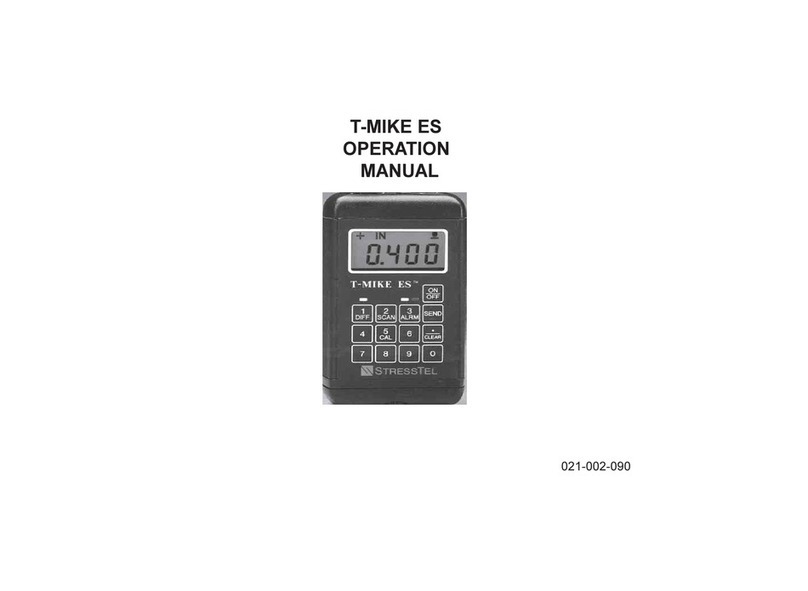

StressTel T-MIKE E User manual

T-MIKE E/P/B

OPERATION

MANUAL

T-MIKE E/P/B

OPERATION

MANUAL

2005 G E Inspection Technologies , LP

50 Industrial P ark R d.

Lewis town, PA 17044

US A

P : 717.242.0327, F : 717.242.2606

www.G E Ins pectionTechnologies.com

T -MIK E E /P /B

OP E R AT ION

MANUAL

R E V H

VERSION 4

2005 G E Inspection Technologies , LP

50 Industrial P ark R d.

Lewis town, PA 17044

US A

P : 717.242.0327, F : 717.242.2606

www.G E Ins pectionTechnologies.com

T -MIK E E /P /B

OP E R AT ION

MANUAL

R E V H

VERSION 4

021-002-147

Table of Contents

IMPORTANT NOTICE................................................................................................................. 1

THEORY OF OPERATION......................................................... ................................................. 5

DIAGRAM OF SYSTEM ............................................................................................................. 7

SPECIFICATIONS ...................................................................................................................... 9

INITIAL SETUP........................................................................................................................... 11

OPERATION .............................................................................................................................13

T-MIKE PROGRAMMABLE.................................................. .......................................................19

T-MIKE BASIC...........................................................................................................................21

HELPFUL HINTS ON OPERATION.............................................................................................23

MAINTENANCE AND TROUBLESHOOTING ................................................................................25

WARRANTY AND SERVICE....................................................................................................... 27

APPENDIX A............................................................................................................................29

APPENDIX B. .........................................................................................................................31

Table of Contents

IMPORTANT NOTICE................................................................................................................. 1

THEORY OF OPERATION......................................................... ................................................. 5

DIAGRAM OF SYSTEM ............................................................................................................. 7

SPECIFICATIONS ...................................................................................................................... 9

INITIAL SETUP........................................................................................................................... 11

OPERATION .............................................................................................................................13

T-MIKE PROGRAMMABLE.................................................. .......................................................19

T-MIKE BASIC...........................................................................................................................21

HELPFUL HINTS ON OPERATION.............................................................................................23

MAINTENANCE AND TROUBLESHOOTING ................................................................................25

WARRANTY AND SERVICE....................................................................................................... 27

APPENDIX A............................................................................................................................29

APPENDIX B. .........................................................................................................................31

1

Important Notice

ThefollowinginformationmustbereadandunderstoodbyanyuserofaGEInspectionTechnologies ultrasonic

thicknessgauge.

Failure to follow these instructions can lead to errors in thickness measurements or other test results. Decisions

basedon erroneous results can, in turn, lead topropertydamage,personalinjuryordeath.

General Warnings

Properuseofultrasonictest equipment requires three essential elements:

· Selection of the correct test equipment

·Knowledgeofthespecific“testapplicationrequirements”

·Trainingonthepartoftheinstrumentoperator

Thisoperating manualprovidesinstructioninthebasicset-upand operationoftheGEInspectionTechnologiesthickness

gauge. Thereare,however,additionalfactors whichaffecttheuseofthe ultrasonictestequipment. Specificinformation

regarding these additional factors is beyond the scope of this manual. The operator should refer to text books on the

subjectofultrasonictestingformoredetailedinformation.

