Stuart Turner Pulse Trade 25-60/130 Guide

STUART

Installation, Operation & Maintenance

Instructions

Please leave this instruction booklet with the end user as it contains

important warranty, maintenance and safety information

Read this manual carefully before commencing installation.

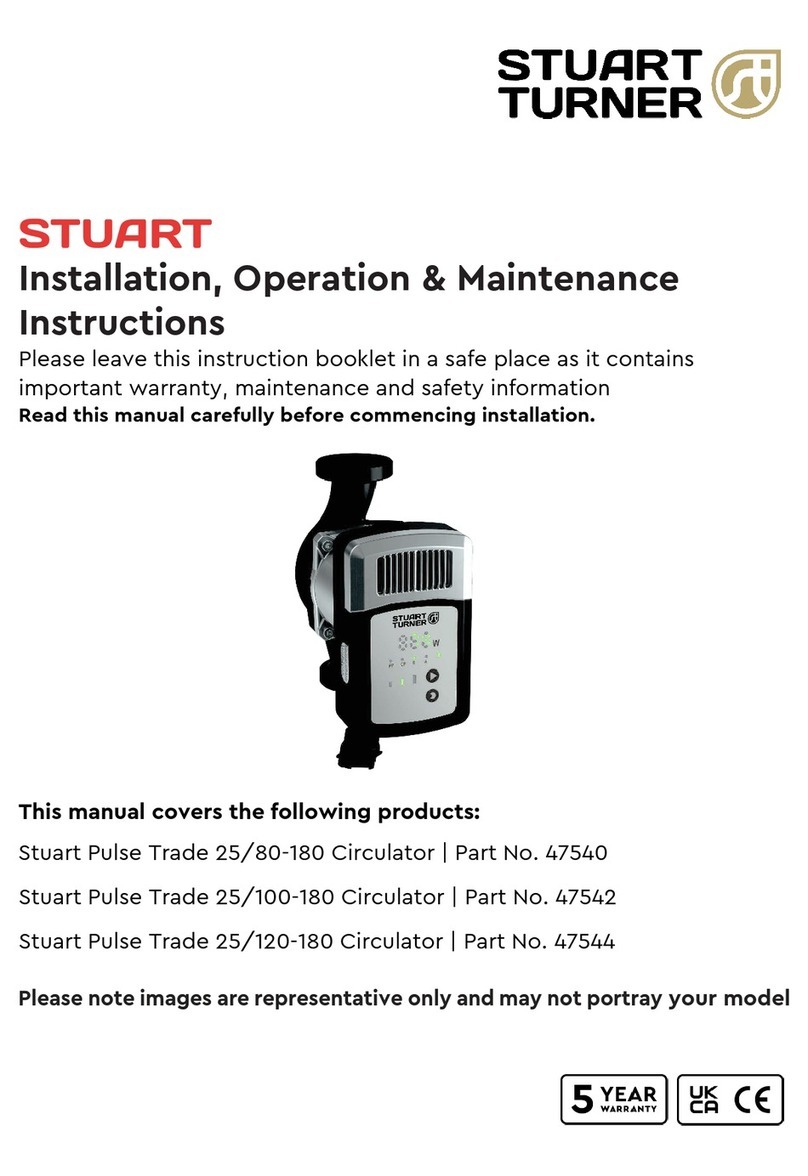

This manual covers the following products:

