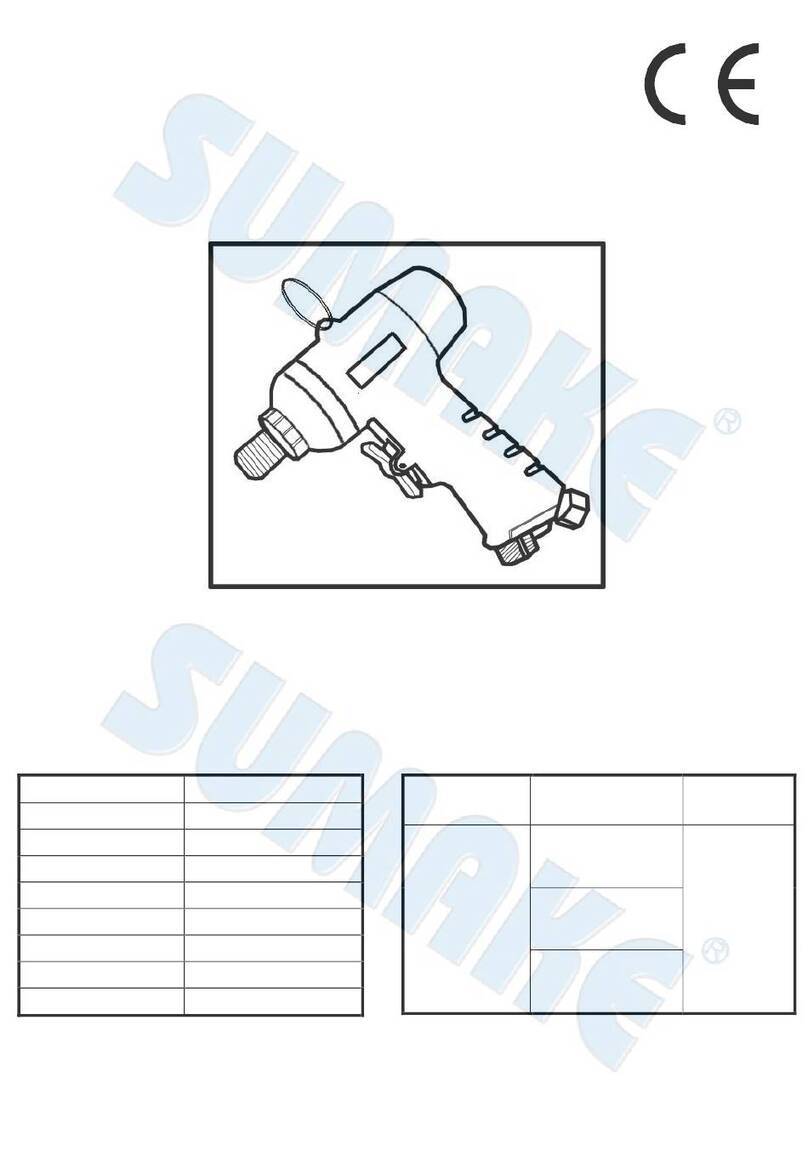

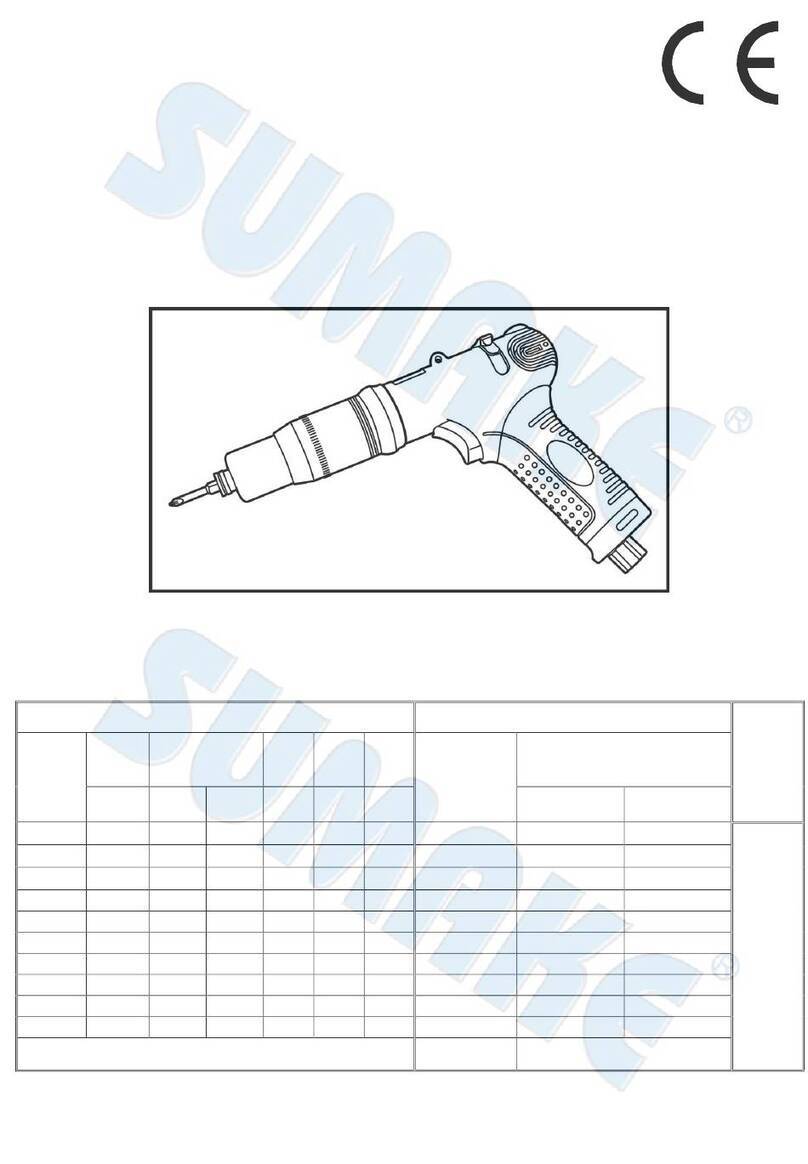

KBP075

PISTOL HANDLE AIR SHUT OFF COMPOSITE SCREWDRIVER

PARTS LIST

No. Parts No. Descri

tion Q't

No. Parts No. Descri

tion Q't

1 D5147-001 Tor

ue Cove

1 51 D5143-036 End Plate 1

2 D5147-002 Rear Housin

1 52 D5NR-20058 Pin 1

3 D5147-003 Housin

Ca

1 53 D5B-606T Ball Bearin

1

4 D5143-001 Rin

1 54 D5147-052 Valve Bod

1

5 D5143-002 Ball Retaine

1 55 D5143-039 S

rin

1

6 D5143-003 Washe

1 56 D5143-040 Washe

1

7 D5143-004 S

rin

1 57 D5143-042 Throttle Leve

1

8 D5147-008 Bushin

1 58 D5P-03150 O-Rin

1

9 D5147-009

Tor

ue Rin

1 59 D5143-044 Throttle Valve 1

10 D5P-311100 O-Rin

2 60 D5P-003 O-Rin

1

11 D5141-020 Pin 3 61 D5P-S009 O-Rin

2

12 D5147-012 Tor

ue Ad

ust 1 62 D5143-047 Valve Bush 1

13 D5147-014

nvil Bushin

1 63 D5143-048 S

rin

1

14 D5147-015 S

ace

1 64 D5NR-20208 Pin 1

15 D5147-016 Washe

1 65 D5143-049 Sto

e

1

16 D51432-057 Inlet Bushin

1 66 D5P-50100 O-Rin

2

17 D5H2-0505

Set Screw 2 67 D5H2-0303

Screw 2

18 D5SB-3-32 Ball 2 68 D5143-068 Cove

1

19 D5147-019

nvi 1 69 D5143-051 Reverse Valve 1

20 D5SB-004-01 Ball 2 70 D5SWI-025B S

rin

Washe

1

21 D51433-053 S

rin

1 71 D5H6-02512 Screw 1

22 D5141-047 Slide Base 1 72 D5143-054 Screw 1

23 D5141-037 Rin

2 73 D5P-40100 O-Rin

1

24 D5147-024 Ball Race 1 74 D5P-010 O-Rin

