Sturtevant Richmont Programmable Torque Verifier FM II User manual

Sturtevant Richmont

Global Reach. Local Support.

Programmable Torque Verifier FM - Generation II

Owner's Manual

Sturtevant Richmont Div. Ryeson Corporation

3203 N. Wolf Road Franklin Park, IL 60131

Phones: 847/455-8677 800/877-1347

Fax: 847/455-0347

URL: www.srtorque.com

E-mail: [email protected]

P/N: 857234A

Rev.: A

Date:May 30, 2003

Thank you for choosing S/R for your assembly solution!

The Programmable Torque Verifier FM - Generation II is simple to operate once you

have become familiar with it. We encourage you to read this manual carefully and use it

when setting up and operating your new unit.

Should you need any additional support, please contact us via e-mail, phone, or fax, or

visit our website: www.srtorque.com.

We encourage you to use our website; the technical support it offers is expanded every

week or two, and is always available. If you have suggestions or recommendations for

additional improvements to it, we would be very happy to hear them!

Thanks Again!

Page 1

Table of Contents

Chapter Page

Chapter 1 - Introduction to the PTVFM Generation II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 2 - Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Chapter 3 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Chapter 4 - Programming the Generation II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Chapter 5 - Operating the PTV-FM Generation II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Chapter 6 - FM Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Chapter 7 - PLC Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Chapter 8 - Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Additional Information

Additional information and updated information on S/R products is made available through our

website. We urge all of our customers to check the Technical Information and FAQ sections of

our site frequently. The 24 hours a day, 7 days a week, instant availability of our site makes it

ideal for those with a question on just about any S/R product.

Our URL is: www.srtorque.com.