Pulse Trade 25-60/130

Pt. No. 47505

2

Contents

1 Safety Instructions ........................................................................... 5

1.1 General ...................................................................................... 5

1.2 Identification of symbols in the operating instructions ........... 5

1.3 Personal qualification ................................................................ 5

1.4 Danger of not observing safety instructions ............................ 6

1.5 Safety-conscious work.............................................................. 6

1.6 Safety instructions for the operator ......................................... 6

1.7 Safety instructions for installation and maintenance work ...... 6

1.8 Unauthorised conversion and production of spare parts .........7

1.9 Unpermitted operation ..............................................................7

2 Transport and storage ......................................................................7

3 Intended Use .....................................................................................7

4 Product information ......................................................................... 8

4.1 Technical data Pulse Trade 25-60/130 ..................................... 8

4.2 Delivery range ........................................................................... 9

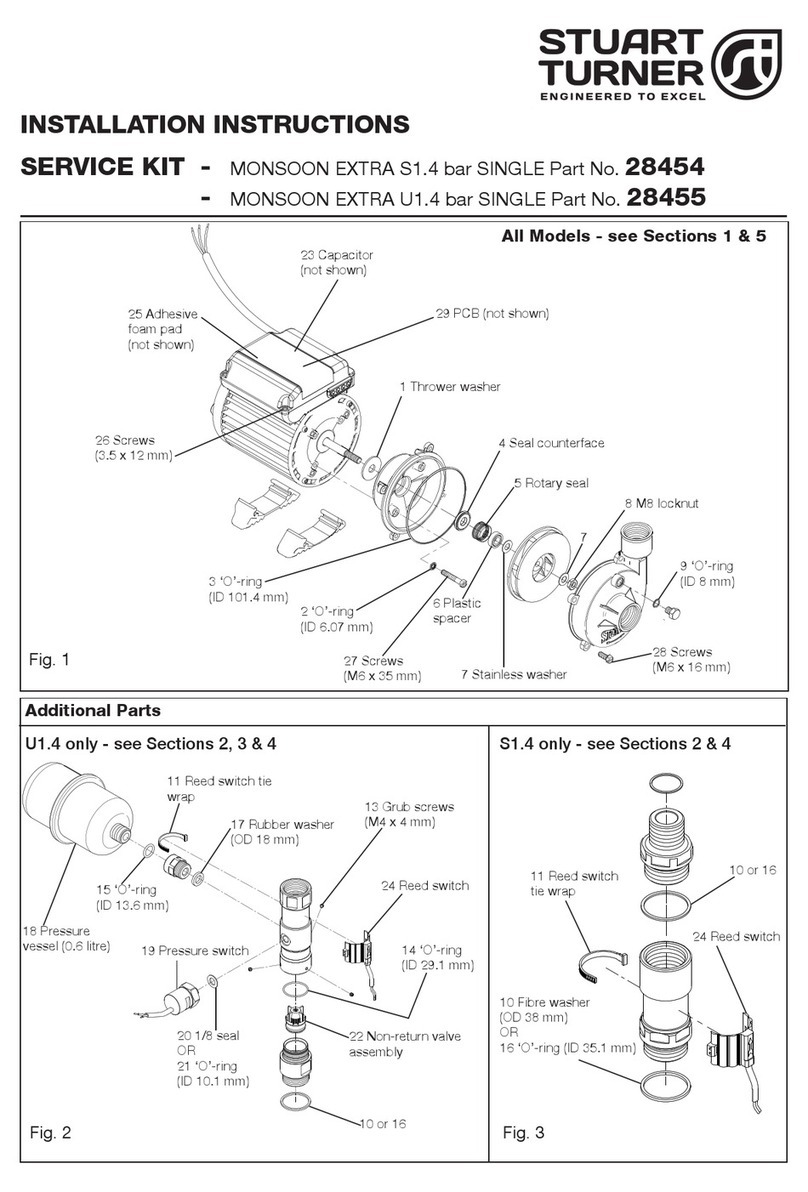

5 Pump description ............................................................................. 9

6 Pump settings and capacity ............................................................ 9

6.1 Buttons ...................................................................................... 9

6.1.1 Service mode, setting the capacity range ............................... 9

6.2 Control panel and LED display ................................................ 10

6.3 Selection of the operating mode and degree of work ........... 10

8.1 Recommendations for selecting a degree of work ................ 12

8.2 Automatic night reduction of power ...................................... 12

9 Filling and venting the installation ................................................. 13

10 Relationship between pump setting and capacity ........................ 14

3

11 Capacity characteristics ................................................................. 14

12 Installation ....................................................................................... 15

13 Electrical Installation/Earthing ....................................................... 17

14 Maintenance/service ...................................................................... 19

15 Malfunctions, causes and elimination ............................................. 19

16 Disposal .......................................................................................... 20

17 Warranty ......................................................................................... 21

4

WARNINGS:

This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

The motor casing can become very hot under normal

operating conditions. Care must be taken to ensure it

cannot be touched during operation.

