STRUMIN LiteMESH User manual

HOME

P a g e | 2

ATTENTION !

TECHNICAL DOCUMENTATION

BEFORE EVERY USE OF THE “LiteMESH” SYSTEM, THE USER SHALL READ THIS TECHNICAL

DOCUMENTATION AND ALWAYS STRICTLY FOLLOW THE RULES DESCRIBED HEREIN. THESE

INSTRUCTIONS WERE PREPARED FOR ALL WORKERS AND PEOPLE THAT WILL WORK ON

TRANSPORTING, UNLOADING, ASSEMBLING, DISASSEMBLING, STORING, CHECKING AND ANY

OTHER WORKS CONNECTED TO THE SYSTEM.

EVERY USER IS OBLIGED TO READ AND GET FAMILIAR WITH THE SYSTEM’S TECHNICAL DOCUMENTATION!

CONTENTS:

INTRODUCTION

1.0 MANUFACTURING BASIS

2.0

USER MANUAL

2.1

TERMINOLOGY AND DEFINITIONS

2.2

PURPOSE AND SCOPE OF USAGE

2.3

WORKING PARAMETERS

2.4

RULES FOR SAFE OPERATION

2.5

TECHNICAL INSPECTION

2.6

MAINTENANCE

2.7

QUALIFICATIONS OF THE PEOPLE USING THE SYSTEM.

2.8

CONNECTING THE SYSTEM WITH A SLING.

2.9

INSTALATION OF THE SYSTEM.

2.10

DISASSEMBLING AND MOVING THE DEVICE BETWEEN WORKPLACES.

2.11

USE OF THE SYSTEM.

