Stuv SWINGLOX User manual

SWINGLOX

Installation Manual

V5

CLAVIS Deutschland GmbH

Schillerstraße 47-51

34117 Kassel

Telefon: +49 (0)561 988 499-0

E-Mail: [email protected]

Internet: www.tresore.eu

www.tresorschloss.de

- 10 -

ENGLISH

Application

Products are designed for highest demands and maximum reliability.

Application and installation recommendations and our comprehensive consulting

service provide support for the choice of our products.

High security locks of the 4.17.11 series are intended for use on doors of secure

storage units. Responsibility for verication and suitability for the respective

application resides with the user!

Changes to the products lead to the loss of the VdS* approval and any guarantee and

warranty claims.

*VdS: German independent testing institution

Content

Read rst

10 Application

11 Basics,

Technical Notes Lock

12 Technical Notes Keypad

Installation

13 Installation Procedure

Step 1

15 Installation Procedure

Step 2

- 11 -

ENGLISH

Lock installation

Basics:

The precise position and mounting of the locking mechanism play a major role in the correct functioning of

the lock. The locking mechanism must be aligned precisely in both horizontal and vertical position. The lock

can be mounted locking to the right, left, top or bottom, resting on the front or back.

Technical notes lock:

Bolt head dimensions

(mm)

Swing bolt 21,4 x 8 x 11,7 (Fig. 1)

Bolt stroke swings in completely

Mounting screws

lock

Cylinderhead screw DIN EN ISO 4762 - M6x30-8.8 or alternatively 3 cylinder-

head screws BSW 1/4 x 30 mm. The screw-in depth must comply with the valid

standards.

Cut out see Fig. 1

Tightening torque 6 Nm

Screw securing A screw securing must be provided by means of safety washers or liquid screw

locking devices. The screw-in depth must comply with the valid standards.

Bolt mechanism

connection

Ensure that the bolt head is not subjected to load in the closed position (for

example, tension in the opening direction). Under no circumstances should it

exceed 2,5 N. Otherwise the lock can not be unlocked.

Lock protection The safe must consist of a steel construction. It must be suitable to protect the

lock against tapping, e.g. by using manganese steel, or knocking off, e.g. sufci-

ently secured by supporting the lock case.

The safe must be constructively designed in such a way that there is no access

to safety-relevant parts of the lock for unauthorized persons with the door open.

Cable position In order to realize the cable connection between lock and tting, a hole in the

door of the safe is necessary. The max. permissible bore diameter is 11.5 mm.

If the lock may need to be mounted behind this hole, it must correspond to the

cable entry hole in the lock.

Lock resilience Adequate clearance of the bolt in locking operation must be ensured. No additio-

nal bars, brackets or similar accessories may be attached to the bolt. Transverse

forces or frictional forces on the lock must be avoided by design measures. The

blocking force in the opening direction is tested with 1 kN. Higher locking forces

must be absorbed by constructive solutions.

Function in combination

with another lock

If another lock is placed on the bolt mechanism, make sure that the swing bolt

lock is always locked rst. Check the correct sequence of locking of both locks.

Read rst

- 12 -

ENGLISH

Technical notes keypad:

Mounting screws

for the base plate

Self-tapping screw DIN 7500 Form C M4 x 25

(Cheese-head screws according to DIN 7985)

Cut out see Fig. 5

Tightening torque 2,7 Nm

Cable entry instead of a keyhole

Fig. 1

Read rst

- 13 -

ENGLISH

Installation procedure Step 1

If the connection cable from the lock to the keypad is guided through a hole into the interior of the safe, a

suitable drilling position, which corresponds to the VdS guidelines, must be dened.

In any case, it is important to ensure that the hole is located centrally in the area of the lock located behind

it, in the middle of the cable entry of the lock and always in the center of the base plate of the keypad.

Ensure that the connection cable is not squeezed during installation and the insulation is not damaged.

