Stuart Turner Pulse Trade 25/80-180 Guide

STUART

Installation, Operation & Maintenance

Instructions

Please leave this instruction booklet in a safe place as it contains

important warranty, maintenance and safety information

Read this manual carefully before commencing installation.

This manual covers the following products:

Stuart Pulse Trade 25/80-180 Circulator | Part No. 47540

Stuart Pulse Trade 25/100-180 Circulator | Part No. 47542

Stuart Pulse Trade 25/120-180 Circulator | Part No. 47544

Please note images are representative only and may not portray

your model

CONTENTS

1PRODUCT OVERVIEW...............................................................................................3

2SAFETY INSTRUCTIONS ............................................................................................4

3CHECKLIST ................................................................................................................ 7

4TRANSPORT AND STORAGE.....................................................................................8

5KEY FEATURES...........................................................................................................9

6PUMP SETTINGS ...................................................................................................... 10

7PWM FUNCTION...................................................................................................... 14

8FILLING AND VENTING THE SYSTEM...................................................................... 21

9RELATION BETWEEN PUMP SETTING AND CAPACITY..........................................22

10 CAPACITY CHARACTERISTICS ...............................................................................23

11 ASSEMBLY................................................................................................................24

12 ELECTRICAL CONNECTION ....................................................................................26

13 MAINTENANCE AND SERVICE................................................................................. 27

14 FAULTS, CAUSES AND REMEDIES...........................................................................28

15 DISPOSAL.................................................................................................................30

16 NOTES...................................................................................................................... 31

17 PRODUCT WARRANTY ...........................................................................................33

18 DECLARATION OF CONFORMITY ...........................................................................34

3

1PRODUCT OVERVIEW

1.1 Product Description

Our Stuart Pulse Trade Circulators features a robust cast iron pump housing

and is ideal for the transfer of liquid within systems for hot-water heating, air-

conditioning and ventilation.

This circulator features variable speed controls to constantly measure pressure

and flow and adjust the speed according to the set operating mode.

1.2 Application

The PULSE high-efficiency pumps are designed for circulating hot water in

central heating systems and are also suitable for pumping low-viscosity media

in the industrial and commercial sector. They also can be used in solar

technology systems.

4

2SAFETY INSTRUCTIONS

2.1 General

These operating instructions are part of the product and contain basic

information that must be observed during assembly, installation, operation

and maintenance. For this reason it must be read by the installer and the

responsible qualified personnel or the operator before performing assembly

works.

Not only the general safety instructions mentioned in point 2 must be

observed, but also the special safety instructions mentioned in the other

sections.

A copy of the EU Declaration of Conformity is provided with these

instructions. In case of a modification, which has not been agreed with us

beforehand, the declaration loses its validity.

2.2 Labelling of symbols in the operating instructions

General danger symbol Warning! Danger of personal injury! The

existing regulations for accident prevention must be observed.

Warning! Danger due to electrical voltage! Danger due to electrical

energy must be excluded. Observe the instructions in local or

general regulations (e.g. IEC, VDE, etc.) and those of the local energy

suppliers.

2.3 Personnel qualification

The personnel, who is carrying out assembly, operation and

maintenance works must provide appropiate qualifications.

The area of responsibility, competence and supervision of the personnel must

be ensured by the operator. If personnel do not provide the required know-

how, they must be trained or instructed accordingly.

This device can be used by

children

aged from 8 years and above, as well as

by persons with reduced physical, sensory or mental capabilities or lack of

experience and know-how, only if they have been given supervision or

instruction concerning use of the device in a safe way and if they understand

the hazards involved.

Children

must not play with the device. Cleaning and

user maintenance works

must not be carried out by

children

without

supervision.

5

2.4 Dangers, if the safety instructions are not observed

Failure to observe the safety instructions may endanger persons, the

environment and the system. Failure to comply with the safety instructions

will result in the loss of any claims for damages.

