Stumpfl MAGNUM 210 User manual

08HW

MAGNUM 210

MAGNUM 300

MANUAL FOR ROLL UP SCREENS

2

INDEX

GENERAL INFORMATION............................................................................... 3

SAFETY INSTRUCTIONS .................................................................................. 5

MAGNUM 210 .................................................................................................. 8

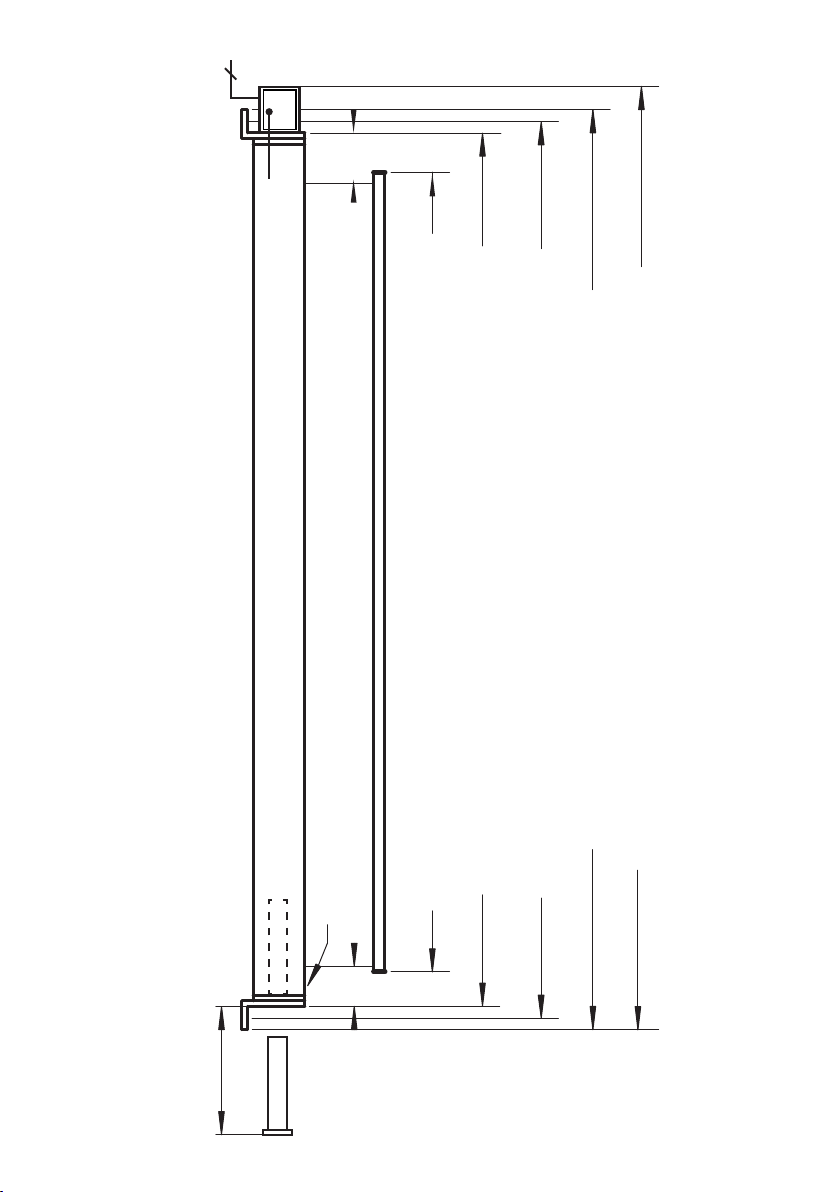

Cross Section MAGNUM 210 Casing

Dimensions of the projection screen

MAGNUM 300 ................................................................................................11

Cross Section MAGNUM 300 Casing

Dimensions of the projection screen

ELECTRICAL INSTALLATION.........................................................................14

EMERGENCY LIMIT SWITCHES....................................................................16

Motor Left/ screen material back...............................................................................16-18

