Connection Diagram ( for PT244-T- AA )W2C30

RTD1RTD2RTD3

1245

PNNOC

230V

SSR +SSR -

1267811

TC

+

-

Caution for your safetyWIRING: The probe and its corresponding wires should never be installed in a conduit next to control or power supply lines. The electrical wiring should be done as shown in the diagram. The power supply circuit should be connected to a protection switch. The terminals admit wires of upto 2.5sq mm.WARNING: Improper wiring may cause irreparable damage and personal injury. Kindly ensure that wiring is done by qualified personnel only.Maintenance: Cleaning: Clean the surface of the controller with a soft moist cloth. Do not use abrasive detergents, petrol, alcohol or solvents.Notice: The information in this document is subject to change in order to improve reliability , design or function without prior notice and does not represent a commitment on the part of the company. In no event will the company be liable for direct, indirect, special, incidental or consequential damage arising out of the use or inability to use the product or documentation, even if advised of the possibility of such damages. No part of this manual may be reproduced or transmitted in any form or by any means without the prior written permission of the company.Controller :Controller should be installed in a place protected by vibration, water and corrosive gasses and where ambient temperature does not exceed the values specified in the technical data.Probe :To give a correct reading, the probe must be installed in a place protected from thermal influences, which may affect the temperature to be controlled. Product MountingInstallation : Fixing and dimensions of panel models:To fix the unit, slide the fastener 1 through the guides 2 as per the position shown in the figure. Move the fastener in the direction of the arrow, pressing tab 3 it permits to move the fastener in the opposite direction of the arrow. 45.5mm45.5mmPanel CutoutDimensions 48mm48mmPVSVPT244-TOperating ManualPT244-T / PT244-K / PT244-T-AA IntroductionA proportional–integral–derivative controller (PID controller or three term controller) is a control loop feedback mechanism widely used in industrial control systems and a variety of other applications requiring continuously modulated control. A PID controller continuously calculates an error value as the difference between a desired setpoint (SV) and a measured process variable (PV) and applies a correction based on proportional, integral, and derivative terms (denoted P, I, and D respectively) which give the controller its name.PT244-T is a two set point PID controller. It is available in touch & keypad version. Customized iconic display interprets status easily.48mm123CONTROLLERGASKETPANELSide LockConnection Diagram ( for PT244-T- )W2C30