3.0 DEVICE’S REGISTER

4.0 RATING PLATE

5.0 TABLE: DANGER RISK PROTECTION

6.0 DESIGNER’S STATEMENT EU

DECLARATION OF CONFORMITY

HOME

P a g e | 3

INTRODUCTION

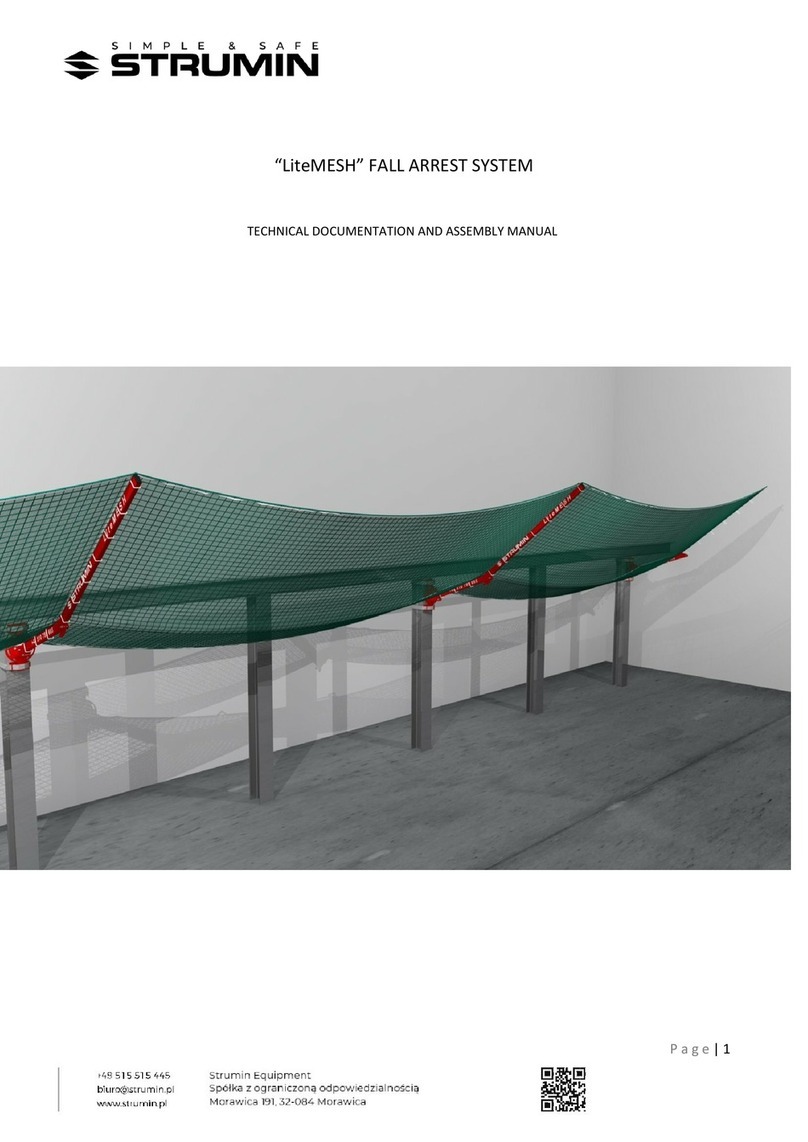

INTRODUCTION This technical documentation contains the guidelines concerning the proper use of

THE SYSTEM. Workers and other people using the system shall always observe the guidelines

contained herein. In case of any events not described in this document, the occupational safety and

health regulations and other regulations, appropriate to the specific situation, shall be observed.

It is forbidden to modify the system in any other way than described in the Technical

Documentation. The manufacturer is not liable for any modifications in the system in a

way that is not described in the technical documentation.

1. MANUFACTURING BASIS

The LiteMESH system is aimed at increasing the safety of works performed at heights.

The design of the LiteMESH system was drawn in accordance with the

applicable laws and technical norms:

EN-1263-1_2015-02E – Temporary constructions used at a working site.

Safety nets,

EN 1090-2..2012,

EN ISO 13920:2000.

HOME

P a g e | 4

2.0

USER MANUAL

2.1

TERMINOLOGY AND DEFINITIONS

Module:

The main part of the system that consists of a console to which the safety net is

assembled.

Console:

An element through which the net is assembled and formed. The console consists of

a universal assembly holder and a moveable arm.

Console's arm:

A moveable element consisting of two arms joined with a swivel joint. It allows to form

the shape of the safety net. The net and its edge line is assembled to the movable arms

and its edge line.

The universal assembly holder:

A holder used to assemble the moveable arm to the floor or the wall. It is also used in

case of the console's assembly adapters – “H” adapter. The holder allows to assemble

the moveable arm in lower configurations (see the Assembly Manual).

Stretching holder:

An additional holder used while attaching the net’s edge to the floor or wall –

depending on a given situation. That holder is used also during the assembly of the

stretches of the extreme consoles.

Assembly adapter “H”:

A device used to assemble the console to the elements of the construction. i.e. balks,

poles etc. in situations when there is no possibility to drill and perform other actions

that would interfere with the building's structure.

Net:

The net consists of two integrated nets of which one is used to catch large objects and the

other one (mosquito net) catches smaller elements. The net used in the system was designed

in accordance with the EN-1263- 1_2015-02E standard:

TYPE S, A2 Q100. It means that it is an A2-class net that absorbs min. 2300 J of

energy. The allowed maximum fall height for objects is below 2 m.

The net consists also of the edge line that works as an intermediate element carrying the

loads from the net to its outer edge and the carrying elements of the system.

Edge line:

Along the edge of the net there is an integrated polypropylene line (Ø12 and

the strength of 30 kN).

Stretching line (lace up):

A Ø8 polypropylene line for connecting the nets (lace up – see the assembly manual).

It is also used for adjusting the tension of the most extreme consoles.

HOME

P a g e | 5

2.2

PURPOSE AND SCOPE OF USAGE

The LiteMESH system is aimed at securing the outer edges of buildings and used as a

protection measure while performing works on lower levels and to secure

communication strings.

The net catches falling objects and protects people standing below.

The LiteMESH system is a connection of two nets with wide and small meshes. It catches both big

and small objects, and even semi-liquid elements. The system is characterised by an easy, universal

and quick assembly to the front and the upper part of a floor, as well as to a wall. Thanks to the

lightness and flexibility of the system, it is possible to adjust it to all building conditions.

The LiteMESH net is a quick and an affordable way to secure construction sites

and works which demand increasing the level of safety.

The use of the LiteMESH system is allowed only on condition that the user adheres to this

Technical Documentation, as well as the proper occupational safety and health regulations.

