Index

1. INTRODUCTION ......................................................................................................................................... 4

2. SAFETY ...................................................................................................................................................... 5

2.1.

T

RANSPORTATION

.......................................................................................................................................... 5

2.2.

I

NSTALLATION

L

OCATION

................................................................................................................................. 5

2.3.

S

TORAGE

..................................................................................................................................................... 5

2.4.

G

ENERAL

S

AFETY

........................................................................................................................................... 5

2.5.

H

ANDLING

................................................................................................................................................... 6

2.6.

D

AMAGED

B

ATTERY

....................................................................................................................................... 6

2.7.

F

IRE

............................................................................................................................................................ 6

2.8.

Q

UALIFIED

P

ERSONNEL

................................................................................................................................... 6

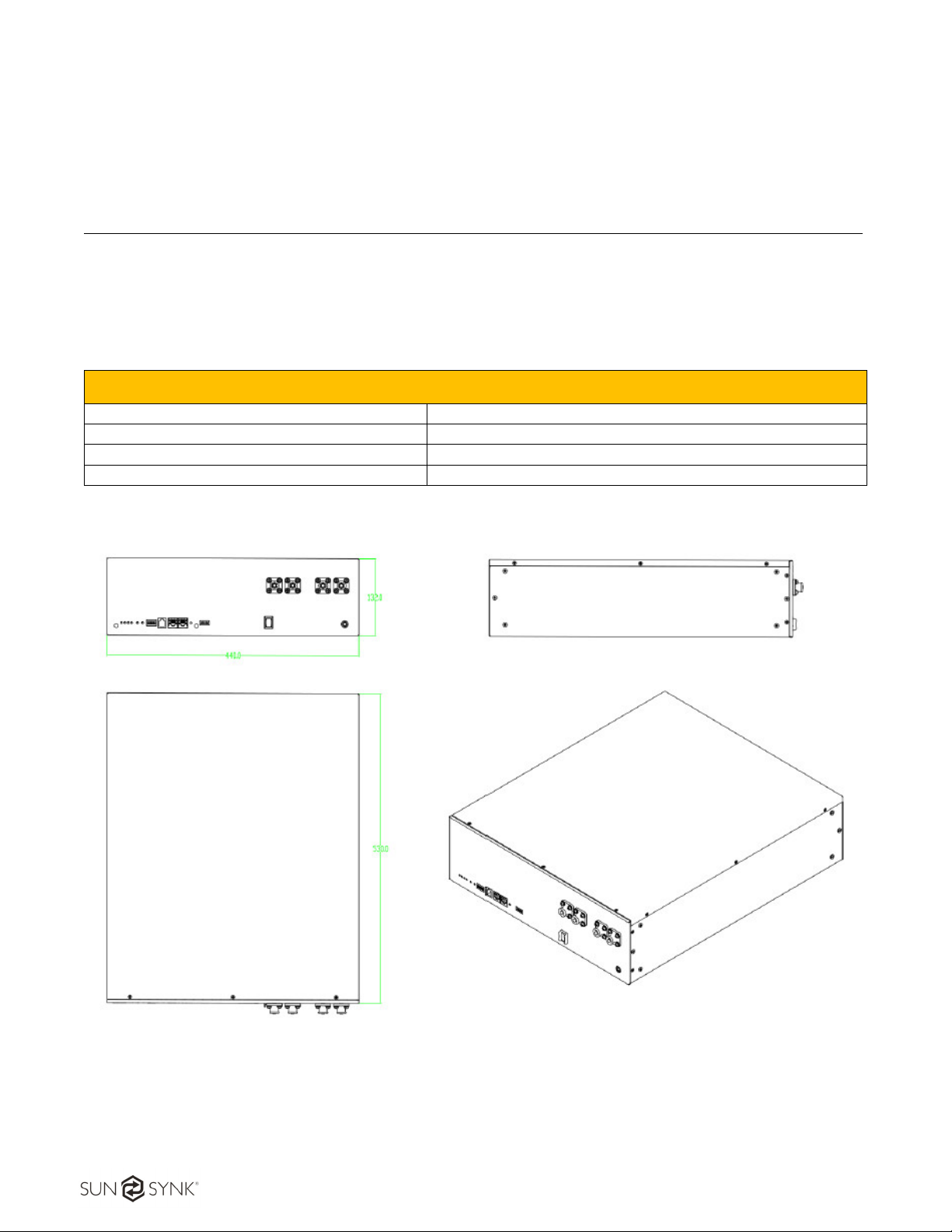

3. SPECIFICATIONS AND FUNCTIONS ............................................................................................................. 7

3.1.

D

IMENSIONS AND

W

EIGH

................................................................................................................................ 7

3.2.

S

PECIFICATIONS

............................................................................................................................................. 8

3.3.

S

YSTEM

I

NTRODUCTION

.................................................................................................................................. 9

4. INSTALLATION ......................................................................................................................................... 10

4.1.

I

NSTALLATION

L

OCATION

E

NVIRONMENT

.......................................................................................................... 10

4.2.

F

RONT

V

IEW

............................................................................................................................................... 11

4.3.

R

ECOMMENDED

DC

B

REAKER

........................................................................................................................ 12

4.4.

DC

C

ABLE

R

EQUIREMENTS

............................................................................................................................. 12

4.5.