Operator Training

Operatorsmustreceive adequatetrainingbeforeusingultrasonic testequipment. Operatorsmustbe trainedingeneral

ultrasonictestingproceduresandintheset-upandperformancerequiredbyaparticulartest. Operatorsmustunderstand:

Soundwavepropagationtheory

2

•Effects of the sound velocity of the test material

•Behaviorofthesoundwave where two different materialsareincontact

•Areascoveredbythesoundbeam

More specific information about operator training, qualification, certification and test specifications is available from

varioustechnicalsocieties,industrygroups,andgovernment agencies.

Testing Limitations

In ultrasonic testing, information is obtained only from within the limits of the sound beam. Operators must exercise

great caution in making inferences about the test material outside the limits of the sound beam. For example, when

testinglargematerials,itmaybeimpossibleorimpracticaltoinspecttheentiretestpiece. When a less-than-complete

inspectionistobe performed, theoperatormustbeshown the specificareastoinspect. Inferencesabout the condition

ofareasnotinspected,basedon data from the evaluated areas, shouldonlybeattemptedbypersonnelfullytrained in

applicable statistical and probability techniques. In particular, materials subjects to corrosion or erosion, in which

conditionscanvarysignificantlyinany given area, should be evaluatedonlybyfullytrainedandexperienceoperators.

Sound beams reflect from the first interior surface encountered. Because of part geometry and overlapped flaws or

overlappedsurface,thicknessgaugesmaymeasurethe distance to an internal flaw rather than totheback wallofthe

material. Operators must take steps to ensure that the entire thickness of the test material is being examined.

UltrasonicThickness Measurement Critical Operating Procedure

Thefollowingoperatingproceduresmustbeobservedbyallusersofultrasonicthicknessgaugesinordertominimize

errors in test results.

3

Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness gauge is that the instrument measures the time of flight of an

ultrasonic pulse through the test piece and multiplies this time by the velocity of sound in the material. Thickness

measuring error is minimized by ensuring that the sound velocity to which the instrument is calibrated is the sound

velocityofthematerialbeingtested. Actual sound velocity in materials oftenvary significantly from the values found in

published tables. In all cases, best results are obtained if the instrument is calibrated on a velocity reference block

made from the same material as the test piece; this block should be flat and smooth and as thick as the maximum

thickness of the test piece. Operator should also be aware that sound velocity may not be constant in the material

being tested; heat treating, for example, can cause significant changes in sound velocity. This must be considered

when evaluating the accuracy of the thickness provided by this instrument. Instruments should always be calibrated

before testing, and the calibration should be checked after testing, to minimize testing errors.

Probe Zero Procedure

Theprobezeroproceduremustbe performed as described in this manual. The zero reference block should be clean

and in good condition, without noticeable wear. Failure to properly perform the probe zero procedure will result in

inaccuratethicknessreadings.

Effects of Temperature on Calibration

Variationsintemperaturechangethesoundvelocityofmaterialsandtransducerdelaylinesandtherefore,zerocalibration.

Allcalibrationsshouldbeperformedon-siteandwithtestblocksatthesametemperatureasthetestpiece,inorderto

minimizeerrorsduetotemperature variations.

Transducer Selection

The transducer used in testing must be in good condition without noticeable wear of the front surface. Badly worn

transducers will have a reduced effective measuring range. The specified range of the transducer must include the

completerangeof thickness tobetested. Thetemperature of thematerialtobe testedmustbewithinthen transducer’s

temperaturerange.

4

Use of Couplants

Operators must be familiar with the use of ultrasonic couplants. Testing skills must be developed so that couplant is

used and applied in a consistent manner to minimize variations in couplant layer thickness and errors in test results.

Calibrationandactualtestingshouldbeperformedundersimilarcouplingconditions,usingaminimumofcouplant

andapplyingconsistentpressureonthetransducer.

Doubling

Ultrasonic thickness gauges will, under certain conditions, display readings which are twice (or in some cases, three

times) the actual material thickness being measured. This effect, commonly known as “doubling,” can occur below

the minimum specified range of the transducer. If the transducer being used is worn, doubling is possible at

thicknessesgreater that the minimum specified range.

When using a new transducer, any reading which is less than twice the minimum specified range of the transducer

may be a “doubled” reading, and the thicknesses of the material being tested should be verified by the use of other

methods. If the transducer shows any sign of wear, doubling may occur at thicknesses greater than twice the

minimumspecificrange. Thisthickness should be determined by calibrating the instrument/transducer combination

on reference blocks that represent the complete range of possible thicknesses that may be encountered in testing.

This is particularly important when the test piece is being ultrasonically measured for the first time or in any case

where the history of thickness of the specimen in unknown.

