Series 20 Weld Head User’s Manual 3

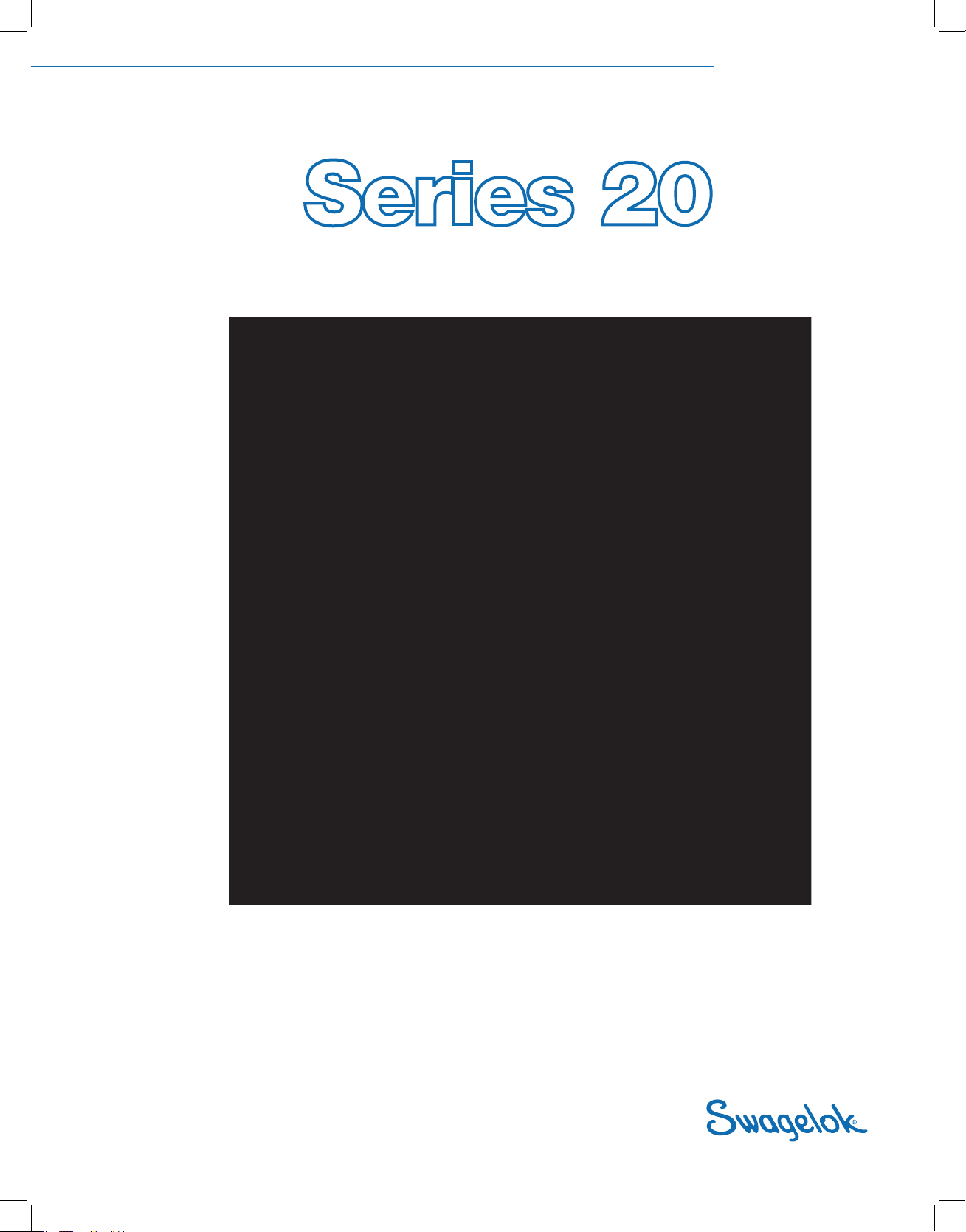

Weld Head

The Series 20 SWS weld head delivers consistent, precise welds for

outside tubing diameters from 1/2 to 2 in. and 12 to 52 mm and pipe

diameters ranging from 1/4 to 1 1/4 in. and 10.2 to 48.3 mm.

A DC motor in the weld head drives a rotor, which carries the tungsten

electrode around the weld joint. Optical circuitry in the weld head

sends precise feedback to the power supply to control the speed of

the rotor.

All moving parts in the weld head are mounted in low-friction devices

to provide smooth, consistent operation.

A spring-loaded, oating brush continuously contacts approximately

one-third of the circumference of the rotor. This conguration ensures

consistent, uniform electrical conductance to the rotor and electrode.