The electrical installation must be carried out in

accordance with the current national electrical

regulations.

The electrical installation must be installed by a

qualified person.

Do not run the pump dry.

System pressure must not exceed 10 bar.

Before starting work on the electrical supply ensure

power supply is isolated.

DO NOT allow the supply cord to contact hot

surfaces, including the motor shell, pump body or

pipework. The cord should be safely routed and

secured by cable clips.

This appliance must be earthed via the supply cord,

which must be correctly connected to the earth point

located in the terminal box.

Please read installation details carefully as they are intended to ensure this product

provides long, trouble free service. Failure to install the unit in accordance with the

installation instructions will lead to invalidation of the warranty.

5

1 Safety Instructions

1.1 General

These installation and operating instructions are a part of the product and

contain basic information that must be observed during installation, operation

and maintenance. For this reason, the installer and specialist personnel or

operators must read these instructions prior to set-up.

Please observe both the general safety instructions listed under section 2 and

the special safety instructions detailed in the other sections.

A copy of the EC Declaration of Conformity is provided with these instructions.

This declaration shall be deemed void in the event of a modification that has

not been agreed with us.

1.2 Identification of symbols in the operating instructions

General hazard symbol Warning! Danger of

personal injury! Observe the relevant accident

prevention regulations.

Warning! Danger from electrical voltage! Prevent

hazards arising from

electrical energy. Observe the instructions in local

or general regulations (e.g. IEC, VDE, etc.), and

those of the local energy supplier.

Bold text indicates useful information for handling the product. It indicates

potential difficulties and aims to ensure safe operation.

Signs attached directly on the product, such as:

direction of rotation arrow

type plate

identification of connections must be strictly observed and kept in an

easily legible state

1.3 Personal qualification

The personal used for mounting, operation and maintenance must have

relevant qualifications. The owner/operator must guarantee areas of

responsibility and monitoring of personnel. If personnel do not have

the necessary knowledge, they must be trained or instructed

accordingly. This device can be used by children at or above the age

of 8 years, as well as by persons with reduced physical, sensory or mental

capabilities, or who lack experience and knowledge, if they are supervised or

have been instructed concerning the safe use of the device and if they

6

understand the hazards arising from its use. Children may not play with the

device. Cleaning and maintenance operations may not be conducted by

children without supervision.

5

1.4 Danger of not observing safety instructions

Not observing the safety information can endanger persons,

the environment and the system. Not observing the safety

instructions shall result in the loss of all claims to

warranty.

Potential dangers include:

• Hazards to persons through electrical and mechanical effects.

• Failure of important system functions.

• Hazard to the environment from escaping fluids resulting

from a leak.

• Failure of prescribed repair and maintenance work.

1.5 Safety-conscious work

Observe the safety instructions detailed in this manual, along with the current

national accident prevention regulations. Should the system operator also

have their own internal regulations, these must also be observed.

1.6 Safety instructions for the operator

Any existing touch guard protecting moving parts may be neither

removed nor shut down while the system is in operation.

In the event of a fluid leak, any fluids must be collected or diverted

in a way that prevents hazards to persons and the environment

from arising.

Prevent hazards arising from electrical energy.

Observe the instructions in local or general regulations (e.g. IEC, VDE,

etc.), and those of the local energy supplier. In the event of hazards

arising from the system due to contact with hot or cold parts, these parts

must be fitted with a touch guard.

Keep flammable substances away from the product.