2.3

ALLOWED WORKING PARAMETERS

The LiteMESH system is a set of elements working together to protect users from falling. For

that reason and in order to use it in a safe manner, it is necessary to get familiar with the rules

of the system's operation and its limitations.

The maximum offset between the consoles: 6 m,

the maximum catching height 2 m,

the maximum distance between the edge line's holders: 3 m,

the nominal value of the energy absorbed by the net: 2,3 kJ.

HOME

P a g e | 6

During the operation of the SYSTEM, workers shall bear in mind the safety of the users,

any personnel or people that may be affected by the operation of the device.

2.4

RULES FOR SAFE OPERATION

The LiteMESH system shall be used only for the purposes described in this manual. Any use not in

compliance with this manual entails the risk of accidents and poses a threat to health and life.

Any use not in compliance with the Technical Documentation voids the guarantee.

The device is used to catch falling objects which may pose a threat for any people standing

below the working area. In case on an improper use of the system, it poses a risk for the user as

well as the other people near the user.

Before using the LiteMESH system, the worker shall read this manual.

During the use of the LiteMESH system, the workers shall meet all the requirements described in the

Technical Documentation and in any laws and regulations that apply.

Any works connected to the assembly, elements installation

and anchoring to the floor lie within the responsibility of the site manager.

The whole scope of works connected to the everyday use of the product lies within the responsibility

of the site manager.

Such actions like a daily and weekly inspection of the system shall be

entered into a system's control card.

After an accident that resulted in damaging any elements of the system, it should be

immediately withdrawn from further use. The damaged elements shall be replaced with new

elements.

Before using the FALL ARREST SYSTEM , the users shall read the technical documentation

of the system.

-

Shall not stand within the range of the DEVICE

during transport.

-

Shall remove any elements not connected to the given work which may pose a threat (cables,

hoses, unnecessary material).

-

The device shall not be used as a provisional platform, as it was not designed to carry

continuous loads or storing objects.

-

The place where the LiteMESH system is used shall have a rescue plan implemented, in

case of an event that led to securing from a fall.

-

Elements not delivered with the complete device shall not be attached to the system. It may

have a negative impact on mechanical parameters and affect the operational safety.

HOME

P a g e | 7

-

The LiteMESH system was designed to catch falling people and objects. The dynamic

strength of the system provides its proper functioning for loads of maximum 100 [kg], falling

from 2 [m]. Exceeding the allowed height and weight leads to uncontrolled and

unpredictable deformations and damages to the parts of the system.

-

During the transport, workers shall act carefully in order to avoid possible impact to the

constructional elements. In case of damaging any elements of the device, it shall be

immediately withdrawn from further operation.

-

The assembly shall be performed with due care. In case of damaging any elements the device, it

shall be immediately withdrawn from further operation or checked by a trained person.

-

The place where the system is used shall have a rescue plan implemented, in case of an

event that led to securing from a fall.

-

If the device is transported with a crane, workers shall pay special attention to any

movements of a crane and keep safe distance from it.

-

Introducing any changes and complementing the equipment/system demands a written

consent from the manufacturer. Any repairs of the system’s elements must be performed in

accordance with the procedures declared by the system's manufacturer.

-

During the assembly of the console's holders, the minimum strength of the anchoring point

shall be 10 kN. Detailed information concerning this topic can be found in the Assembly

Manual.

-

In case of selling the system abroad (to a different country than the country where it was

intended to be used in), the seller shall provide the operation, maintenance and periodical

inspection instructions in the language of a country where the equipment is to be used.

HOME

P a g e | 8

2.5

SYSTEM'S CHECK

QUICK CHECK

Before each use of the system, its technical condition shall be checked

in terms of:

-

completeness of the system’s elements,

-

completeness of screws, connectors,

-

no damages to any welds,

-

no damages to the net, edge line and mosquito net,

-

any bent, broken, cut or otherwise damaged elements,

-

check if all assembly holes are unobstructed and do not

hamper the proper assembly,

-

check the product's markings, its readability, lack of damages

(i.e. they are not wiped, broken etc.).

If any of these requirements are not met, the user shall stop using the system and

inform the manufacturer about the need to perform a detailed inspection.

