Polski Rejestr Statków S.A. al. gen. Józefa Hallera 126, 80-416 Gdańsk, Poland

According to European standard EN365:2004 and EN795:2012 type B a requirement to check the legibility of the product

PROTEKT Grzegorz Łaszkiewicz ul.Starorudzka 9 93-403 Łódź

- personal fall protection equipment must not be used by a person with

medical condition that could affect the safety of the equipment user in

normal and emergency use.

- prepare a rescue plan to be implemented whenever necessary.

- it is forbidden to make any alterations or additions to the equipment

without prior written consent given by the manufacturer.

- any repair shall only be carried out by manufacturer of the equipment or

his certified representative.

- personal fall protection equipment shall not be used for any purpose other

than intended.

- personal fall protection equipment provides individual protection and shall

be used by one person only.

- before each use make sure that all parts of fall protection system

cooperate correctly. Periodically examine connections and fitting of

components of the equipment to prevent any accidental loosening or

disconnection.

- it is forbidden to use a combination of equipment where function of any

one item is affected by, or interferes with the function of any other.

- before each use of personal fall protection equipment, a pre-use check

should be carried out to ensure that it is in a serviceable condition and

operates correctly.

- in particular, inspect all accessible elements of the equipment for any

damages, excessive wear, corrosion, abrasion, cutting or improper function.

For individual devices pay particular attention to:

