SMC Networks CKZT Series User manual

Other SMC Networks Industrial Equipment manuals

SMC Networks

SMC Networks Electro Industries ProtoCessor User guide

SMC Networks

SMC Networks CJP2 Series User manual

SMC Networks

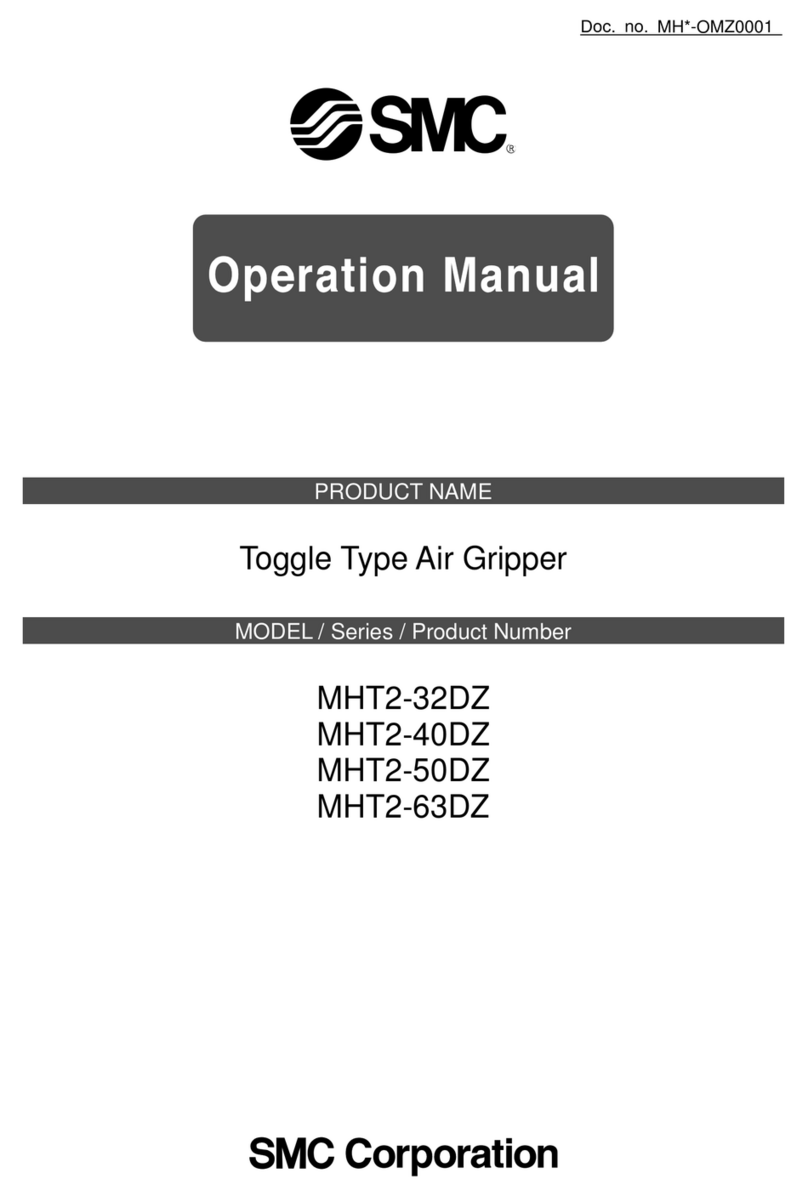

SMC Networks MHT2-32DZ User manual

SMC Networks

SMC Networks VR2110 User manual

SMC Networks

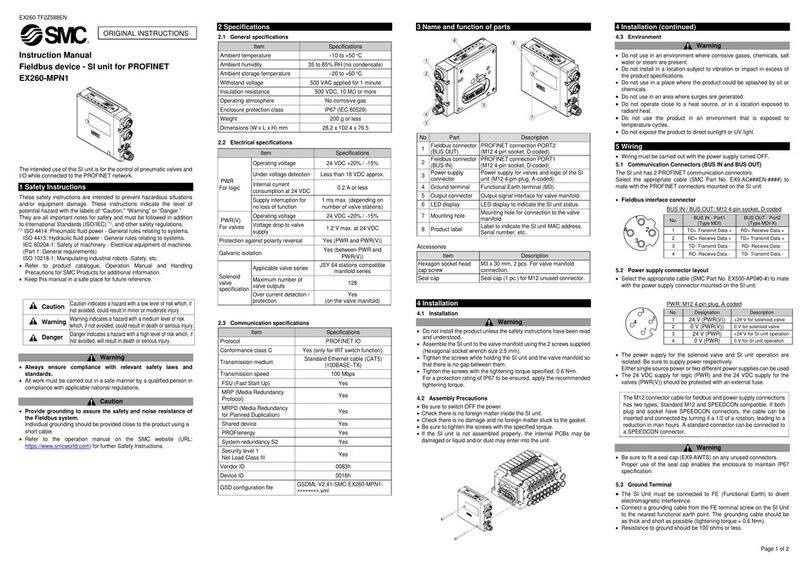

SMC Networks EX260-MPN1 User manual

SMC Networks

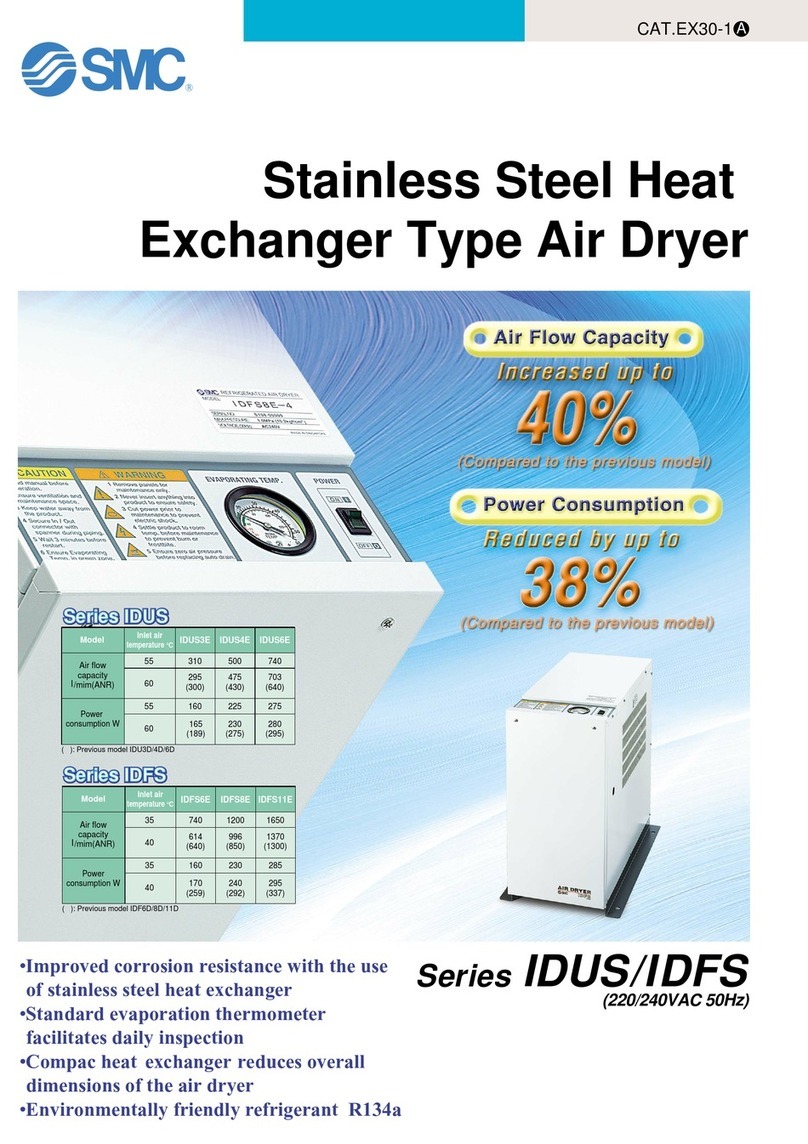

SMC Networks IDUS Series User manual

SMC Networks

SMC Networks MGZ Series User manual

SMC Networks

SMC Networks ZXP7-PFL1-ZP X1 Series User manual

SMC Networks

SMC Networks FHIAF-10-M G Series User manual

SMC Networks

SMC Networks CP96N Series User manual

SMC Networks

SMC Networks ZSE50F User manual

SMC Networks

SMC Networks ZA Series User manual

SMC Networks

SMC Networks CKZ3T-X2734 Series Owner's manual

SMC Networks

SMC Networks MSQ Series Manual

SMC Networks

SMC Networks SFDA Series User manual

SMC Networks

SMC Networks MGQ Series User manual

SMC Networks

SMC Networks IT Series User manual

SMC Networks

SMC Networks AFD20 D Series User manual

SMC Networks

SMC Networks HECR Series Use and care manual

SMC Networks

SMC Networks MHZ2-6 Series User manual