Air Nutrunner Push to Start Shut-off Operator’s Manual

1

For safety use, Please Follow the instructions. The operation without your local regulations may cause serious injury. Read thoroughly and understand

this instruction manual and keep this within reach for future reference.

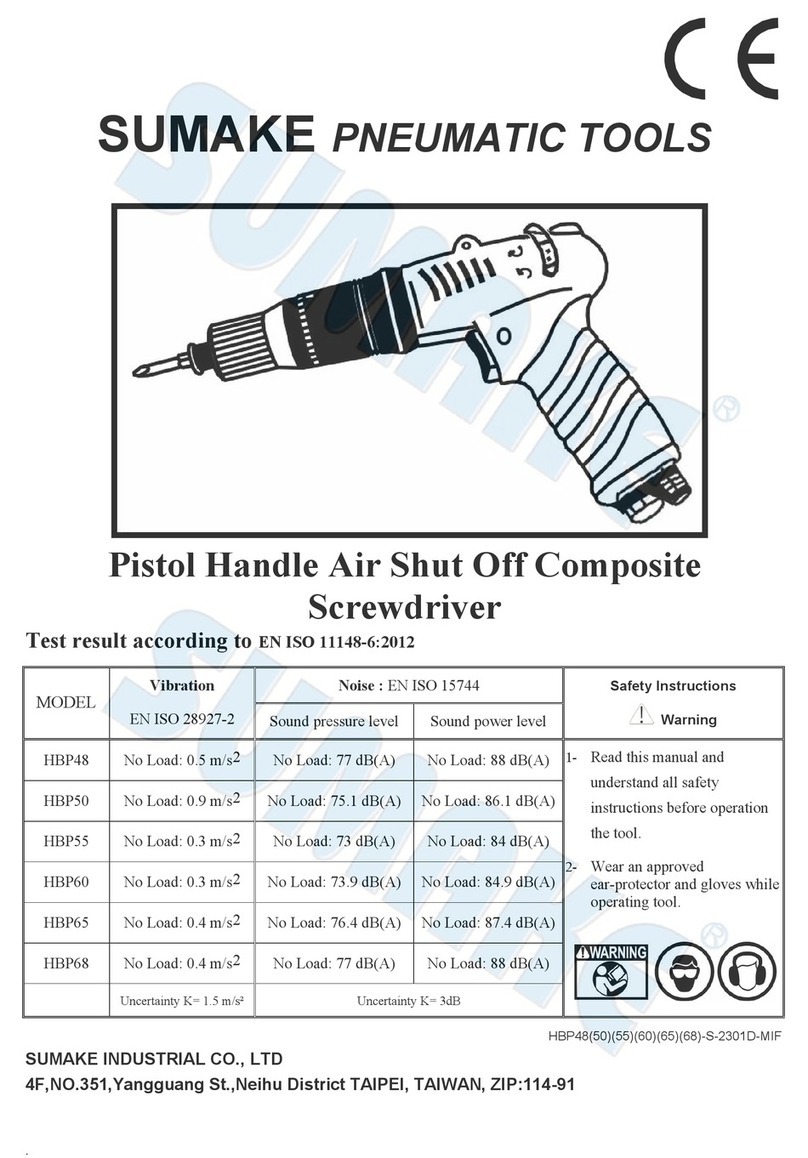

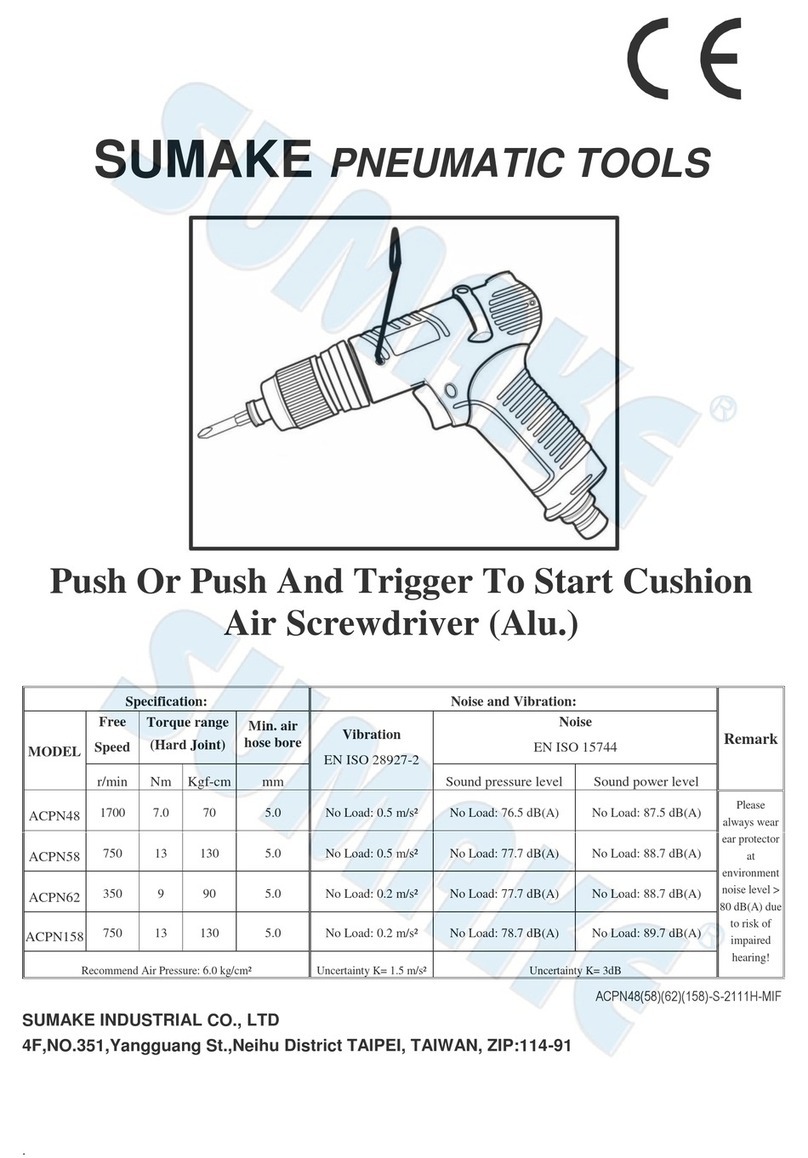

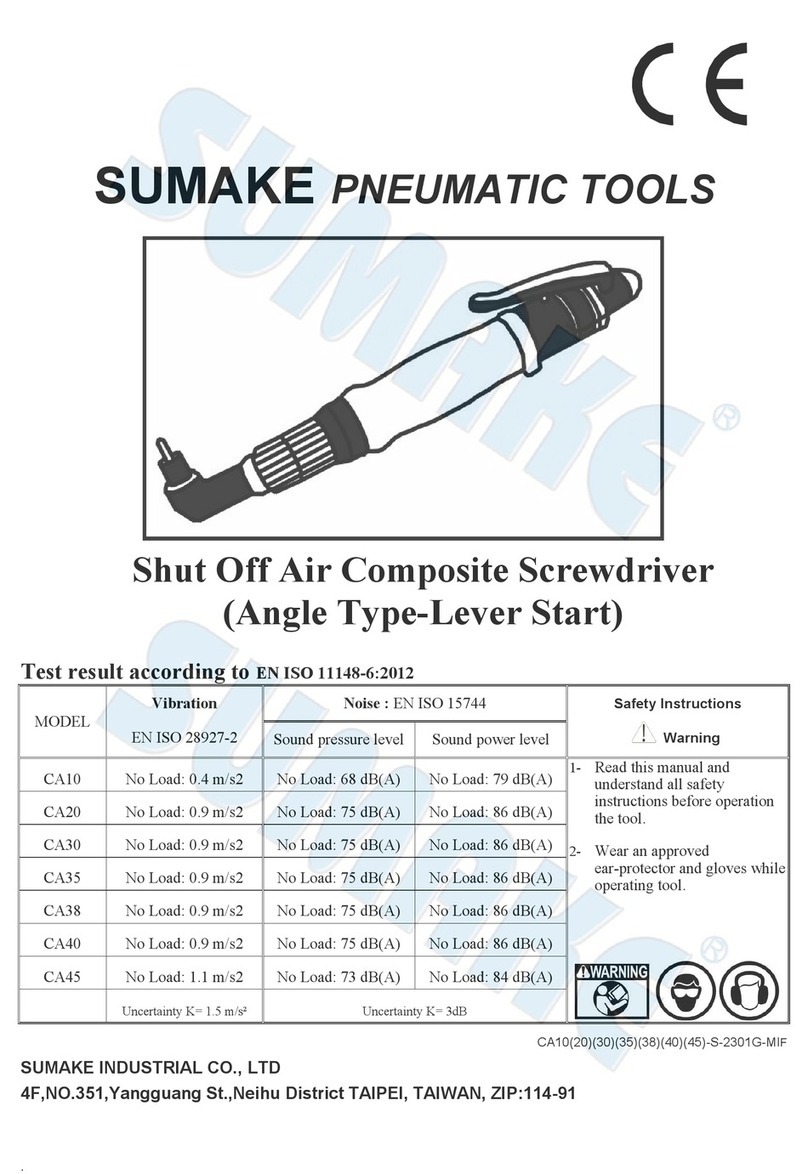