Motor right/ screen material front.............................................................................19-21

OPERATION LIMIT SWITCHES .....................................................................22

Motor Left/ screen material back...............................................................................22-24

Motor right/ screen material front.............................................................................25-27

ACCESSORIES..................................................................................................28

TENSIONING UNIT.........................................................................................30

DECLARATION OF CONFORMITY...............................................................31

3

ROLL-UP PROJECTION SCREEN MAGNUM

Roll-up screens MAGNUM 210 and MAGNUM 300 are permanently installed projection screens

consisting of a roll-up tube that is attached to a drive system (asynchronous tube motor) on one side

and and pivoted on the opposite.

The safety devices according to DIN 56950-1 consists of a mechanical safety brake unit and a

rotary limit switch with two adjustable emergency stop positions. Both safety devices are

connected to the winding shaft. The lateral bearing positions are connected to a two-part screen

casing made of aluminum sheet (protective casing). The projection material is rolled up on the winding

The winding tube maintains the height and the projection material is unrolled downwards.

The drive (tubular motor) can be exchanged without dismantling the projection screen if necessary.

MAGNUM projection screens can be mounted to the ceiling or to the wall via a separate bearer

construction on site.

Detail information on the roll-up screen and the serial number VAT can be found on the type plate on

the back of the screen material in the bottom left corner and at the top of the protective casing.

The screen material corresponds to a building material class in accordance with DIN 4102-1, NFPA 701

or EN 13501-1and is in line with the limit values for waviness according to ÖNORM A 2115.

corresponding product data sheet. www.AVstump.com/projectionmaterials

GENERAL INFORMATION

4

QUALITY AND SAFETY

The roll-up projection screen is in line with the applicable European guidelines and standards

(incomplete excerpt):

Directive 2006/42/EC on Machinery

Low Voltage Directive 2014/35/EU

Electromagnetic Compatibility Directive 2014/30/EU

DIN 19045-2 Projection of still pictures and motion pictures - Part 2: Screens

DIN 56950-1 Entertainment Technology - Machinery Installations - Part 1: Safety requirements and

inspection

DIN 56950-4 Entertainment Technology - Machinery Installations - Part 4: Safety requirements for

serially manufactured projection screens

DECLARATION OF CONFORMITY

According to the EU-Machinery Directive (2006/42/EG) the roll up screen MAGNUM is a machine.

WARRANTY

The roll up screen MAGNUM may only be used as a projection screen.

No persons are allowed to stay in the operation area. For all damages to persons and property

which occur from inappropriate use the warranty will be invalid and the manufacturer cannot be

held responsible. The intended use also includes the observance of all instructions and information

contained in this operating manual.

regulations with media control panel operation on page 14.

The general terms and conditions are available at www.AVstump.com/generalterms

UNAUTHORIZED MODIFICATIONS

warranty claims.

CHANGING THE IMAGE HEIGHT - WARRANTY OF FLATNESS

and for maintenance work.

5

SAFETY INSTRUCTIONS

cases of transport damage is provided on the info sheet IMPORTANT INFORMATION.

Before assembly make sure that the wall or the ceiling is able to carry the load. Choose the screws/

attachment material in accordance with the weight of the projection screen and the condition of wall

or ceiling. The permissible loads on walls, fastenings, connecting and transmission elements must not

exceed the maximum holding force and catch torque.

radiators, ventilation and air condition systems. To ensure safe and trouble-free operation make sure

The roll-up screen must be secured during transport and assembly

in accordance with the total weight. During lifting work, no person

must remain in the danger zone below the suspended load

The total weight is displayed on the roll-up screen type plate or on the packaging. For mounting use

hoisting equipment which is approved for the weight of the roll up screen. Make sure the roll-up

screen is transported and mounted horizontally and torsion-free to prevent the safety brake from

engaging. Do not put additional mechanical load on the lightweight aluminium casing.