1.7 Safety instructions for installation and maintenance work

The system operator is responsible for ensuring that qualified personnel

conduct all installation and maintenance work. These persons must also have

familiarised themselves in advance with the product using the operating

instructions. Conducting work on the pump is only permitted when the

system has been isolated, and has been allowed to cool.

Ensure that the device is securely disconnected from the power supply.

7

Disconnect the device plug to achieve this. Prescribed instructions for

shutting down the device can be found in the operating instructions. All

protective mechanisms, such as a touch guard, must be correctly reattached

after work.

1.8 Unauthorised conversion and production of spare parts

Modification or conversion of the product is only permitted after prior

consultation with the manufacturer. Only use original spare parts for repairs.

Only use accessories that have been approved by the manufacturer. The

manufacturer shall bear no liability for any consequences resulting from the

use of other parts.

1.9 Unpermitted operation

If the pump is disconnected from the power supply, wait at least 1 minute

before reactivating. Otherwise, the pump's inrush current limit has no effect,

which can lead to functional errors or damage to any connected heating

controller. The pump's operational safety can only be ensured if it is

used as intended. Please observe section 3 of these operating

instructions here. Ensure compliance with the limit values detailed

in the technical data.

2 Transport and storage

After receiving the product, inspect it immediately for damage caused in

transport. Should you

detect any transport damage, assert a claim with the haulier.

Incorrect transport and storage can lead to personal injury or damage to the

product.

Protect the product against frost, moisture and damage during

transport and storage.

Only carry the pump by the pump housing, and never by the

connection cable or terminal box.

If the packaging weakens due to moisture, this can lead to the pump

falling out and causing severe injury.

3 Intended Use

These high efficiency pumps are designed to circulate hot water in

central heating systems and are also suitable for pumping low

density liquids in industrial and commercial applications. They are

8

also suitable for solar installations.

4 Product information

4.1 Technical data Pulse Trade 25-60/130

Maximum elevation height 6.0 m

Maximum flow rate 3600 l/h

Power consumption P1 (W) 4.5 - 38

Supply voltage 1 x 230V 50Hz

Sound pressure level <43 dB(A)

EEI 0.20

Protection type IP 42

Temperature class TF 110

Ambient temperature

0 °C to 40 °C

Medium temperature

+5 to110 °C

System pressure

Max. 10 bar (1MPa)

Permitted media

Heating water acc. to VDI 2035

Connection

G1 ½”

Supply pressure Acceptable range of application

Medium

temperature

Minimum

supply pressure

< 75 °C 0.05 bar 0.005 MPa 0.5 m

75 °C - 90 °C 0.3 bar 0.03 MPa 3.0 m

90 °C - 110 °C 1.1 bar 0.11 MPa 11.0 m

Attention!

The use of unsuitable media can destroy the pump and injure you. It is

necessary to observe the manufacturer’s information and safety data

sheets!

Temperature range at

maximum

ambient temperature

Permissible

medium

temperature

25 °C 5 °C to 110 °C

40 °C 5 °C to 95 °C

Pulse Trade 25-60/130 | 47505

9

4.2 Delivery range

Original assembly and operating manuals

Pump

2 flat gaskets

Pump plug

Insulation

5 Pump description

In an average household, 10 to 20% of electricity consumption is used by

conventional standard pumps. We have developed a circulation pump with

an energy efficiency index ≤ 0.20. By using Pulse Trade 25-60/130, energy

consumption can be reduced by up to approx. 80% compared to a

conventional circulation pump. The hydraulic capacity can be kept almost the

same as with the standard pumps. The pump capacity adapts to the actual

system demand as it works according to the proportional pressure method.

6 Pump settings and capacity

6.1 Buttons

All pump functions can be controlled with just two buttons. The button

switches the night reduction function on and off. The button controls the

operating modes. The selected operating mode is shown in the clear field of

the LED indicator.

6.1.1 Service mode, setting the capacity range

The capacity range can be changed to 4m or 6m in service mode.

