Cont ...

INSTALLATION INSTRUCTIONS

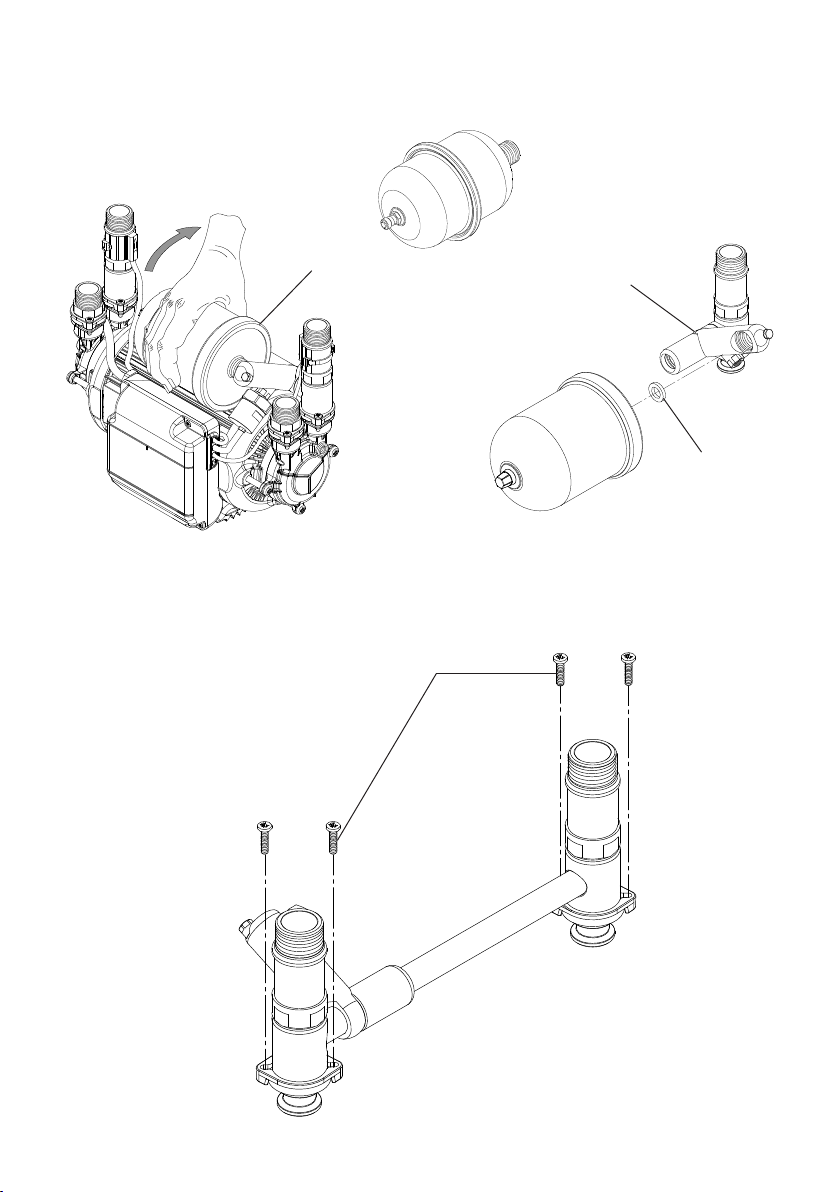

SERVICE KIT FLOW SWITCH MANIFOLD REPLACEMENT KIT.