MECHANICAL MOUNTING

TRANSPORT – MOUNTING

The electrical installation is to be performed by a trained electrician

from a licensed expert company only. Please hand over this manual

and the connection directions that are supplied separately with every

motor or switch or control unit to the executing expert.

The electrical installation must only be carried out in a voltage-free and secured against

Prior to the installation check the isolation of the connecting cable and the cable feedthrough at the

casing for damage. Check that there is no ohmic continuity between the connecting cable and the roll-

up screen casing so that any danger by indirect contact is excluded. Control units must not be installed

in the operating area of the roll-up screen.

ELECTRICAL INSTALLATION

6

FIRST-TIME OPERATION

are signs of danger or danger situations roll-up screen operation must be stopped immediately.

During the test run the operator must always have full and direct sight of the roll-up screen.

in the roll-up screen casing during transport or assembly and that the screen material can unwind

OPERATION

The operator must undergo a training regarding the technical construction and operating principle to

ensure safe operation. The operator must have basic knowledge of the industry safety standards.

Take appropriate measures to ensure that the roll up screen cannot be operated by untrained

persons or activated unintentionally.

The projection screen must only be operated in a well lit environment so as to recognize any danger

situations that might occur. During operation the operator must always have full and direct sight of the

roll-up screen so as to be able to stop it immediately when a danger situation occurs.

Supervision by adults is required when putting the roll-up screen into operation.

During operation the movement range and the immediate area of the roll-up screen must be

Before winding up the screen check the bottom bar and the screen material for damage and remove

any possible obstacles within the movement range. No additional loads must be attached to / or lifted

by the bottom bar.

In the case of recognizable damage to the roll-up screen it must immediately be taken out of service. It

can only be put back into service after being repaired and checked/cleared for use by an expert.

MAINTENANCE TIPS - CLEANING

During work at the roll-up screen make sure that it cannot be started accidentally.

Protect the screen material from soiling. If necessary clean it with a slightly damp and soft cloth.

Do not use any aggressive cleaning agents, such as acetone, terpentine, cellulose thinners or ethyl

alcohol or similar substances.

7

MAINTENANCE

Drives, bearings and other rotating parts of the roll-up screen are permanently lubricated and are

maintenance-free. The roll-up screen must be protected from soiling.

Maintenance and repair work must only be carried out be authorized experts.

SAFETY INSPECTION

MAGNUM roll-up screens must undergo annual safety inspection.

In case of visible damage or unusual noises during the operation the roll-up screen must

immediately be taken out of service. It must only be returned to service upon successful repair

and inspection/clearance for use by an expert.

national legal regulations (installing person/company, TÜV, consulting engineer).

The inspection must be performed in accordance with DGUV 17 (BGV C1) and the regulations

according to DIN 56950-1 Appendix A and the applicable national regulations.

We recommend performing the following measures:

•

• Perform a test run

• Visual inspection of winding behavior

• Check for operating noises at the bearing locations

• Check operating limit switches (stop point of upper and lower limit switches)

• Check function of the emergency limit switch (by mechanical triggering or triggering by previous

adjustment of the operating limit switches)

• Visual inspection of the connection between bottom bar and screen material

• Check electrical control unit and safety installations

• Check “dead man’s control” for screens with more than 5 m width or height

DISASSEMBLY

For disassembly the same safety instructions apply as listed for TRANSPORT - MOUNTING on page 5.

DISPOSAL

At the end of its lifetime this product must not be disposed of with normal household waste but needs

to be taken to a collection site for recycling.

Disassembly of a MAGNUM roll-up screen takes a few steps only and by separate disposal of the waste

you can make an important contribution towards environmental protection.

In separated form the materials can be recycled.

Casing components and bottom bar are made of aluminum and the lateral bracktes are made of steel.

For the projection screen material refer to the type plate.

The motor drive is to be disposed of at a collection center for electric devices.

Contact your local disposal company for the address of a collection center.