5

Chapter I

Theory of Operation

A. Ultrasonic Wave

TheT-MikeEmeasuresthethicknessofamaterialbylaunchinganultrasonic wave into the material using an

ultrasonictransducerandcalculatingthetime for the wave to passthroughthematerialandreflectbackto the

transducer. The time is multiplied by the previously determined velocity in the material and the thickness is

then displayed on the readout in inches or millimeters.

B. Zero Probe Function

Eachtransducer(probe) and theelectronicsvariesinthe amountoftimetotransmit the signaltobemeasured.

Thistime mustbesubtractedfromthetotaltransmission time. Thetimecorrectionisaccomplishedautomatically

by performing a “PROBE” recognition operation. The means to perform this simple task is resident on theT-

Mike E and will be explained in detail later.

C. Single Point Velocity Calibration

Upon recognition of the probe a calibration of the velocity of the material to be measured must be done. A

representativepieceofthematerialtobe measured should be used for the CAL operation. Through the CAL

operationtheT-MikeEmeasures the ultrasonictransittime,calculatesthe velocityofthematerialand implants

the velocity calculation in the T-Mike E’s memory for future measurements. If the velocity of the material is

already known then it may be entered using the keypad. Important: Since this velocity constant is used to

determine thickness for all measurement (until it is changed through another CAL or PROBE function) the

accuracy of the thickness measurement depends upon the constancy of the ultrasonic properties in the

materialbeingmeasured.

6

Inordertoensure accurate measurementboththetransducerfaceand the materialtobemeasuredshould be

wipedclean. Adropofcouplant should then beappliedtoeithertheprobe face or contactpoint on the material

beingmeasured. Foreignmatterbetweentheprobeandthematerialcandistortorpreventreadings.

To maximize measurement accuracy select a calibration piece that has the same shape and approximate

thickness as the work piece being measured. Re-calibrate the T-Mike E when the temperature of the work

piecechanges5oCormorefromthecalibrationpiece.

7

PROBE

T-MIKE E

COUPLANT USED

BETWEEN THE

PROBE AND BLOCK

BLOCK

Chapter II

Diagram of a System

8

Chapter III

Specifications

T-MIKE E/P/BSPECIFICATIONS

Approximate Measuring range 0.040-19.999”

(Material and Application Dependent)

Resolution 0.001in. Display Measurement Backlit 4 ½ digitAl-

lowable Surface Temperature 0oF to 200oF

Cable Length 4 ft.

Battery Power Supply Alkaline

Optional Batter Power Nicad

Continuous Operating Time with Backlight80hours

Normal Operating Time 300hours

Weight 11 oz.

Dimension 2.5 x 4.5 x 1.25”

9

Chapter IV

Initial Setup

A. Introduction

For those settings which are seldom changed during operation of the T-Mike E the INITIAL SET UP

procedureisdesignedtoallowtheoperator

access to those settings without unnecessary complication of the units normal operation.

Thesesettingsinclude:

Backlight on/off

Selection of Metric or English units of measure

CalibrationLock

TheINITIALSETUPprocedureisaccessedbyholdingtheCALkey down andpressingtheON/OFFkey.

Whenthisisdone theT-Mike E willdisplaytheversioncodeof the operating softwarecontainedin the unit

until the CAL key is released. This information will be useful should the unit require service or updated

softwareisdesired.

Uponreleaseof the CAL key the SETUP procedure continues as follows:

B. Backlight On/Off

When the CAL key is first released the T-Mike E will display the words ON or OFF to indicate the status of the

backlight. The backlight setting can be selected by pressing the UP or DOWN arrow key.

10

NOTE: Itisrecommencedthat the backlight beOFFwhenmeasurementsaremade in well-illuminated areas,

as this will greatly increase battery life.

C. Metric/English Units

Press the CAL key a second time.

The T-Mike E will display the units in which it is set to measure thickness (IN or MM).

Press the UP or DOWN arrow keys to select the desired unit of measurement.

D. CALIBRATION LOCK

Press the CAL key a third time.

The T-Mike E will display the status of the calibration lock function (CAL or LOC).

WhenCALisdisplayedthevelocity calibrationfunctioncan beperformedasdescribed inChapterV,Operation.

When LOC is displayed the calibration function is disabled. The velocity used in measurement cannot be

changed without entering this SETUP procedure again to change settings to CAL.

It is recommended that the lock feature be used when supervising personnel wish to prevent unauthorized

changeofthecalibratedvelocity.

Pressingthe CALkeyafinaltimecompletestheSETUPprocedureandreturnstheT-Mike Etothemeasurement

mode.

11

Chapter V

Operation

A. ON / OFF Function

Press this key to turn the T-Mike E on. The

unit will display a reading of zero. The T-Mike E is now ready for measurement or calibration. In order to

compensateforanychangeintheultrasonictransducer,aPROBEZERO function should be performed at

this point.