Page 2

Page 3

Chapter 1 - Introduction to the PTVFM Generation II

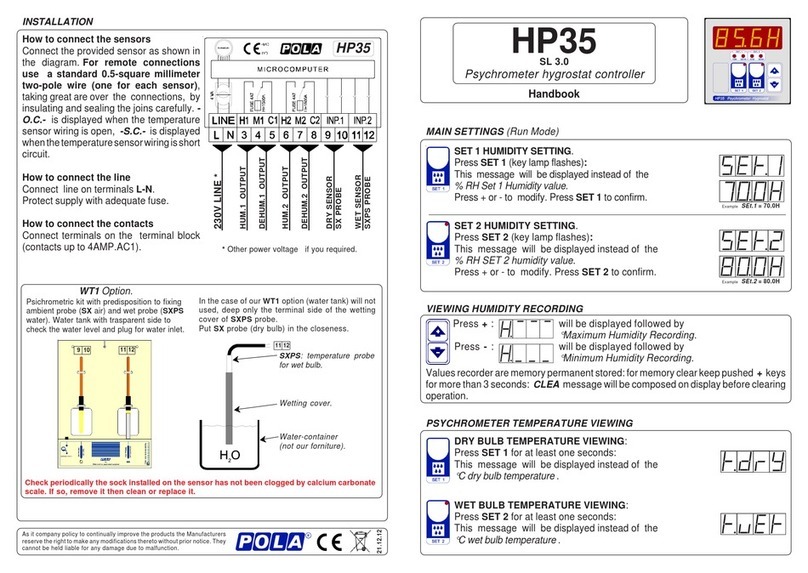

Photograph 1

Key to Photographs 1 through 4

1. Antenna Mount 2. Case 3. Front Panel Screws (4)

4. Faceplate 5. Key Lock 6. Beeper

7. Run LED 8. Setup LED 9. P-Set LED

10. LED Panel 11. Accept LED 12. Reject LED

13. Suspend LED 14. Down Keyswitch 15. Up Keyswitch

16. Set LED 17. Mode LED 18. Suspend LED

19. Power Cord 20. Antenna 21. Parameter Switch

22. Serial Port 23. PLC Connector 24. On/Off Switch

25. Power Entry Module 26. Power Setting Notice

Page 4

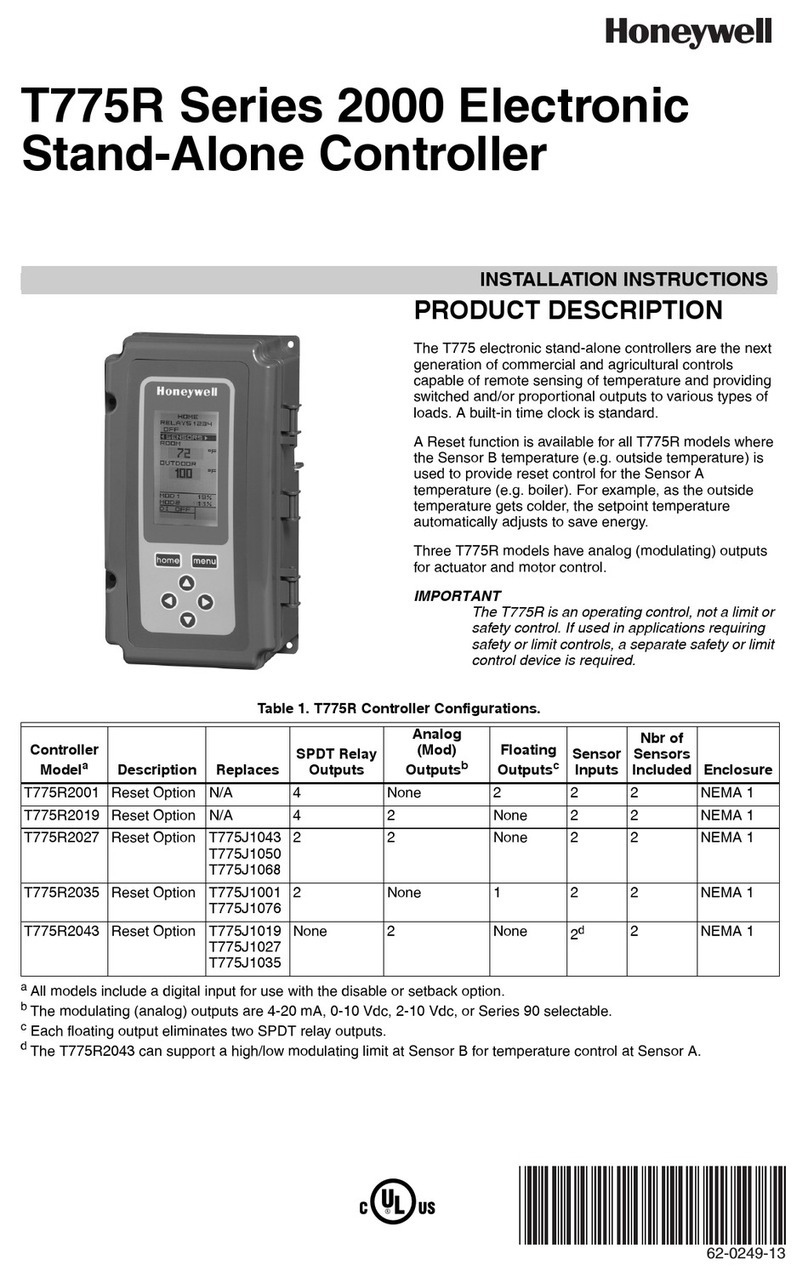

Photograph 2

Photograph 3

Page 5

1. Antenna Mount

The antenna mount is where the antenna (20) is attached to the unit. The antenna receives the

FM radio signal from the FM Switch Wrenches.

2. Case

The case houses all of the electronics components. It is made of steel and has a black crinkle

finish.

3. Front Panel Screws (4)

The four (4) front panel screws attach the front panel of the case to the sides and rear. Unlike

the 1st generation of the PTV-FM, they are only removed for repair purposes. “Teaching” the

PTV-FM a new wrench is performed without front panel removal.

4. Faceplate

The faceplate houses all programming keyswitches and all LED’s used for programming and

communications.