(Fig. 2)

Pull the connecting cable through the cable entry of the lock and insert the plug of the cable into the mat-

ching plug socket on the lock. (Fig. 3)

Then secure the lock to the bolt mechanism using three fastening screws. (Fig. 2)

Fig. 2

Fastening screws

Cable entry of lock

Door

Cable entry of base plate

Base plate for keypad housing

Installation

- 14 -

ENGLISH

Fig. 3

Cable entry of lock

Plug

Connection cable

A suitable strain relief for the connecting cable must be established between the plug connection of the

lock and the mounting plate of the keyboard. This may be, for example, a cable xer or something similar.

It is important that a sufciently long piece of the connection cable (min. 150 mm) protrudes from the bore

of the door, in order not to make the battery change unnecessarily difcult. (Fig. 4)

Cable length 150 mm

Fig. 4

Strain relief between lock and

mounting plate

Installation

- 15 -

ENGLISH

The keypad housing must be placed in the middle of the cable entry hole or the existing key hole.

Screw the mounting plate to the safe door. The base plate of the keypad must be securely screwed to

the safety door using two screws (self-tapping screw DIN 7500 Form C M4 x 25 Cheese-head screws

according to DIN 7985). The horizontal or vertical hole stencils can be used. (Fig. 5)

Care must be taken to ensure that the appropriate core hole diameters are inserted into the safe door

for the respective screws.

ATTENTION ! The display marks must be at the top! (Fig. 5)

Fig. 5

horizontal

vertical

Display marks

Installation procedure Step 2

01

Installation

- 16 -

ENGLISH

02 Connect the connection cable „Lock - Keypad“ to the keypad. (Fig. 6)

03 Connect a battery (9V block 6LR61) to the battery contact. (Fig. 6 and Fig. 7)

04 Insert the battery into the lower part of the keyboard housing. (Fig. 8)

05 Place the keypad housing on the base plate. In this case, the marking of the keypad

housing must be aligned with the display mark 1 of the base plate. (Fig. 9)

ATTENTION ! When installing the keypad housing, make sure that all cables are in the

housing and that no cable is pinched between the housing and the base plate.

06 When the housing is placed at on the base plate, turn the keypad housing clockwise until the

marking of the keypad housing is aligned with marking 2 of the base plate. (Fig. 10)

07 The system is now ready for use.

ATTENTION! Check the proper operation according to the user manual with the door open.

Fig. 6 Fig. 7

Plug connection

Connection cableBattery contact Battery (9V Block 6LR61)

Installation

- 17 -

ENGLISH

Fig. 8 Fig. 9

Cable in housing

Battery in housing Marking keypad housing

Mark 1 Mark 2

Fig. 10

Mark 2

Installation

ATTENTION: during assembly / disassembly of the keyboard housing make sure

there is a exact match between the marking of the housing and the indicator marks 1 or 2.

Steinbach & Vollmann

GmbH & Co. KG

Parkstraße 11

42579 Heiligenhaus

Germany

Telefon +49 2056 14-0

Telefax +49 2056 14-251

E-Mail info@stuv.de

Internet www.stuv.de

04/2019 Printed in Germany - 6.00.2017.3

Zumutbare Abweichungen in Modellen und Farben sowie Änderungen zur Anpassung an den neuesten Stand der Technik

und Produktion bleiben ausdrücklich vorbehalten.

Copyright © 2019 Steinbach & Vollmann

Dieses Handbuch darf weder als Ganzes noch in Auszügen ohne schriftliche Genehmigung von Steinbach & Vollmann

reproduziert, vertrieben, übersetzt oder in anderer Art und Weise oder mit anderen Mitteln elektronischer oder mechanischer

Art übertragen werden. Dies schließt Fotokopien, Aufzeichnungen oder Speichern in jedweder Art ein.