DETAILED CHECK

The detailed check of the fall arrest system shall be performed by the manufacturer or

any appropriate entity:

-

always before delivering the system to a construction site,

-

after 12 months of using the system,

-

always when the system has not been used for longer than 3 months,

-

after every information from the user about the need to perform the detailed check.

For the detailed check, performed at the request of the user, shall be charged a fee.

PERIODICAL CHECK, CHECK

AFTER A FALL

In order to provide proper operation and safety of the system, the periodical check of the

system shall be performed at least once every 12 months (each element that is included in the

system).

The check must be performed by a competent person holding proper

authorizations.

In any situation when the SYSTEM was used – i.e. in case of a fall of an object – the used

elements of the system shall be immediately withdrawn from further operation and handed

over for a check.

The check shall be performed by the manufacturer or a person who was trained by

STRUMIN.

HOME

P a g e | 9

PERIODICAL CHECK EXPIRATION DATE

The periodical check expiration date is clearly marked on the outer edge of the check label

[term (year and month) of the next check]

2.6

MAINTENANCE

The elements of the FALL ARREST SYSTEM are protected with

lacquer.

While cleaning and performing the maintenance of the elements there shall always be used

substances that do not react with lacquer.

In case of any chips, they shall be filled with proper lacquer coating.

2.7

QUALIFICATIONS OF THE SYSTEM’S USERS. Workers operating the system

should:

-read the complete TECHNICAL DOCUMENTATION OF THE FALL ARREST SYSTEM – the training shall be

confirmed in writing,

-finish a training on the occupational safety and health,

-undergo a training about using

the personal and collective protective equipment.

HOME

P a g e | 10

2.8

CONNECTING THE FALL ARREST SYSTEM WITH A SLING

-Connection of the SYSTEM with a crane's sling shall be performed only by a person holding

qualifications described in 2.7 and the permissions for a hook operator.

-The crane's sling can be attached only in places that allow for the safe transport and firm

assembly of the load (what means an assembly that protects the elements of the system from

sliding out, breaking etc.).

The workers shall check if:

-the slings are certified, do not contain any visible defects and are proper for transporting the

system's elements,

-flexible connectors are not twisted or tied up,

-the bond between the slings and a transport bracket is firm,

-the crane’s hook is complete.

2.9

INSTALATION OF THE FALL ARREST SYSTEM

The assembly of the SYSTEM can only be performed by a person who has read the technical

documentation. The site manager or another authorized person is responsible for the deployment

and the choice of working places.

Before the assembly, it shall be checked if the system is complete and

has no visible signs of damages.

The assembly of the system shall be performed with caution. In case of damaging any elements

of the system, it shall be immediately replaced or checked by a trained person.

The vertical transport shall be performed with a crane, in accordance with the guidelines

described in 2.8.

2.10

DISASSEMBLING AND MOVING THE DEVICE BETWEEN WORKPLACES

During the disassembly of the SYSTEM workers shall keep all security measures and

comply with the same regulations as during the assembly process.

During the disassembly of the SYSTEM the user shall unfix all elements not belonging to the

system.

2.11

USE OF THE SYSTEM

During the use of the system, the workers shall meet all the requirements described in the

Technical Documentation and in any laws and regulations that apply.

HOME

P a g e | 11

3.0 DEVICE’S REGISTER

DEVICE’S REGISTER

Name of the product:

Model and type / identification:

Trade name:

ID No.:

Producer:

Address:

Phone No., e-mail,

web page:

Date of production / Date of expiry

Date of purchase:

The date of the first

use:

Other important information (e.g. document No.):

PERIODICAL CHECKS AND THE HISTORY OF REPAIRS

Date:

Reason (periodical check or

repair):

Defects found, repairs

performed and other

relevant

information:

Name and signature of a

competent person:

Periodical check –

next term:

HOME

P a g e | 13

THE SYSTEM

Name / Type: LiteMESH system

Serial number: 025

Year of production: 2022

Weight:

EN-1263-1_2015-02E

P.P.H.U STRUMIN

32-084 MORAWICA 191

The maximum height

of catching 2 m

The nominal value of the

absorbed energy

Read the safety instruction / User

manual

Use personal protective equipment

(PPE)

•

The information contained on a

rating plate allow to precisely

identify each device based on its

ID/Serial number.