5. Key Lock

The key lock provides or denies access to programming functions via the keyswitches.

Programming can only be performed when access is permitted.

6. Beeper

The beeper provides audible signals pertinent to fastener tightening process acceptability and

batch completion during operation of the unit.

7. Run LED

This LED is lit when the unit is in operating mode.

8. Setup LED

This LED is lit when the unit is in the setup or programming mode.

9. P-Set LED

The P-Set LED is lit when the unit is

10. LED Panel

The LED panel displays the information needed during both setup/programming of the unit and

operation of it.

11. Accept LED

The green accept LED lights when the signal from the FM Switch Wrench meets the specification

for the fastener as programmed into the PTV-FM. It indicates the torque wrench has been prop-

erly used to tighten the fastener.

Page 6

12. Reject LED

The red reject LED lights when the FM Switch Wrench has been pulled for more than the maxi-

mum specified period of time for the programmed requirements for the fastener. This almost

always means the fastener has been overtorqued. When this LED is lit, the fastener must be

loosened, then properly torqued.

13. Suspend

This LED lights when the unit has suspended counting signals received from the FM Switch

Wrench(es). The primary use for this function is during the wrench torque setting operation.

14. Down Keyswitch

The down keyswitch is used to page through menu selections or lower numeric values during

programming of the PTV-FM.

15. Up Keyswitch

The up keyswitch is used to page through menu selections or increase numeric values during

programming of the PTV-FM.

16. Set Keyswitch

The set keyswitch is used in conjunction with other keyswitches during programming to lock in,

or “set”, certain values during programming of the unit.

17. Mode Keyswitch

The mode keyswitch is used in conjunction with other keyswitches to display element settings

during operation.

18. Suspend Keyswitch

The suspend keyswitch suspends counting signals received from the FM Switch Wrench(es).

This function is most commonly used during the torque setting operation on the tools.

19. Power Cord

The power cord depicted is the one used for 120 VAC operations. Both the 120VAC and 240

VAC cords have one end that plugs into the Power Entry Module (PEM), and one end that con-

nects into the power supply. For PTV-FM units used with 240 VAC power, the correct power

cord must be ordered with the unit.

20. Antenna

The antenna receives the signals from the FM Switch Wrench(es). It is mounted atop the PTV-

FM on the antenna mount.

