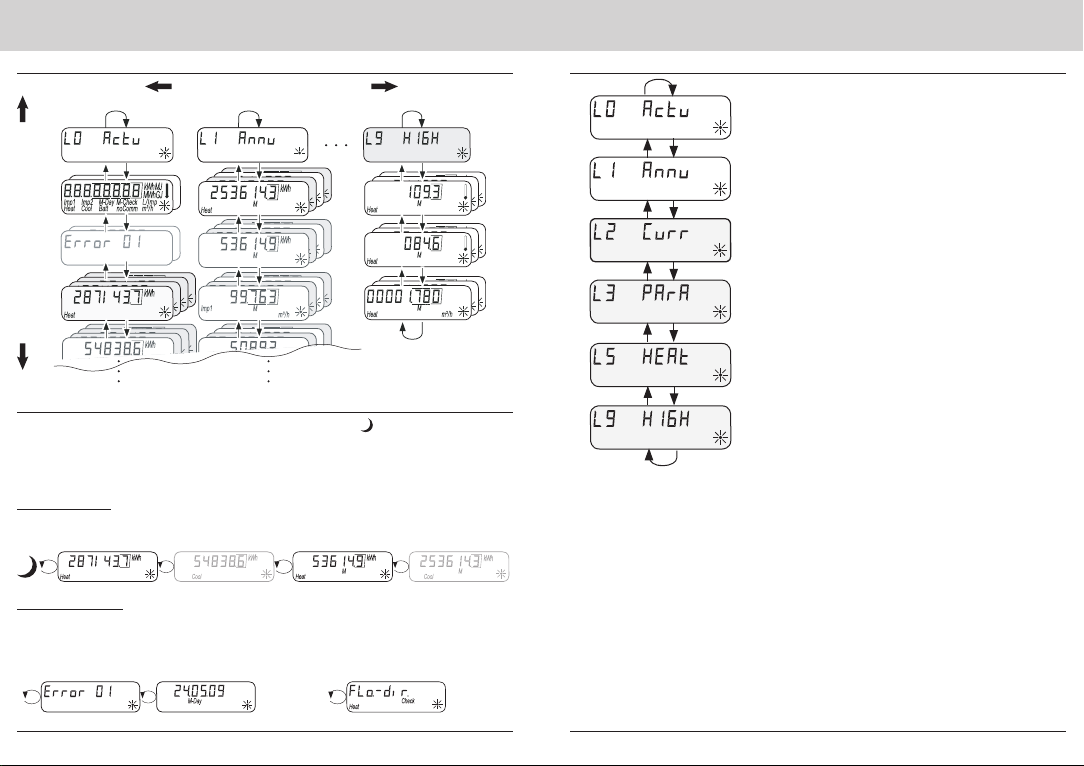

Operating scheme ........................................................................................ 8

Fast readout mode ....................................................................................... 8

Standard loop ............................................................................................ 8

Error messages ......................................................................................... 8

Display............................................................................................................ 9

Overview of levels ........................................................................................ 9

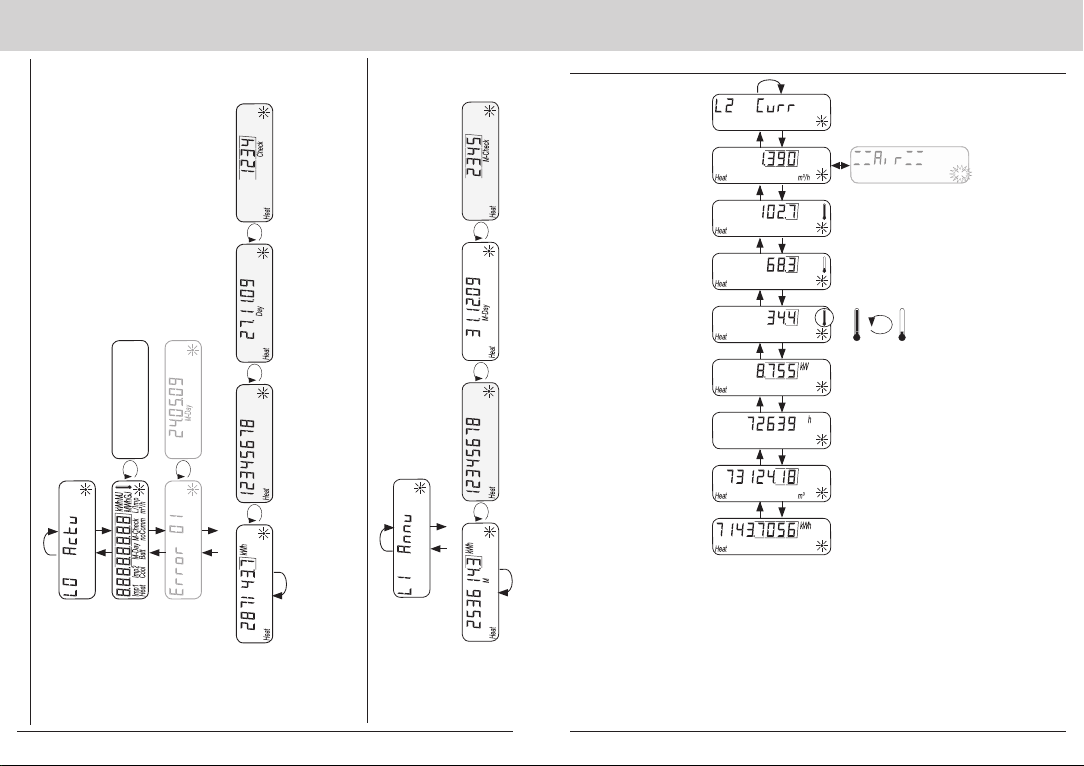

Display level L0 – Current consumption values.......................................... 10

Display level L1 – Annual consumption values........................................... 10

Display level L2 – Current values ................................................................11

Display level L3 – Parameters.................................................................... 12

Display level L5 – Monthly values heat ...................................................... 13

Display level L9 – Current values ............................................................... 14

Special operating states ............................................................................. 14

Error messages .......................................................................................... 15