Copyright © 2011 Sumitomo Electric Industries, LTD.

SMF : G.652, G.657

MMF : MM50(OM2), MM50(OM3), MM50(OM4), MM62.5(OM1)

The Lynx-CustomFit® Splice-On Connector is designed and

manufactured to assure personal safety. Improper operation

can result in bodily injury and serious damage to this product.

Please read and observe all warnings instructions given in this

operation manual.

Wear safety glasses to protect your eyes when

handling optical fiber.

Never look into the end of a microscope or optical

cable connected to an optical output device that is

operating. Laser radiation is invisible, and direct

exposure can severely injure the human eye.

Alcohol is flammable, causes irritation and is harmful

if swallowed or inhaled. Keep alcohol away from

heat, sparks, skin, and avoid contact with eyes.

In the case of the work at the high place, please be

careful not to drop an assembling tool.

!

!

!

1. Improper assembly will result in a loss of performance.

Please read instructions given in this operation manual

and the operation manual of the fusion splicer.

2. Never touch the fiber of the stub. It has been inspected

in the factory.

3. The product is sensitive to dirt or dust. Do not take out

any parts from the package until it is to be used.

4. The characteristic will be influenced by the fiber

cleaved surface condition. Please use a cleaver which

has a good cleaving characteristic.

5. Do not remove the dust cap until the connector has

been completely assembled in order not to cause an

high insertion loss due to them.

For your safety operation

!