Page 7

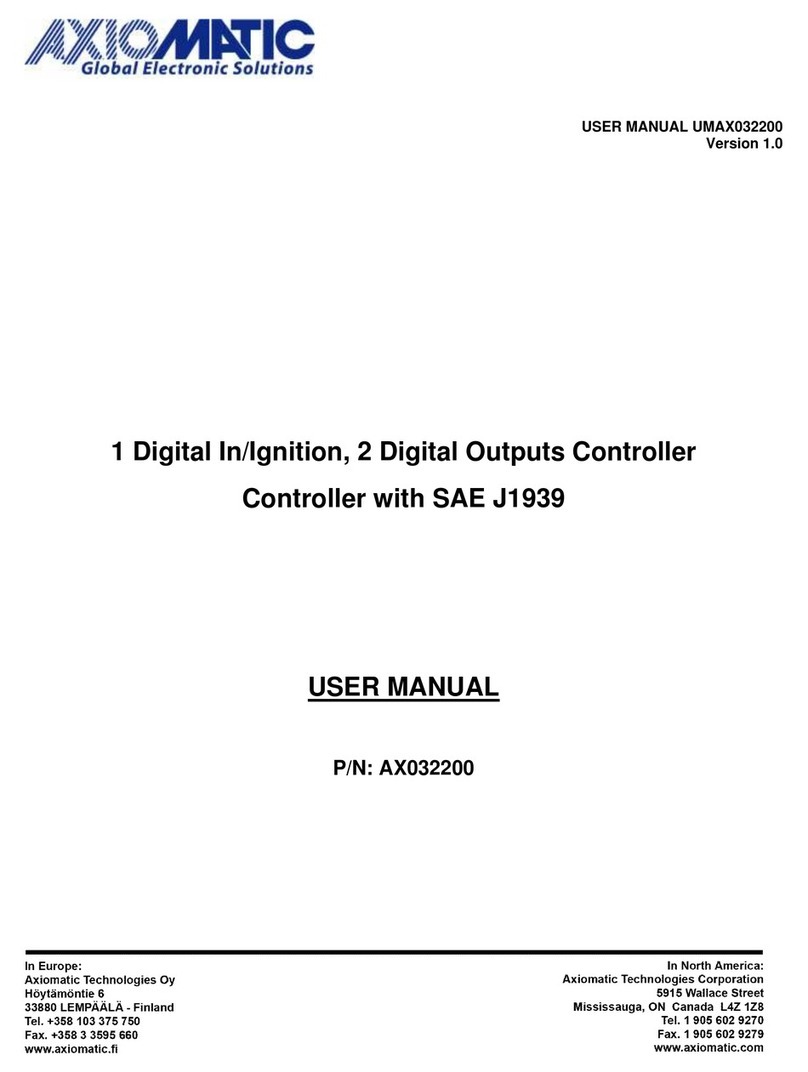

21. Parameter Select Switch

The parameter select switch allows the user to select which set of parameters the PTV-FM is to

use. A set of parameters includes: FM Switch Wrench (one only per parameter), FM channel (1

channel only per parameter) minimum pull time, maximum pull time, TBC (Time Between Clicks),

TBB (Time Between Batches), and the number of fasteners in each batch. This is a significant

addition to the Generation II PTV-FM, and is discussed more fully in the next chapter of this

manual.

22. Serial Port

The serial port connector is used by the factory to download the original firmware. The port is for

factory use only.

23. PLC Connector

The PTV-FM uses a 19-pin PLC connector for communicating with PLC’s controlling operations

related to the output of the fastening operation on which the PTV-FM is used. For more on this

topic, see Chapter 6.

24. On/Off Switch

This rocker-type power switch controls power to the PTV-FM.

25. Power Entry Module (PEM)

The PEM is new to the Generation II PTV-FM. It serves as the connection point for the power

cord, provides the ability to select 120 VAC or 240 VAC operation, and holds the fuse that pro-

tects the circuitry and the operator. For more on this topic, see Chapter 3.

26. Power Setting Notice

The power setting notice is a tape strip affixed to the PEM. It tells the user whether the unit was

shipped with the PEM set for 120 VAC or 240 VAC operation. Do NOT remove this strip until

you have read Chapter 3 and understand the functions of the PEM thoroughly.

Warning

Do NOT remove the Power Setting Notice strip until you have read Chapter 3 and

understand the functions of the PEM thoroughly.

There expanded capabilities of the Generation II models of the PTV-FM make it significantly dif-

ferent in installation, programming, and operation from the first generation. Owners of first gen-

eration units need to read this manual carefully, since the expanded capabilities resulted in new

and different procedures in these areas.

Page 8

How to Distinguish First Generation PTV-FM Units from Generation II PTV-FM Units

First Generation Generation II

Attached Power Cord Separate Power Cord

No Power Entry Module Power Entry Module on right side of unit.

No Parameter Select Switch Parameter Select Switch on left side of unit.

Delivered through 4/15/03. Delivery began 3/1/03.

Page 9

Chapter 2 - Principles of Operation

Overview

The PTV/Switch Wrench System is designed to assist the manufacturer in closing several loops

in the quality system which have been, until now, gaps in their quality improvement efforts. The

key capabilities this system enables:

1. Ability to integrate hand torque tools into the automated line control system.

2. Process control of the actual torque wrench use process, not just the wrench calibration

process.

3. Rapid and effective training in proper torque wrench use, with reinforcement of proper use

provided with every wrench click.

This chapter will cover the system, starting with the concepts involved in the use of the

Generation II PTV-FM and FM Switch Wrench system, than move to line integration.