Potential dangers include:

•dangers to persons due to electrical and mechanical effects

•failure of important functions of the system

•danger to the environment due to leakage of liquids as a result of a leak

•failure of prescribed repair and maintenance works

2.5 Safety-conscious work

Observe the safety instructions detailed in these operating instructions, along

with the current national accident prevention regulations. Should the system

operator also have their own internal regulations, these must also be

observed.

2.6 Safety instructions for the operator

•Any protection against contact with moving parts must not be removed

or disabled, while the system is in operation.

•If liquids leak out, they must be collected or diverted in such a way, that

no danger to persons or environment can arise.

•Hazards due to electrical energy must be excluded.

•For this purpose observe the instructions in local or general regulations

(e.g. VDE, etc.) and those of the local energy suppliers.

•If hazards should occur in the system due to hot or cold parts, these must

be provided with a touch guard.

•Highly flammable substances must be kept away from the product.

6

2.7 Safety instructions for assembly and maintenance works

The system operator is responsible for ensuring that all assembly and

maintenance works are carried out by qualified personnel. They must have

previously familiarised themselves with the product, using the operting

isntructions. Conducting of works on the pump is only permitted when the

system is shut down.

Ensure that the device is securely disconnected from the power supply.

Disconnect the device plug to achieve this. Prescribed instructions for

shutting down the device can be found in the operating instructions. After

completion of the works, all protective devices, such as touch guard, must be

refitted in accordance with the regulations.

2.8 Unauthorised modification and use of spare parts

Modifiactions or alterations of the product are only permitted after prior

consultation with the manufacturer. Use only original spare parts for repairs.

Only accesories approved by the manufacturer can be used. If other parts are

used, any liability of the manufacturer for the resulting consequences is

excluded.

2.9 Inadmissible operating modes

If the pump is disconnected from the power supply, wait at least 1

minute before switching it on again. Otherwise, the pump's inrush

current limit has no effect, which can lead to functional errors or

damage to any connected heating controller. The pump's operational safety

can only be ensured if it is used as intended. Point 4 ot these operating

instructions must be observed. Ensure compliance with the limit values

detailed in the technical data.

7

3CHECKLIST

IMPORTANT: With the appliance removed from its packaging check for any

damage prior to installation. If any damage is found contact Stuart Turner Ltd

within 24 hours of receipt.

Item Description Qty

A Instruction guide 1

B Pulse Trade Circulator 1

C Flat gaskets 2

D Mains cable 1

E Insulation 1

Your product may vary slightly from the photo above.

8

4TRANSPORT AND STORAGE

After receiving the product, inspect it immediately for damage caused in

transport. If any transport damage is found, this must be claimed by the

carrier.

Improper transport and storage can lead to personal injuries or

damages to the product.

•Protect the product against frost, moisture and damage during transport

and storage.

•Only carry the pump by the pump housing, and never by the connection

cable or terminal box.

•If the packaging has been softened by moisture, the pump may fall out

and cause severe injuries.

9

5KEY FEATURES

5.1 Technical data

Pulse Circulator Model

25/80-180

25/100-180

25/120-180

Maximum delivery head

8.0 m 10.0 m 12.0 m

Maximum flow rate

8000 l/h 9000 l/h 10000 l/h

Power consumption P1 (W)

80 W 120 W 180 W

Supply voltage

1 x 230V 50Hz

Emission sound pressure level

<43 dB(A)

EEI

≤ 0.23

Thermal class

TF 110

Ambient temperature

0 °C to 40 °C

Media temperature

+2 to 110 °C

Maximum system pressure

10 bar (1MPa)

Permitted pumped media

heating water according to VDI 2035

water/glycol mixture 1:1

Supply pressure Permitted range of temperature

Medium

Temperature

Minimum supply

pressure

Temp range at

max ambient

temperature

Permissible

medium

temperature

< 75 °C 0.05 bar 0.005

MPa 0.5 m

25 °C 5 °C to 110 °C

75 °C - 90 °C 0.3 bar 0.03 MPa

3.0 m

40 °C 5 °C to 95 °C

90 °C - 110 °C 1.1 bar 0.11 MPa

11.0 m

10

6PUMP SETTINGS

6.1 Button

All pump functions can be controlled with just two buttons. The button

switches the night reduction function on and off. The button controls the

operating modes. The selected operating mode is shown in the clear field of

the LED indicator.