Precautions

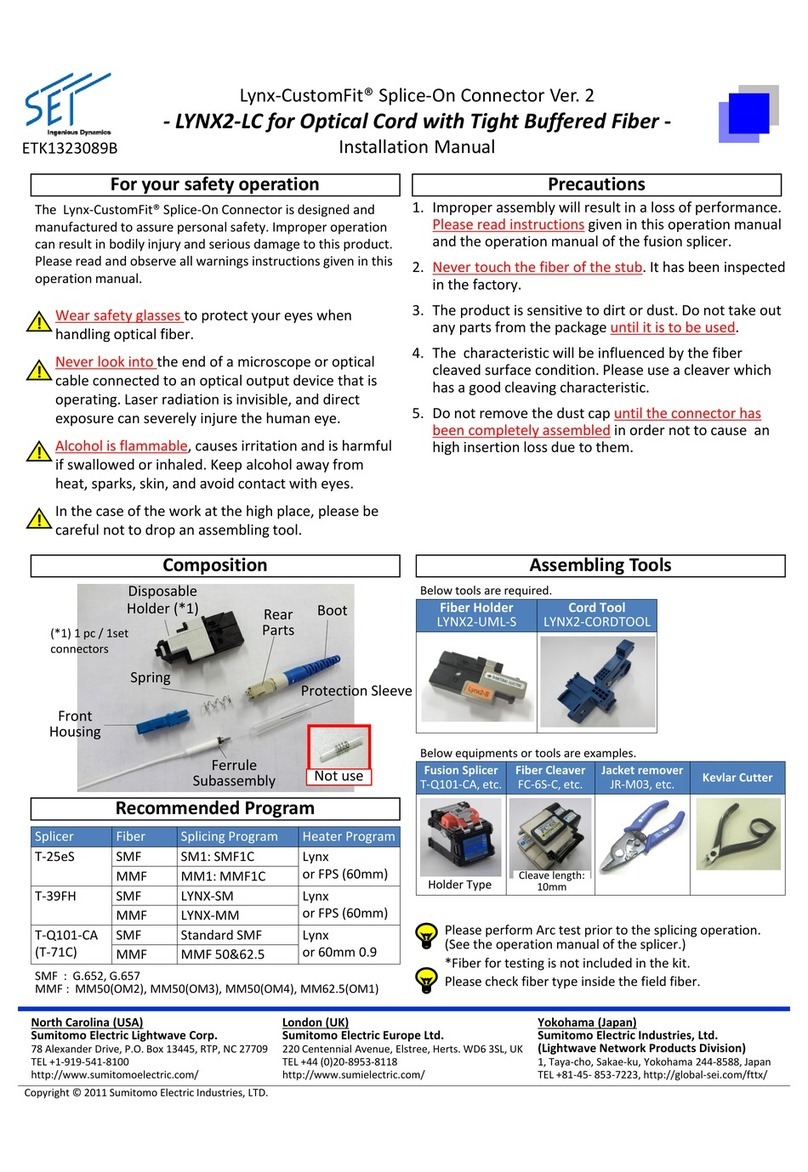

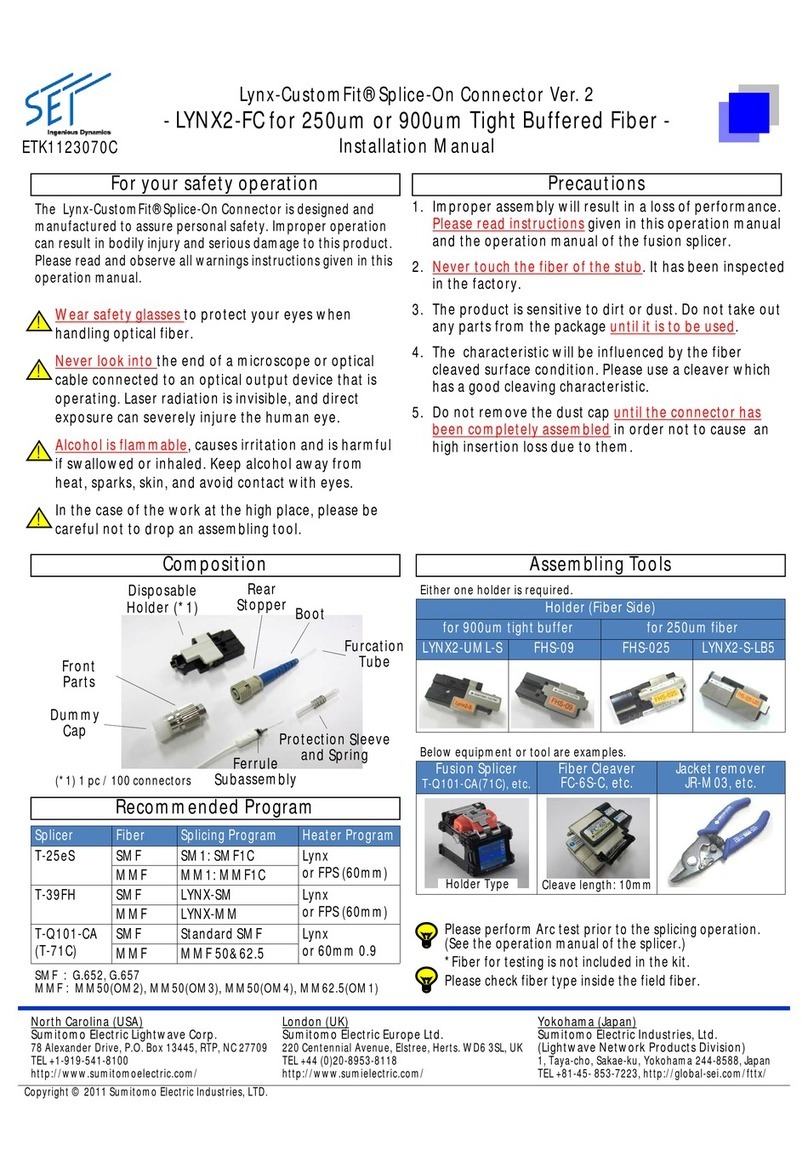

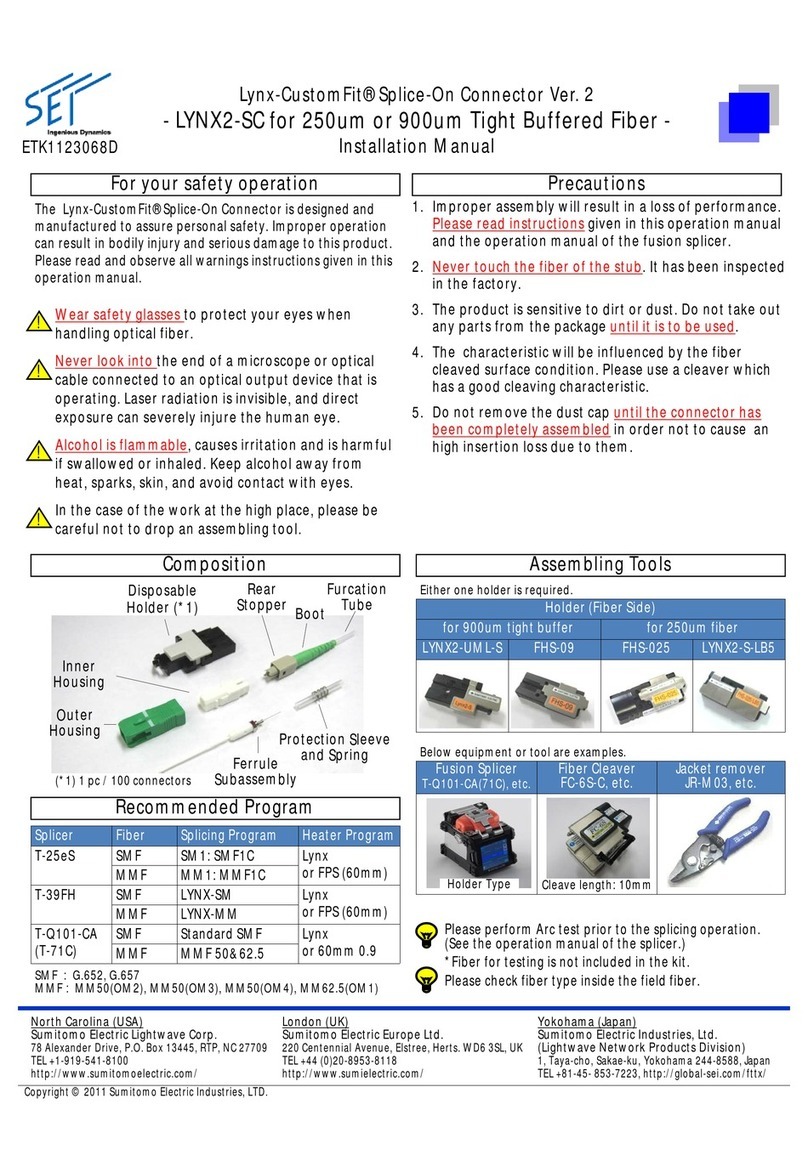

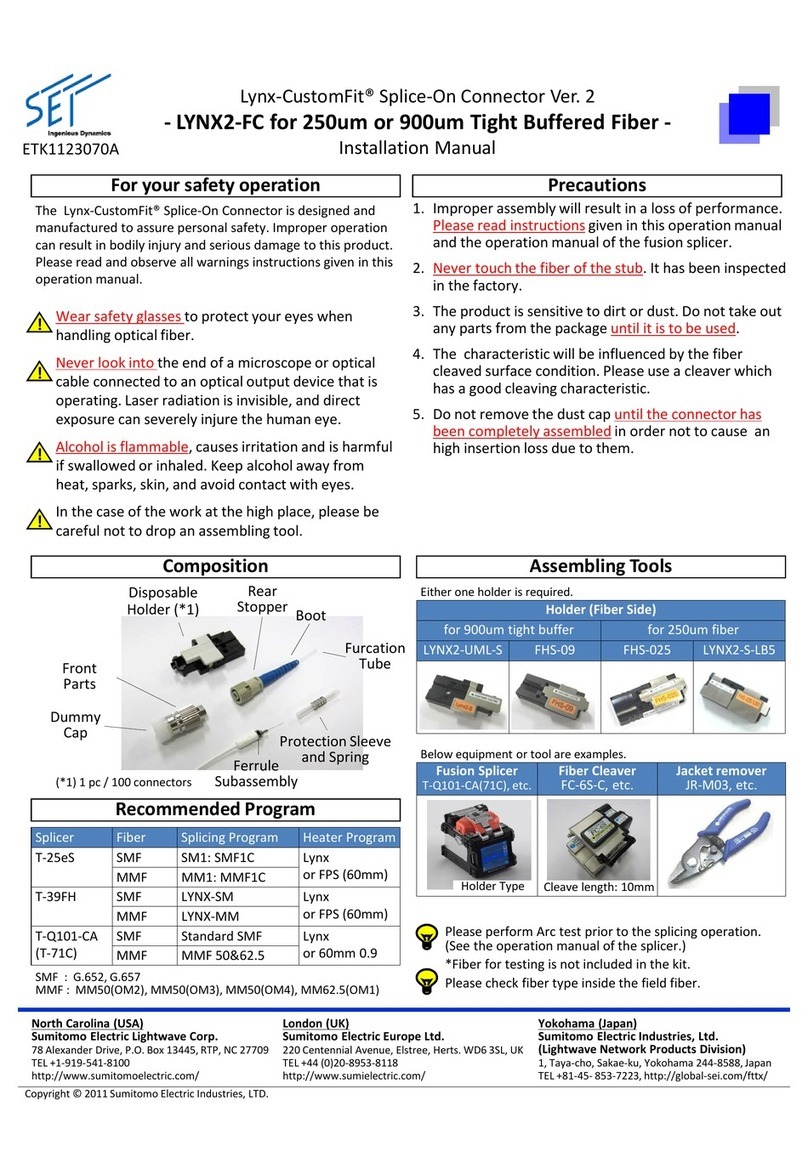

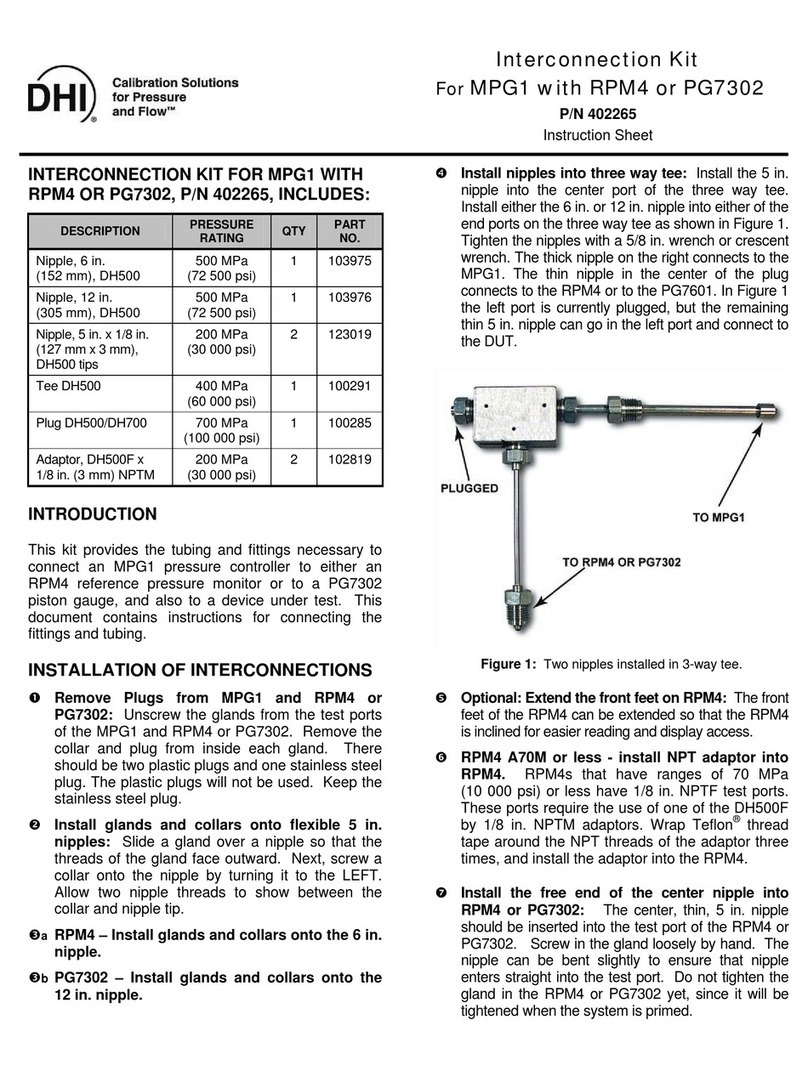

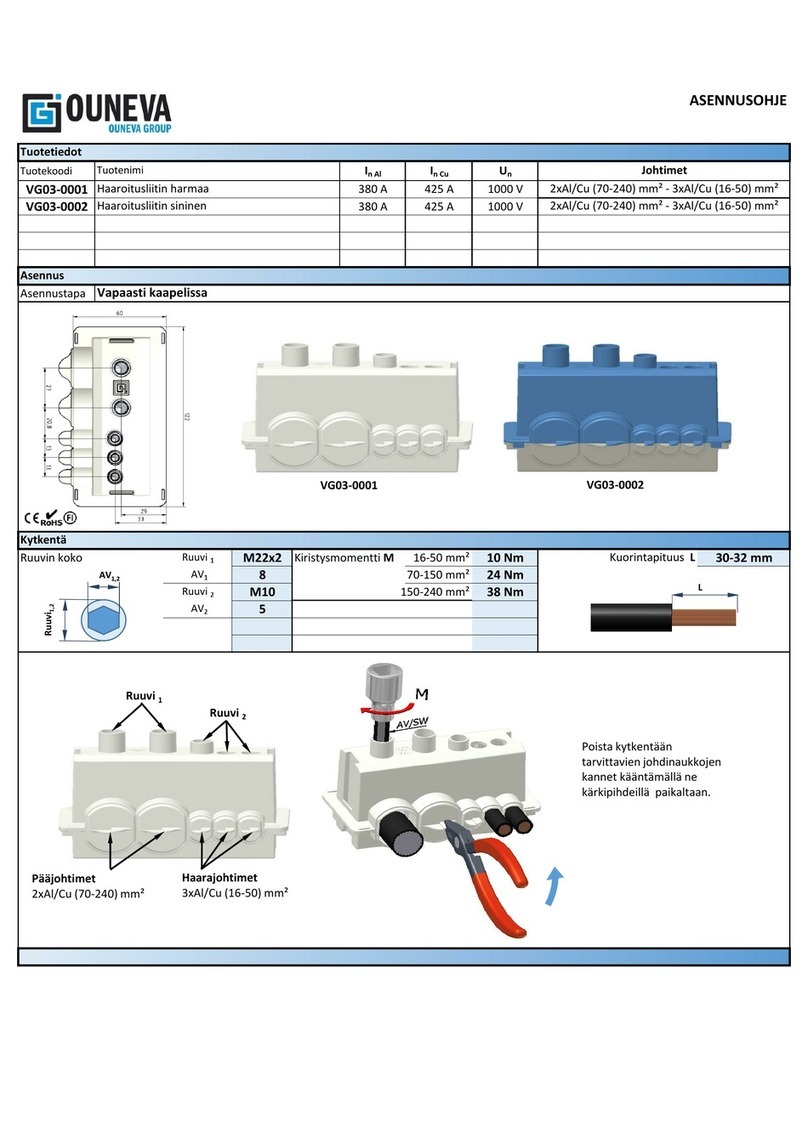

Composition Assembling Tools

Fusion Splicer

T-Q101-CA, etc.

Fiber Cleaver

FC-6S-C, etc.

Jacket remover

JR-M03, etc. Kevlar Cutter

Recommended Program

Splicer Fiber Splicing Program Heater Program