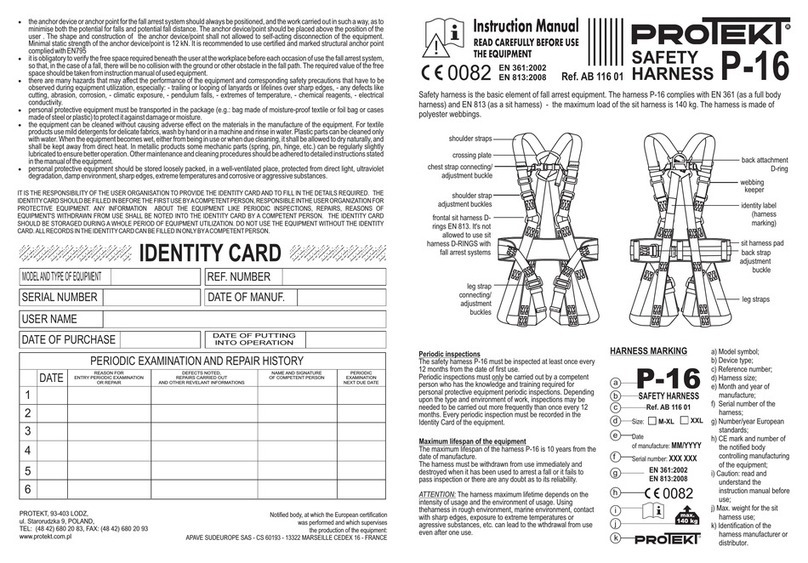

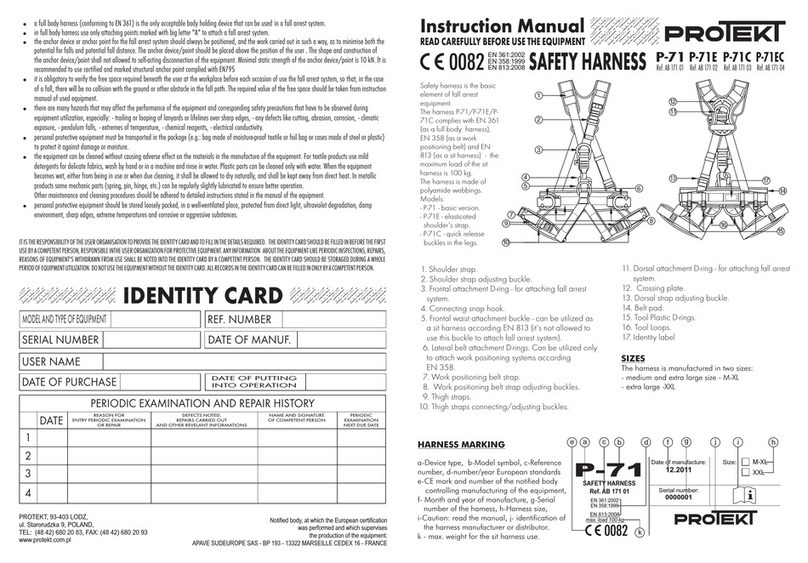

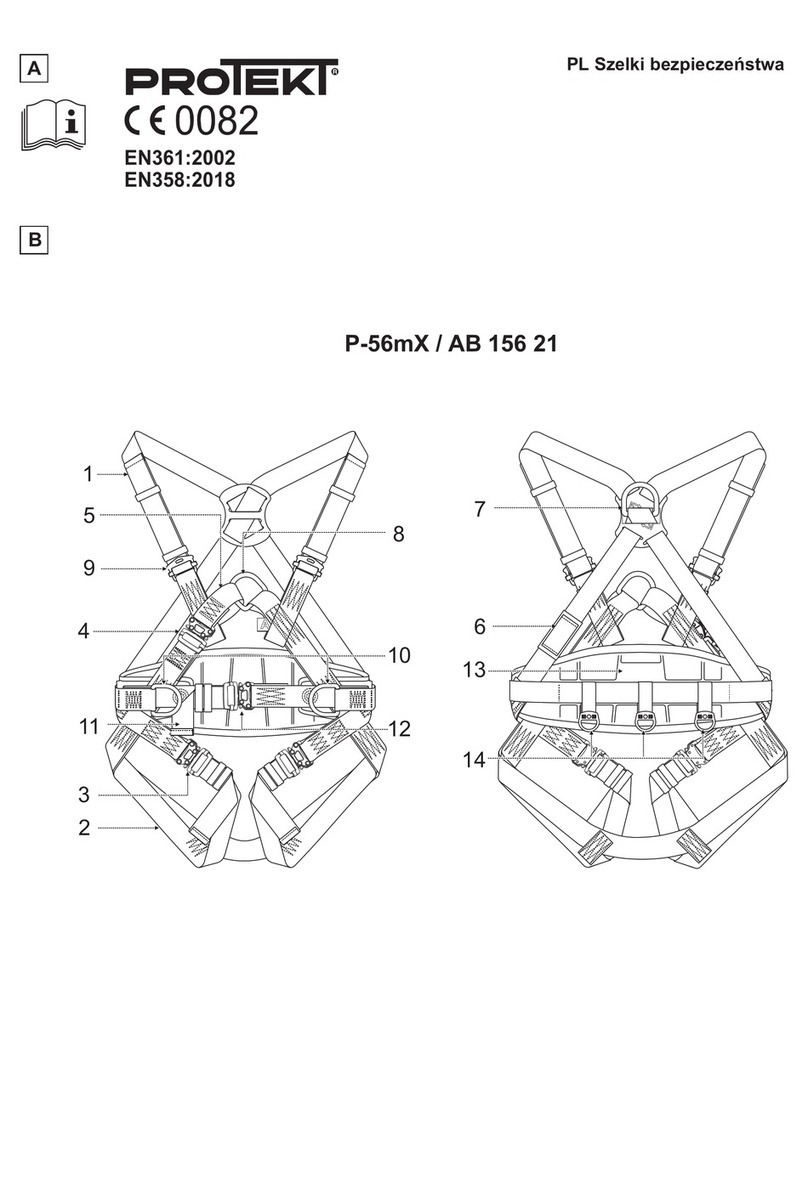

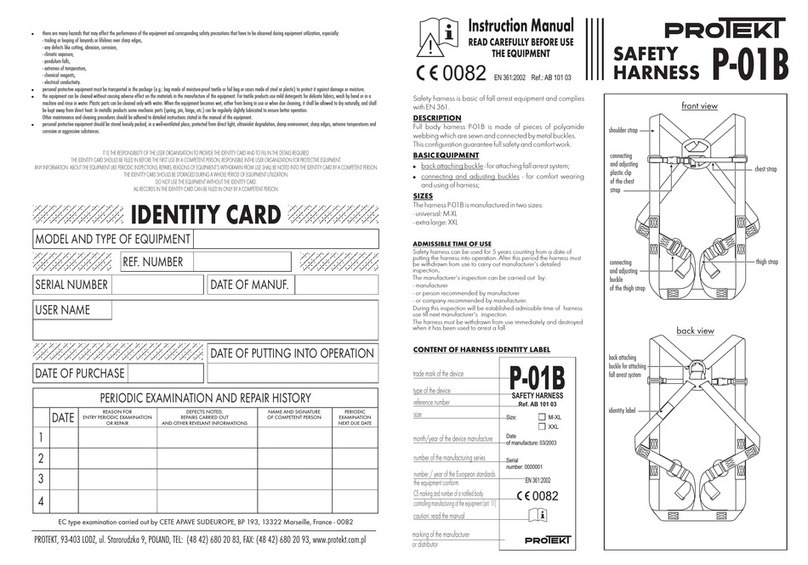

- in full body harnesses and work positioning devices: buckles,

regulating elements, attachment points (buckles), webbing, seams, belt

loops;

- in energy absorbers: attachment loops, webbing, seams,

housing, connectors;