•

All documents attached to the

device, such as the device's

register after check or the user

manual, are related to the ID /

serial No. on the device in order to

avoid any mistakes.

•

The warning field on the rating

plate informs, with the use of text

and symbols about possible

dangers when the device is

working.

Dangers

•

Act accordingly to the safety

instructions and use personal

protective equipment (PPE)

4.0 RATING PLATE

HOME

P a g e | 14

5.0 TABLE: DANGER RISK PROTECTION

No.

DANGER

RISK

RISK ASSESSMENT

PROTECTION MEASURES

1

N

OT SUFFICIENT MECHANICAL

DURABILITY

Using of a damaged

floor foot.

Fall of the construction.

Danger to health and life.

Check, control and properly store

the elements of the system.

Using a damaged or

destroyed console's

arm.

Fall of the construction.

Danger to health and life.

Check, control and properly store

the elements of the system.

Damaging of destroying

of the net's edge

line due to

overloading.

Fall of the construction.

Danger to health and life.

Check, control and properly store

the elements of the system.

Do not allow the risk of heavy

objects falling from height to arise.

2

Smashing

,

Squashing

Placing a foot, hand or

other body part under

the holders while

twisting or tightening.

Smashing, cutting, injuring or

scraping any part of the body.

Danger to health and life.

Be careful while assembling and,

especially, while placing the

modules on the floor. The risk of

falling from height, use personal

protective equipment. Use gloves,

shoes and protective helmets with a

chin strap.

3

Hitting

The risk of being hit by

the system's elements

during transport and

moving.

Hitting the construction or other

working surface, especially the

balks of the net (length 6 m).

Danger to health and life.

Be careful while moving and avoid

carrying long elements by only one

worker.

Use a protective helmet with a chin strap.

Not securing the

skewed arm during the

assembly.

Hitting with head or any other part

of the body of people that are on

the bottom level.

Danger to health and life.

Be careful while assembling, take notice

of any protective measures of elements

and avoid uncontrolled movements, i.e.

turning, moving, slipping etc.

Not securing the upper

arm from sliding out.

Risk for people on the lower

levels of hitting with head or

any other part of the body.

Danger to health and life.

Be careful while assembling, take notice

of any protective measures of elements

and avoid uncontrolled movements, i.e.

turning, moving, slipping etc.

4

F

ALLING OR THROWN

AWAY OBJECTS

Improper securing

of the objects

around the

workspace.

Hitting, breaking, injuring

or burning any part of the

body.

Danger to health and

life.

Wear proper personal protective

equipment. Define the safe work’s

system.

Define a safety area during the

assembly and disassembly of the

system, which amounts to (horizontally)

1/10 height of the building, but no less

than 6 m.

5

Weather

CONDITIONS

Hitting by a lightning,

wind.

Electrocuting, burning. Danger

to health and life.

Avoid performing any works during storms

and working when the wind blows

with the strength over 10 m/s.

HOME

P a g e | 15

6.0

DESIGNER’S STATEMENT

According to art. 20(4) of the "Building Code" I hereby declare that

this project documentation

of the constructional part for the fall-arrest system

was drawn in accordance with the provisions of the code, rules and guidelines of technical

knowledge (art. 20 point 4 of the 16 April 2004 Act, amending the 7 July 1994 Act – "Building

Code" Journal of Laws no. 6, pos. 41/2004), binding technical and building provisions, as well

as Polish and European Standards, and was handed in full to serve its purpose.

designer's readable signature and seal

HOME

P a g e | 16

EU DECLARATION OF CONFORMITY NO.: …….

1. “LiteMESH” system (serial No.............................................................................................................................. ),

2. Name and address of the manufacturer:

PPHU STRUMIN, Kamil Strumiński, 32--084 MORAWICA Morawica

191, TIN: 944 21 77 757,

3. This declaration was issued for the sole responsibility of the manufacturer: PPHU STRUMIN, Kamil

Strumiński,

4. Object of the declaration: The “LiteMESH” system as described in the Technical Documentation in the

appendices no. 1 and 2 to this declaration:

„LITEMESH - operating manual - PL.pdf”

„LITEMESH - assembly manual - PL.pdf”

5. The object of this declaration described in 4 herein complies with the provisions of the EU's standards.

6. References to the standards describing the declared compliance:

The design of the LiteMESH system was drawn in accordance with

the applicable laws and technical norms:

EN-1263-1_2015-02E – Temporary constructions used at a working site.