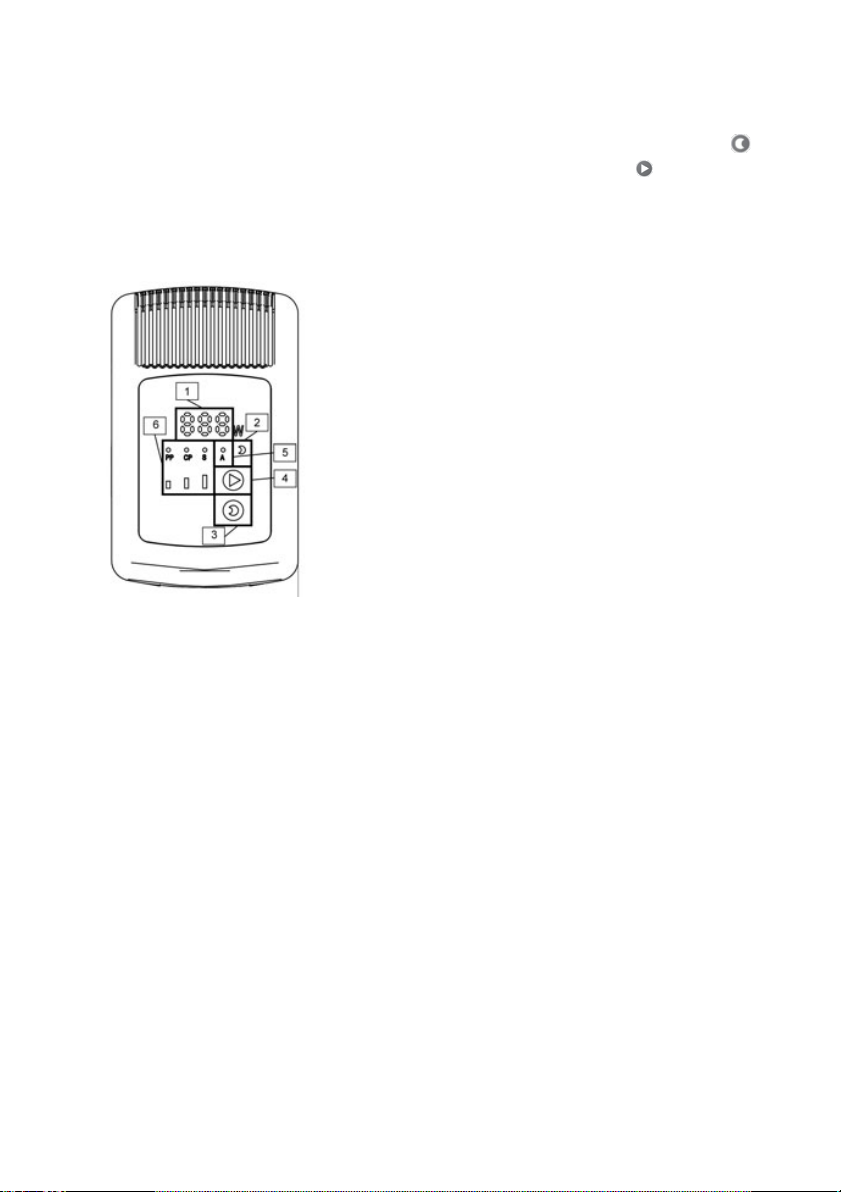

6.2 Control panel and LED display

1. Display of energy consumption in watts

2. Automatic night reduction display

3. Button for activating the automatic night

reduction

4. Operating mode selection button

5. Display for activated AUTO Smartadapt

mode

6. Display of the nine operating levels

(characteristics) of the pump

6.3 Selection of the operating mode and operating level

1. Constant speed mode I, II and III

In this operating mode, the pump rotates at a constant speed over the entire

characteristic curve.