8

26,5154

34

207

207

29

40

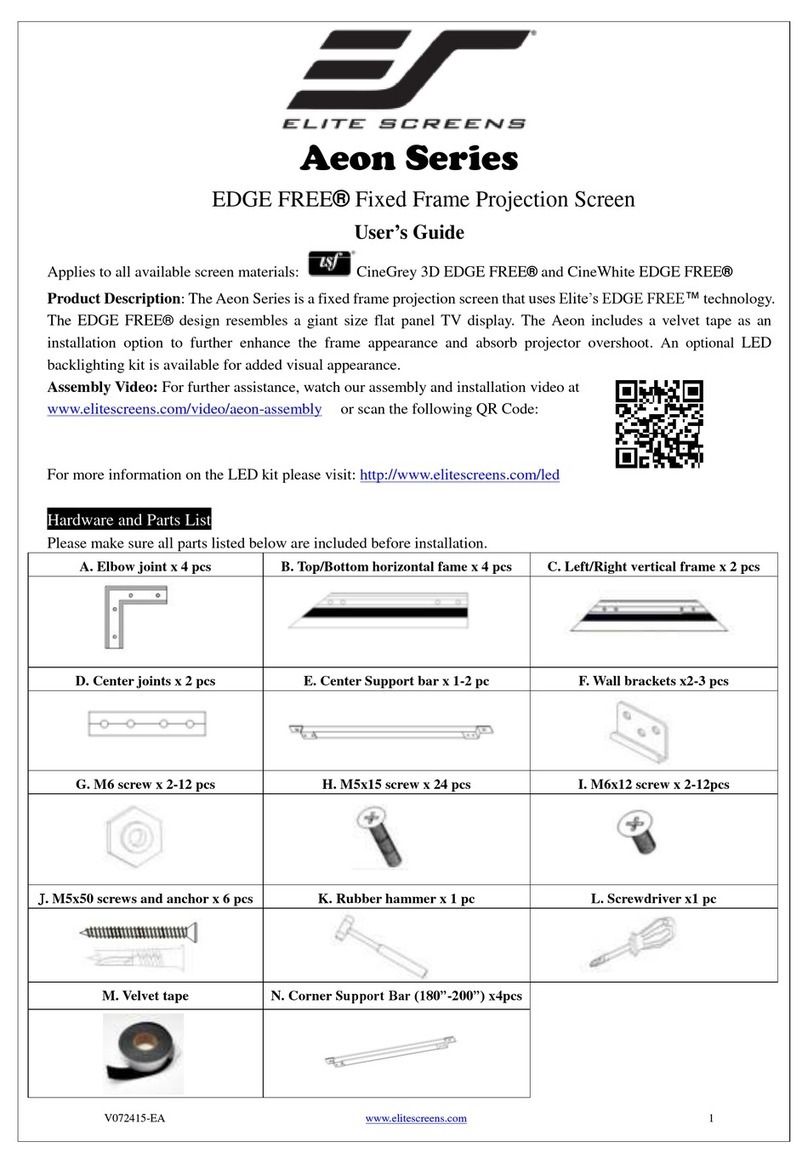

CROSS SECTION MAGNUM 210 CASING

UNIVERSAL MOUNTING BRACKET

FOR CEILING MOUNTING

9

MAGNUM 210

Dimensions of the projection screen

* For servicing and adjusment of the rotary limit switch and safety catch the casing must be accessible

at least from the front and the bottom.

8x 0,75²

~61mm ~61mm

Fabric

length of bottom bar = fabric width +26mm

MAGNUM 210 casing

casing length = fabric width +123mm

hole center distance = fabric width +159mm

overall length mounting brackets = fabric width +195

overall length: +/- 5mm

overall length = fabric width +360

connecting cable : length 5m, gray

Casing for rotary limit

switch with safety catch*

Service area for motor

exchange min. 800mm

Stop position adjustment

10

170

197,5

MAGNUM 210

fabric front

Dimensions of the projection screen

* For servicing and adjusment of the rotary limit switch and safety catch the casing must be accessible

at least from the front and the bottom.

