3

MS-12-37

Revision 2 12-02-CP

Operation

1. Open the pump bypass valve by turning the

handle counterclockwise at least 1/2 to 1 turn.

It may be necessary to first close the valve

completely by turning the handle clockwise until

it stops.

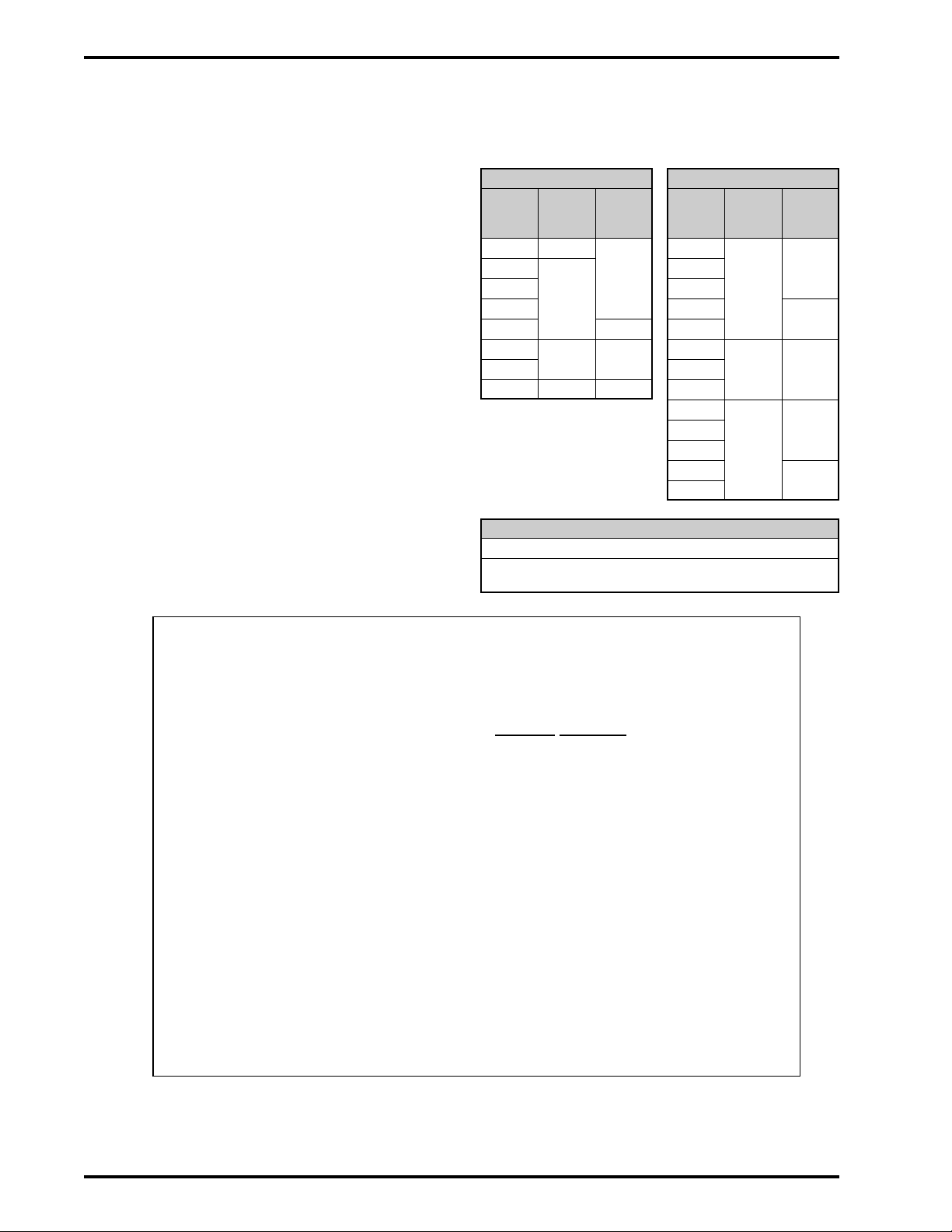

2. Install the Swagelok nut and ferrules onto the

die head in the order and orientation shown

until finger-tight and all die threads are covered

by the nut.

3. Push the indicator knob forward until it snaps

into place. The knob shoulder should be flush

with the hydraulic housing.

Note: If the indicator knob does not snap into

place or is not flush with the housing the piston

may not be fully retracted. This problem may

be caused by the bypass valve being closed or

by the piston binding. Do not proceed until unit

is functioning properly. Contact your

independent Swagelok sales and service

representative for further assistance.

4. Prepare tube ends by deburring or using the

Swagelok chamfer block (as follows and as

shown on the instruction decal in the MHSU

case). The chamfer block procedure should be

followed when using the up to and including

one inch tubing on the MHSU.

A. Cut tubing squarely. Use of a Swagelok

tube saw guide is recommended.

B. For up to and including one inch MHSU,

use the chamfer blocks provided. Insert cut

end of tubing in to the chamfer block and

while firmly holding the tubing, strike the

chamfer block with a hammer to coin the

end (as shown on the instruction decal).

C. If a file is used on the OD, make a 10° x

0.06 in. (1.5 mm) chamfer.

D. Remove any burrs. Use of Swagelok tube

deburring tools is recommended.

NOTE: Deburring is important for proper

fitting function as well as for clean, leak-

free systems. If burrs are not removed from

the OD of the tube, it could prevent the

tube from being fully inserted through the

nut, ferrules or against the shoulder of the

fitting body. ID burrs could also break off

and cause damage in other parts of the

system by lodging in small holes or vents,

or by scratching valve seats or soft seals.

5. Insert tubing into the nut until it rests firmly

against the piston shoulder. Refer to the

Recommended Minimum Wall Thickness of

Tubing for Use with the MHSU table on page

4. Use of tubing below the recommended

minimum wall may result in the tube sticking in

the die head.

6. Close the pump bypass valve to the finger-tight

position by rotating valve handle clockwise until

it stops.

7. While holding the tubing against the piston

shoulder, increase the hydraulic pressure by

using the hand pump until the indicator knob is

released.

Do not keep pumping after the indicator

knob releases. Stop pumping immediately

after the indicator knob pops.

8. Open the pump bypass valve by turning the

handle 1/2 to 1 turn counterclockwise.

9. Unthread the Swagelok nut, and remove the

preswaged assembly from the housing.

10. Inspect the tube end for a radial indentation

bottom marking (see decal in MHSU case).

This indentation indicates the tubing was

properly bottomed in the MHSU. If there is not

a visible indentation, the preswaged assembly

should not be used.

11. Install the preswaged assembly into the fitting

body. Turn the nut onto the fitting body until it is

finger-tight. Hold the fitting body stable and

tighten the nut 1/2 turn with a wrench.

Use the Swagelok MHSU gap inspection

gauge to assure the installer or

inspector that the fitting has been

sufficiently tightened.

Gauging Instructions

Position the Swagelok MHSU gap inspection gauge

adjacent to the gap between the nut and body hex.

■ If the gauge will not

enter the gap, the

fitting is sufficiently

tightened.

■If the gauge will enter

the gap, additional

tightening is required.

Nut Back

ferrule

Front

ferrule

Die

head