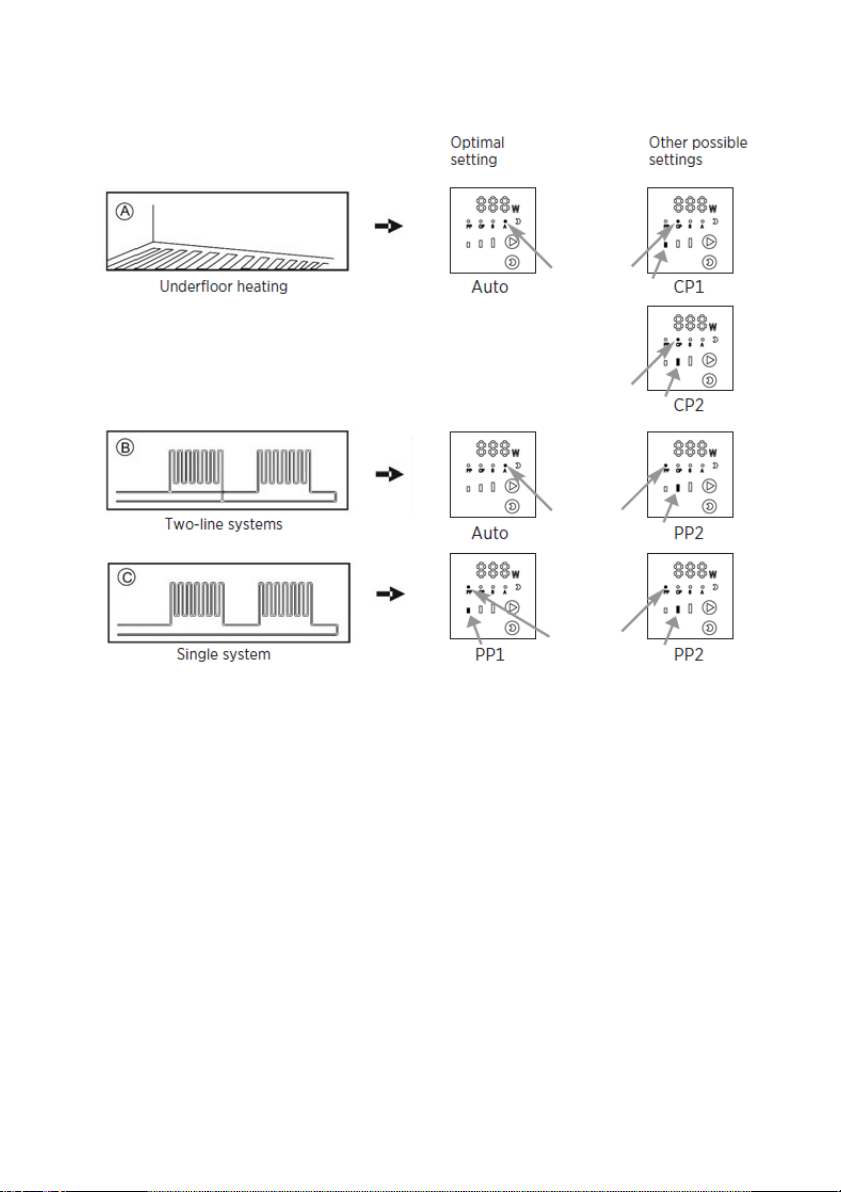

2. Constant pressure mode CP 1, CP 2, CP 3

In this control mode, the pressure generated by the pump is kept at a

constant level. This control mode is particularly suitable for use in underfloor

heating systems.

