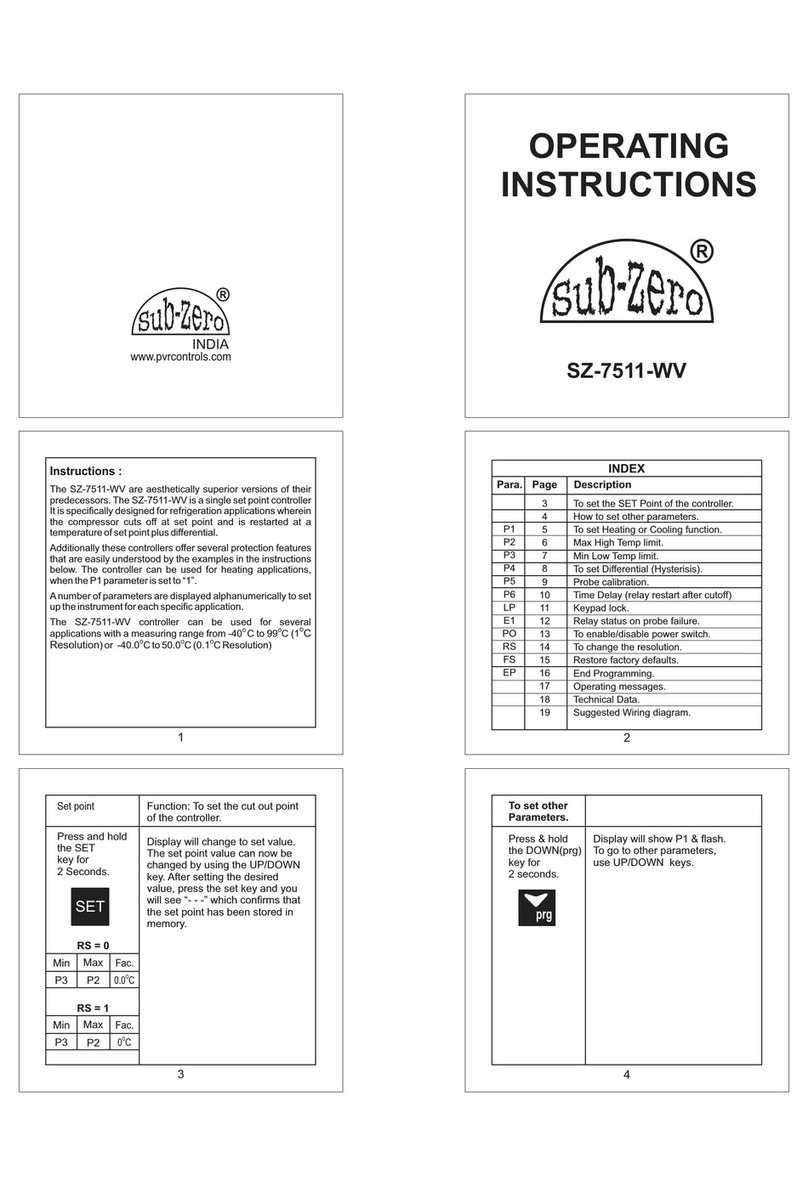

16 17

4.4 WaterPump

PUMP is the first device to be

activated after the chiller has

started. Pump functioning has

absolutepriorityamongstall other

devices.

The pump’s status is always ON

even if the set temperature has

beenachieved.

ALARMS

Thealarmsthatcanblock

thepumpare:

WATERFLOWSWITCH

(Thisalarmisignoredfor

a selectedtimeas

per parameter P1&P2)

PUMPOVERLOAD

LOWLIQUIDLEVEL

4.6 Set-PointandDifferential

Set point is the temperature at

which the chiller has to be

regulated.At this temperature the

compressor will switch off.

Differential is the temperature

added to the set point after which

the compressor restarts. For

0

example, If the Setpoint is 7 C,

0

and the differential is 2 C, the

0

compressor will switch off at 7 C

0 0 0 0

andrestartat9 C(7 C+2 C=9 C).

4.7 Antifreeze

The antifreeze procedure

activates when the AFT probe

temperature reaches or goes

below the selected threshold in

parameter A1, The compressors

are immediately stopped, without

pump-down procedure and the

liquid line solenoid valve is de-

energised.Theantifreezealarmis

displayedontheLCD.

The system will not allow a restart

until AFT temperature reaches or

goesaboveA1+A2.

To disable the ANTIFREEZE

based on the internal AFT

probe, change A0 parameter

to0.

4.5 Watertemperature

Regulation of the water

temperature is based on the

CONTROL PROBE. This control

probe can be installed by the user

at the inlet or outlet of the

evaporator, or any other location,

where he wants to regulate the

water/media.

4.8 PUMP-DOWN

The PUMP-DOWN procedure can

beenabledthroughH1parameter.

PUMP-DOWNSTAGE:

A. De-energisation of the Liquid

SolenoidValve.

B. The compressor keeps

operating until the LOW pressure

cutout input intervenes.

C.Whenthesystemcutsoffonthe

inputfrom the low pressure cutout,

the compressor turns OFF and the

PUMP-DOWNprocedureisover.

If the compressor remains on for

more than 50 seconds without

cutting off on the low pressure

switch, Megachill will force a

compressor shut down and

indicate a FAULTY PUMP-DOWN

procedure provided the CUT IN

temp has not been achieved. In

this case check the LIQUID

SOLENOID VALVE and LOW

PRESSURE CONTROL. If within

50 seconds, the CUT IN temp has

been achieved, the system will

activate the solenoid and continue

operating normally without pump

down.

PUMP-DOWNCYCLE

A pump-down cycle is used to

pump all refrigerant into a receiver

orcondensor during theOFF cycle.

The purpose is to prevent

refrigerant from migrating to the

crankcase, where it can condense

and saturate the oil. Without a

pump-down cycle, the crankcase

can fill liquid refrigerant during a

long off-cycle.At start up, the liquid

refrigerant can flood the cylinders

and damage the compressor much

like a floodback. (Large

compressors have springs on

intake)After the system has cooled

the evaporator sufficiently, a

solenoid valve closes in the liquid

line and the compressor pumps

refrigerant into the condenser or

receiver, where it remains until the

nexton-cycle.

4.9 WaterLevel

System controls the level of water

in the evaporator tank via three

water level sensors, High, Med &

Low. As soon as the level of water

goes below the Medium level, the

controller will activate a Water

Solenoid Valve. In case the level

goes below the Low level sensor,

thesystemtripsanddisplays a Low

LiquidLevelFault.

WARNING

If the machine controlled by mega chill is not using

the water level sensing feature, it is necessary to

short all water inputs concerning the water level.

Thiswilldisabletheliquidlevelerrors.

2 COMPRESSOR2 COMPRESSOR

WATER

MEDIUM

WATER

LOW WATER

SV