T-25eS SMF SM1: SMF1C Lynx

or FPS (60mm)

MMF MM1: MMF1C

T-39FH SMF LYNX-SM Lynx

or FPS (60mm)

MMF LYNX-MM

T-Q101-CA

(T-71C)

SMF Standard SMF Lynx

or 60mm 0.9

MMF MMF 50&62.5

Please perform Arc test prior to the splicing operation.

(See the operation manual of the splicer.)

*Fiber for testing is not included in the kit.

Please check fiber type inside the field fiber.

ETK1423002

Holder Type Cleave length:

10mm

Below equipments or tools are examples.

Disposable

Holder (*1)

Dummy

Cap

Front

Parts

Rear

Parts

Ferrule

Subassembly

Boot

Protection

Sleeve

Lynx-CustomFit® Splice-On Connector Ver. 2

- LYNX2-FC for Optical Cord with Tight Buffered Fiber -

Installation Manual

Fiber Holder

LYNX2-UML-S

Cord Tool

LYNX2-CORDTOOL

Below tools are required.

North Carolina (USA)

Sumitomo Electric Lightwave Corp.

78 Alexander Drive, P.O. Box 13445, RTP, NC 27709

TEL +1-919-541-8100

http://www.sumitomoelectric.com/

Yokohama (Japan)

Sumitomo Electric Industries, Ltd.

(Lightwave Network Products Division)

1, Taya-cho, Sakae-ku, Yokohama 244-8588, Japan

TEL +81-45- 853-7223, http://global-sei.com/fttx/

London (UK)

Sumitomo Electric Europe Ltd.

220 Centennial Avenue, Elstree, Herts. WD6 3SL, UK

TEL +44 (0)20-8953-8118

http://www.sumielectric.com/

(*1) 1 pc / 1set

connectors

Not use

Spring