CLAVIS Deutschland GmbH

Schillerstraße 47-51

34117 Kassel

Telefon: +49 (0)561 988 499-0

E-Mail: [email protected]

Internet: www.tresore.eu

www.tresorschloss.de

Kundendienst

Other manuals for SWINGLOX

2

Table of contents

Other Stuv Lock manuals

Popular Lock manuals by other brands

SISO

SISO 14.60.290-0 user manual

Finger Crystal

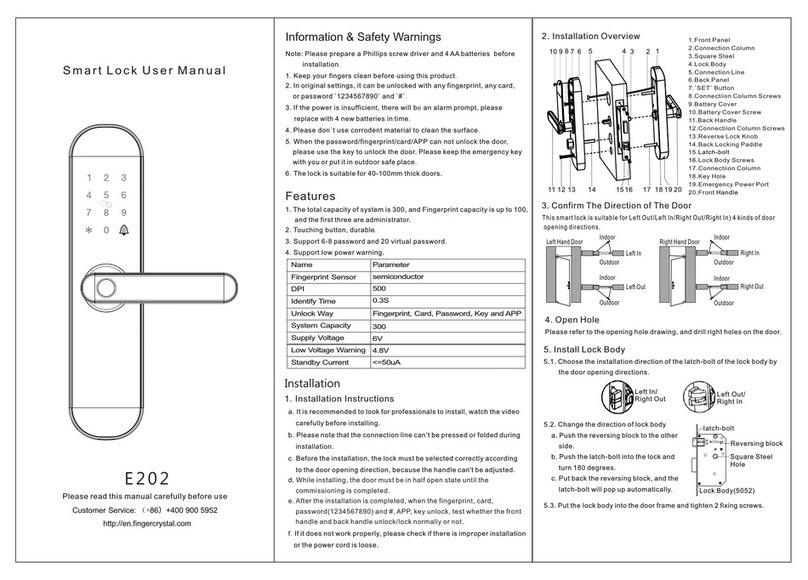

Finger Crystal E202 user manual

Dormakaba

Dormakaba La Gard Reset Box user guide

Nationwide Industries

Nationwide Industries Keystone Advantage KLADV-P2 Installation, adjustment and maintenance instructions