8x 0,75²

~61mm ~61mm

Fabric

length of bottom bar = fabric width +26mm

MAGNUM 210 casing

casing length = fabric width +123mm

hole center distance = fabric width +159mm

overall length mounting brackets = fabric width +195

overall length: +/- 5mm

overall length = fabric width +360

Casing for rotary limit

switch with safety catch*

Stop position adjustment

connecting cable : length 5m, gray

Service area for motor

exchange min. 800mm

11

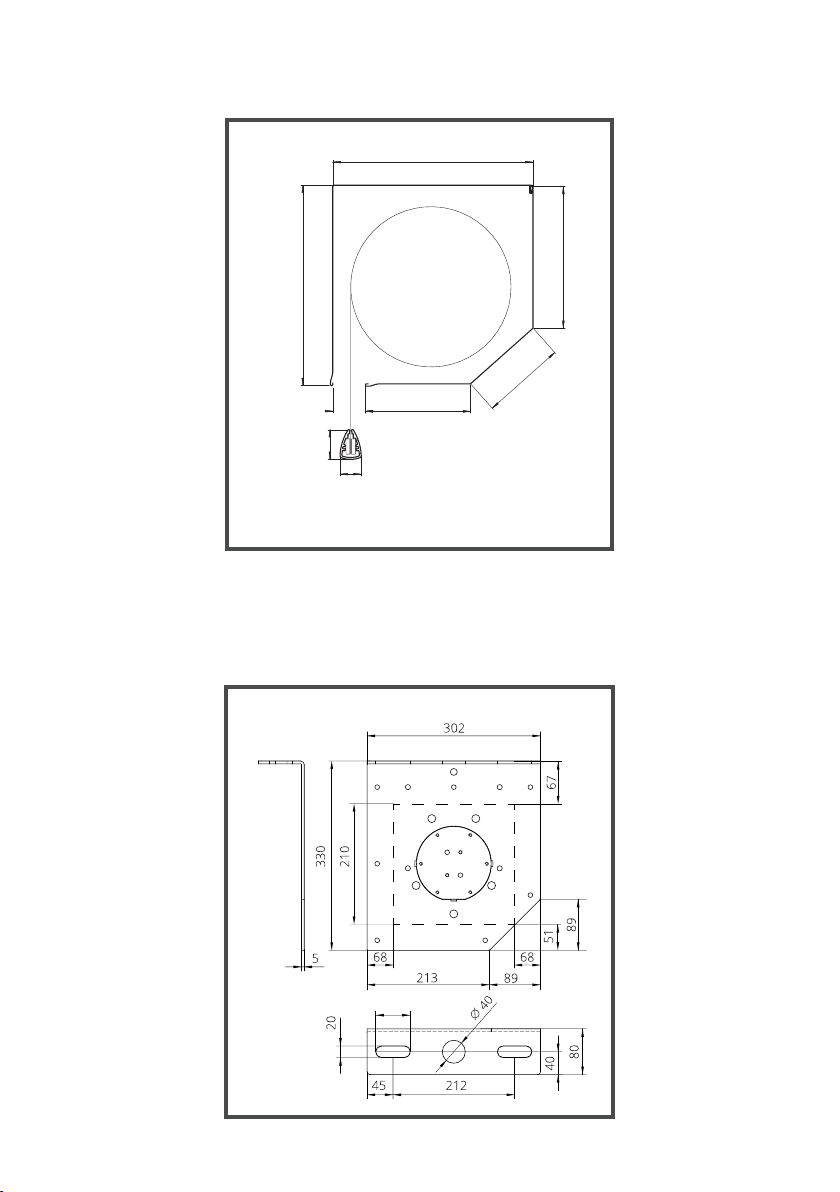

300

214

300

125

157

49

40

29

60

CROSS SECTION MAGNUM 300 CASING

MOUNTING BRACKET MAGNUM 300

FOR CEILING MOUNTING

12

8x 0,75²

215

210

MAGNUM 300

Dimensions of the projection screen

* For servicing and adjusment of the rotary limit switch and safety catch the casing must be accessible at least from the front and the

bottom.

