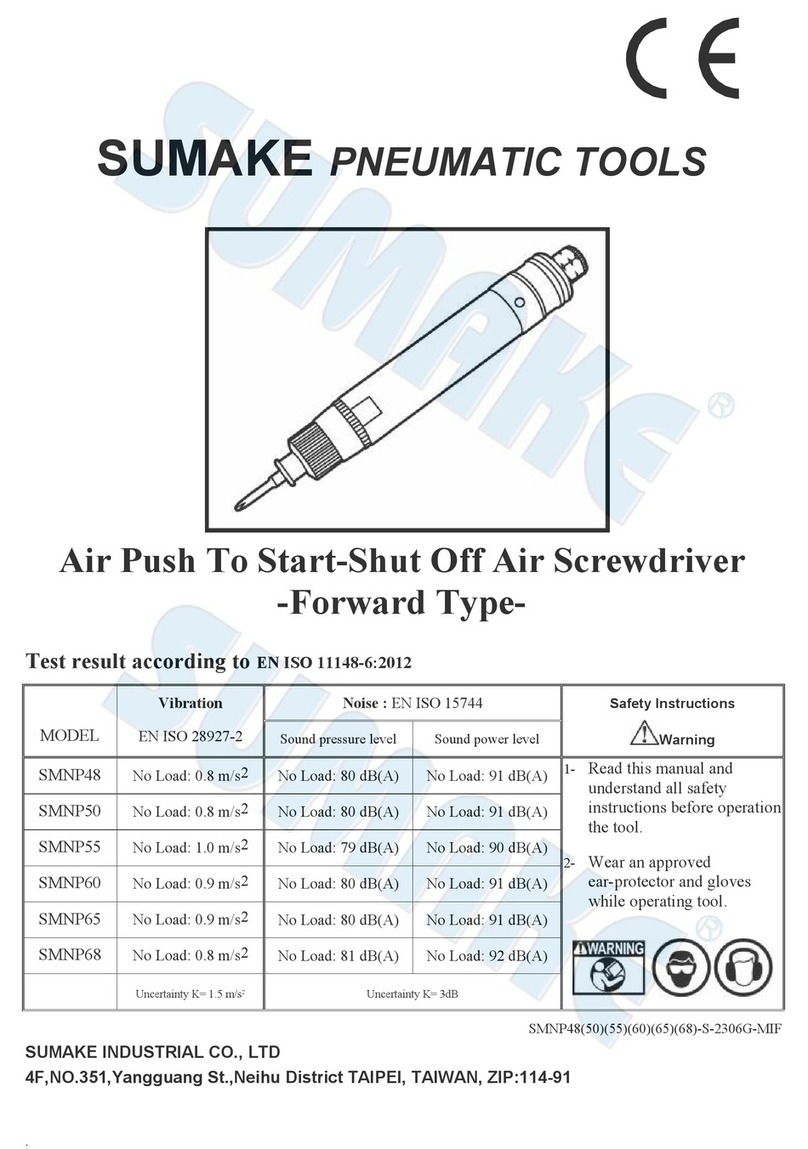

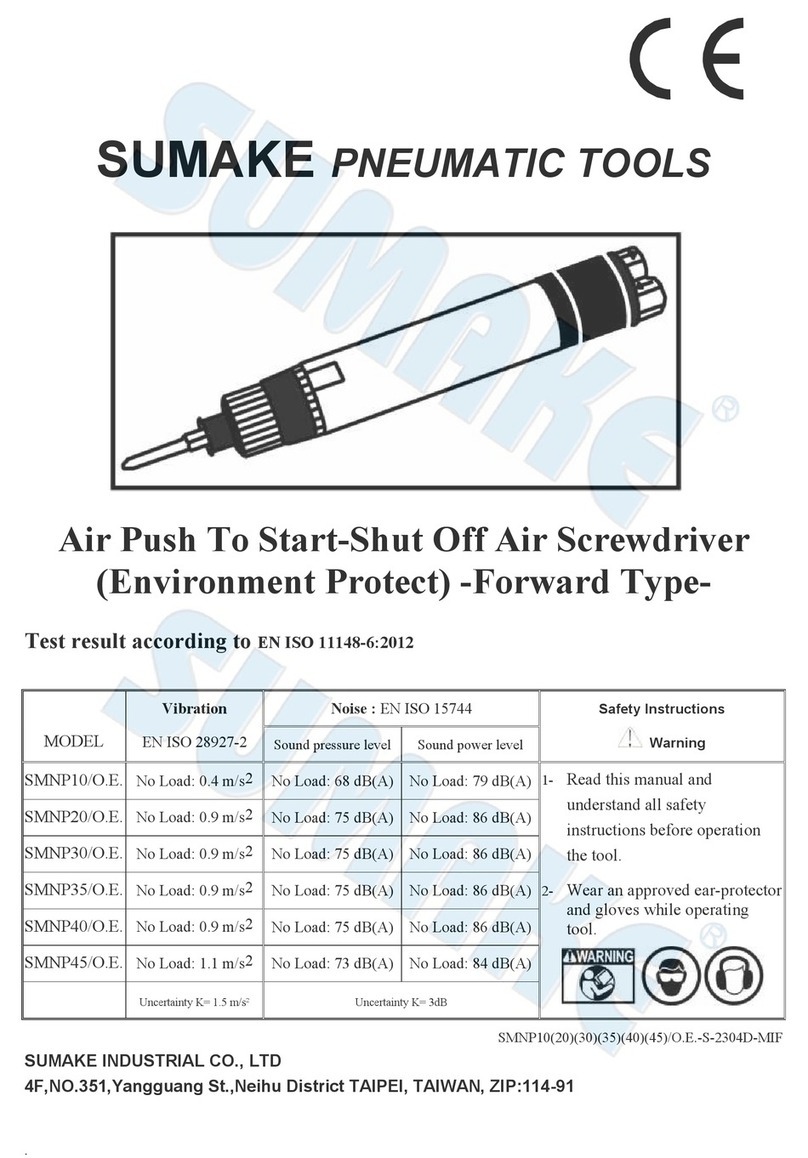

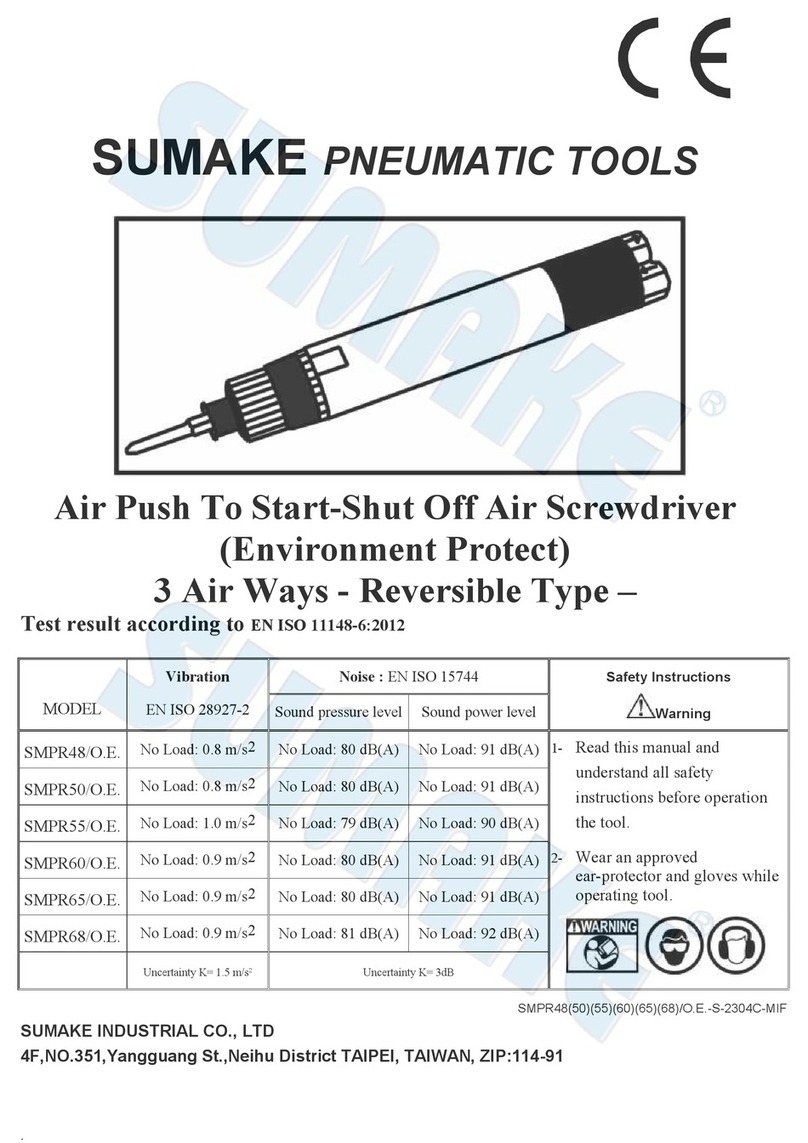

Air Nutrunner Motors Operator’s Manual

1

For safety use, Please Follow the instructions. The operation without your local regulations may cause serious injury. Read thoroughly and

understand this instruction manual and keep this within reach for future reference.

CLASSIFIED CAPACITY SPECIFICATIONS

Attention: If the nut runner will be attached heavier chuck or universal adaptor to anvil, the high-speed air nut runner might be shut off earlier. In

order to solve the problem, we would recommend to change adaptor material from steel to aluminum or change air nut runner to low-speed model.

Please use qualified 1/4” air plug to avoid air leakage or thread damaged problem. Before connect air hose, please be aware that there is no

abnormal stuff inside the hose.

OPERATIONS

1. To avoid the extra grease led to nut runner motor abnormal operation at low pressure condition, the new tool before usage please run the tool at air pressure

6kgs/cm to remove grease.

2. Please do not idle running the tool.

3. M5 Signal port fitting is used for transmission of 1) Start signal of tools, and 2) Stop signal of torque. The purpose is to record tightening screw numbers or

detect if the tightening task is correct.

4. Push to start type could increase torque precision and efficiency.

