07 08

0.1ºC 10.0ºC 2.0ºC

EXAMPLE: If this parameter is set at 3

minutes, the compressor will cut off at the

set temperature, but will not restart for a

minimum of 3 minutes. This time delay is

also effective at 'Power On’ of the system.

This safety feature is used to protect the

compressor from restarting within a short

period due to power fluctuations.

Range

Min Max Fact. Set

0 Min 20 Min 3 Min

Use UP/DOWN keys to set desired

value.

0 0

(10.0 C + 2.0 C).

0

EXAMPLE: If the set point is setat 10.0 C

0

and differential is setas 2.0 C, then when

0

the system reaches 10 C,the compressor

0

will cutout. Since differential is 2.0 C, the

0

compressor will cut in(restart) at 12.0 C

To change DIFFERENTIAL

parameter,press the set key.

05

Range

Min Max Fact. Set

Range

Min Max Fact. Set

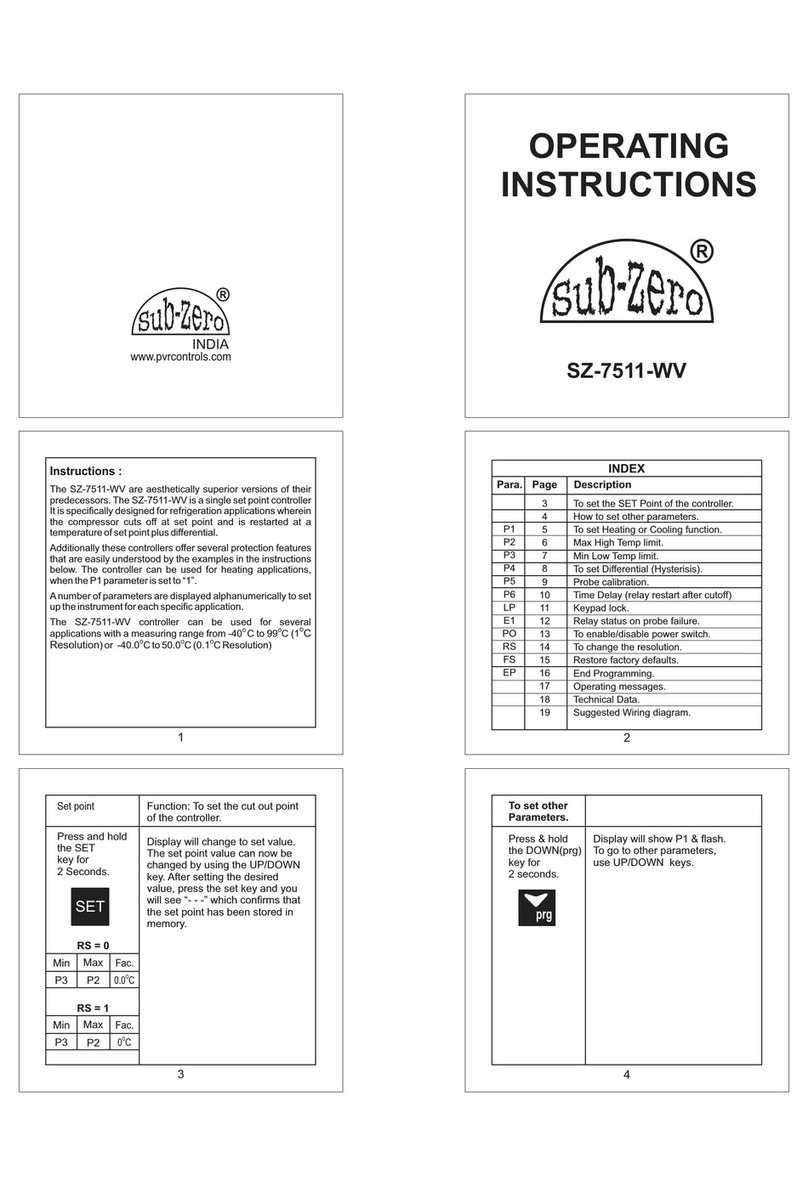

DIFFERENTIAL Function: To set temperature differential

for compressor restart.

Sr.No.

Parameter (LCD Message)

Description of parameters and functions.

Parameter setting method.

HIGH TEMP. ALARM

First Press set key once & release

Parameter value will flash. Now UP /

DOWN keys to set desired value.

To change High Temp

parameter,press the set key.

06

Function: To set maximum allowable

high temperature limit and alarm.

Set Point -1 50.0ºC 50.0ºC

EXAMPLE : If this parameter is set to

0

50.0 C, then once chiller temperature

0

goes above 50.0 C then controller will

show “Ht” and alarm will be ON.

Range

Min Max Fact. Set

Range

Min Max Fact. Set

Range

Min Max Fact. Set

AFT SET TEMP

Use UP/DOWN keys to set desired

value.

EXAMPLE: If this parameter is set to

5.0ºC controller will trip the compressor

on Antifreeze fault if the AFT sensor

goes below 5.0ºC.

To change AFT SET TEMP.

parameter, press the set key.

09

Function: To set Antifreeze tripping point.

-30.0ºC Lt-0.1ºC 4.0ºC

Sr.No.

Parameter (LCD Message)

Description of parameters and functions.

Parameter setting method.

function of the controller

Enable = It enables the Antifreeze Trip

Use UP/DOWN keys to set desired

value.

function of the controller

Disable = It disables the Antifreeze Trip

To change AFT PROBE

STATUS parameter, press the

set key.

08

Function : To enable or disable

Antifreeze function.

EXAMPLE: Setting this parameter at

0

5.0 C will not allow the set point to go

0

below 5.0 C Also, if the temperature

0

reaches or goes below 5.0 C the display

will show Low Temp. Alarm and at this

point the alarm will activate.

AFT Set

Temp.

+0.1ºC -0.1

Set Temp. 5.0ºC

Disable Enable Disable

LOW TEMP. ALARM

07

Function: To set minimum allowable low

temperature limit and alarm.

To change the Low Temp

parameter, press the set key.

First Press set key once & release

Parameter value will flash. Now UP /

DOWN keys to set desired range.

AFT PROBE STATUS

NC-120A NC-120A