RTD1RTD2RTD3

12345

PNNO1C1

230V

SSR +

1267811

TC

+

-

SSR

NC1

Connection Diagram ( for PT244-T/K-W2C34 )12345678101211

RTD1

SSR +SSR -

PNNO1C1NO2C2TC

230V

RTD2RTD3

+

-

Connection Diagram ( for PT244-T/K-W*C34 )12345678101211

RTD1

SSR +SSR -

NO1C1NO2C2TC RTD2RTD3

+

-

+

-

PowerSupply ** 12Vac/dc or 24V ac/dc on request

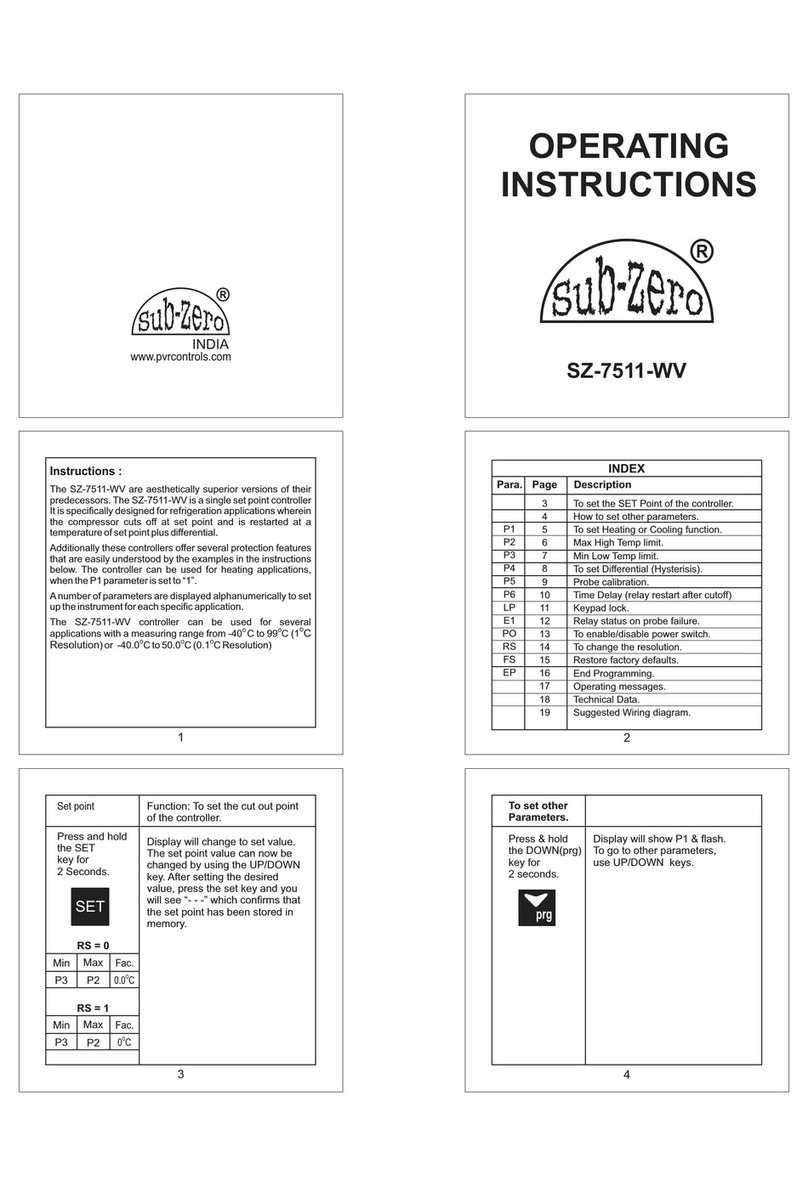

134567Control1 set point.Sets the type of input sensor .Sets input correction.Sets the lower limit of PV input.Sets the upper limit of PV input.Sets the dwell time.Level1 Parameter2Control2 set point.IndexSr. No.Para.DescriptionUser InterfaceTechnical SpecificationInitial display when Power is ONParameter setting modeWorkingInput types & Input rangeSet modeSets cycle time for PID action.Sets proportional band.Sets integration time.Sets differential time.Sets the hysteresis1Runs auto tuning.Sets control action for relay1 / SSR.8910Sets control action for relay2. (for 2 Relay)Sets the hysteresis2. (for 2 Relay)Sets the alarm type. (for 2 Relay)Sets AL1 icon as alarm relay. (for 2 Relay)11121314151617Factory reset parameter.181920Sets Control1 output.Lock keypad.21LED IndicationsAlarm TypesLevel2 ParameterError Messages Pro-key (On-request) Ordering Information To enable Dwell timer.Low temperature limit. (for 1 Relay)High temperature limit. (for 1 Relay)222324Sr. No.DescriptionProcess Value (PV)RUN mode : Displays current measured value.SETTING mode : Displays parameter.Set value (SV)RUN mode : Displays set value. Displays countdown time when Dwell timer is running. SETTING mode : Displays set value of parameter.Turns ON while control output1 is ON.421Displays the Temperature unit.3User Interface47611253289101113PVSVPT244-T8Turns ON while control output2 is ON. (for two relay)Turns ON when auto tuning is in progress.57Flashes during Dwell timer is in progress. Continuous ON : Dwell time elapsed. Turns ON when the corresponding alarm out turns ON.69Turns ON when keypad is locked.10Next key : Used to enters parameters level, moves to nextparameters. Press & hold this key atleast 2 seconds to enterin set mode.Press & hold this key atleast 4 seconds to enterin Level1 Parameters.Press & hold this key atleast 6 seconds to enterin Level2 Parameters.11DownUsed in Program mode to decrement parametervalue.Used to reset the Dwell timer.. / Reset Key : 13Up / AT Key :value.Press this key for 2 seconds to start or stop auto-tuning.Used in Program mode to increment parameter12Exit Key :Press this key to save the setting value and to exitthe programing mode.Input types & Input rangeInput TypeThermocoupleJK1DecimalPoint1DisplayOInput Range (C)O-50 to 750CO-50 to 1200CRTDPt10010.1O-99 to 400CO-99.9 to 400.0CThe Auto-tuning function automatically computes and sets the proportional band (P), Integral time (I), Derivative time (D) as per process characteristics.While Auto-tune is in progress "AUTO" led will turn ON.After Auto-tuning is complete the "AUTO" led will turn OFF.If auto -tuning is not complete after 3-4 cycles, it is suspected to fail. In this case, check the wiring & parameters such as the control action, input type etc.Carry out the auto-tuning again, if there is a change in setpoint or process parameters. PID-time proportionalwith auto reset & rate Working2. ON/OFF control action (For reverse mode)The relay is ‘ON’ up to the set temperature and cuts”OFF” above the set temperature . As the temperature of the system drops ,the relay is switched ‘ON’ at a temperature lower than the set point .HYSTERESIS:The difference between the temperature at which relay switches ‘OFF’ is the hysteresis or dead band.1. Auto tuningNote : In Auto Tuning running time, user can not change the parameter value.1. PT244-T-W2C34 / PT244-K-W2C34 - Two Relay2. PT244-T-W2C30AA - Single Relay3. PT244-T-W2C30 / PT244-K-W2C30 - Single Relay4. PT244-T-W5C34 / PT244-K-W5C34 - Two RelayModel DescriptionTechnical SpecificationHousing : Polycarbonate PlasticDimensions : Frontal : 48 X 48mm, Depth : 78mmPanel Cutout : 45.5 X 45.5mmMounting : Flush panel mounting with fasteners.Protection : IP65 FrontConnections : Terminal connectors. < 2.5sq mm terminal only.Display : 4 X 17mm 7 segment Red/White display, 4 X 8mm 7 segment Green display 7 Iconic LEDs for IndicationData storage : Non-volatile flash memoryOperating temp. : 0°C to 60°C (non-condensing)Operating humidity : 20% to 85% (non-condensing)Storage temp : -25°C to 60°C (non-condensing)Power input : 230 Vac ±15 % , 50/60Hz Standard. 85 to 265Vac, 12/24Vdc on request.Control output : (For all PT244-T- / PT244-K) Relay : 5A, 230V AC (Res.) or SSR (field selectable) : 10V DC, 30mA Except - (For PT244-T-W2C30 / PT244-K-W2C30) Relay : 10A, 230V AC (Res.) or SSR (field selectable) : 10V DC, 30mA (For PT244-T-W2C30AA) Relay : 16A, 230V AC (Res.) or SSR (field selectable) : 10V DC, 30mAAuxiliary output : (For all PT244-T / PT244-K) Relay : 5A, 230V AC (Res.)Input Type : RTD : Pt100 Thermocouple : J, K OOResolution