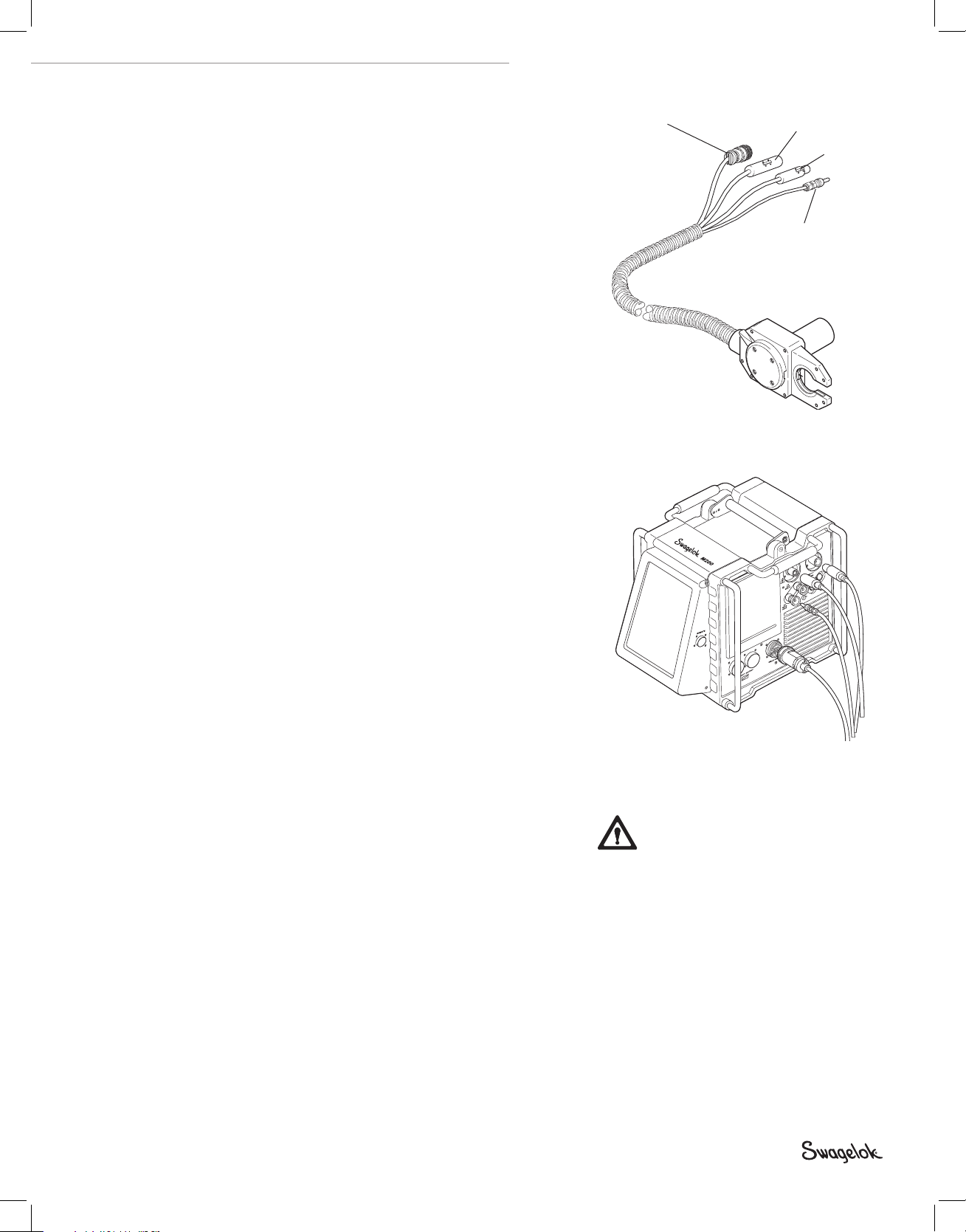

Fixture Block

The Series 20 SWS xture block accurately aligns and holds tubing,

ttings, and valve bodies. The modular design allows you to select

different side plates and create the conguration needed for the job.

The xture block is separate from the weld head, allowing work pieces

to be easily aligned and xtured before welding. Using multiple xture

blocks can increase productivity.

Each xture block is designed to accommodate a range of work

piece sizes. A Universal Collet Insert (UCI) ts into the xture block to

match the diameter of the work piece. The collet design rmly holds

tubing and ttings that vary ±0.005in. (0,13mm) from nominal outside

diameter. Collets are also available for thin wall pipe. The collets

exchange quickly, making the xture block very adaptable to changing

work requirements.

Figure 1 Series 20 Weld Head

Figure 2 Series 20 Fixture Block

13-205R4.indb 3 2/1/13 2:43 PM