IHT Cordynamic

IHT Cordynamic IDL707 installation instructions

Orbis

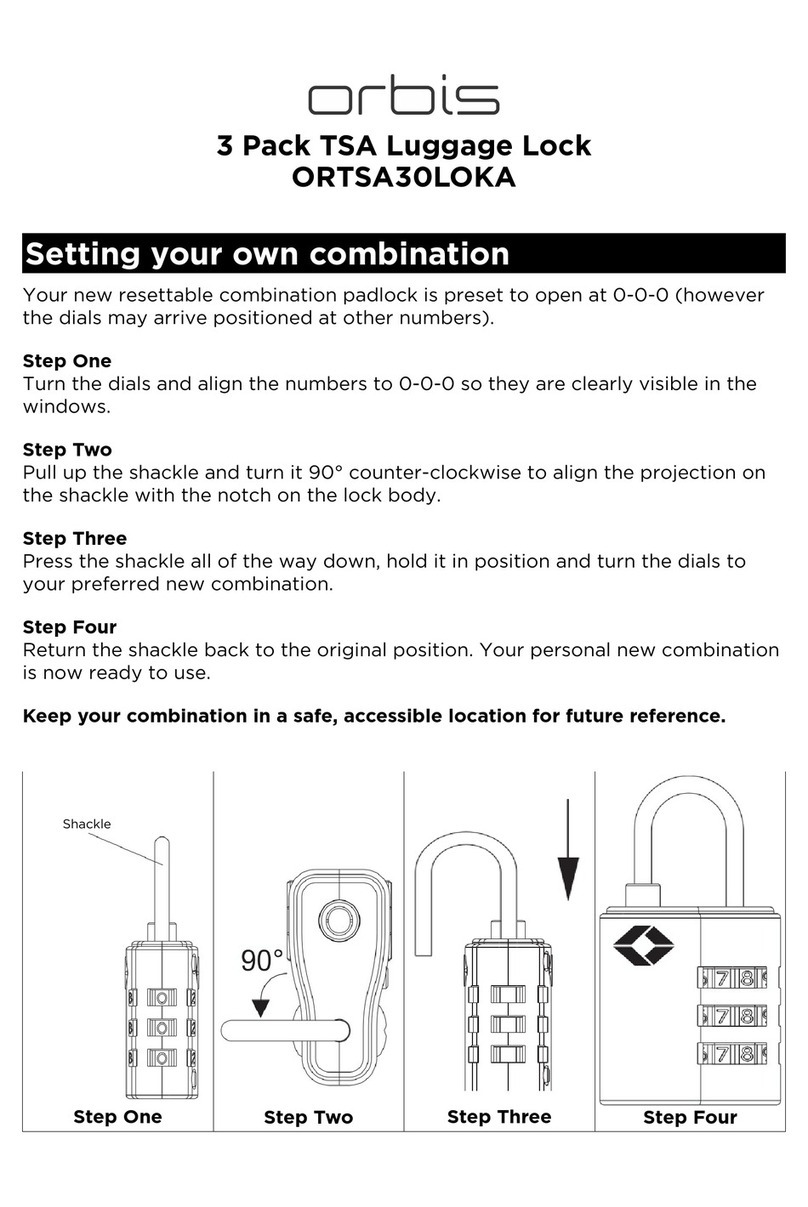

Orbis ORTSA30LOKA user manual

Weiser

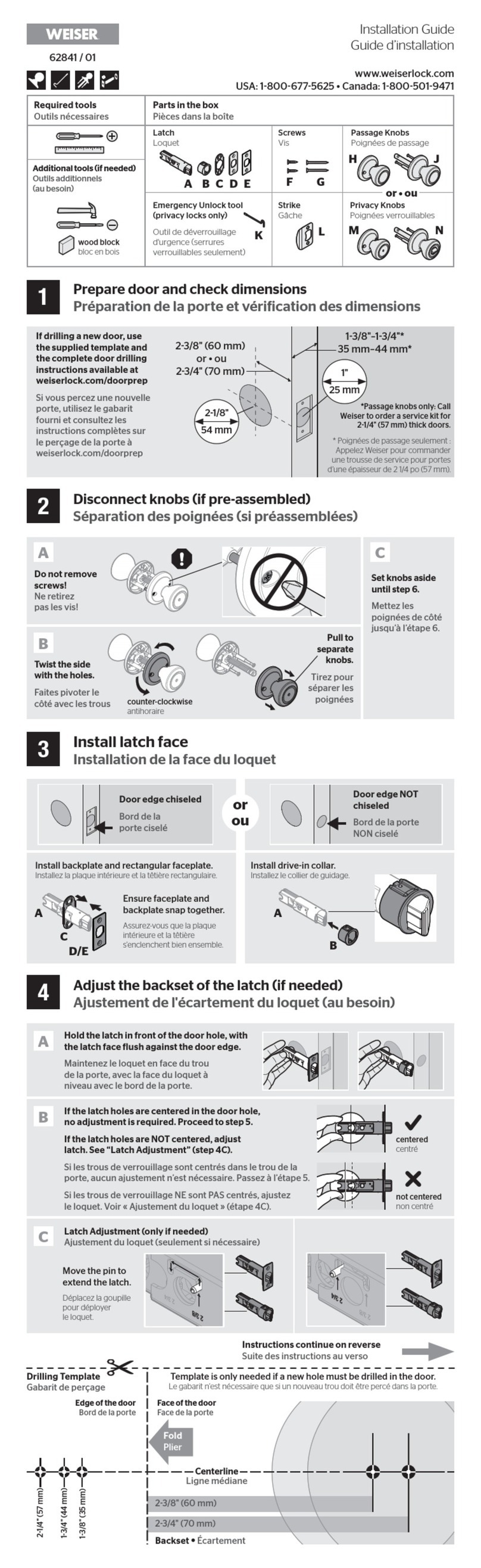