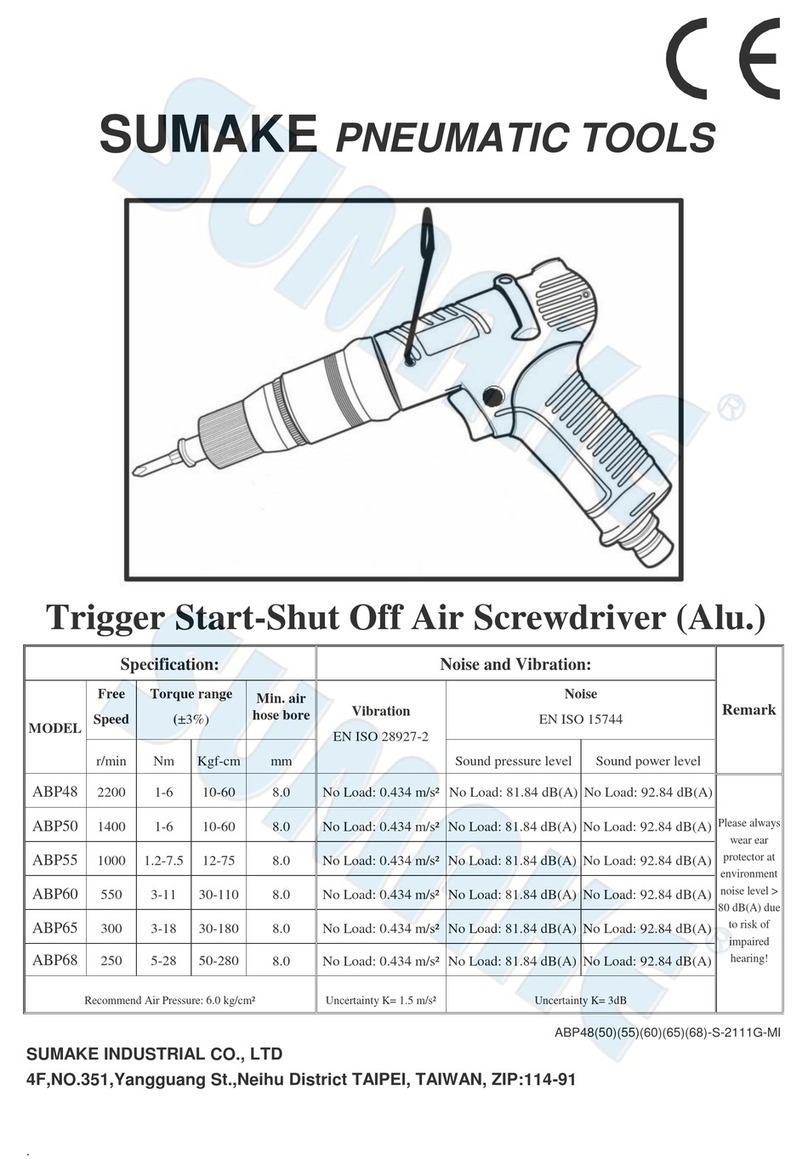

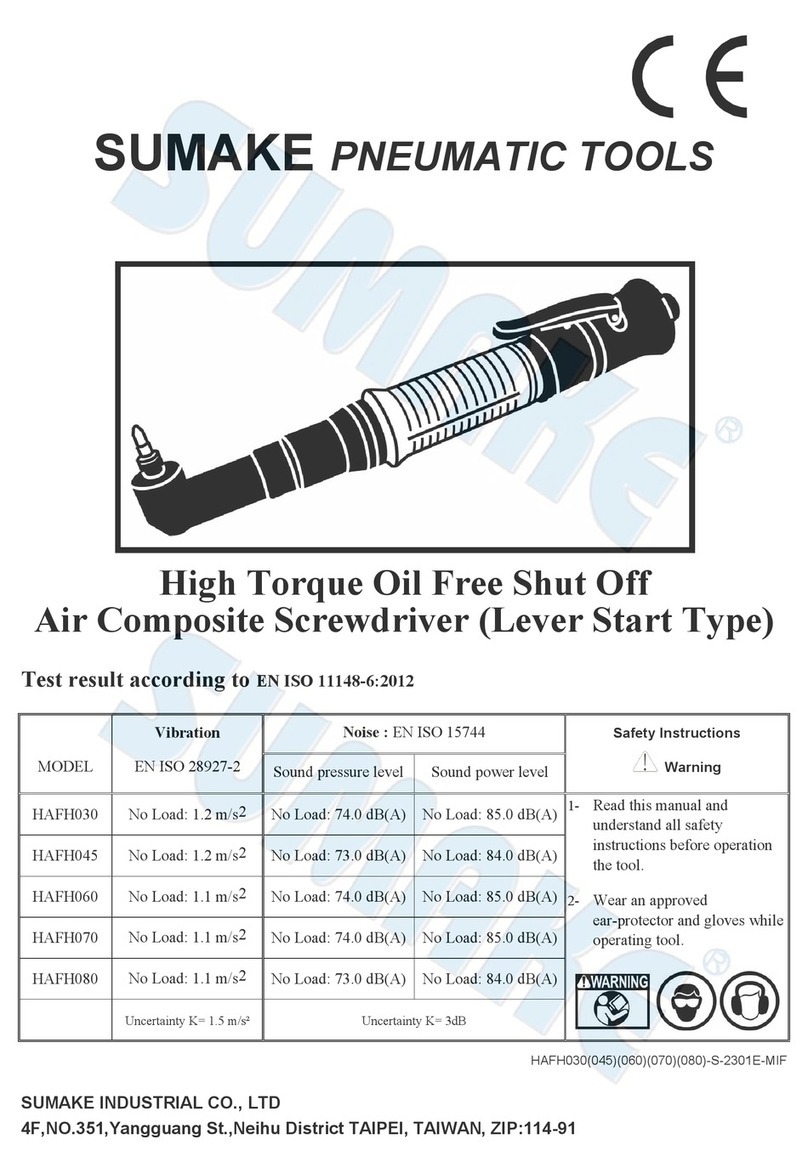

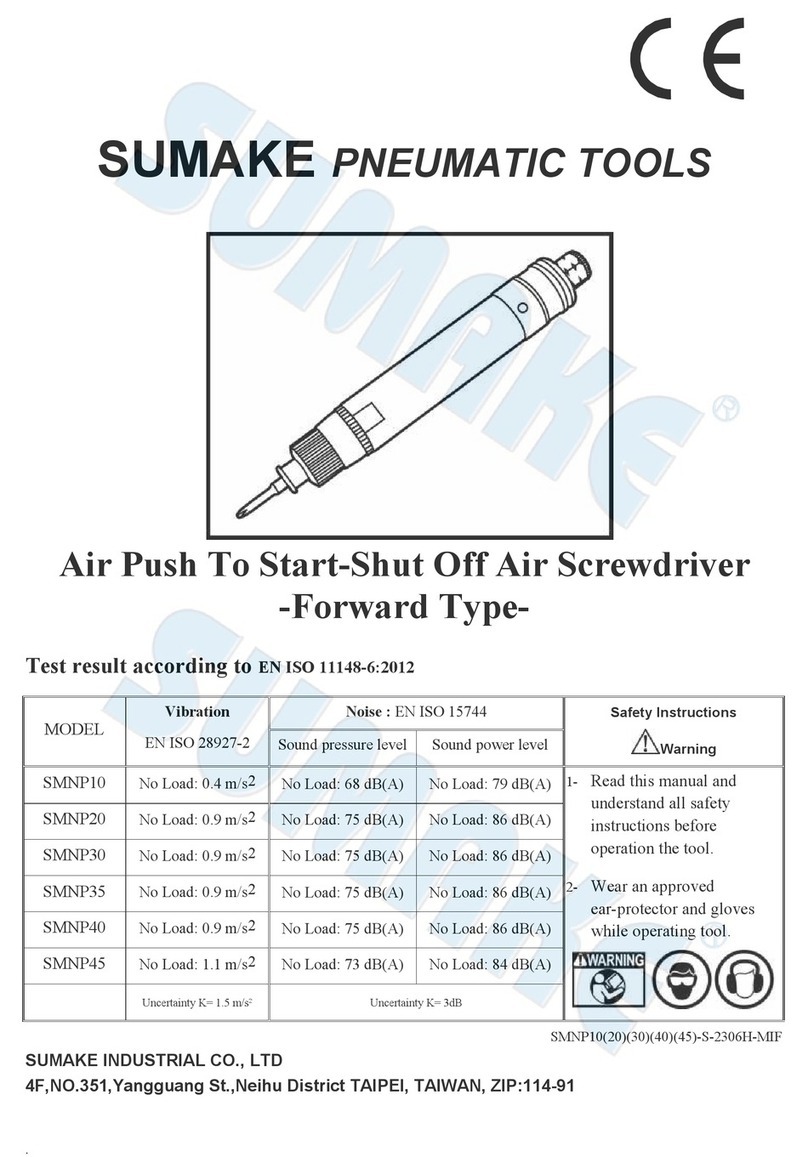

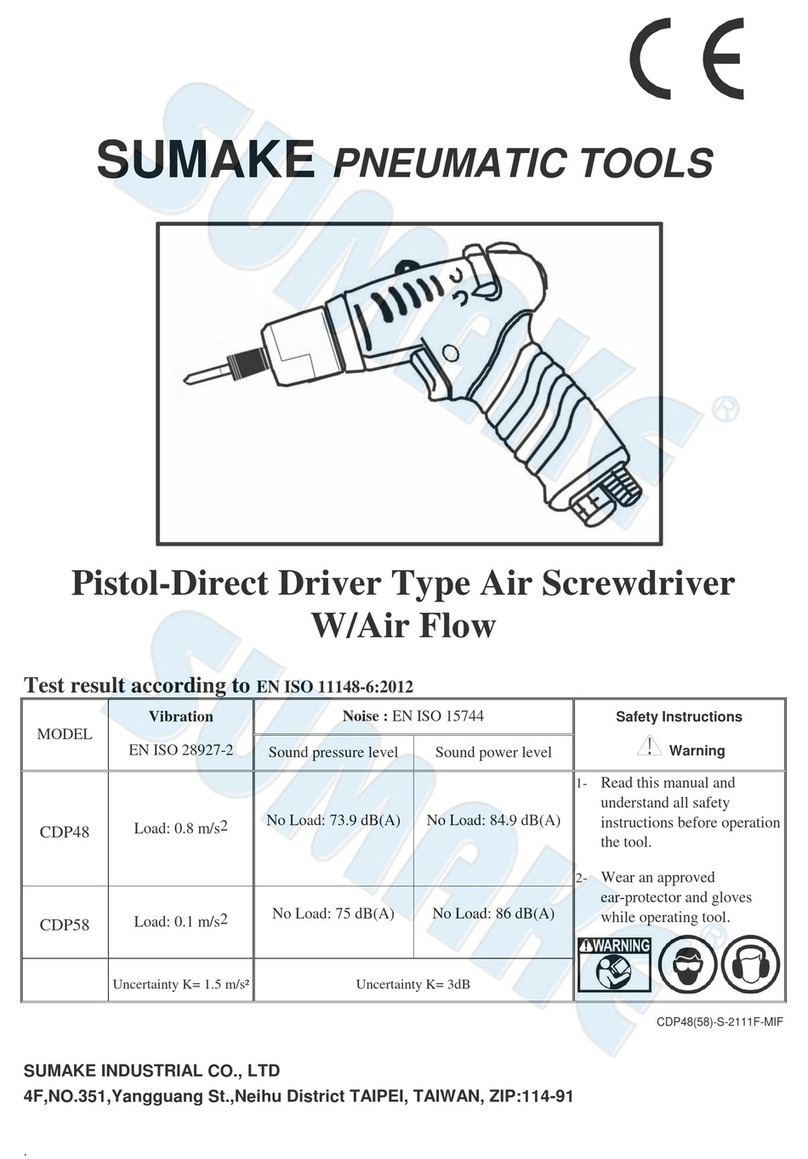

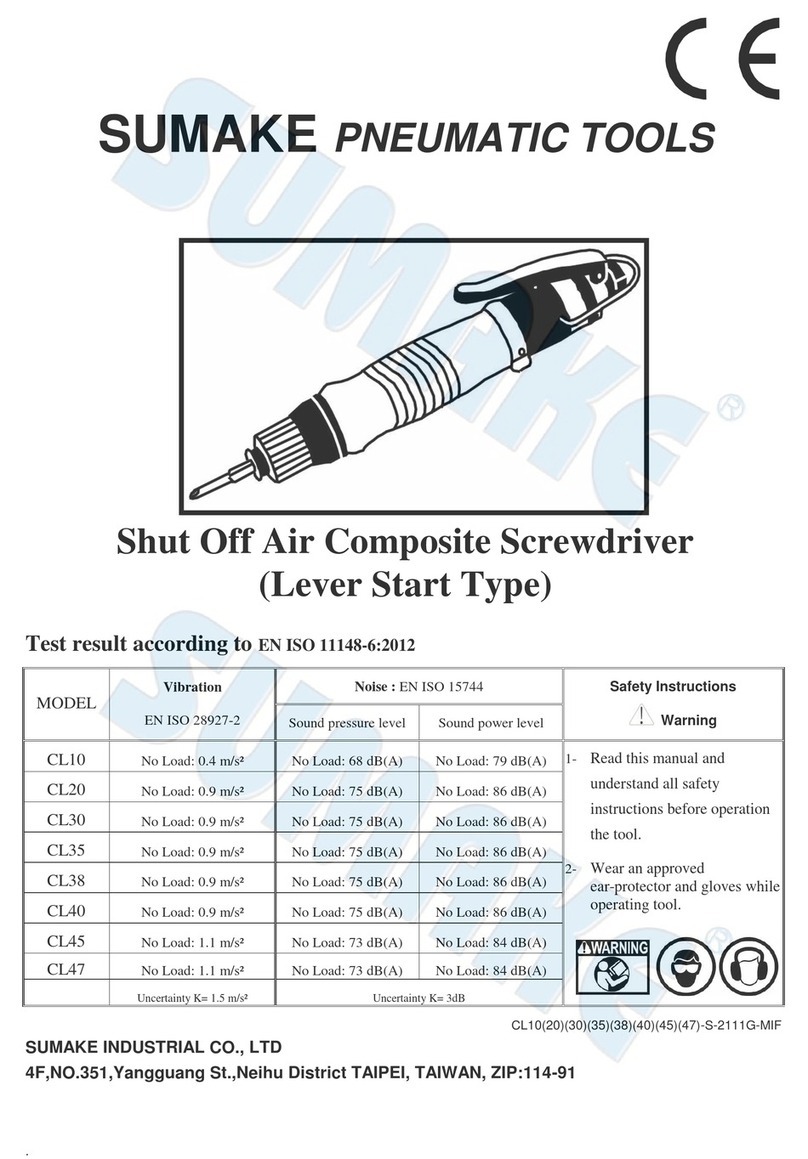

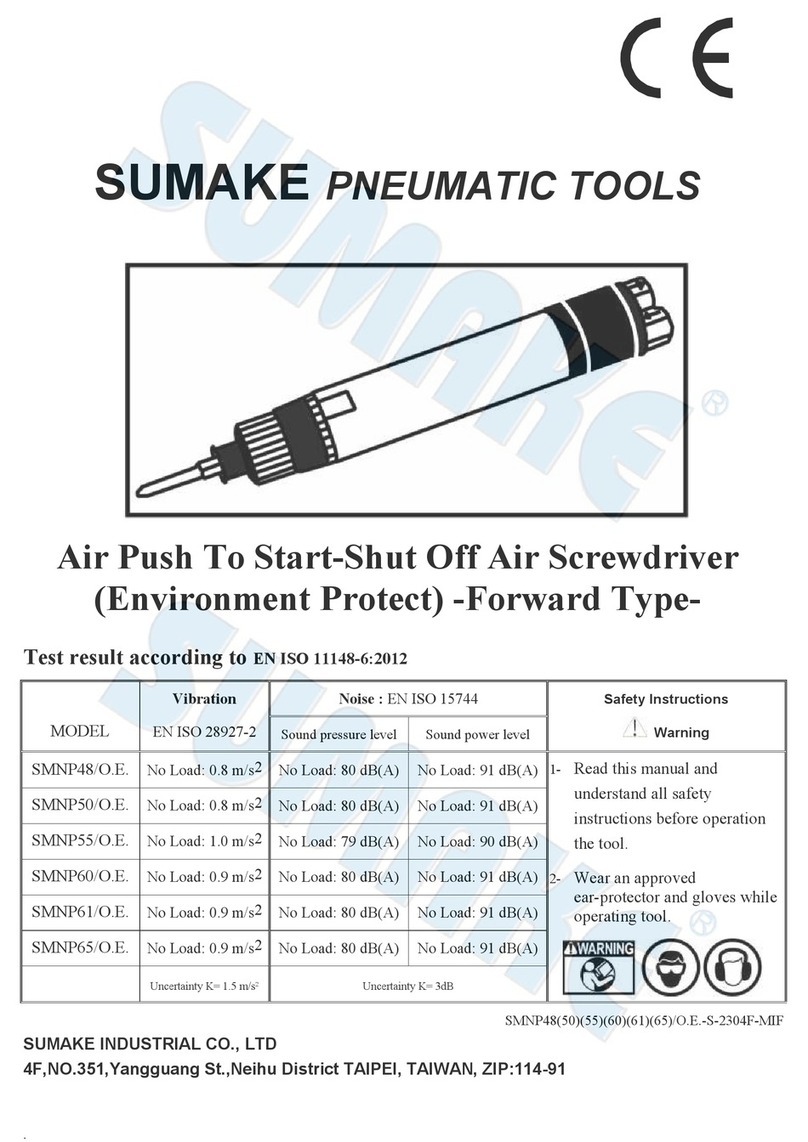

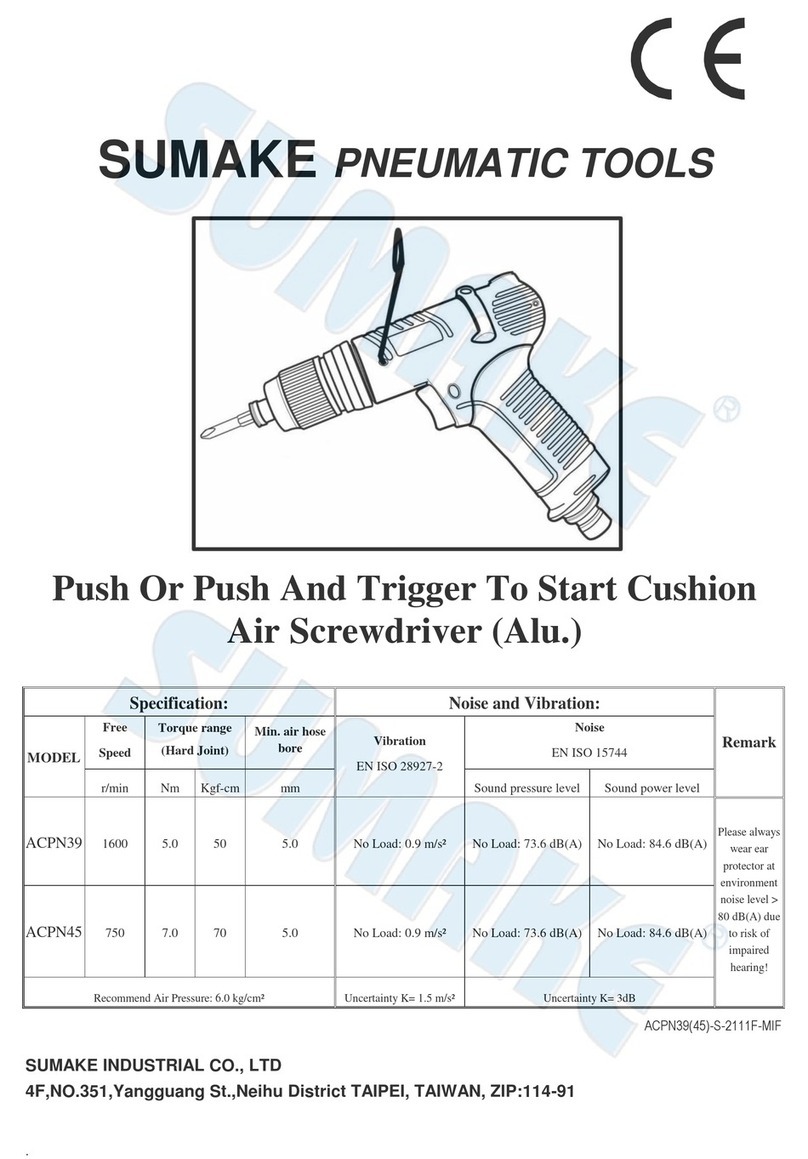

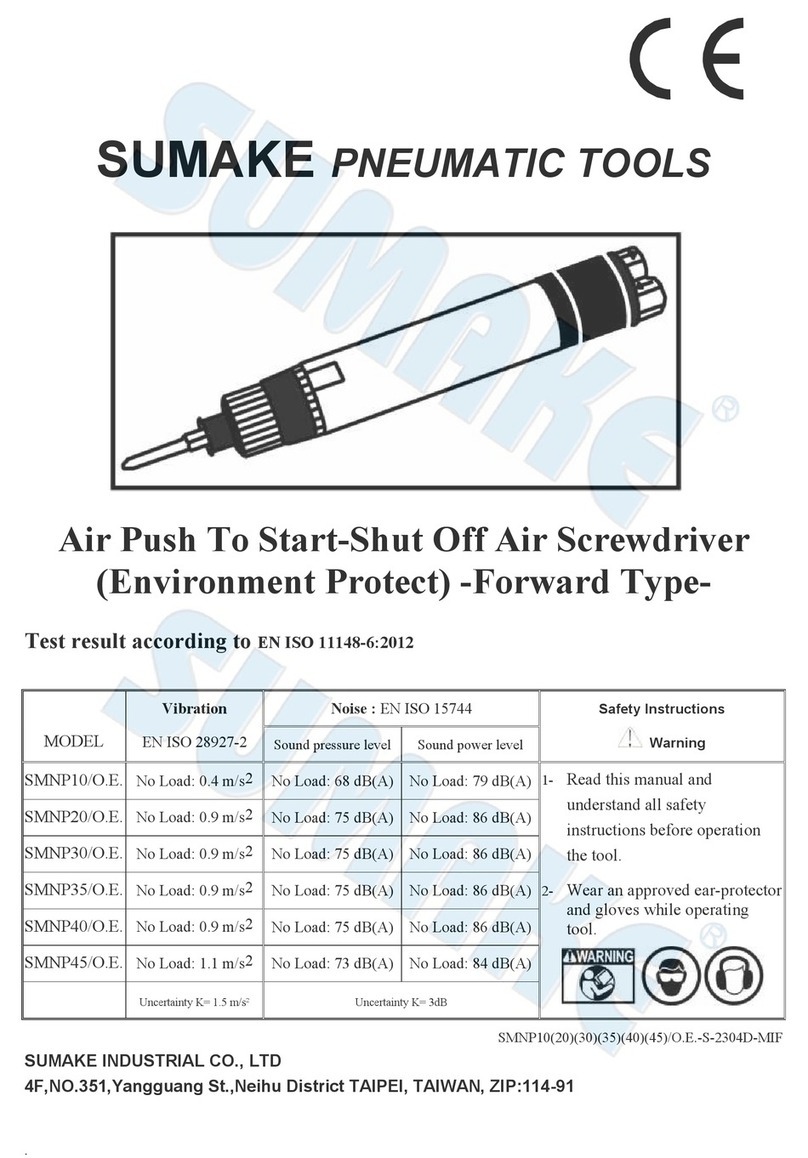

CLASSIFIED CAPACITY SPECIFICATIONS

OPERATIONS