3. Proportional pressure mode PP1, PP2, PP3

In this mode the pump is controlled according to proportional-pressure

principle. In this case, the pressure generated by the pump adapts to the

changing flow rate. This operating mode is particularly suitable if the pump is

intended for use as a heating circulation pump.

4. AUTO Smart Adapt

The AUTO Smart Adapt function is designed for two-circuit heating systems

and underfloor heating systems. In this mode the pump performance adapts

automatically to the actual heat demand of the system. The adjustment of the

pump performance happens gradually and can take longer then a week. If the

power supply to the pump in interrupted, the pump saves the last settings

and resumes the adjustment as soon as the power supply is restored. On

11

delivery, the pump ist set to the AUTO Smart Adapt operating level. By

repeatedly briefly pressing of the selection button, the operating modes:

constant speed, constant pressure, proportional pressure and AUTO Smart

Adapt are switched through continously. The selected operating mode is

indicated by the corresponding LED with characteristic symbols.

No. of button

presses

Display Description Symbol

on display

0

AUTO

(factory

settings)

AUTO Smart Adapt

1 PP1 Minimum proportional pressure

control mode

2 PP2 Medium proportional pressure

control mode

3 PP3 Maximum proportional pressure

control mode

4 CP1 Minumum constant pressure

control mode

5 CP2 Medium constant pressure

control mode

6 CP3 Maximum constant pressure

control mode

7 I Constant speed control mode I

8 II Constant speed control mode II

9 III Constant speed control mode III

10 AUTO AUTO Smart Adapt

12

6.4 Automatic night reduction display

Display of means that automatic night reduction is activated.

6.5 Button for activating automatic night reduction

•By pressing the buton in section 3, automatic night reduction is

switched on or off.

•When the automatic night reduction is activated, the symbol lights up

in the display field 2.

The "Automatic Night Reduction" function is not available in the constant

speed levels.

6.6 Selection of the operating level

•Pressing the button switches between the operating levels.

•The factory configuration of Auto Smartadapt will be re-established by

pressing the button ten times.

6.7 Automatic night reduction

Conditions for automatic night reduction:

Pumps installed in gas boilers with low water capacity must never be set to

automatic night reduction:

If the heating system does not supply enough heat to the radiators, check

whether the automatic night reduction function is active. If necessary,

deactivate the automatic night reduction function.

To ensure that night reduction functions properly, the following requirements

must be met:

1.

The pump must be installed on the supply.

2.

Heating system must be equipeed with automatic temperature

adjustment on the supply.

How automatic night reduction works

Press the button to activate the night reduction function. If the adjacent

highlighted field is lit, the night reduction is activated and the pump

automatically switches between normal operation and night reduction.

Swiching depends on the flow temperature. The pump automatically switches

to night temperature reduction if the flow temperature drops by more than

10°-15°C in 1 hour. Switching to normal operating mode takes place

immediately as soon as the flow temperature rises again by 3°C.

The "Automatic Night Reduction" function is not available in the constant

speed levels.

13

6.8 Recommendations for the selection of the operating level

Factory setting = AUTO Smart Adapt

14

7PWM FUNCTION

7.1 Optional special function PWM input

This function allows the pump speed to be controlled by an external

controller. To use this function, the pump must have the appropriate input.

This external input can be recognized by an additional 3-pole connection

cable to which a suitable external control can be connected. After connecting

the PWM signal, the pump automatically switches to the PWM operating

mode. Switching is indicated by the indication P1 (heating mode) in the LED

field 4. The display field alternately shows the currently consumed electrical

power and the set PWM operating mode. By briefly pressing the button, you

can switch between the two PWM operating modes: heating mode P1 and

solar mode P2.