Concept Principles

Any and every clicker-type torque wrench can be operated in essentially three ways:

It can be clicked too quickly, or “jerked”.

This can result in either undertorquing because the torque was not transmitted to the fas-

tener, or overtorquing if it was jerked and too much rotation was applied, even though the

time period was very brief.

It can be used properly, with force applied smoothly until the wrench clicked, then the force

immediately released.

When a preset wrench is used, this results in accurate transmission of the preset torque to

the fastener.

It can be pulled past the click.

This results in overtorquing the fastener by rotating it past the point where the correct

torque was attained.

The fact that there are two operator-induced process failure modes in clicker-type torque wrench

use has always been a weak point in their selection as assembly tools. A probability of occur-

rence for each failure mode exists even when the tool is used by a trained, experienced and

Page 10

quality-conscious assembler. The probability of occurrence rises with any lack of attention, train-

ing, or experience - individually and in combination.

On assemblies with multiple fasteners, the previously-listed failure modes that exist for each fas-

tener are joined by a fourth failure mode:

Failure to torque all fasteners.

This may occur due to an interruption in the process which causes the assembler to

resume torque application starting with the wrong fastener after the interruption.

This increases the process failure mode count to three, with only one possible correct assembly

mode.

The PTV/Switch Wrench system directly addresses all three of these failure modes, reducing the

probability of occurrence and increasing the probability of detection of each. Further, the proba-

bility of detection is immediate, and immediately communicated to the operator.

The first two failure modes - jerking the wrench and pulling past the click - are directly related to

time. The PTV/Switch Wrench System uses this linkage to obtain control of the process,

