I

CCoonntteennttss

1 About this Manual ....................................................................................... 1

1.1 Intended Use................................................................................................ 1

1.2 Target Group................................................................................................ 1

1.3 How to Use This Manual............................................................................... 1

1.4 Symbol Explanation...................................................................................... 1

2 Function Description .................................................................................. 3

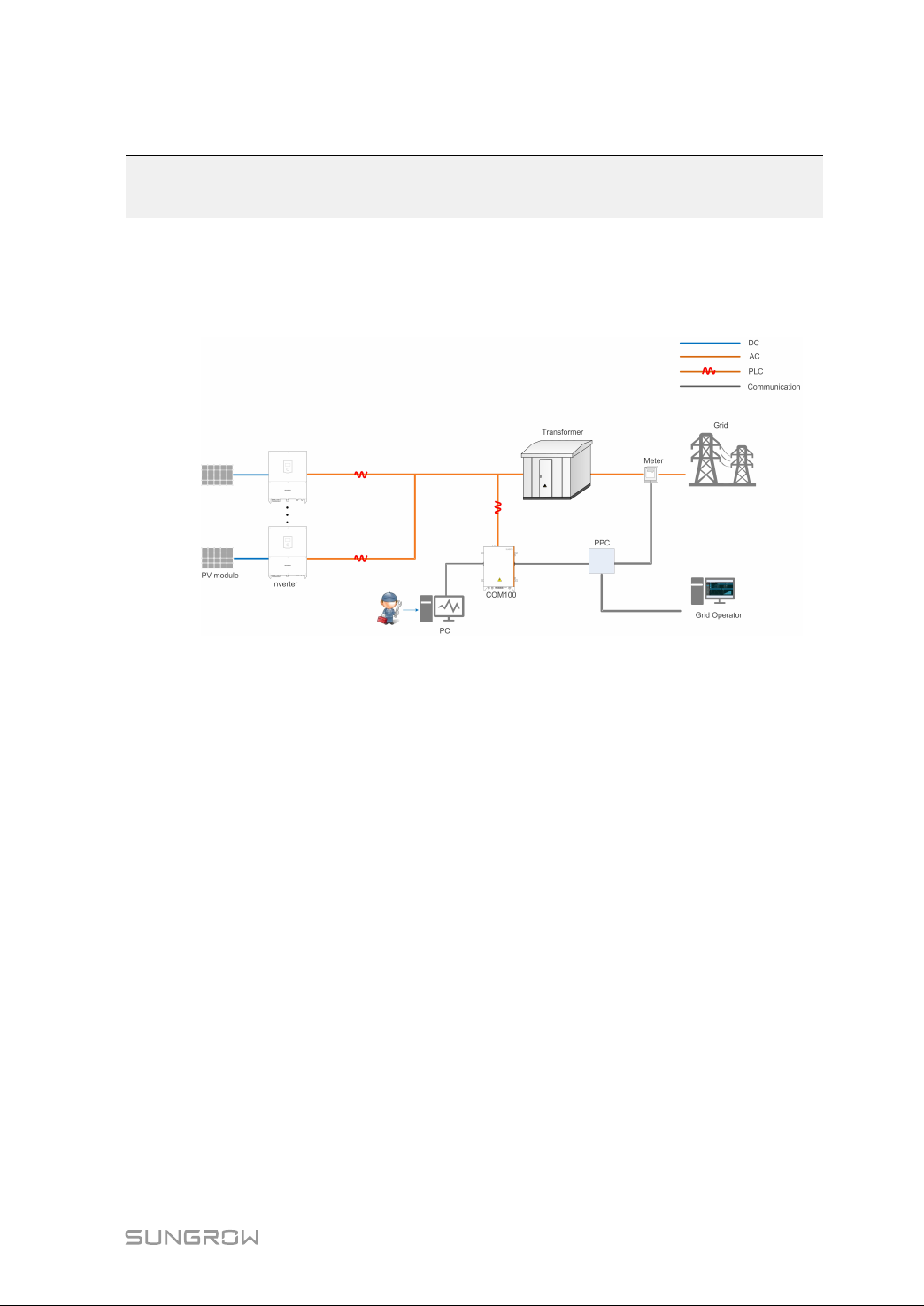

2.1 Function Introduction ................................................................................... 3

2.2 Main Features.............................................................................................. 3

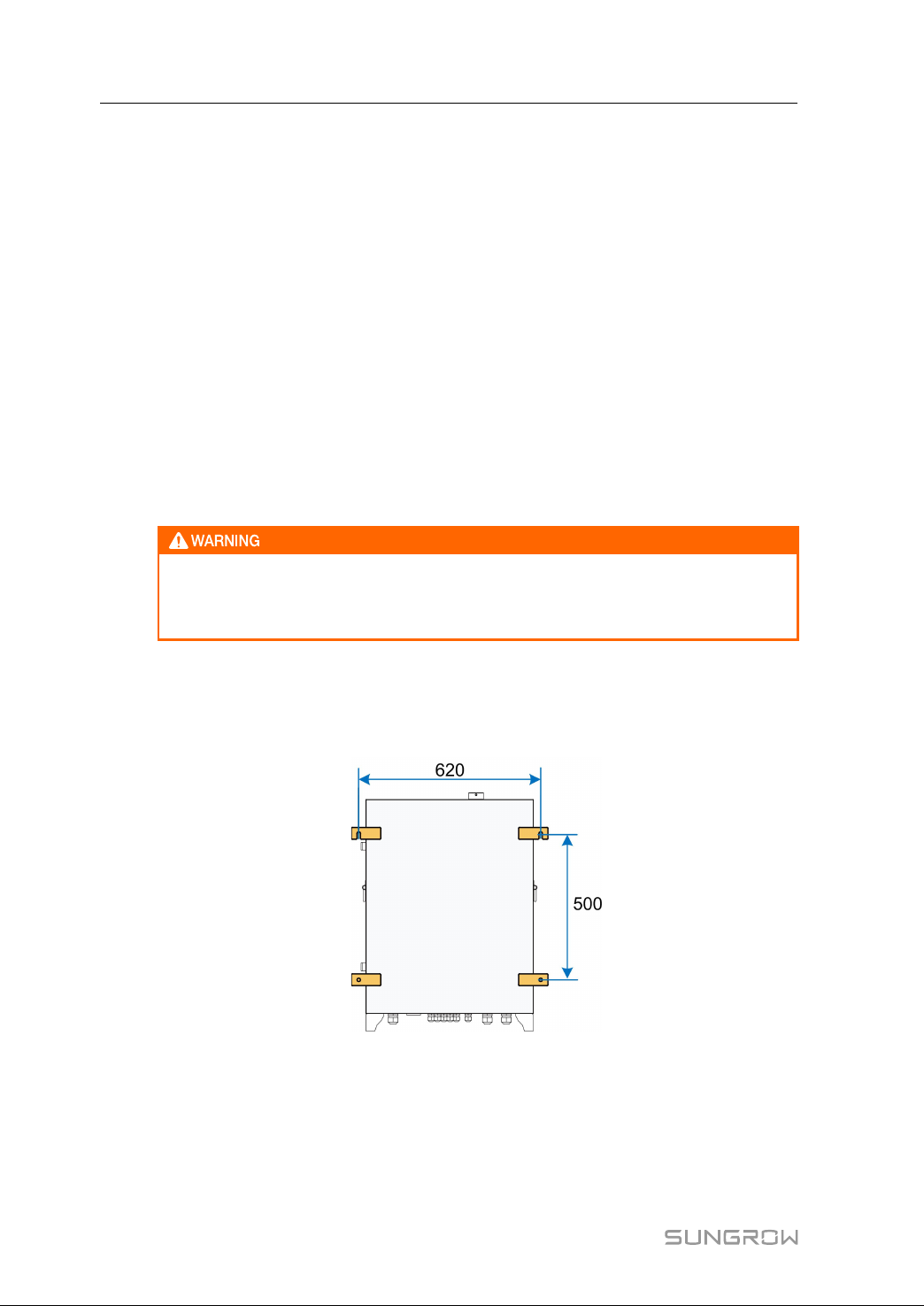

2.3 Dimensions.................................................................................................. 3