If the PWM signal is switched off or interrupted by a damage to the cable, the

pump automatically switches to the internal control logic. If, for safety

reasons, the pump is to switch to maximum speed in the event of a PWM

cable failure, stage III for constant speed adjustment must be set. This setting

ensures that the pump switches to maximum speed in the event of a failure of

the PWM control signal.

The maximum cable length is 3m! The polarity of the PWM cable must

correspond to:

BLACK = GND/earthing,

YELLOW = PWM feedback signal (Out)

RED = PWM control signal (In)

The signal line is galvanically insulated from the pump electronics by an

optocoupler. The PWM connection cable should be adapted to work with a

rated operating voltage of 230V AC.

15

Second side connected:

•Must reliably prevent direct contact with the cable conductors when

installed, i.e. the terminals must be touch-proof and the terminal

connections must be protected against unintentional contact by a fixed

cover.

•Must meet the requirements of protection class I (connection to

protective earthing). The device can be launched only after correct

connection of PWM signal.

The open-collector PWM output must be connected to the output electronics

via a suitable Pullup resistor. The operating voltage must be below 20V and

the input current must be between 2mA and 10mA. Or a voltage of 20V, the

recommended Pullup resistor value is: 4.7 kOhm - 10 kOhm 1/4W.

16

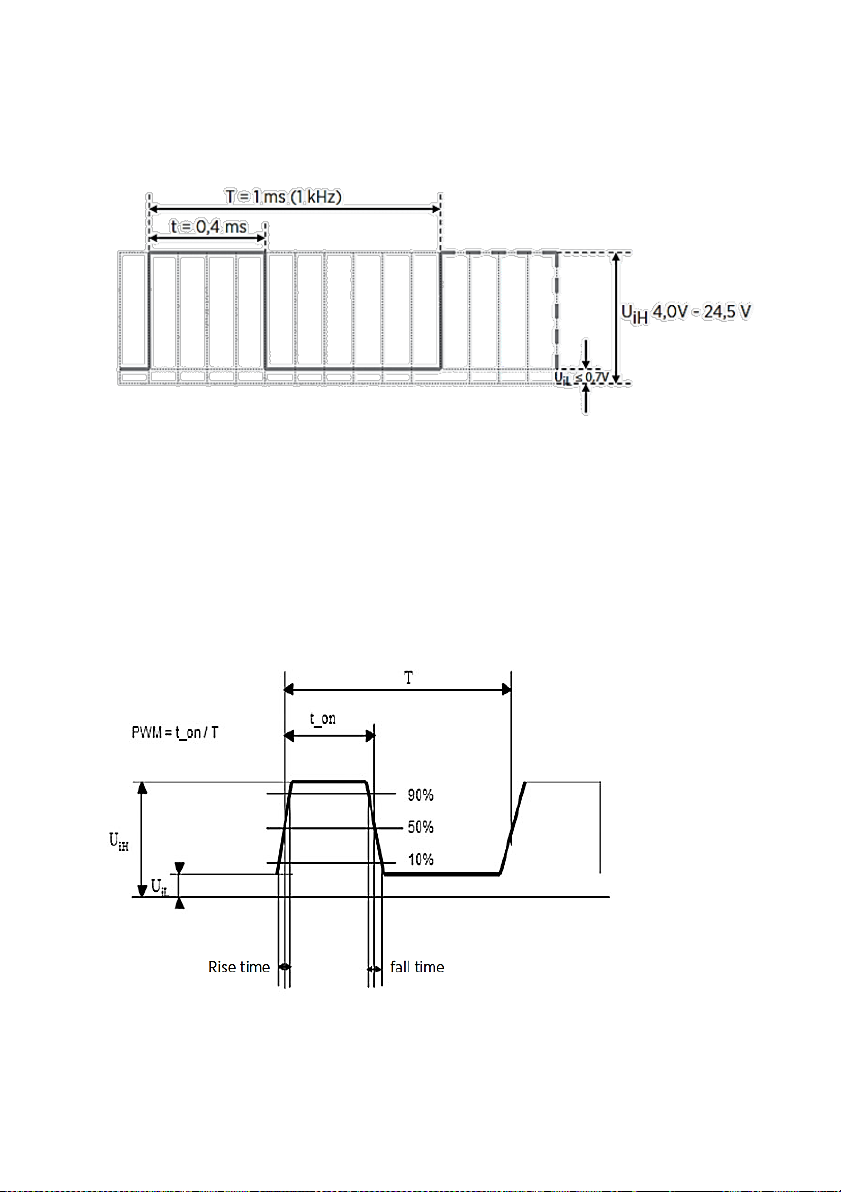

The PWM control signal is a digital signal in which the rotational speed

information is included in the pulse width. The control signal must meet the

following requirements:

Example of a PWM signal with a value of 40%:

PWM % = 100 * t / T

PWM % = 100 * 0.4 / 1 = 40 %

For T, frequencies between 200 Hz and 4 kHz are acceptable.