Weiser 62841/01 installation guide

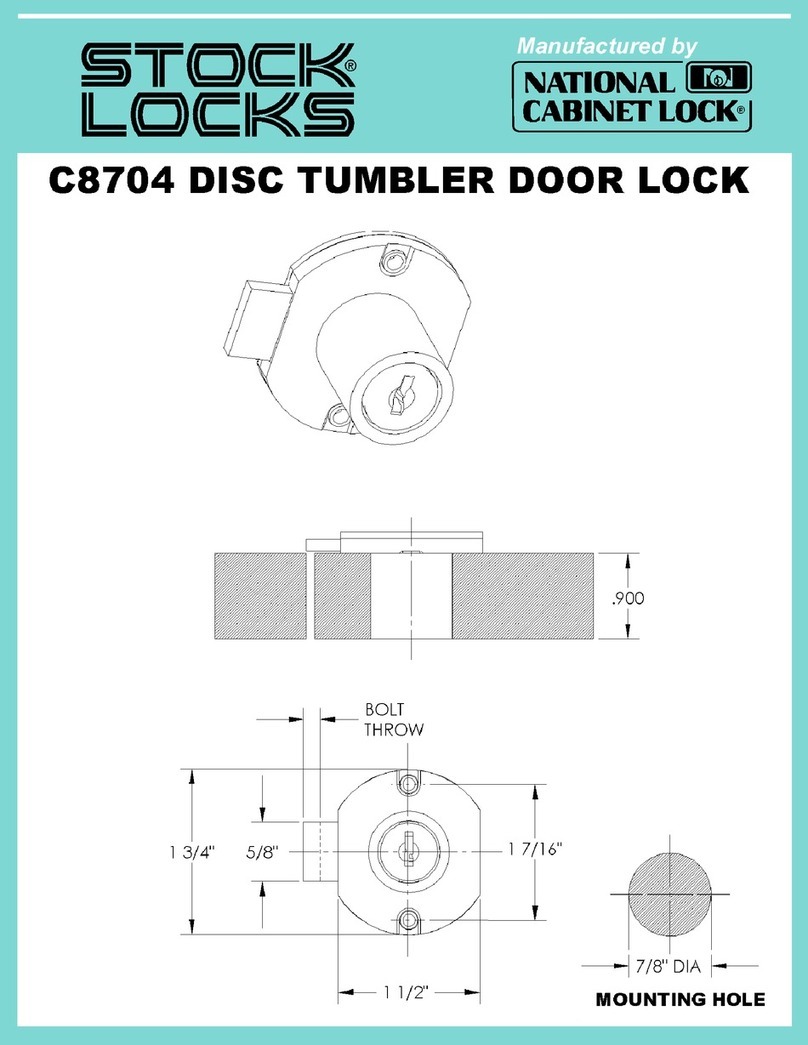

National Cabinet Lock

National Cabinet Lock C8704 Dimensional drawing