The pump must be disconnected from the

230V mains voltage for at least 15 seconds.

Connect the pump to the 230V mains voltage.

Press the and buttons simultaneously

within 3 seconds.

Then release both buttons.

Select the capacity range with the button .

-4 = 4m

-6 = 6m

The pump must be disconnected from the

230V mains voltage for at least 15 seconds.

Connect the pump to the 230V mains voltage

10

The setting process is now complete. The pump is now running in the

selected capacity range. If necessary, the pump setting can be readjusted at

any time.

6.2 Control panel and LED display

1. Display of energy consumption in watts.

2. Automatic night reduction display.

3. Button for activating the automatic night

reduction.

4. Operating mode selection button.

5. Display for activated AUTO Smartadapt mode.

6. Display of the nine operating levels

(characteristics) of the pump.

6.3 Selection of the operating mode and degree of work

6.3.1 Constant speed adjustment I, II, III

In this operating mode, the pump runs at a constant rotational speed over the

entire characteristic curve.

6.3.2 Constant pressure adjustment CP 1, CP 2

In this type of adjustment, the pressure generated by the pump is kept at a

constant level. This type of adjustment is especially suitable for use in

underfloor heating systems.

6.3.3 Proportional pressure adjustment PP1, PP2

The pump is controlled by the proportional pressure method. In this case, the

pressure generated by the pump is adapted to the changing flow rate. This

operating mode is especially useful when the pump is to be used as a

circulation pump for heating.

6.3.4 Smartadapt

The Smartadapt AUTO function is designed for two-circuit heating systems

and underfloor heating systems. The pump capacity is automatically adjusted

to the actual heat demand of the installation. The pump power is adjusted

gradually and may take more than a week. If the power supply to the pump is

1

2

3

4

6

5

11

interrupted, the pump remembers the last setting and resumes adjusting as

soon as power is restored. Upon delivery, the pump is set to the AUTO

Smartadapt operating level. Multiple brief presses of the select button will

continuously toggle between the constant speed, constant pressure,

proportional pressure and AUTO Smartadapt modes. The selected operating

mode is indicated by the appropriate LED with characteristic symbols.

7 Automatic night reduction display

Display of means that automatic night reduction is activated.

Button for activating automatic night reduction

By pressing the button in section 3, automatic night reduction is

switched on or off.

When the automatic night reduction is activated, the symbol lights up

in the display field 3.

The "Automatic Night Reduction" function is not available in the constant

speed levels.

8 Selection of the degree of work

Pressing the button switches between the operating levels.

12

8.1 Recommendations for selecting a degree of work

Factory configuration = AUTO Smartadapt

8.2 Automatic night reduction of power

Conditions for automatic night reduction:

Pumps installed in gas boilers with low water capacity must never be set

to automatic night reduction.

If the heating system does not supply enough heat to the radiators,

check whether the automatic night reduction function is active. If

necessary, deactivate the automatic night reduction function.

To ensure that night reduction functions properly, the following requirements

must be met:

1. The pump must be installed on the supply

2. The heating system must be equipped with automatic temperature

adjustment on the supply.

13

How automatic night reduction works

Press the button to activate the night reduction function. If the adjacent

highlighted field is lit, the night reduction is activated and the pump

automatically switches between normal operation and night reduction.

Switching depends on the flow temperature.

The pump automatically switches to night temperature reduction if the flow

temperature drops by more than 10°-15°C in 1 hour.

Switching to normal operating mode takes place immediately as soon as the

flow temperature rises again by 3°C.

9 Filling and venting the installation

Fill and vent the installation properly. To vent the pump, the electronics

should be set to level III and operated in this position for at least 20 minutes.

Caution After this procedure, you can set the pump to the desired control

mode.

Incomplete venting will cause noise in the pump and system.

Warning! Danger of burns!

Depending on the operating status of the installation,

the entire pump can become very hot.

15

14

10 Relationship between pump setting and capacity

The characteristic curves show the relationship between pump settings and

pump capacity.

