3

CAUTION

If the indicator knob does not snap into place

or is not flush with the housing, the piston

may not be fully retracted. This problem may

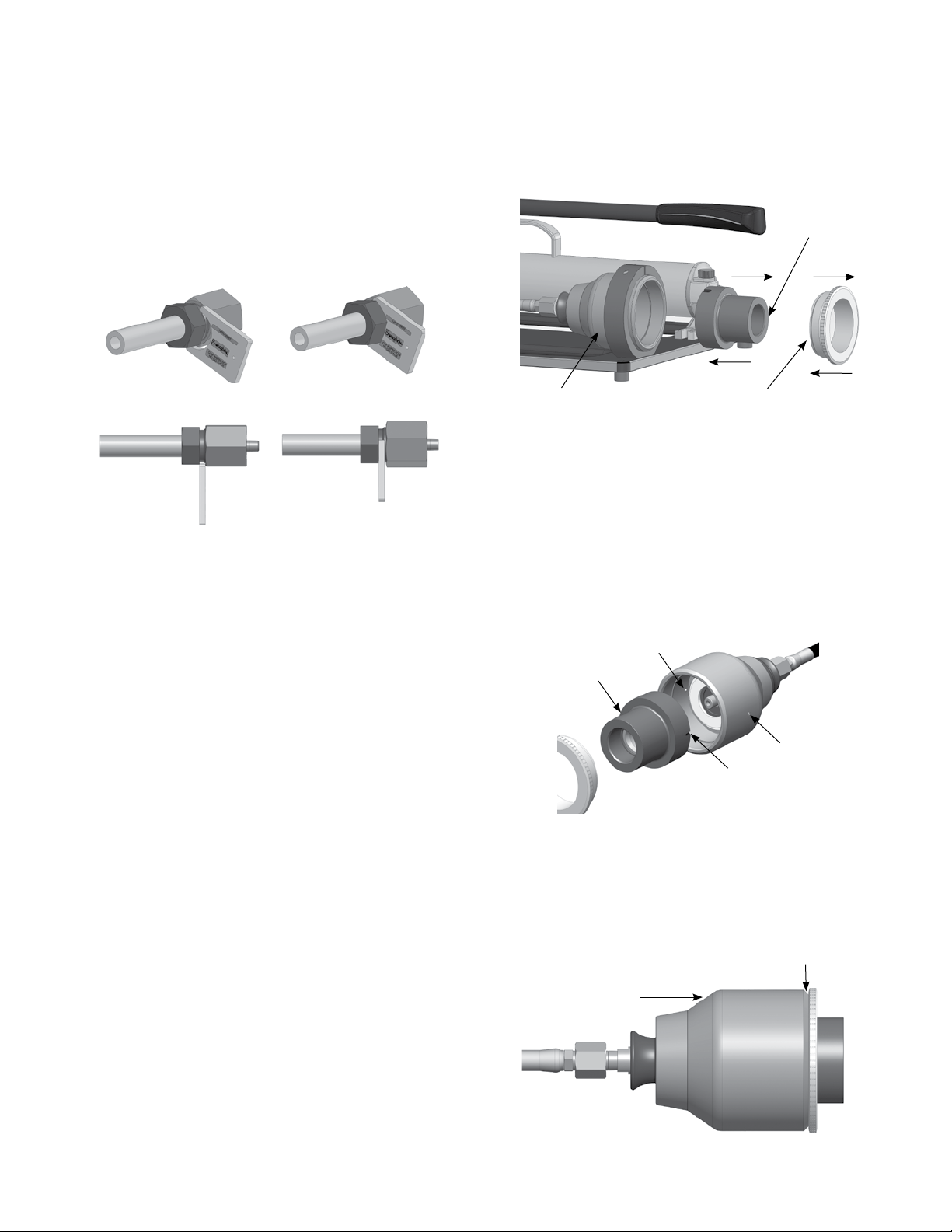

be caused by the bypass valve being closed

or by the piston binding. Do not proceed

until the unit is functioning properly. Contact

your authorized Swagelok sales and service

representative for further assistance.

6. Close the pump bypass valve to the finger-tight

position by rotating the valve handle clockwise

until it stops.