Permissible input current IH =: 3.5mA/4700Ω - 10mA/100 Ω

UIH input signal voltage level: 4.0V - 24.5V

Voltage level for LowLevel UIL † 0.7V

Rise time, signal fall time † T/1000

17

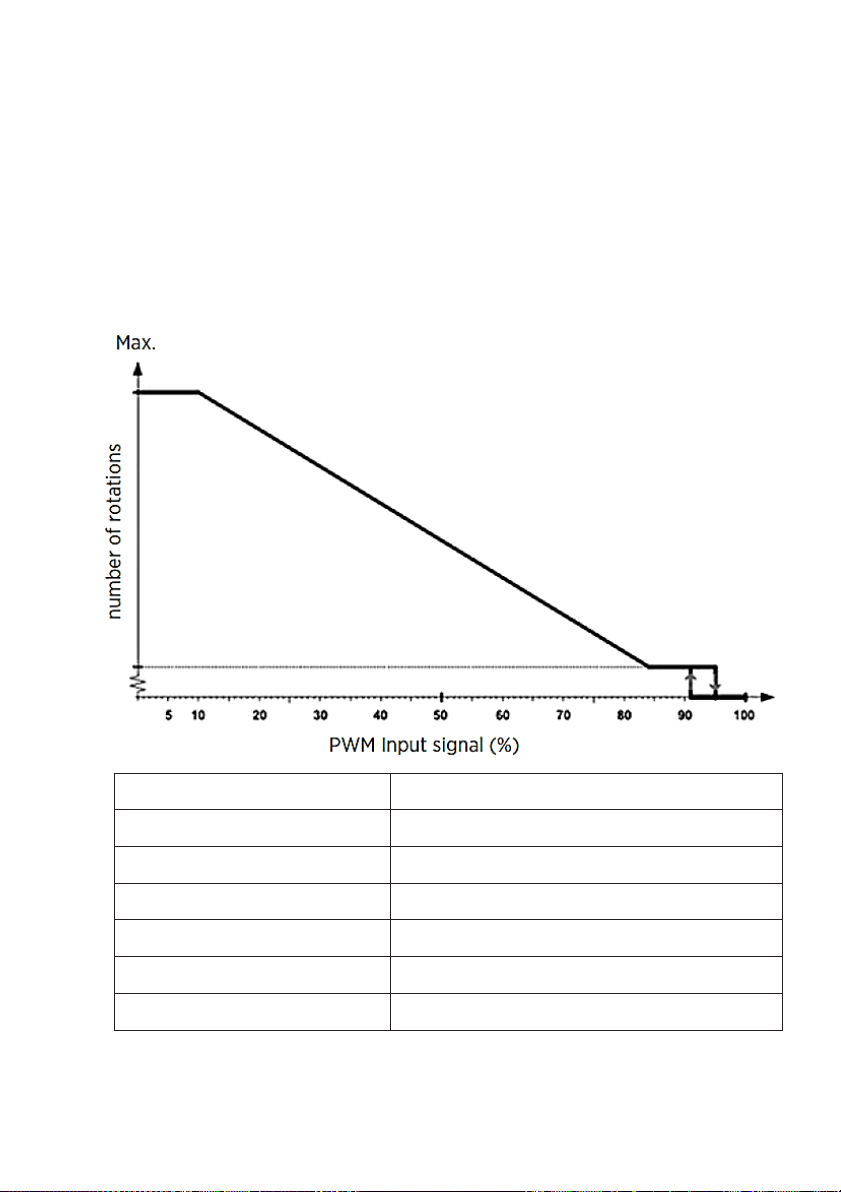

7.2 Heating characteristics P1

In the range from 0 to 10% of the PWM signal, the pump runs at maximum

speed for safety reasons.

(The prerequisite is that the pump is set to constant rotatioinal speed

adjustment III when selecting the operating level (chapter 6.3)).

In the event of a disturbance in the PWM adjustment or damage to the cable,

this ensures that the heat generated by the heat generator is transferred. This

is to prevent the system from overheating. In the range between 91 and 95%

of the PWM, the hysteresis prevents the pump from continually switching

when the PWM signal oscillates around the switch point.

PWM input signal (%) Pump status

PWM = 0 The pump switches to internal control

0 < PWM ≤ 10 Maximum rotational speed: Max.

10 < PWM ≤ 84 Variable speed: max. to min.

84 < PWM ≤ 91 Minimal rotational speed: Min.

91 < PWM ≤ 95 Hysteresis range: on/off

95 < PWM ≤ 100 Standby mode: off

18

7.3 Solar characteristics P2

In the range from 0 to 5% of the PWM, the pump stops for safety reasons. If

the PWM signal is switched off, e.g. due to a fault in the controller or an

interruption in the signal cable, the pump stops. This is to prevent overheating

of the solar system. In the range between 5 and 8% of the PWM, the

hysteresis prevents the pump from continually switching when the PWM

signal oscillates around the switch point.

(For the pump to run at maximum speed in the range of 98% to 100% of the

PWM, it must be set to constant rotational speed adjustment III when