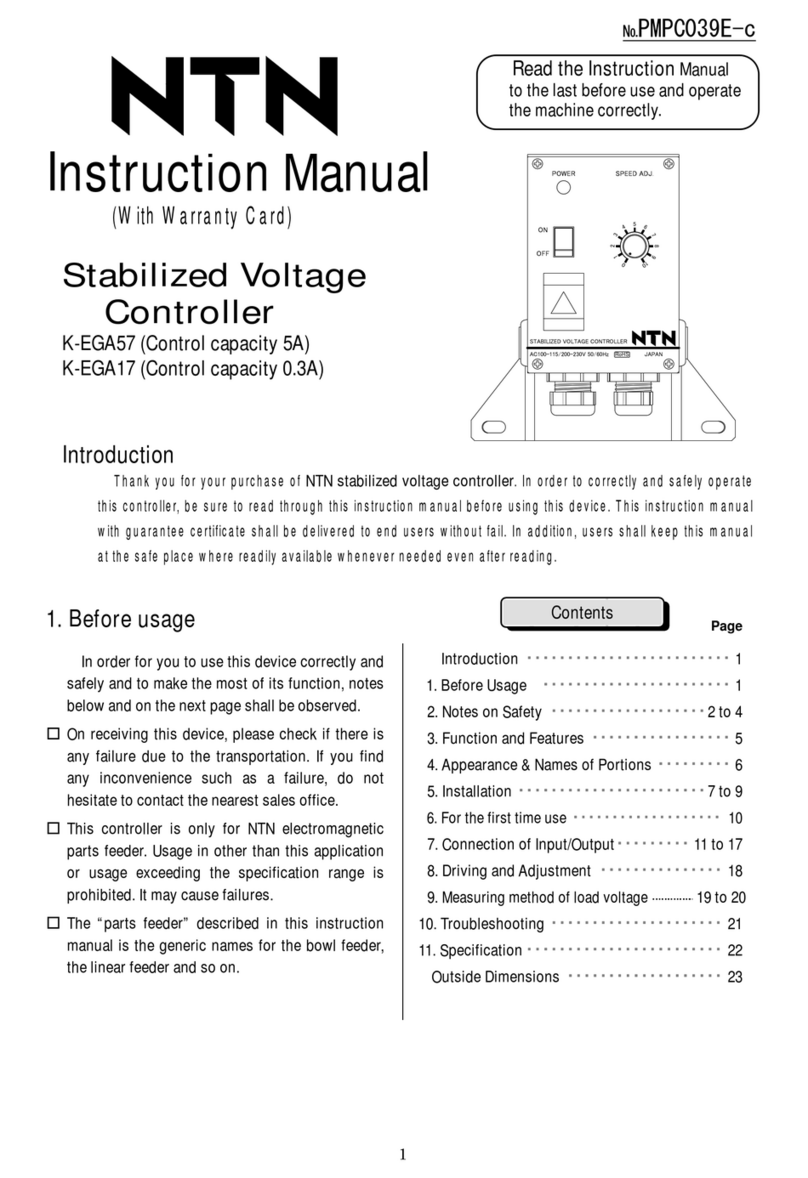

Diagram 1 shows a chart with three elements. The X-axis is time, and the Y-axis is signal

strength. The principle is that the signal begins when the wrench clicks, and ends when the

operator releases pressure on it and allows it to reset. Signal transmission may be by almost

any means (hardwire, FM radio, laser, sound) as long as it begins at the click and ends when the

pressure is released. The threshold element is present to avoid any problems related to noise in

the signal, again, regardless of means of transmission.

When a clicker-type torque wrench is

used properly on a joint, there is a period

of time in which the wrench is clicked

before release; the click has a proper

duration. If a wrench is “jerked” it is

cycled in a shorter period of time than if

properly used. If the wrench is pulled

past the click, it spends a longer period of

time inside the “click”; the duration of a

proper use is exceeded.

In Diagrams 1 - 5, the vertical axis is time

0 seconds, the start of the wrench “click”.

Page 11

By determining the correct amount of

time a wrench should spend in the

“clicked” position on any given joint, we

can rule out any shorter or longer peri-

od in that position as unacceptable.

Diagram 2 depicts the addition of mini-

mum and maximum acceptable times

for the wrench to be in the “clicked”

position. For convenience, the mini-

mum acceptable time is called “TMIN”

and the maximum acceptable time is

labeled “TMAX”.

In Diagram 3 the wrench has been

jerked, or clicked too quickly. The

measure of time for the signal from the

wrench starts at the left and continues

until pressure on the wrench is

released and it resets, ending the click.

Since the wrench was jerked, it did not

spend sufficient time in the clicked

position to properly torque the fastener.

It never got to time “TMIN”, and there-

fore would not count as a properly

tightened fastener.

Diagram 4 depicts the signal from a

wrench that has been properly used.

The wrench was neither jerked nor

pulled past the click. The duration of

time the wrench spent in the clicked

position was correct; it was more than

the minimum time and less than the

maximum time. This means the

wrench was used to properly tighten

the fastener.

Page 12

Diagram 5 shows the signal from a

wrench that was pulled past the click,

most likely overtorquing the fastener.

The time the wrench spent in the

clicked position exceeds the maximum

allowable time for that joint. This fas-

tener is rejected for overtorque.

The PTV-FM works with the FM Switch Wrench to bring systematized control to the use of manu-

al torque wrenches. The control is applied as follows:

1. The FM Switch Wrench is a preset clicker-type torque wrench. The torque is preset using a

torque tester to assure the wrench is accurately set, then the torque setting is locked in.

2. The joint is tested with the FM Switch Wrench and an indicating torque wrench to determine

the proper duration of a click on the joint.

3. The maximum and minimum duration of a click is programmed into the PTV-FM.

4. The FM Switch Wrench is used to tighten a fastener. As soon as the wrench clicks, an FM

radio signal is sent to the PTV, and a timer starts. The signal is continuous for as long as the

wrench is in the clicked position.

5. When the pressure is released on the wrench, it resets, turning off the FM signal. This stops

the timer and the PTV compares the time to the minimum (TMIN) and maximum (TMAX)

allowable times for signal duration.

6. The PTV-FM communicates immediately to the operator the acceptability of that use of the

wrench. Front panel LED’s and a buzzer inform the operator whether or not the fastener was

accepted.