- in lanyards and textile guides: rope, loops, thimbles, connectors,

regulating parts, splices;

- in lanyards and steel guides: rope, wires, clamps, loops,

thimbles, connectors, regulating parts;

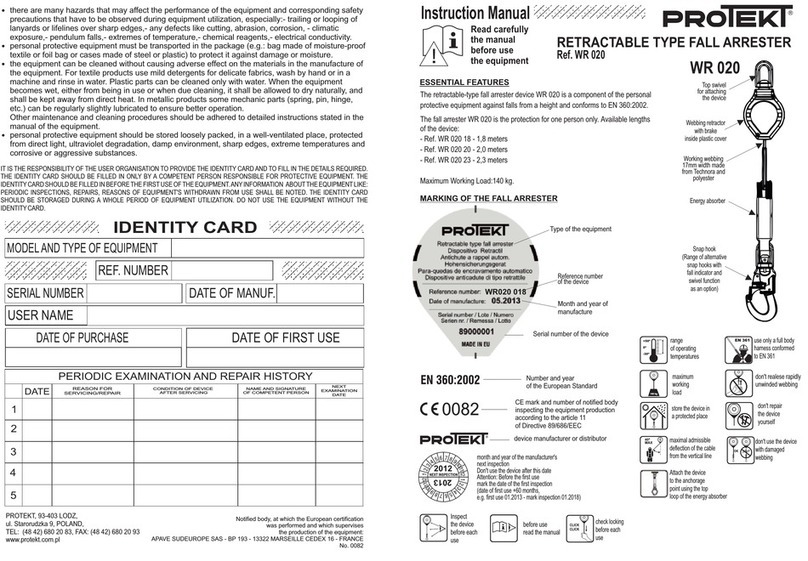

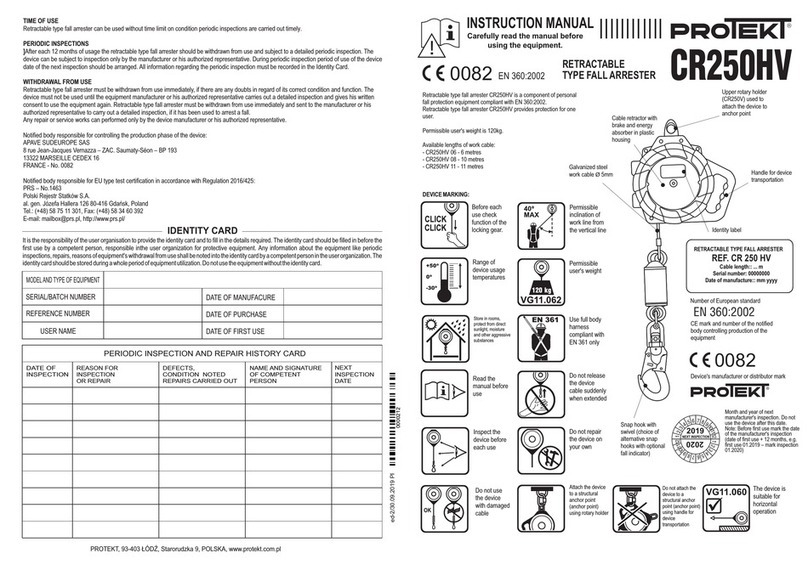

- in retractable type fall arresters: lanyard or webbing, retractor

and locking mechanism for proper operation, housing, energy absorber,

connectors;