11 Capacity characteristics

Pulse Trade 25-60/130 | 47505

15

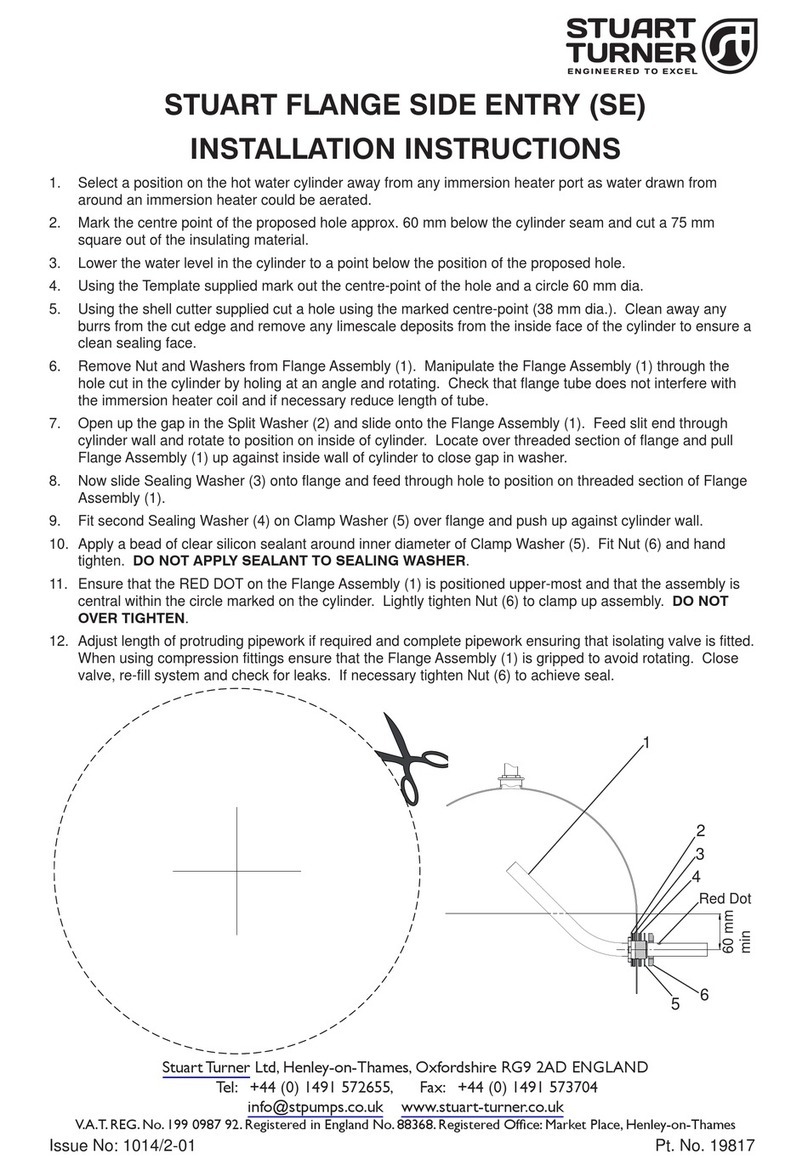

12 Installation

Correct installation position of the pump.

A voltage-free installation must be conducted with the pump motor in a horizontal

position (the direction arrow on the pump body shows the direction of flow –

ensure inlets/outlets fitted correctly). When performing thermal insulation, make

sure that the pump and the electronics body are not insulated. If the installation

position is to be changed, the pump must be rotated as follows.

Loosen the hexagon socket screws

Rotate the engine case

Re-screw and tighten the hexagon socket screws.

16

G

System dimensions

Dimensional sketch and dimension table.

Pump

Type

Dimensions Technical Data

H

(mm)

H1

(mm)

L

(mm)

B

(mm)

G (“) Weight

kg

(without

cable)

Current (A) Elevation

height

(m)

Trade 25-60/130 138 112 130 93 1 ½ 2.12 0.04-0.25/0.04-0.31 0-4/0-6

17

13 Electrical Installation/Earthing

13.1 Regulations: The electrical installation must be carried out in

accordance with the current local regulations by a qualified person.