3 Mechanical Installation .............................................................................. 5

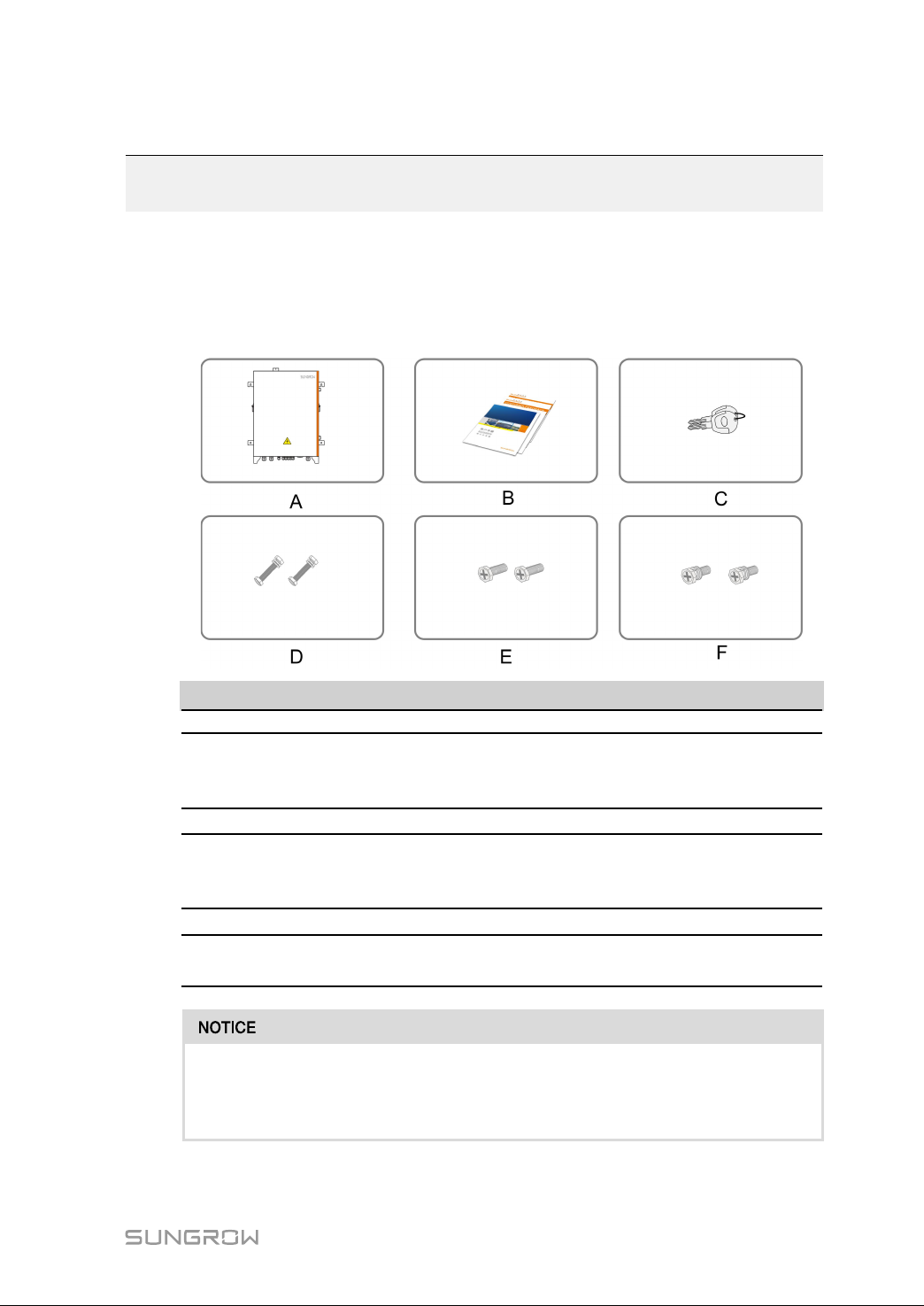

3.1 Inspection before Installation ........................................................................ 5

3.2 Location Requirements ................................................................................ 6

3.3 Installation Method....................................................................................... 6

3.3.1 Wall Mounting .................................................................................... 6

3.3.2 Ground Mounting ............................................................................... 7

3.3.3 Pole Mounting (optional)..................................................................... 8

4 Electrical Connection ............................................................................... 10

4.1 Waterproof Terminal Description ................................................................ 10

4.2 Internal Structure........................................................................................ 10

4.3 Preparation Before Connection................................................................... 12

4.4 Electrical Connection Steps........................................................................ 13

4.4.1 Grounding ........................................................................................ 13

4.4.2 RS485 Communication Terminal Connection .................................... 15

4.4.3 Optical Fibre (Optional) ..................................................................... 16

4.4.4 AC 220V Connection ........................................................................ 16

4.4.5 PLC Port Connection ........................................................................ 17

4.5 Communication Methods ........................................................................... 21

5 Commissioning ........................................................................................... 22

5.1 Inspection before Commissioning............................................................... 22

5.2 Commissioning Steps................................................................................. 22