Part Nos. 31778, 31784

Monsoon Universal Twin Pumps

KIT CONTENTS

ITEM QTY ITEM QTY

1 Flow Switch Manifold Assembly 1 5 ‘O’-Ring (ID 15.0 mm x 3.5 mm sec) 2

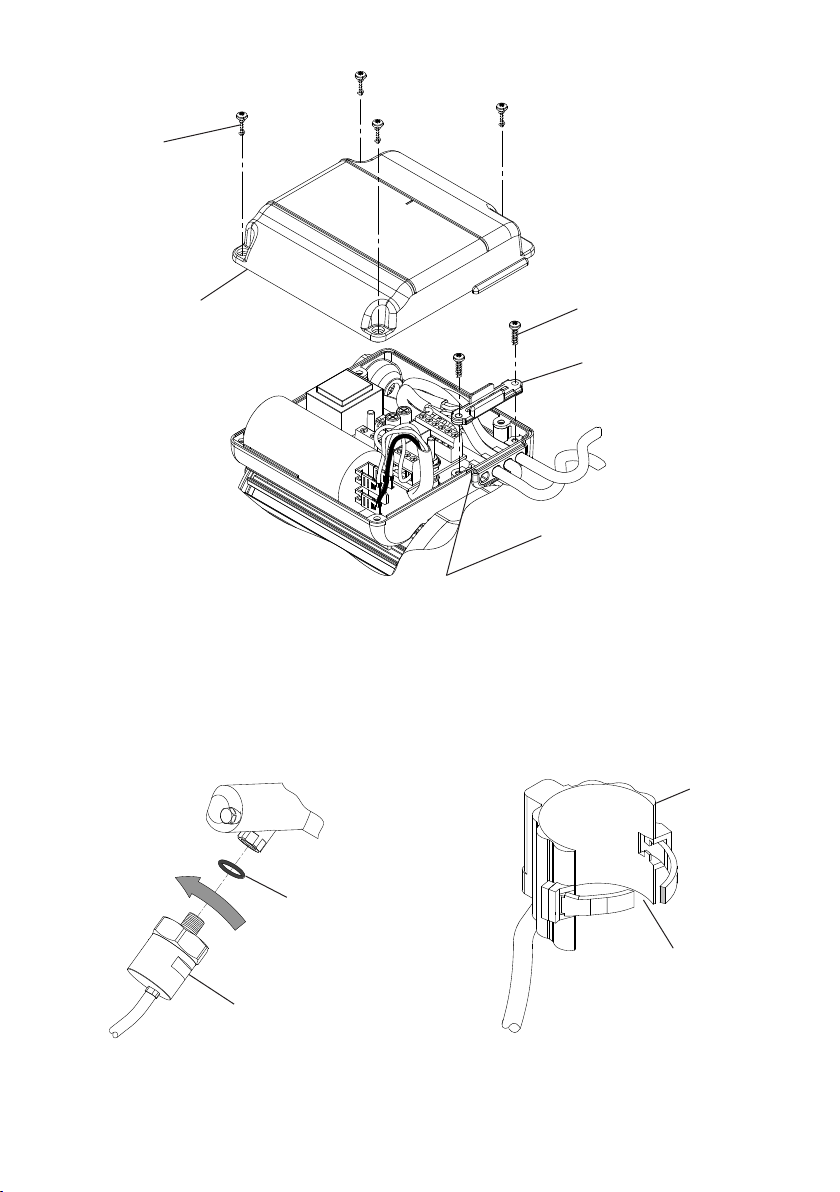

2 ‘O’-Ring (ID 10.1 mm x 1.6 mm sec) 1 6 Screw Self Tapping M4 × 16 4

3 Tie Wrap 1 7 ½ “ BSP Rubber Washer 1

4 ‘O’-Ring (ID 24.6 mm x 2.4 mm sec) 2 8 Screw Self Tapping 3.5 × 12 4

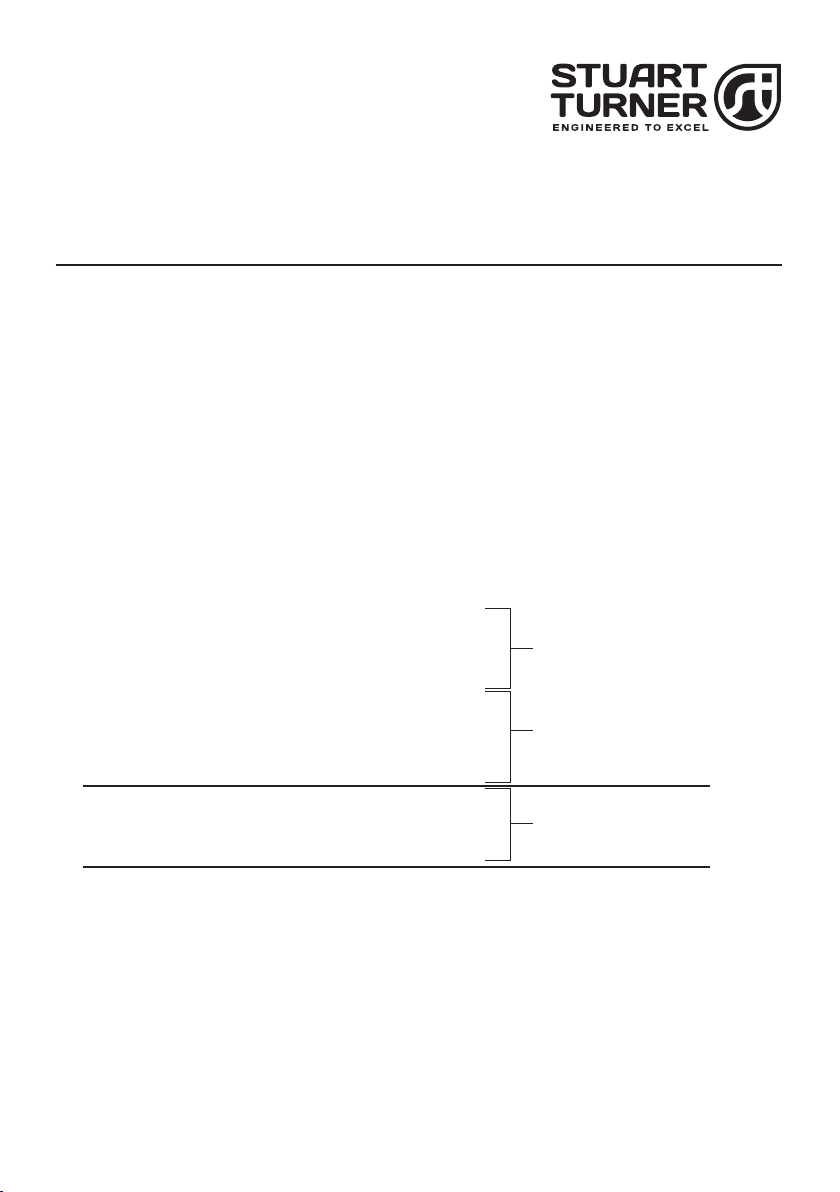

WIRING DIAGRAM

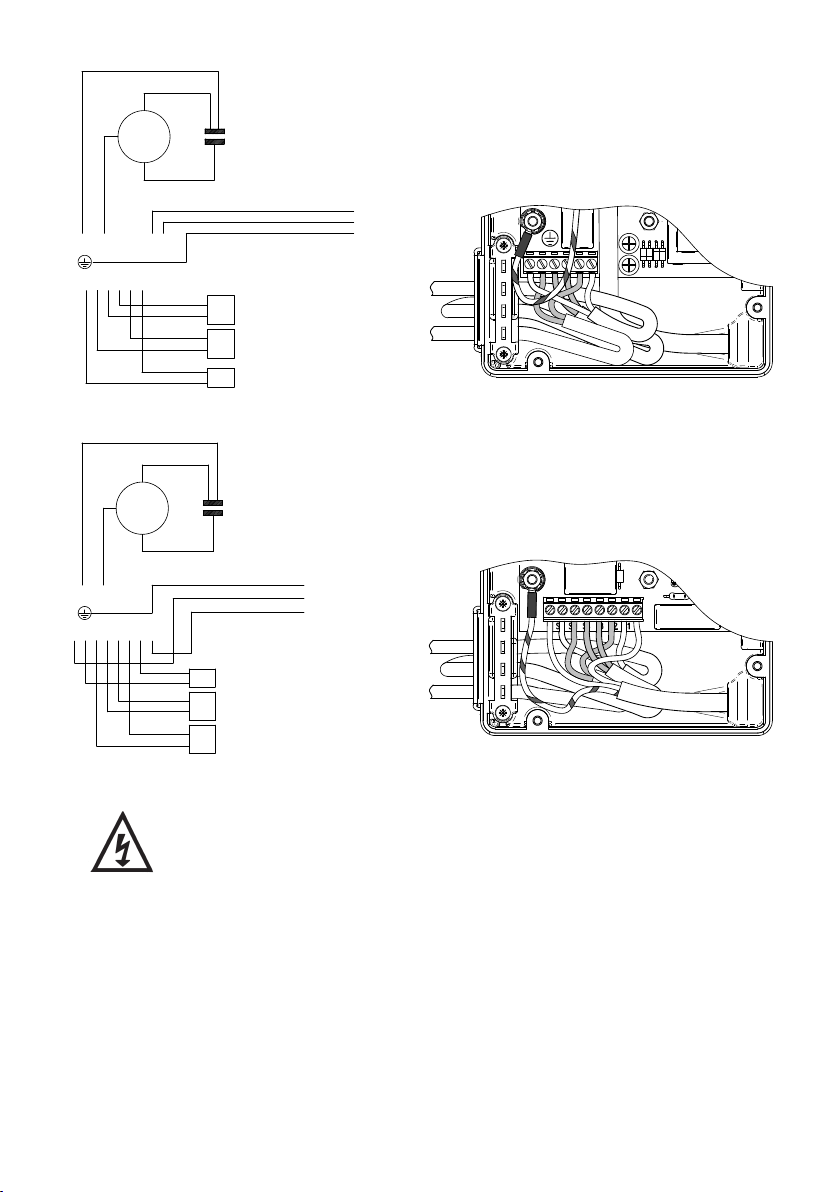

Before the removal of the flow switch manifold assembly can be achieved, the pressure

switch must be disconnected electrically and removed as shown:

Fig. Pump UK Eire

1 Monsoon Universal N2.5 bar Twin ü–

Monsoon Universal N3.5 bar Twin ü–

Monsoon Universal N4.1 bar Twin ü–

Monsoon Universal N1.5 bar Twin – ü

Monsoon Universal N2.5 bar Twin – ü

Monsoon Universal N3.5 bar Twin – ü

Monsoon Universal N4.1 bar Twin – ü

Monsoon U1.5 bar Twin üü

Monsoon U2.0 bar Twin üü

Monsoon U3.0 bar Twin üü

Monsoon U4.0 bar Twin üü

Monsoon U4.5 bar Twin üü

2 Monsoon Universal N1.5 bar Twin – ü

Monsoon Universal N2.5 bar Twin – ü

Monsoon Universal N3.5 bar Twin – ü

Monsoon Universal N4.1 bar Twin – ü

Manufactured from

November 2008

Manufactured from

October 2009

Manufactured up to

October 2008