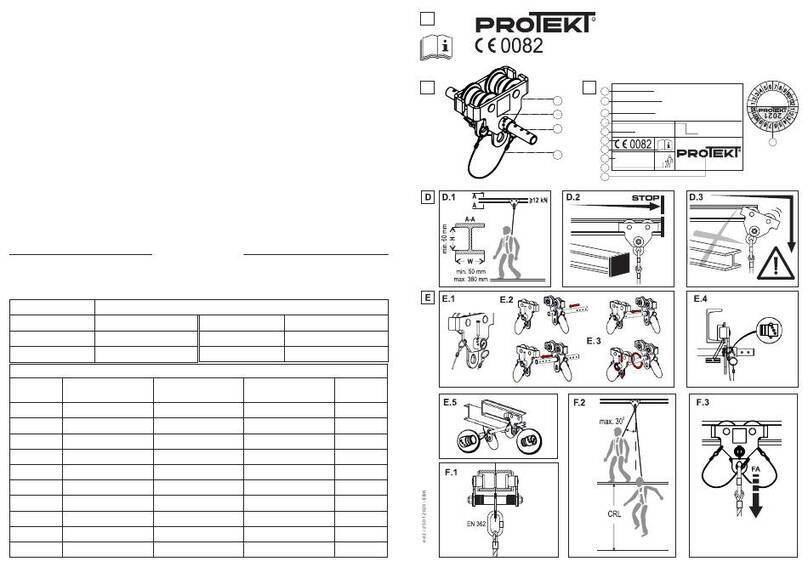

- in guided type fall arresters: body, proper guiding, locking

mechanism for proper operation, rollers, bolts and rivets, connectors,

energy absorber;

- in connectors (snap hooks): load-bearing body, rivets, main

pawl, function of locking gear.

- at least once a year, after every12 months of use, personal fall protection

equipment must be withdrawn from use to carry out periodic detailed

Periodic inspection can be carried out by a properly trained and skilled

person.

Periodic inspections can be carried out also by manufacturer of the

equipment or his authorized representative, or an authorized company.

Inspect in detail all accessible elements of the equipment paying attention to

any damages, excessive wear, corrosion, abrasion, cutting or incorrect

function (see the above item.) In some cases, if the fall protection

equipment has a complex design (e.g. fall arresters), periodic inspections can

be carried out by manufacturer of the equipment, or his authorized

representative only. After the periodic inspection, date of the next

inspection should be defined.

- regular periodic inspections are essential in respect of the equipment

condition and safety of users which is dependant on the equipment

functionality and durability.

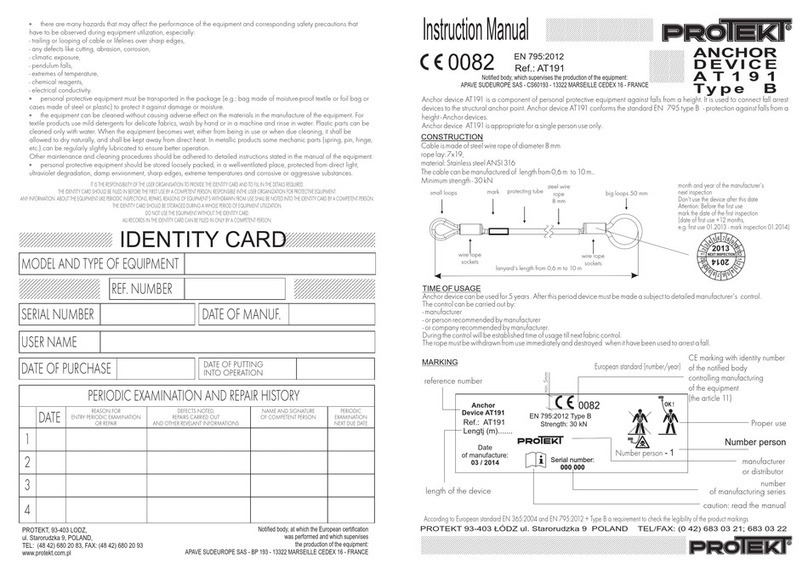

- during periodic inspection it is necessary to check the legibility of all the

equipment markings (identity label of the device).