1. Precision adjustment has been made around case, gear and rotating section

2. M5 Signal port fitting is used for transmission of 1)Start signal of tools, and 2)Stop signal of torque.

3. Air start means automatic stop at torque set value and air supply stop of M5 signal port fitting and motor. You must stop the air supply in

order to reset the Air nutrunner motors to the initial status, then Air nutrunner motors will restart when air supplied

4. Easy adjusting fastening torque by tightening or loosening nut torque indication.

5. Tighten to the right: increase torque. Loosen to the left: decrease torque

6. Air motor will automatically stop when the load reaches at the pre-set torque.

7. The color ring –for torque manages and identifies ………..Using site management.

8. To avoid defective of motor, please screw tight the tools at Locking space when fixing Air nutrunner motors.

9. Warning: In case O.E. type, Incorrect direction of air inlet(black) and air exhaust(silver) may causes defective of air nutrunner motors .

AIR SUPPLY

1. Air tools are adversely affected by moisture. Since air from compressor contains much moisture and dust, it is desirable to provide a

filter and lubricator in the pipeline to remove such undesirable elements. Also take the drain out from air tank every day.

2. When using brand-new air hose or air pipe. Blow and clean the inside of air hose or pipe before installation.

3. Keep inside of air hose or air pipe clean to prevent airdrop problem caused by the lots of drain and dust accumulated and possibly make

the inside diameter smaller in the long use.

4. When disconnect air hose from air tool while in the operation do not drop air hose end to the floor as dust or other element may come

into air hose.

5. Use air regulator to keep stable air pressure at 5.5kg/cm2-6.0kg/cm2 at the toll. It is important to get proper air pressure at the toll.

6. After lubrication, oil will discharged the exhaust upon operation. Flush motor for a few seconds.

LUBRICATION

1. Lubrication is indispensable to air tolls. The most ideal maintenance is to install one lubricator to a toll for automatic oil feed, but if it is not

available, manual lubrication twice every day is recommended for longer life and keeping the efficient function of mechanism.

2. For manual lubrication, disconnect air hose from bushing air inlet and full up spindle oil(#40-#60) into the air feed in take and push the bit.

SM(N)P10(20)(30)(40)(45)(48)(50)(55)(60)(65)(68)-I-2208D-MI