~75mm ~72mm

Fabric

length of bottom bar = fabric width +26mm

MAGNUM 300 casing

casing length = fabric width +146mm

hole center distance = fabric width +216mm

overall length = fabric width +440mm

overall length: +/- 5mm

overall length mounting brackets = fabric width +296mm

connecting cable : length 5m, black

Casing for rotary limit

switch with safety catch*

Service area for motor

exchange min. 800mm

Stop position adjustment

13

* For servicing and adjusment of the rotary limit switch and safety catch the casing

must be accessible at least from the front and the bottom.

8x 0,75²

~72mm ~75mm

Fabric

length of bottom bar = fabric width +26mm

MAGNUM 300 casing

casing length = fabric width +146mm

hole center distance = fabric width +216mm

overall length = fabric width +440mm

overall length: +/- 5mm

overall length mounting brackets = fabric width +296mm

Casing for rotary limit

switch with safety catch*

Stop position adjustment

connecting cable : length 5m, gray

MAGNUM 300

fabric front

Dimensions of the projection screen

14

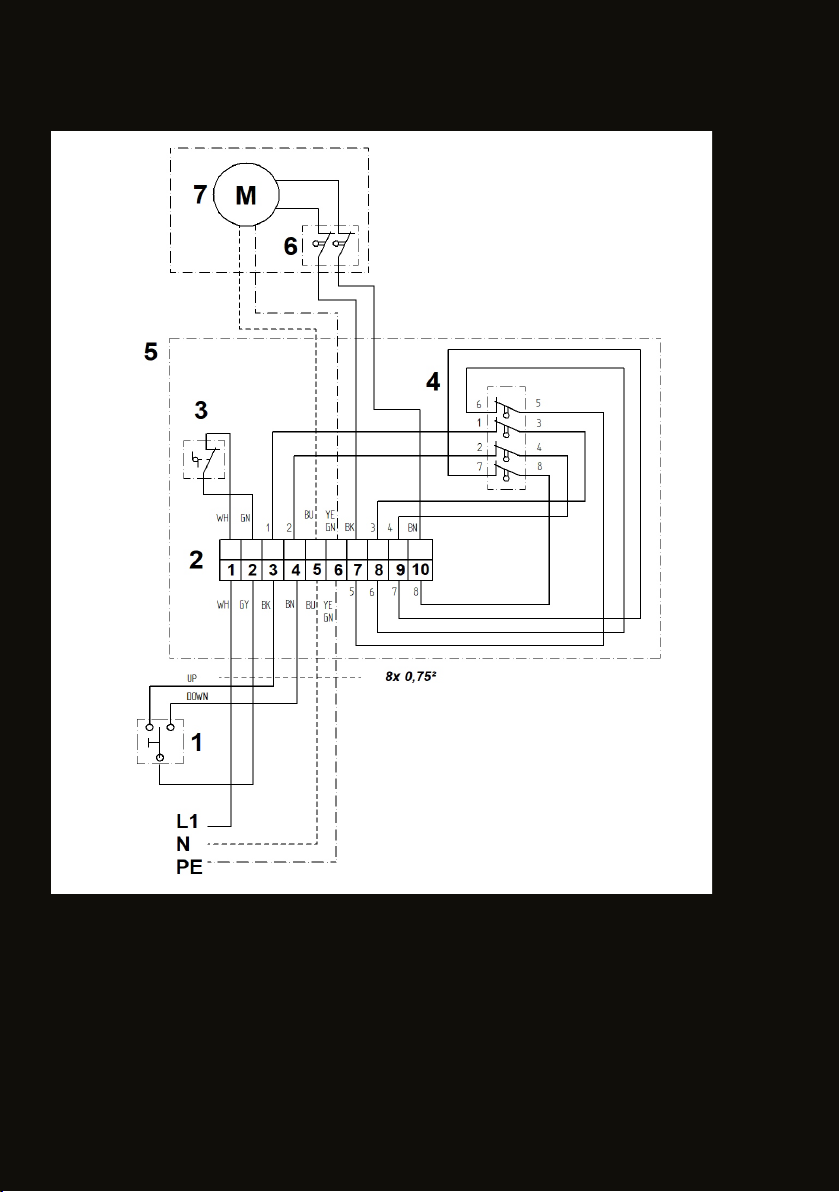

ELECTRICAL INSTALLATION

Work at mains voltage (230 V) must only be performed by a licensed

electrical company. Please hand over this manual and the connection

directions that are supplied separately with every motor or switch

or control unit to the executing expert.To get further important

instructions refer to chapter SAFETY INSTRUCTIONS on page 4:

INDIVIDUAL CONTROL - 230 V

(See circuit diagram)

Incorrect control of the tube motor results in electrical overload on the limit switches and may change

the set stop positions. In extreme cases permanently welded contacts of the the limit switches can

occur. This causes the motor to be permanently activated and the projection screen to be damaged.

IN ORDER TO AVOID AN ELECTRICAL OVERLOAD OF THE LIMIT SWITCHES IN THE TUBE MOTOR,

THE WIRING AND THE CONTROL COMMANDS ‚ MUST COMPLY WITH THE FOLLOWING

REGULATIONS:

1. Do not run two or more motors in parallel from one output.

A separate contact must be available for every drive and running direction.

2. switches and controls must not allow simultaneous UP-and DOWM commands.

Simultaneous up and down commands cause a short-circuit of the operating capacitor.

