9001A: Parts Breakdown & Operating Manual 2 rev. 04/29/06

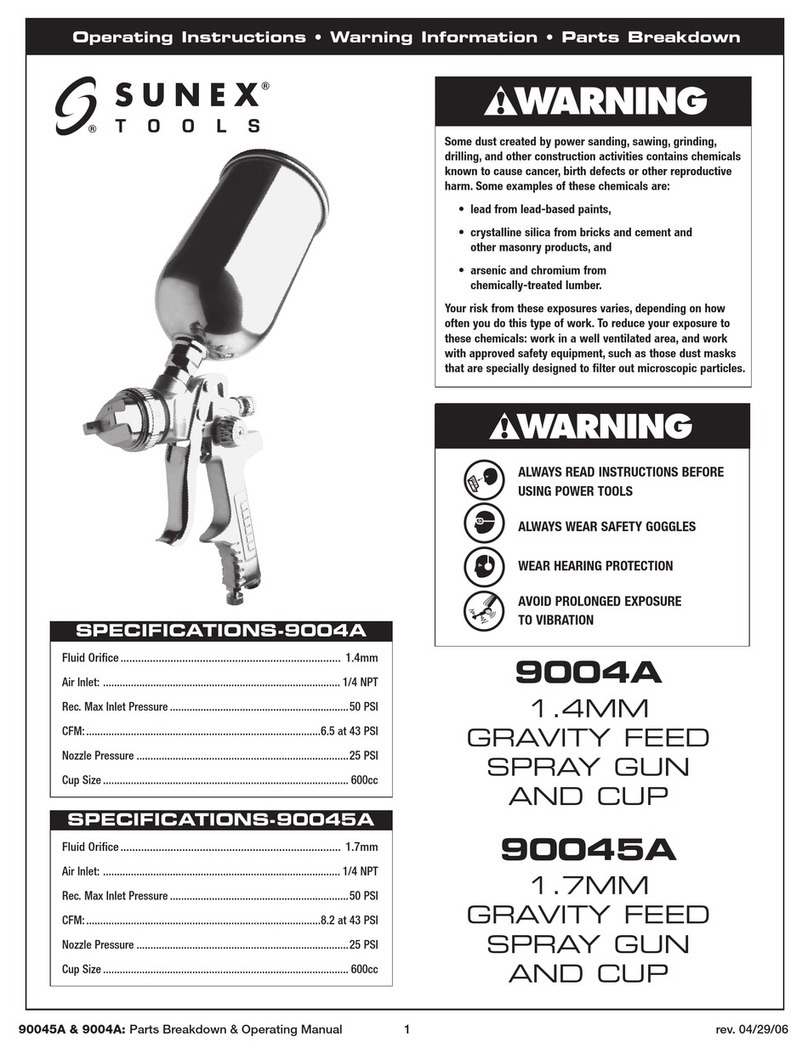

• During cleaning and flushing, solvents can be

forcefully expelled from fluid and air passages.

Some solvents can cause eye injury.

• Be sure all in the area are wearing

impact-resistant eye and face protection.

• Even small projectiles can injure eyes and

cause blindness.

• Air under pressure can cause severe injury.

Always shut off air supply, drain hose of air

pressure and disconnect tool from air supply

when not in use, before changing accessories or

when making repairs. Never direct air at

yourself or anyone else. Whipping hoses can

cause serious injury. Always check for damaged

or loose hoses and fittings. Never use quick

change couplings at tool. They add weight and

could fail due to vibration. Instead, add a hose

whip and connect coupling between air supply

and hose whip, or between hose whip and

leader hose. Do not exceed maximum air inlet

pressure of 43 PSI.

• Always use tool a safe distance from other

people in work area.

• Maintain tools with care. Keep tools clean and

oiled for best and safest performance. Follow

instructions for lubricating and changing

accessories. Wiping or cleaning rags and other

flammable waste materials must be placed in a

tightly closed metal container and disposed of

later in the proper fashion.

• Do not wear loose or ill-fitting clothing; remove

watches and rings.

• Do not over reach. Keep proper footing and

balance at all times. Slipping, tripping and

falling can be a major cause of serious injury

or death. Be aware of excess hose left on the

walking or work surface.

• Do not force tool. It will do the job better and

safer at the rate for which it was designed.

• Do not abuse hoses or connectors. Never

carry tool by the hose or yank hose to

disconnect from air supply. Keep hoses from

heat, oil and sharp edges. Check hoses for weak

or worn condition before each use, making

certain that all connections are secure.

• High sound levels can cause permanent

hearing loss. Protect yourself from noise.

Noise levels vary with work surface.

Wear ear protection.

• When possible, secure work with clamps or

vise so both hands are free to operate tool.

• Repetitive work motions, awkward positions

and exposure to vibration can be harmful to

hands and arms.

• Avoid inhaling dust or handling debris from

work processes which can be harmful to your

health.

• Operators and maintenance personnel must be

physically able to handle the bulk, weight and

power of this tool.

• This tool is not intended for using in explosive

atmospheres and is not insulated for contact

with electric power sources.

• Solvent and coatings can be highly flammable or

combustible especially when sprayed. Adequate

exhaust must be provided to keep air free of

accumulations of flammable vapors.

• Smoking must never be allowed in the

spray area.

• Fire extinguishing equipment must be present in

the spray area.

• Never spray near sources of ignition such as pilot

lights, welders, etc.

• Halogenated hydrocarbon solvents — for

example, methylene chloride — are not

chemically compatible with the aluminum

that might be used in many system components.

The chemical reaction caused by these

solvents reacting with aluminum can become

violent and lead to an equipment explosion.

Guns with stainless steel fluid passages may

be used with these solvents. However,

aluminum is widely used in other spray

application equipment - such as material pumps,

cups and regulators, valves, etc. Check all other

equipment items before use and make sure they

can also be used safely with these solvents.

Read the label or data sheet for the material

you intend to spray. If in doubt as to whether or

not a coating or cleaning material is compatible,

contact your material supplier.

• Sprayed materials may be harmful if inhaled, or

if there is contact with the skin. Adequate

exhaust must be provided to keep the air free

of accumulations of toxic materials. Use a mask

or respirator whenever there is a chance of

inhaling sprayed materials. The mask must be

compatible with the material being sprayed and

its concentration.

- FOLLOW THESE RULES FOR SAFE OPERATION!