Safety nets,

Part 1: Requirements concerning safety, research methods,

EN 1090--2:2008+A1:2011, Technical requirements for the execution of steel and aluminium structures,

Part 2: Technical requirements concerning the

steel constructions,

EN ISO 3834--2:2007; Quality requirements for the welding of

metal materials,

7. The object of this declaration, described in Point 4. Herein, complies with the type, in accordance with the

Company's production inspection system No. ZKP/STRUMIN/01 and the rules of the supervised product

inspections in random time intervals).

Signing on behalf of: Kamil Strumiński, PPHU STRUMIN

(place and date of issuing):

MORAWICA

21-03-2022

Other manuals for LiteMESH

1

Table of contents

Other STRUMIN Safety Equipment manuals

Popular Safety Equipment manuals by other brands

schmersal

schmersal AES 1235 operating instructions

Ferno

Ferno 430 Series quick start guide

EDELRID

EDELRID BICOLOR manual

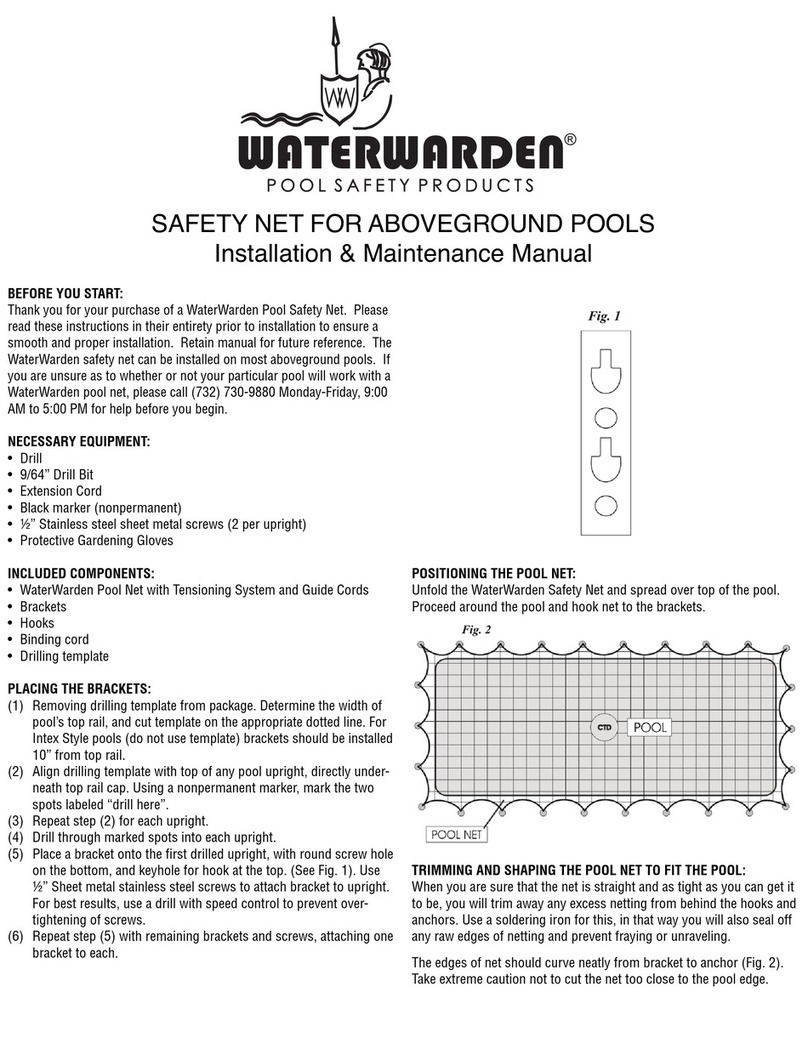

WaterWarden

WaterWarden SmartPool Pool Safety Net Installation & maintenance manual

IKAR

IKAR ANCHORAGE SLINGS Instructions for the use and inspection records

EUCHNER

EUCHNER MGB-L B-PN Series operating instructions