For that reason only electrically or mechanically locked single switches (no light switches) must

be used.

3. The CHANGEOVER-DELAY BETWEEN UP AND DOWN COMMAND MUST BE 500ms at least.

Switching periods under 0,5s results in extremely high currents, which may result in the limit switches

being welded together and therefore the projection screen being damaged.

OPERATION VIA A MEDIA CONTROL SYSTEM (DRY CONTACT)

Any damage to the motor and consequential damage caused by non-integration of a motor control

unit are excluded from the warranty.

Motor control unit-> See chapter “Accessories”

ELECTRIC SUPPLY

230VAC 50Hz. Line circuit breaker 10 A. Motor cable 4x0,75mm²

Tubular motors are not suitable for continuous operation and have a duty cycle of 3-4 minutes. If the

roll-up screen is operated for a longer period of time, a thermal protection relay switches the motor

15

ELS - UP (6-5)

OLS - UP (1-3)

OLS - DOWN (2-4)

ELS - DOWN (7-8)

3- SAFETY CONTACT - SAFETY BRAKE

WIRING SCHEME

GEAR LIMIT SWITCH WITH 4 CONTACTS

16

1 2

3

EMERGENCY LIMIT SWITCH

MOTOR LEFT/ SCREEN MATERIAL BACK

The movement range of a MAGNUM 210 and 300 roll-up screen is additionally limited by a gear-type

limit switch with emergency limit switches for both stop positions.

The emergency limit switches and operating limit switches are factory-set according to the ordered

image size.

If the installation situation requires a reduction of the movement range, the emergency limit switches

must be adjusted before setting the operating limit switches.

see chapter Adjustment of stop positions (page 22-24)

Do a test run.

1-2 Start by removing the front and lower casing

cover (2,5mm hexagonal Allen key).

2-3In order to get access to the cam unit, (red)

remove the cover (yellow) of the gear limit

switch. (Phillips or slot screwdriver).

LOSS OF WARRANTY

The projection screen is factory set according the dimensions orderedand the gear limit switch is

sealed.

Damage and consequential damage due to incorrect limit switch adjustment are not covered by

warranty.

17

4

ADJUSTING THE UPPER EMERGENCY LIMIT SWITCH

In order to ensure safe operation of the roll-up screen the stop point of the upper emergency limit

screen is pulled into the screen casing and consequently falls down.