DC

C

ABLE

M

OUNTING

.................................................................................................................................. 12

4.5.1

M

ATERIAL

L

IST

.................................................................................................................................................. 12

4.5.2

S

TEPS

.............................................................................................................................................................. 12

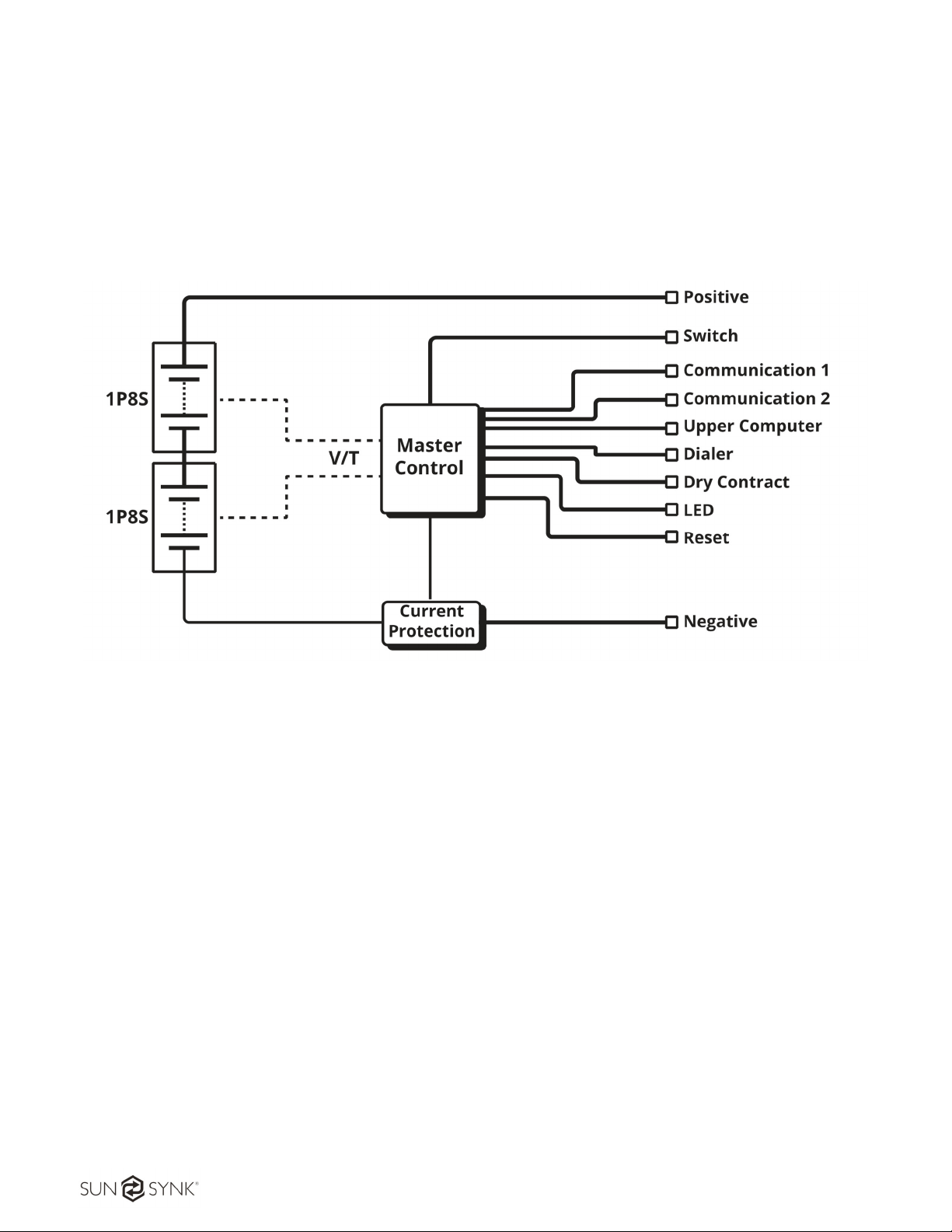

4.6.

M

ASTER

-S

LAVE

C

ONFIGURATIONS

................................................................................................................... 13

4.6.1

S

INGLE

U

NIT

..................................................................................................................................................... 13

4.6.2

M

ULTI

-U

NITS

.................................................................................................................................................... 13

4.7.

C

OMMUNICATION

........................................................................................................................................ 16

4.7.1.

D

EFINITION OF

V

OLTAGE

S

AMPLING

C

ONNECTOR

................................................................................................... 16

4.7.2.

D

EFINITION OF

T

EMP

.

S

AMPLING

C

ONNECTOR

....................................................................................................... 16

4.7.3

P

ORT

RS485

AND

RS232 ................................................................................................................................... 17

5. BATTERY OPERATION AND COMMISSIONING ............................................................................................. 17

5.1.

S

YSTEM

P

OWER

ON ..................................................................................................................................... 17

5.2.

S

YSTEM

P

OWER

OFF .................................................................................................................................... 18

5.3.

S

LEEP AND WAKE UP FUNCTION

....................................................................................................................... 18

5.4.

B

UZZER FUNCTION

....................................................................................................................................... 18

5.5.

S

YSTEM

S

TATUS

I

NSTRUCTION

........................................................................................................................ 18

5.6.

LED

T

WINKLE

S

TATUS

.................................................................................................................................. 19