7. If the fastener was properly tightened, the PTV-FM advances the count of fasteners tightened

in the batch by one. This assists the operator in keeping track of wherever they stand in a

multi-fastener assembly.

Page 13

The PTV-FM reduces the probability of missing a fastener in a multi-fastener assembly in two

ways:

1. Displaying the count of properly-torqued fasteners (or quantity remaining to be torqued) in the

batch at all times.

2. Sending a “Batch Accept” signal to the PLC and an audible signal to the operator when the

correct number of fasteners on the assembly has been properly tightened. The PTV auto-

matically resets to zero (or the number of fasteners to be tightened on the next assembly)

upon completion of the batch.

The operator is actually provided multiple signals at each step of the process, both for each indi-

vidual fastener and for the assembly batch.

Parameters

The definition of what is interpreted by the PTV-FM as a “proper” tightening is called a “parame-

ter”. Each parameter consists of a set of elements:

a minimum signal duration (TMIN),

a maximum signal duration (TMAX),

the FM channel the wrench will use (0-7),

which wrench will be used,

and the number of fasteners in the batch.

Time Between Clicks and Time Between Batches are additional optional elements.

The Generation II can store up to four parameters. At any given time, only one of the four may

be active. Switching among them may be performed manually via the Parameter Select Switch

on the left side of the unit, or be activated by a PLC command sent through the PLC Connector.

This provides the ability to tighten up to four different joints using only one Generation II PTV-

FM, a significant advance over the first generation. The four parameters can use from one to

four wrenches (for different torque levels or fastener sizes), or one to four different fastener

counts, or any combination that does not require more than four definitions of “proper” tightening

of the fasteners.

Two examples of how the Generation II works follow. The first example uses a Generation II

PTV-FM and a single FM Switch Wrench. This example assumes that the torque for all three

fasteners is the same. The second example uses six fasteners at two different torques to

demonstrate how the multiple parameter capability may be used.

Page 14

First Example

In this drawing we see the product to be assembled,

and the three fasteners to be tightened at this assem-

bly station. The operator has been provided with an

FM Switch Wrench preset to the proper torque for the

three fasteners. The operator has been told to tighten

the fasteners with the FM Switch Wrench, and to do

so in the sequence shown.

The PTV-FM is silent, and displays the count 0.

The operator uses the FM Switch Wrench to tighten

the first fastener to specification, as shown to right.

Since the wrench was used properly, the PTV displays

the green Accept LED, and the count advances to 1

on the LED Panel.

Even if the operator were interrupted now, when work

resumes he would only need to look at the LED Panel

to know which fastener had been tightened.

The operator then resumes tightening in the estab-

lished 1-2-3 pattern. He uses the wrench properly in

tightening the second fastener.

Upon completion of tightening the second fastener,

the PTV again gives him a green Accept LED, and the

count on the LED Panel advances from 1 to 2.

Page 15

The operator then tightens the third fastener in the

series, but uses the torque wrench incorrectly by

pulling past the click. This results in the red Reject

LED lighting on the PTV, and the beeper going off.

The count does not advance, since the wrench was

not used properly.

The operator next uses the wrench to loosen the fas-

tener, and retightens it properly. Because the wrench

was used correctly, the green Accept LED lights, the

beeper sounds twice to announce the completion of

the batch, then the LED Panel resets to 0 for the next

assembly. At the same time, a Batch Accept signal is sent to the PLC port. If a connected PLC

is programmed to advance the line upon completion of the operation, the signal from the PTV

can trigger the advance. This removes the necessity for operator intervention to achieve line

advance, reducing the probability of error or delay.

Second Example

In this second example there are six fasteners to be tightened at the workstation, two on the front

of the assembly and four on the rear. The two on the front each have the same torque. The four

on the rear have the same torque as each other, but the torque is different from the fasteners on

the front. Further, the front joint is a hard joint (metal to metal), and the rear joint is a soft joint

that has a gasket, necessitating different signal durations (click times).