Corbin Russwin

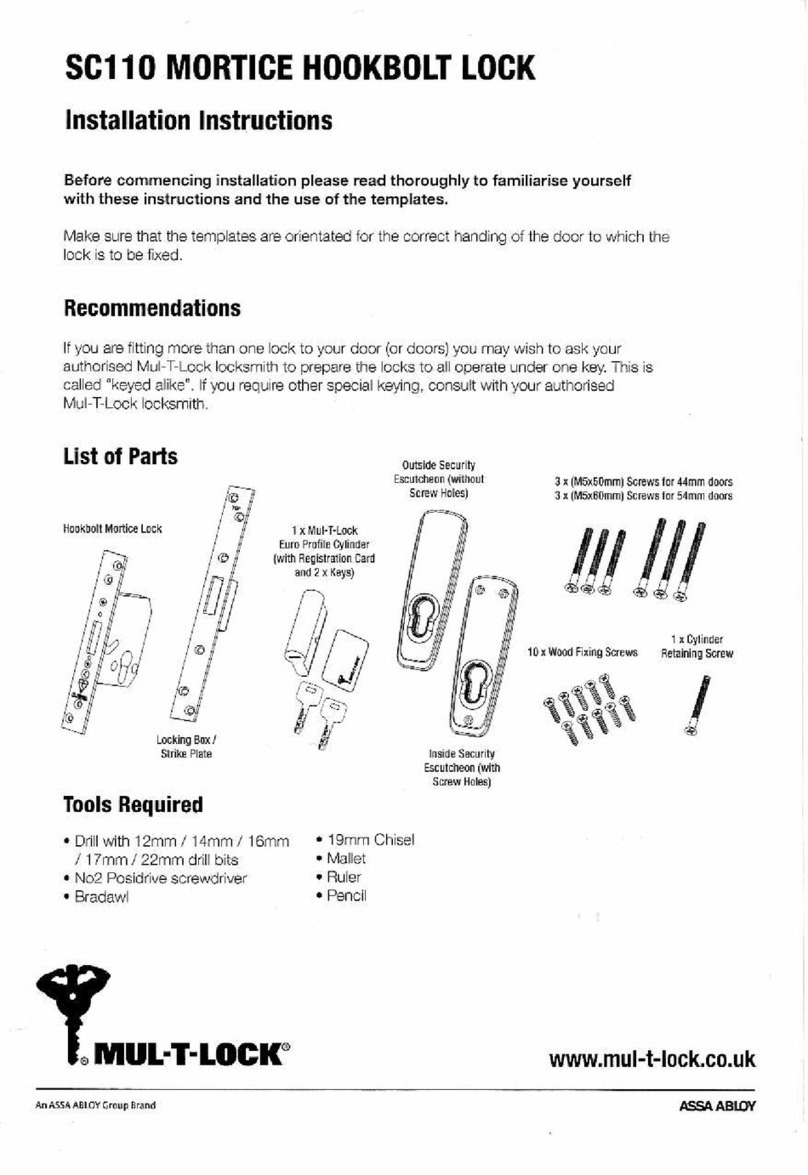

Corbin Russwin ASSA ABLOY Museo MP6600 Series installation instructions

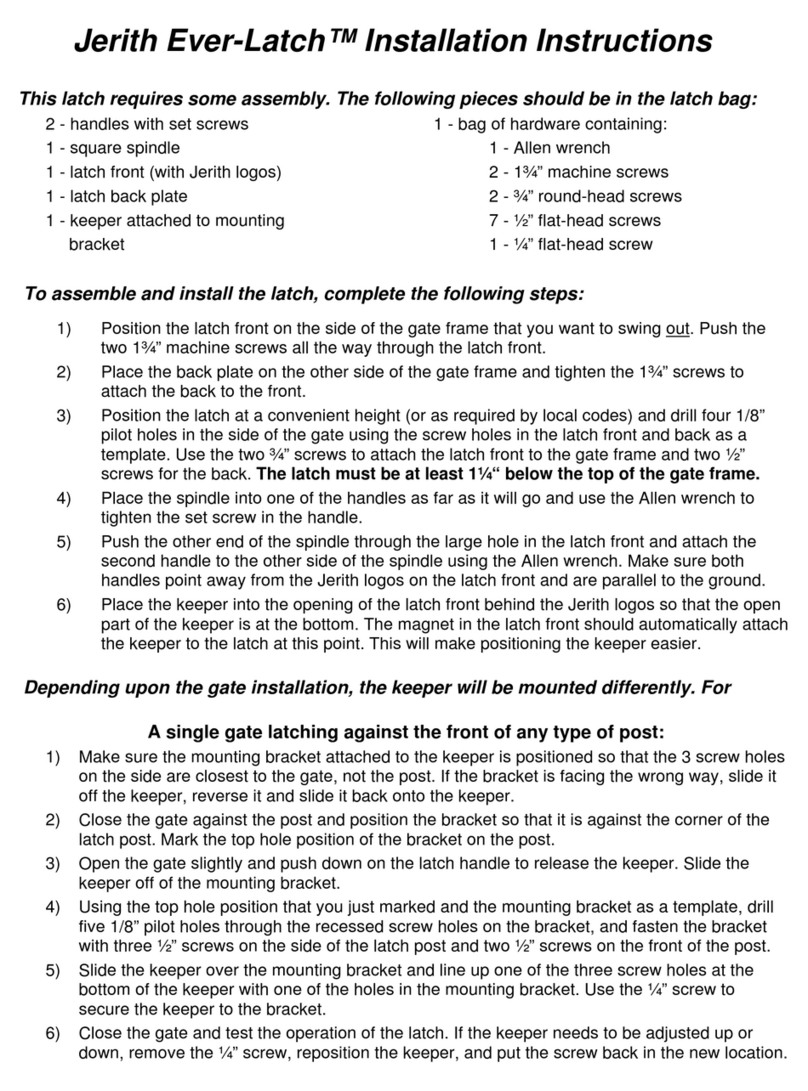

Jerith