B. Probe Zero Function

ThePROBEZEROfunctioncompensates theT-Mike E for the fixed delay of the ultrasonic transducer.

Thisfunctionshouldbeperformedatthe start of each day (to compensate for transducer wear) or when-

ever the transducer is changed. Apply a drop of couplant to the end of the transducer. Press the ON/OFF

button on the keyboard to turn on the T-Mike E.

Place the transducer in steady contact with the probe disk located on the top of theT-Mike E. DO NOT

use another 0.250 test piece since the velocity of the probe disk is carefully controlled and errors will

result.

The T-Mike E recognizes that the probe is in contact with the probe disk, and automatically performs the

PROBE ZERO function. Upon completion of the function Prb 0 will appear on the display indicating that the

appropriatetransducerdelayfactorhasbeen entered in memory.

ON

OFF

12

NOTE: During the PROBE function, the T-Mike E velocity is temporarily reset to the velocity of the probe

disk(0.2330 in./msec.). Upon completion of the PROBE function the velocity will return to the last calibrated value.

This allows the operator to continue measurements on the previously calibrated material.

C. Material Calibration to Known Thickness

The following procedure is used to calibrate the T-Mike E sound velocity to a known sample of material. Some

materials may exhibit sound velocity variations which can cause errors in measurement. Be sure to check a

representative group of samples to determine if such variation is present.

First follow the above PROBE ZERO procedure to calibrate the delay of the ultrasonic transducer being used.

Apply a drop of couplant to the representative piece of material of known thickness. This piece is called the

sample.

Place the probe in steady contact with the surface of the sample. The T-Mike E will display a thickness reading

using the last calibrated velocity.

Press the CAL key to lock in the reading. The transducer may now be removed from the sample. The

display on the T-Mike E will momentarily display CAL. Small arrows will appear in the upper left portion of the

display above the thickness readings. This indicates that the T-Mike E is in the calibration mode and enables the

UP/DOWN arrow keys.

Adjust the thickness shown on the T-Mike E display by using the UP and DOWN arrows. Note that when

these keys are held continuously, the speed at which the thickness changes will increase, making it easy to make

the large adjustments for materials such as plastic and aluminum.

13

When the correct thickness appears on the display,

press the CALkey again to display the sound velocity of the calibrated material as calculated by the T-

Mike E. The display of sound velocity will be indicated by the appearance of appropriate velocity units

(IN/ms or M/S) above the displayed velocity value. Press the CAL key one final time to accept this

soundvelocityandreturntothemeasurementmode.

Check the calibration by replacing the probe on the sample piece. The T-Mike E should display the

corrected thickness of the sample.

NOTE: When the T-Mike E is in the CALIBRATION mode the unit will not make further measurement

untilthecalibrationprocedureiscompleted.

D. Calibration From Known Velocity

Thefollowing procedure is used to calibrate theT-Mike E to a givenmaterialvelocity.

FollowtheabovePROBEproceduretocalibratethedelayoftheultrasonictransducerbeingused.

Press the CALkey. The arrow symbols will appear in the upper left portion of the display

indicatingtheUP/DOWNarrowkeysareactive.

Press the CAL key a second time. The display on the T-Mike E will display the current velocity

andtheappropriateunitsofmeasure.

CAL

14

UP

DOWN

Or if metric units are selected:

Use the UP and DOWN arrow keys to scroll the velocity to the known velocity of the material.

Note that when these keys are held continuously, the speed that the velocity changes will increase, making

it easy to make the large adjustments for materials such as plastic and aluminum.

When the desired velocity appears on the display, press the CALkey again to enter that

velocity for use in thickness measurements and to return to the measurement mode.

E. Thickness Measurement

Removedirt,loosematerial,andcouplantresiduefromthesurfaceofmaterialatpointswhere

measurementsare desired. Verify that the PROBE and CALfunctions have been performed.

Place a drop of couplant on the material surface at the measurement point.

Place the transducer in steady contact with the surface of the material at the measurement point.

When a detectable echo is received from the back surface of the material, the echo indicator in the

upper right of the display will indicate the detection of an echo by changing in appearance to

representcontactbetweenthepicturedtransducerandthesamplesurface.

CAL

This manual suits for next models

2

Table of contents

Other StressTel Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

LaserLiner

LaserLiner DistanceCheck manual

Nidec-Shimpo

Nidec-Shimpo FG-3000R Operation manual

Compressed Air Alliance

Compressed Air Alliance FLP10000 Series user manual

Fluidwell

Fluidwell F010-U manual

Anritsu

Anritsu VectorStar ME7838 4 Series Maintenance manual

Keysight Technologies

Keysight Technologies U1701B quick start guide