13.2 Safety: In the interests of electrical safety a 30 mA residual current

device (R.C.D. not supplied) should be installed in the supply circuit.

This may be part of a consumer unit or a separate unit.

13.3 Before starting work on the electrical supply ensure power

supply is isolated.

13.4 Earthing: This appliance must be earthed via the supply cord, which must be

correctly connected to the earth point located in the terminal box.

13.5 Cable fitting: The pump must be factory fitted supply cord and permanently

connected to the fixed wiring of the mains supply, via a dedicated double pole

switched fused spur off the ring main.

13.6 DO NOT allow the supply cord to contact hot surfaces, including the motor shell,

pump body or pipework. The cord should be safely routed and secured by cable clips,

alternatively the cord must be protected by an insulating sleeving with appropriate

temperature rating.

13.7 Wiring of connection unit:

WARNING: This appliance must be earthed.

The wires in the mains lead (supply cord) are coloured in accordance with the following

code:

Green and Yellow: Earth (PE)

Blue: Neutral (N)

Brown: Live (L)

As the colours of the wires in the mains lead of this appliance may not correspond with

the coloured markings identifying the terminals in your connection unit proceed as

follows:

The wire which is coloured green and yellow must be connected to the

terminal in the connection unit which is marked with the letters PE or by the

earth symbol : or coloured green or green and yellow.

The wire which is coloured blue must be connected to the terminal which is

marked with the letter N or coloured black.

18

The wire which is coloured brown must be connected to the terminal which is

marked with the letter L or coloured red.

Fuse: The pump MUST use a 5 Amp fuse.

Connect the power cord to the pump as shown in the below picture.

Caution mains voltage! Always observe the necessary safety measures, VDE

regulations and local regulations.

Caution Danger to life!

Incorrect installation and incorrect electrical connection can be life-threatening.

Electricity hazards must be ruled out.

Installation and electrical connection may only be performed by qualified

personnel and in accordance with the applicable regulations (e.g. IEC, VDE, etc.).

The type of current and voltage must comply with the data on the rating plate.

Comply with the regulations of the local power supply company.

Comply with the accident prevention regulations.

Never pull on the power cord.

Do not bend the cord.

Do not place any objects on the cord.

There is a risk of sharp and jagged edges during assembly.

Never transport by holding the power cord.

There is a risk of injury from dropping the pump.

19

14 Maintenance/service

Before carrying out maintenance, cleaning and repair work, disconnect

the system from the power supply and secure it against being switched

on again by unauthorized persons.

At high water temperatures and system pressures, wait for the pump

to cool down beforehand. There is a risk of burns!

15 Malfunctions, causes and elimination

Maintenance work or repair attempts may only be performed by qualified

personnel. Before conducting maintenance, cleaning and repair work, disconnect

the system from the power supply and secure it against being switched on again

by unauthorized persons. At high water temperatures and system pressures, wait

for the pump to cool down beforehand. There is a risk of burns!

20

If the defect cannot be eliminated, contact a specialized dealer.

After 10 seconds without pressing a button, the display turns off.

Pressing one of the two buttons turns it back on.

16 Disposal

The pump and its individual parts must not be disposed of with the municipal

waste but must be disposed of in an environmentally friendly manner! To do this,

use the services of public or private waste disposal companies. You can find a list

of the materials used in our products in the download area of our website.

Advice:

All illustrations in this manual are schematic representations. Please note that

purchased electric pumps and accessories may differ from the illustrations in

this manual.

Product performance is constantly improved and all products (including

appearance and colour, etc.) are subject to physical products; no notification

will be given in the event of changes.