Jerith Ever-Latch installation instructions

Tapkey

Tapkey Smart Lock quick start guide

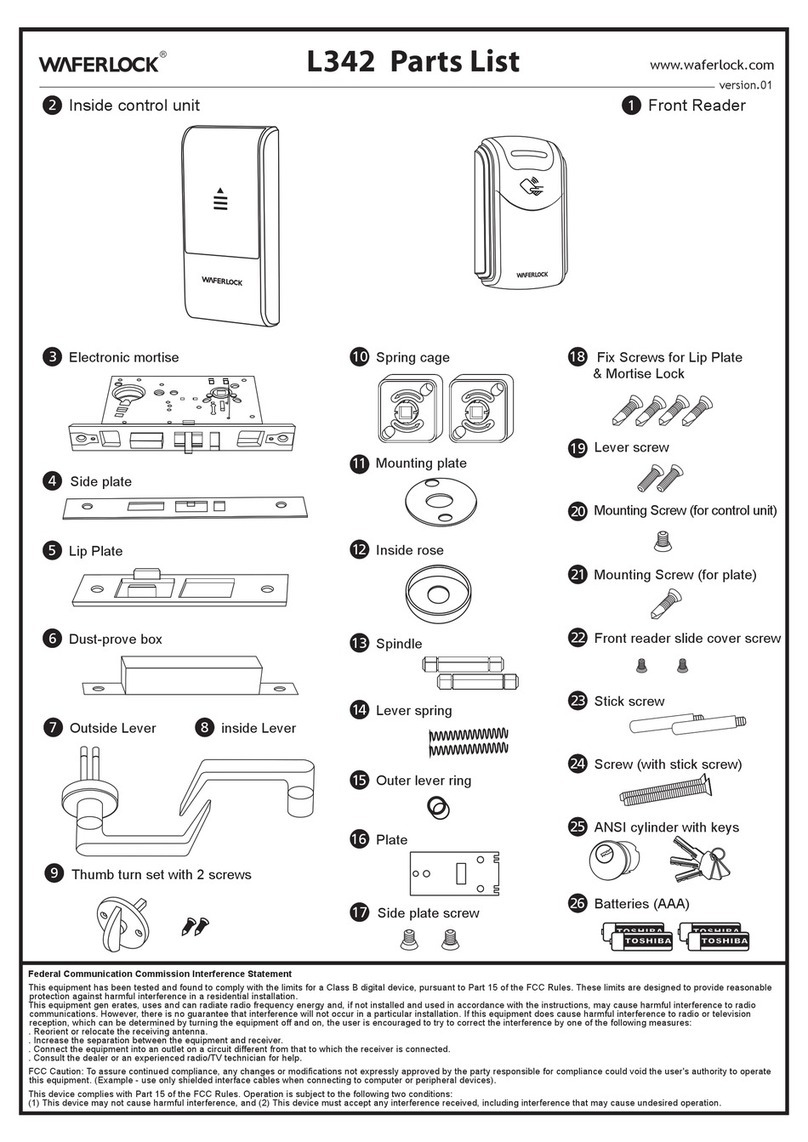

Waferlock

Waferlock L342 installation manual