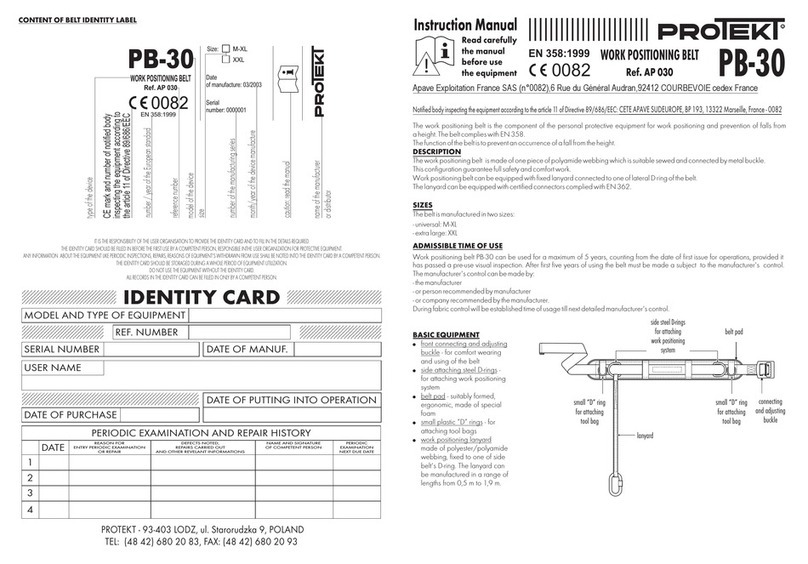

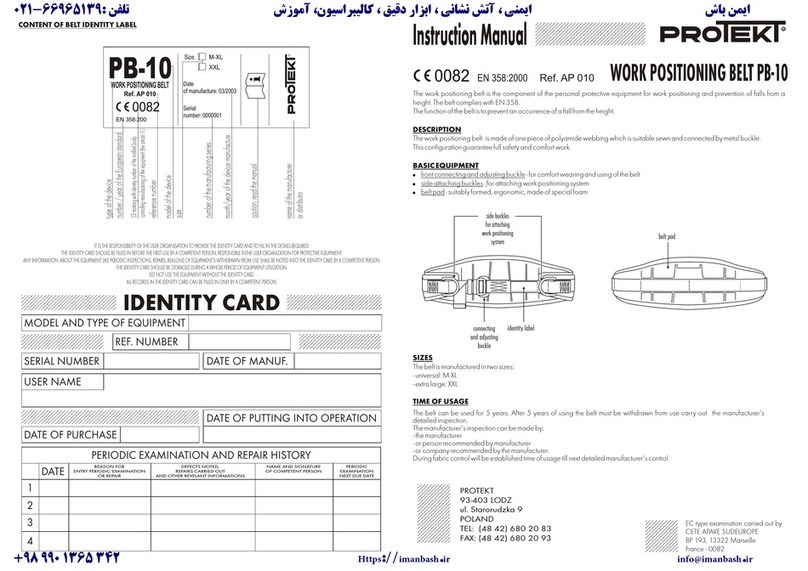

- all information on protective equipment (name, serial no., purchase date

and date of first use, name of user, information on repairs and inspections

and withdrawal from use) must be provided in the identity card of the

device. It is responsibility of user’s organisation to provide the Identity card

and to fill in the required details. The Identity card should be filled in by a

person in charge of fall protection equipment in user’s organisation. It is

forbidden to use personal fall protection equipment if the Identity Card is

not filled in.

- if the equipment is re-sold outside the original country of destination the

reseller must provide instructions for use, for maintenance, for periodic

inspection and for repair in language of the country where the product is to

be used.

- personal fall protection equipment must be withdrawn from use

immediately if any doubts arise in regard of its condition, or proper

operation. The equipment must not be used until manufacturer of the

equipment carries out a detailed inspection and gives his written consent to

use the equipment again.

- personal protection equipment must be withdrawn from use immediately

and destroyed if it has been used to arrest a fall.

- full body harness is the only admissible device to be used to support the

user’s body in personal fall protection equipment.

- in full body harness use only attaching points (buckles, loops) marked with

capital letter “A” to attach a fall protection system.