selecting the operating level (chapter 7.3)).

PWM input signal (%) Pump status

PWM = 0 The pump stops

0 < PWM ≤ 5 Standby mode: off

5 < PWM ≤ 8 Hysteresis range: on/off

8 < PWM ≤ 15 Minimal rotational speed: Min.

15 < PWM ≤ 90 Variable speed: max. to min.

90 < PWM ≤ 98 Maximum rotational speed: Max.

98 < PWM ≤ 100 The pump switches to internal control

19

7.4 PWM feedback signal (power consumption)

By means of a PWM feedback signal, it is possible to send information about

the operating status of the pump to an external control. It contains

information about the actual power consumption and errors of the pump. The

output signal has a constant frequency of 75 Hz and is galvanically insulated

from the rest of the pump electronics. The table below shows which PWM%

values correspond to each operating statuses:

20

PWM input

signal (%)

QT *

(s)

Pump feedback DT *

(s)

Priority*

95 0 Standby (Stopp) 0 1

90 30 Error, pump rotor blocked 12 2

85 0-30 Alarm, stop: electronics

error 1-12 3

75 0 Warning 0 5

0-70 /

8m: 0-80W

(slope of 7/8 %PWM/W)

10m: 0-140W

(slope of 7/12 %PWM/W)

12m: 0-180W

(slope of 7/18 %PWM/W)

/ 6

The output

frequency 75Hz +/- 5%

QT* = (Qualification time) This value indicates how long the operating state

must be present for proper feedback to occur.

DT* = (Disqulification time) This value indicates the time after which the error

message is reset if the error no longer occurs.

Priority* = This number indicates the priority with which the operating status is

reported. The lower the number, the higher the priority.

This manual suits for next models

5

Table of contents

Other Stuart Turner Industrial Equipment manuals