This manual suits for next models

1

Table of contents

Other Stuart Turner Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Festo

Festo PVGA Series manual

Huawei

Huawei FusionModule1000A40 ICT Solution Initial Configuration Parameter Manual

Quantronix

Quantronix Cubiscan 110-XT Operation and technical manual

Lincoln

Lincoln D Series Owner's/operator's manual

ABB

ABB HT582253 Operation manual

Siemens

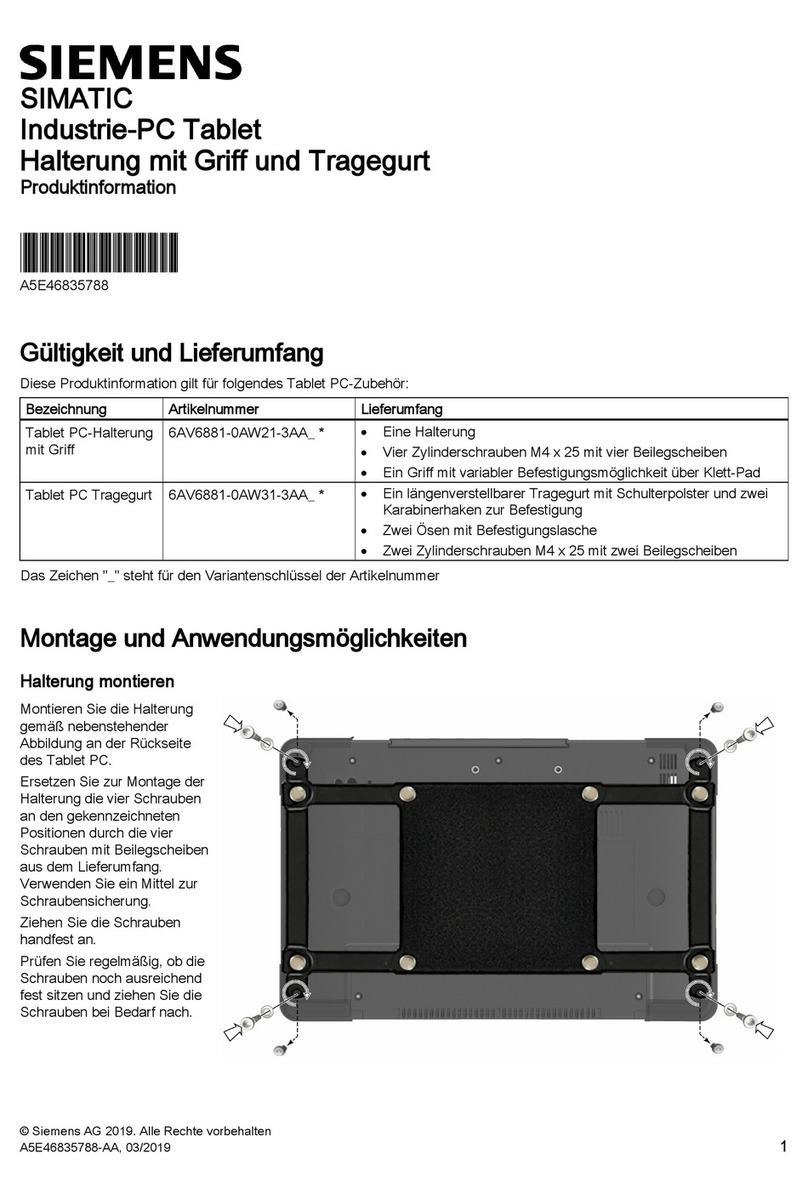

Siemens SIMATIC 6AV6881-0AW21-3AA Series Product information

SCHUNK

SCHUNK PFH 30 Assembly and operating manual

MICRO-EPSILON

MICRO-EPSILON ELTROTEC Endolight FOT Halogen 150 instruction manual

Hamworthy

Hamworthy Stratton mk3 manual

ipf electronic

ipf electronic OT15 Series manual

HayssenSandiacre

HayssenSandiacre Ultima SV 12-19HR instruction manual

Tyco

Tyco TY-FRB Series manual