7

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

depending on the congured

intervals;

3)controls the operaon of the

circulaon pump of the central

heang;

4)controlstheoperaonofthepumpof

thedomeschotwater;

5)opon for control by room

thermostat;

6)mer;

•Photo-sensor - monitors the power of

the burner ame

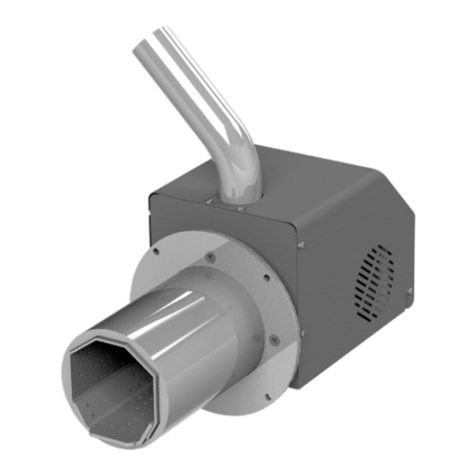

•Internalauger

•Dry contactless resistance heater

assuring ignion of fuel

•Innovave cleaning system of the

combuson chamber

•Air feed fan, step-regulated (from 0%

to100%).

2.2.Burnersafetydevices

•Thermostac protecon (80°С). The

thermostac protecon is ed on the

feeder chute. When the surface of the

feeder chute reaches 80°С, the control

stops the feeding of pellets into the

burner and signals for fault.

•Temperature safety valve with sensor

on screw mechanism. Temperature

safety valve is connected to a water

tank.

•Fuse. In case of electrical fault in the

system of the burner (short circuit, high

current, etc.), the overload is borne by

the electrical fuse ed on the main

control panel of the burner (10А).

•Power interrupon. In case of power

interrupon, all parameter sengs are

stored in the memory of the controller.

Upon the subsequent restart of the

burner, the controller resumes the

execuon of the program from the

point when the power interrupon

occurred.

•STB - emergency thermostat (with

probe inserted into the socket of the

boiler). When boiler temperature is

increasing above 100°C, the STB –

thermostat stop the operaon of feed

screw.

3. FUEL

All pellets are biomass manufactured

from common low-growing plants and

trees. The most common household type

pellets are made of sawdust and milled

wood chippings which are waste material

from wood used in the producon of

logs, furniture and other products. Wood

is the richest raw material which does

not have any impact on the producon

costs of food products or ethyl alcohol

(ethanol). The raw material is processed

under high-pressure and temperature

and is pressed to produce small-size

cylindrical pellets. The producon

process may ulize so wood material

(such as sowood, pine), hardwood (oak)

as well as recycled waste wood. Wood

pellets are produced in hammer mills or

wood pellet plants.

Advantagesofwoodpellets:

Convenient storage. Pellet bags can be

stored on a small area in a dry garage,

basement, service room or shed.

Easy loading. In most cases the boiler

hopper needs loading only once a week –

this depends on the hopper capacity.

Beercontroloffuelquanty. The small

size of the pellets allows for precise fuel

feeding. On the other hand, the supply

of air for reaching opmal combuson

eciency is easier to adjust since the

fuel quanty in the combuson chamber

remains constant and predictable.