5. The nut runner shall stop operation automatically when setting torque is reached, the valve shall stop air supply and M5 signal port will create pressure stop

signal. After stop pressure finishing, the nut runner could be restarted to operate.

6. Torque adjustment is convenient; rotate torque adjustment ring to right direction is to increase torque and left side is to reduce torque.

7. Torque color ring design is convenient for nut runner torque management and identification.

8. Please clamp the nut runner at locking space in order to avoid motor operation disturbance.

9. There are two M5 screws inside anvil, outer is for fix purpose and inner one is to adjust nut runner shut off time. In case the operation is only shut off correctly

at first tightening work, please tighten inner M5 screw further. In case the nut runner cannot shut off correctly, please loose the inner M5 screw. After finishing

inner M5 screw adjustment task, please put back 2 pieces steel ball and then tighten outer M5 screw.

10. For O.E. type, incorrect direction of air inlet (black) and air exhaust (silver) might cause defective of nut runner motor.

AIR SUPPLY

1. Air tools are adversely affected by moisture. Since air from compressor contains much moisture and dust, it is desirable to provide a filter and lubricator in the

pipeline to remove such undesirable elements. Also take the drain out from air tank every day.

2. When using brand-new air hose or air pipe. Blow and clean the inside of air hose or pipe before installation.

3. Keep inside of air hose or air pipe clean to prevent airdrop problem caused by the lots of drain and dust accumulated and possibly make the inside diameter

smaller in the long use.

4. When disconnect air hose from air tool while in the operation do not drop air hose end to the floor as dust or other element may come into air hose.

5. Main air hose recommend pressure at 7.0kg/c m2 or 8.0kg/cm2. Use air regulator to keep stable air pressure at 5.5kg/cm2-6.0kg/cm2at the tool. It is important

to get proper air pressure at the tool for proper performance. Overloading air pressure might reduce the nut runner lifespan. Please select proper air hose per

specification information.

6. Equip air regulator to stable air pipe pressure and ensure accuracy (repetition accuracy) of the torque of the nut runner.

LUBRICATION

1. Lubrication is indispensable to air tolls. The most ideal maintenance is to install one lubricator to a tool for automatic oil feed, but if it is not available,

manual lubrication twice every day is recommended for longer life and keeping the efficient function of mechanism.

2. For manual lubrication, disconnect air hose and drop spindle oil(#30-#60) into the air feed inlet and then connect air hose for ideal running 2secs and then

finish lubrication maintenance. Every day once or twice maintenance could extend the tool lifespan.

SMNP61 O.E.-I-2208B-MI