Fig. 2 Indicator Knob in Swaging Position

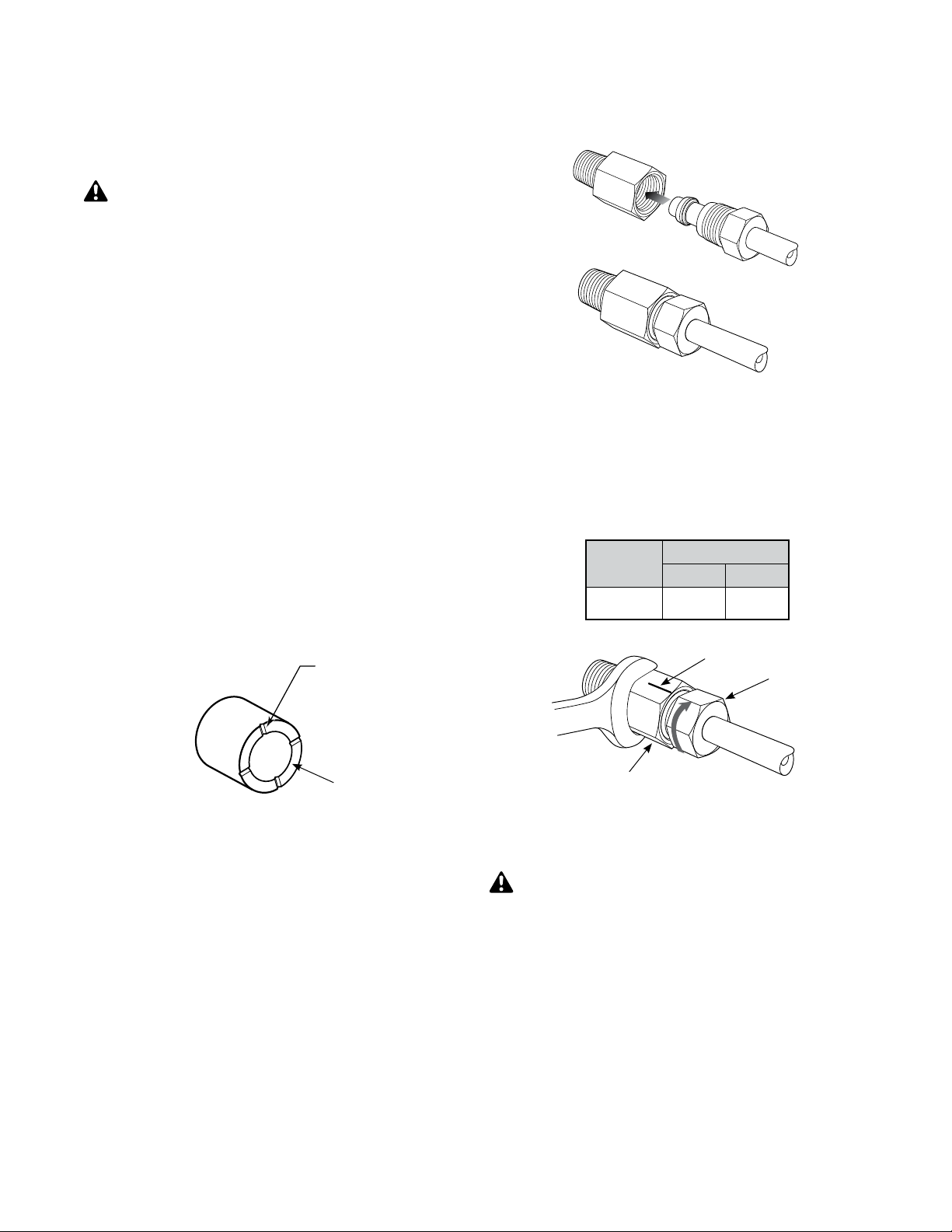

Fig. 1 Nut and Ferrule Orientation

3. Insert the arbored nut and ferrule set into the

Swagelok medium-pressure die. Thread the

nut into the die head to finger-tight. Remove

the arbor, leaving the nut and ferrules in the die

head. The orientation of the nut, rear ferrule,

and front ferrule should be as shown in Fig. 1.

D. If a file is used on the OD, make a 10° x

0.06 in. (1.5 mm) chamfer (as shown below).

C. For the 16FK MHSU, use the chamfer block

provided. Insert the cut end of the tubing

into the chamfer block, and while firmly

holding the tubing, strike the chamfer block

with a hammer to coin the end (as shown

below).

Front ferrule

Back ferrule

Nut Die head

Arbor

Arbor

Operation

1. Open the pump bypass valve by turning the

handle counterclockwise at least one-half to one

turn. It may be necessary to first close the valve

completely by turning the handle clockwise until

it stops. (If the bypass valve is in the full open

position upon receipt of the MHSU unit, it will

not be possible to open it an additional one-half

to one turn.)

2. Prepare tube ends by deburring or using the

Swagelok chamfer block as follows.

Note: Use the chamfer block when preparing up

to and including 1-inch tubing.

A. Cut tubing squarely. Use of a Swagelok tube

saw guide is recommended.

B. Remove any burrs. Use of a Swagelok tube

deburring tool is recommended.

WARNING

Deburr the OD of the tube to ensure

that it properly rests against the piston

shoulder. If the tube is not resting against

the piston shoulder, it could result in

inadequate preswaging, which, in turn,

could lead to premature tube failure and

result in loss of life, injury, or property

damage. One of the causes of the tube

not seating properly could be because it

hasn’t been properly deburred.

4. Insert the tubing into the die head until it rests

firmly against the piston shoulder. Tighten the

nut until finger-tight.

5. Push the indicator knob forward until it snaps

into place. The knob shoulder should be flush

with the hydraulic housing. See Fig. 2.

Knob shoulder is

flush with housing.

Indicator knob

Housing Tubing

Tubing

10°

0.06 in. (1.5 mm)

Strike end with

a hammer to

coin tube end

Tubing

Chamfer block