Page 16

This requires the use of two different FM Switch Wrenches, each set to a different torque. It also

uses the multiple parameter capability of the Generation II PTV-FM. This is not done just

because of the two wrenches required, but also because the soft joint requires a different time to

work properly. The soft joint requires more time in the clicked position to torque the joint proper-

ly. The definition of “properly” has changed from that of the front joint.

The first FM Switch Wrench will be preset for the torque for Nuts #1 & #2, and the times and

other components of the parameter will be programmed into the Generation II as Parameter 1.

The second FM Switch Wrench will be preset to the torque for Nuts #3 - #6, and the times and

other components of the parameter will be programmed into the Generation II as Parameter 2.

Again, all the operator needs to do is follow the correct sequence using the correct tools. A color

coding can be applied to the wrenches (colored tape or a daub of paint) as additional visual cues

for the operator during assembly.

In operation, the steps and feedback for each would be as follows:

1. The assembly moves into the assembly station. The operator picks up Switch Wrench #1,

and torques the first nut properly. The operator receives a green Accept LED and the count

on the LED Panel advances from 0 to 1.

2. The operator then uses the same torque wrench to tighten the second fastener in the

sequence, and performs the second tightening properly. The operator again receives a green

Accept LED on the PTV, a double beep is sounded to signal the completion of the batch, a

batch accept signal is sent to the PLC Connector, and the count is reset to 0 for this parame-

ter.

3. The operator returns Switch Wrench #1 to the workbench, and obtains Switch Wrench #2.

He then rotates the Parameter Selector from A to B. Since no fasteners have been tightened

for this parameter, the count displayed on the LED Panel is 0.

4. The operator uses Switch Wrench #2 to tighten Nut #3. Since he performs the operation

properly, a green Accept LED is lit and the count advances from 0 to 1.

5. The Supervisor comes up and asks the operator a question. A three-minute discussion

ensues before the operator returns to the task. He need only look at the PTV-FM to see the

number of fasteners correctly tightened, and knows to work on Nut #4. He performs this task

properly, and again receives a green Accept LED, and the count advances from 1 to 2.

Page 17

6. On Nut #5 the operator inadvertently jerks the wrench. Since there is no green Accept LED

lit and the count did not advance, he knows he must retorque the fastener. He loosens the

fastener, then properly retorques it. The green Accept LED lights and the count advances

from 2 to 3 on the LED Panel.

7. The operator then moves to the last fastener on the assembly. The FM Switch Wrench is

used properly, applying the proper torque and earning the operator a green Accept LED, a

double-beep from the beeper to indicate the batch of fasteners is completed, and a reset to 0

on the LED Panel in preparation for the next assembly. A Batch Accept signal is sent to the

PLC Connector to signal completion of the assembly to the PLC.

In this second example, the operator changed the parameter in use by rotating the Parameter

Select Switch. The PLC had been programmed to count the batch accept signals coming from

the PTV, and advance the line only on the even numbered signals.

The change in active parameter from A to B could have been accomplished via PLC command

instead. The batch accept from Parameter A could have triggered the command to switch to

Parameter B.

The means by which the signals to the PLC are used to control the line are limited only by the

PLC hardware and the desire of the PLC programmer.

Please note that S/R does not perform PLC programming. Our expertise is in torque application

and measurement. We provide the signals at the connector, and leave their application to the

ingenuity of our customers.

Page 18

Table of contents

Other Sturtevant Richmont Controllers manuals

Popular Controllers manuals by other brands

Honeywell

Honeywell WEB-600E manual

Sensus

Sensus 441-S Installation and maintenance instructions

Emerson

Emerson Bettis RGS Q-Series Installation, operation and maintenance manual

CaryMart

CaryMart WF-8-1R manual

Rinnai

Rinnai MC-100V Operation & installation manual

Federal Signal Corporation

Federal Signal Corporation UltraVoice Installation, operation and service manual