2

25 D5SB-002J Ball 64 75 D5143-056 Screw 1

26 D5147-026 End Clutch 1 76 D5147-073 O

eratin

Rod 1

27 D5147-027 Center Clutch 1 77 D5P-032 O-Rin

1

28 D5SB-004J Ball 2 78 D5147-075 Valve Plate 1

29 D5147-029 Rear Clutch 1 79 D5147-076 S

rin

1

30 D5147-030 Ball Race 1 80 D5P-12100 O-Rin

2

31 D5147-031 S

rin

2 81 D5143-060 Inlet Bushin

1

32 D5147-032 Poilt Pin 1 82 D5P-6 O-Rin

1

33 D5B-6001 Bearin

1 83 D5P-010

O-Rin

1

34 D5147-034 Front Housin

1 84 D5143-062 Screw 1

35 D5141-030 Internal Gea

1 85 D5143-041 Housin

1

36 D51425-034 Second Gear Ca

e 1 86 D5P-24150 O-Rin

1

37 D51433-038 Pin 4 87 D5143-067 Silence

1

38 D51433-037 Second Gea

4 88 D5143-064 Exhaust Diffuse

1

39 D51433-036 Transform Gea

1 89 D5143-063

ir Inlet 1

40 D51433-035 Second Gear Base 1 90 D5141-071 Screwdrive Head 1

41 D51421-030 Pin 4 91 D5141-072 Screwdrive Head 1

42 D51425-033

Second Gea

4 92 D5143-071 Rin

1

43 D5RTW-016 Retainin

Rin

1 93 D5L2-4.0MM Hex. Wrench 1

44 D5B-688 Bearin

1 94 D5141-065 Tor

ue Reaction Rin

1

45 D5147-044 Front End Plate 1 95 D55025-049

Clam

Rin

1

46 D5NR-20038 Pin 1 96 D55025-050

Clam

Rin

B1

47 D5143-034 C

linde

1 97 D5SPP-30120 S

rin

Pin 1

48 D5143-033 Blade 6 98 D5H1-0515 Head Ca

Screw 1

49 D51471-049 Roto

1 99 D5ARD12-042 Rubber Gasket 1

50 D5143-035 Pin 1 100 D5ARD12-041 Head Handle 1

KBP075-P-2205A-D5