The bottom bar falling down may cause serious injuries to persons within the danger area below the

projection screen.

4 The stop point for the upper emergency limit switch is set by means of the set screw at the top

switching cam (red).

Turning the screw clockwise moves the stop point UP.

CAUTION: There is a danger that the bottom bar of the projection screen is pulled into the

screen casing and consequently falls down.

Turning the screw counter-clockwise moves the stop point DOWN.

Proceed by doing a test run.

Then set the upper operating limit switch. (See chapter operating limit switch on page 23)

EMERGENCY LIMIT SWITCH

MOTOR LEFT/ SCREEN MATERIAL BACK

18

5

EMERGENCY LIMIT SWITCH

MOTOR LEFT/ SCREEN MATERIAL BACK

Turning the screw clockwise moves the stop point UP.

Turning the screw counter-clockwise moves the stop point DOWN.

The screen material falling down may cause severe injuries to persons within the danger area below

the projection screen.

ADJUSTING THE LOWER EMERGENCY LIMIT SWITCH

5The stop point for the lower emergency limit switch is set by means of the set screw at the lower

switching cam (red).

Proceed by doing a test run.

Then set the lower operating limit switch. (See chapter operating limit switch on page 24)

19

1 2

3

MOTOR RIGHT/ SCREEN MATERIAL FRONT

EMERGENCY LIMIT SWITCH

The movement range of a MAGNUM 210 and 300 roll-up screen is additionally limited by a gear-type

limit switch with emergency limit switches for both stop positions.

The emergency limit switches and operating limit switches are factory-set according to the ordered

image size.

If the installation situation requires a reduction of the movement range, the emergency limit switches

must be adjusted before setting the operating limit switch.

see chapter operating limit switches (page 25-27)

Do a test run.

1-2 Start by removing the front and lower casing

cover (2,5mm hexagonal Allen key).

2-3In order to get access to the cam unit,

(green) remove the cover (yellow) of the gear

limit switch. (Phillips or slot screwdriver).

LOSS OF WARRANTY

The projection screen is factory set according the dimensions orderedand the gear limit switch is

sealed.

Damage and consequential damage due to incorrect limit switch adjustment are not covered by

warranty.

20

4

MOTOR RIGHT/ SCREEN MATERIAL FRONT

4The stop point for the upper emergency limit switch is set by means of the set screw at the top

switching cam (red).

Turning the screw clockwise moves the stop point DOWN.

Turning the screw counter-clockwise moves the stop point UP.

(CAUTION: There is a danger that the bottom bar of the projection screen is pulled into the

screen casing and consequently falls down.)

Proceed by doing a test run.

Then set the lower operating limit switch. (See chapter operating limit switch on page 24)

EMERGENCY LIMIT SWITCH

ADJUSTING THE UPPER EMERGENCY LIMIT SWITCH

In order to ensure safe operation of the roll-up screen the stop point of the upper emergency limit

screen is pulled into the screen casing and consequently falls down.

The bottom bar falling down may cause serious injuries to persons within the danger area below the

projection screen.

This manual suits for next models

1

Table of contents

Other Stumpfl Projection Screen manuals

Popular Projection Screen manuals by other brands

Rehau

Rehau Relazzo R24600 Screen technical information

SCREENLINE

SCREENLINE COPERNICO BIFORMAT instructions

DecisionVision

DecisionVision DV-15 Operator's manual

AVstumpfl

AVstumpfl MONOBLOX 32 instructions

Screen Int

Screen Int FLAT ELASTIC VELVET CURVED installation manual

Stewart Filmscreen

Stewart Filmscreen RP-1013 owner's manual

Avtek

Avtek FOLD user manual

Elite Screens

Elite Screens EDGE FREE Aeon Series user guide

Elite Prime Vision

Elite Prime Vision EPVMAX series user guide

Draper

Draper Signature E Series Installation & operating instructions

Topcon

Topcon CC-100 Series Quick manual

Elite Screens

Elite Screens MicroFlip Screen user guide