Specifications are subject to alteration without notice.

10 www.swegon.se

4 ELECTRICAL WIRING

Important!

The installation work shall be carried out by an authorized

electrician.

4.1 Wiring to the mains power

The power cable must be arranged through the front

panel of the unit. A permanent cable gland has been fac-

tory-fitted to the side of the inspection door.

The location of the gland varies slightly depending on the

size of cooling unit.

The incoming cable for 400 V power (5-wire system) must be

connected directly to the safety switch, which has four nor-

mally-closed contact functions. The safety switch is installed

in the built-in electrical cubicle. The terminal block for incom-

ing earth is situated adjacent to the safety switch.

If a 4-wire system is used, a jumper should be fitted be-

tween the earth and zero terminal blocks in the Cooler.

For access to the connections of the safety switch, the

safety guard above the electrical cubicle components has

to be dismantled.

4.1.1 Size 14 Coolers

The cable gland is located to the right at the top of the

front panel.

The fuse for the cable shall be rated for 20 A(T).

When sizing the cable, take into account the ambient tem-

perature and how the cable will be arranged.

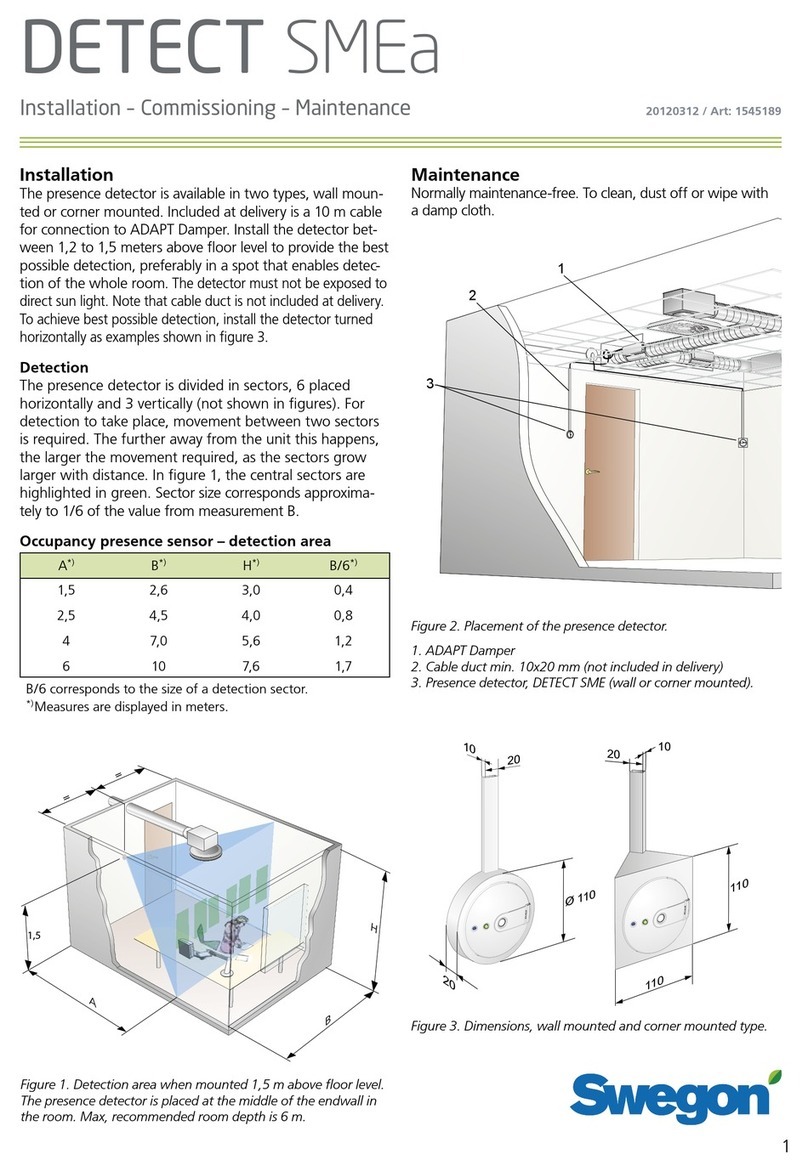

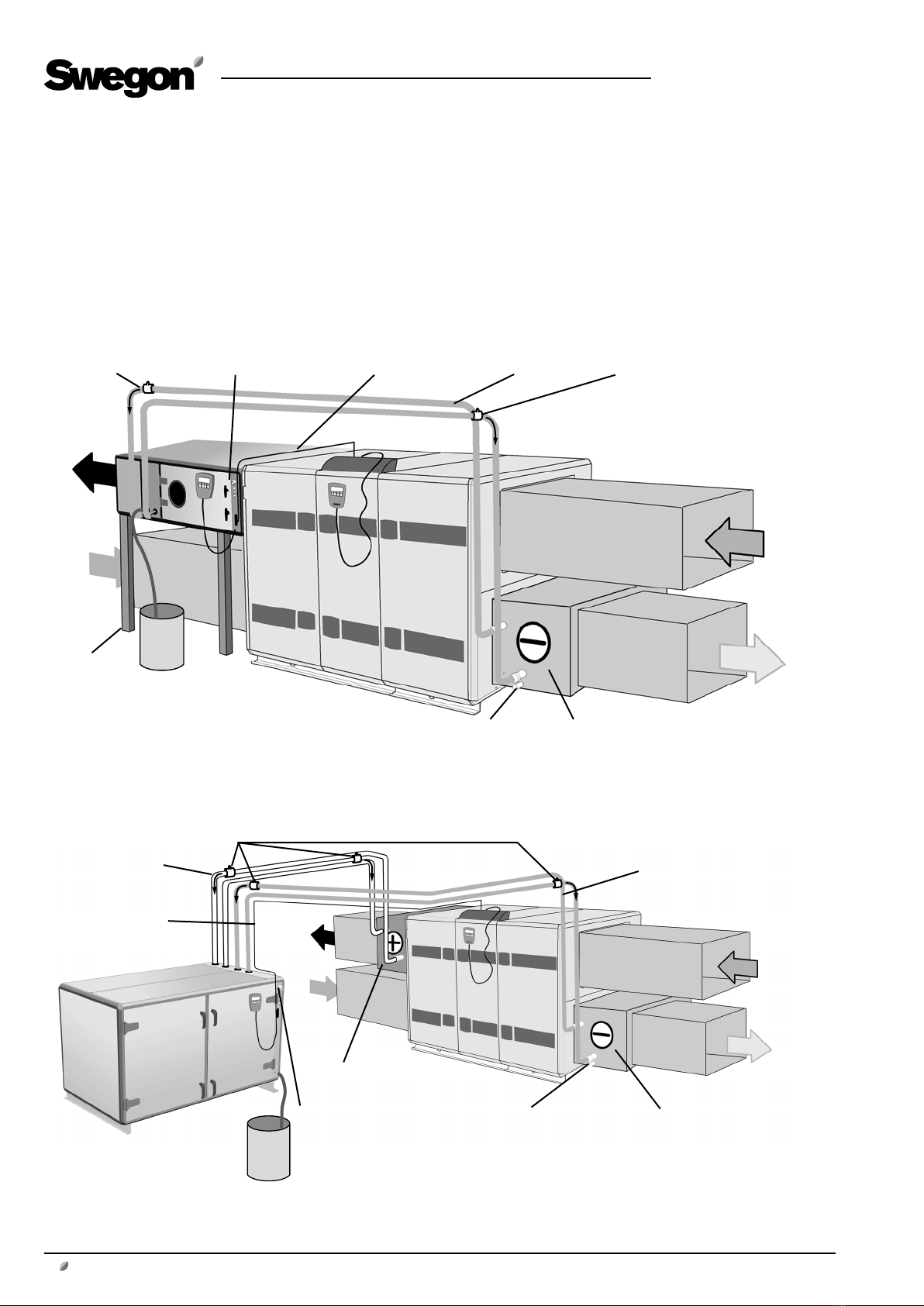

See Fig. 10.

4.1.2 Size 18 Coolers

The cable gland is located at the bottom edge of the front

panel.

Fuse for the cable should be rated for 25 A(T). When sizing

the cable, take into account the ambient temperature and

how the cable will be arranged.

See Fig. 10.

4.1.3 Size 24 and 34 Coolers

The cable gland is located uppermost and to the right on

the front panel.

The fuse for the cable shall be rated for 32/35 A (T) for the

size 24 Coolers and 35 A(T) for the size 34 Coolers. When

sizing the cable, take into account the ambient temperature

and how the cable will be arranged.

See Fig. 10.

4.1.4 Cooler sizes 48 - 60

The cable gland is located uppermost and to the right on

the front panel.

The fuse for the cable shall be rated for 63 A(T). When siz-

ing the cable, take into account the ambient temperature

and how the cable will be arranged.

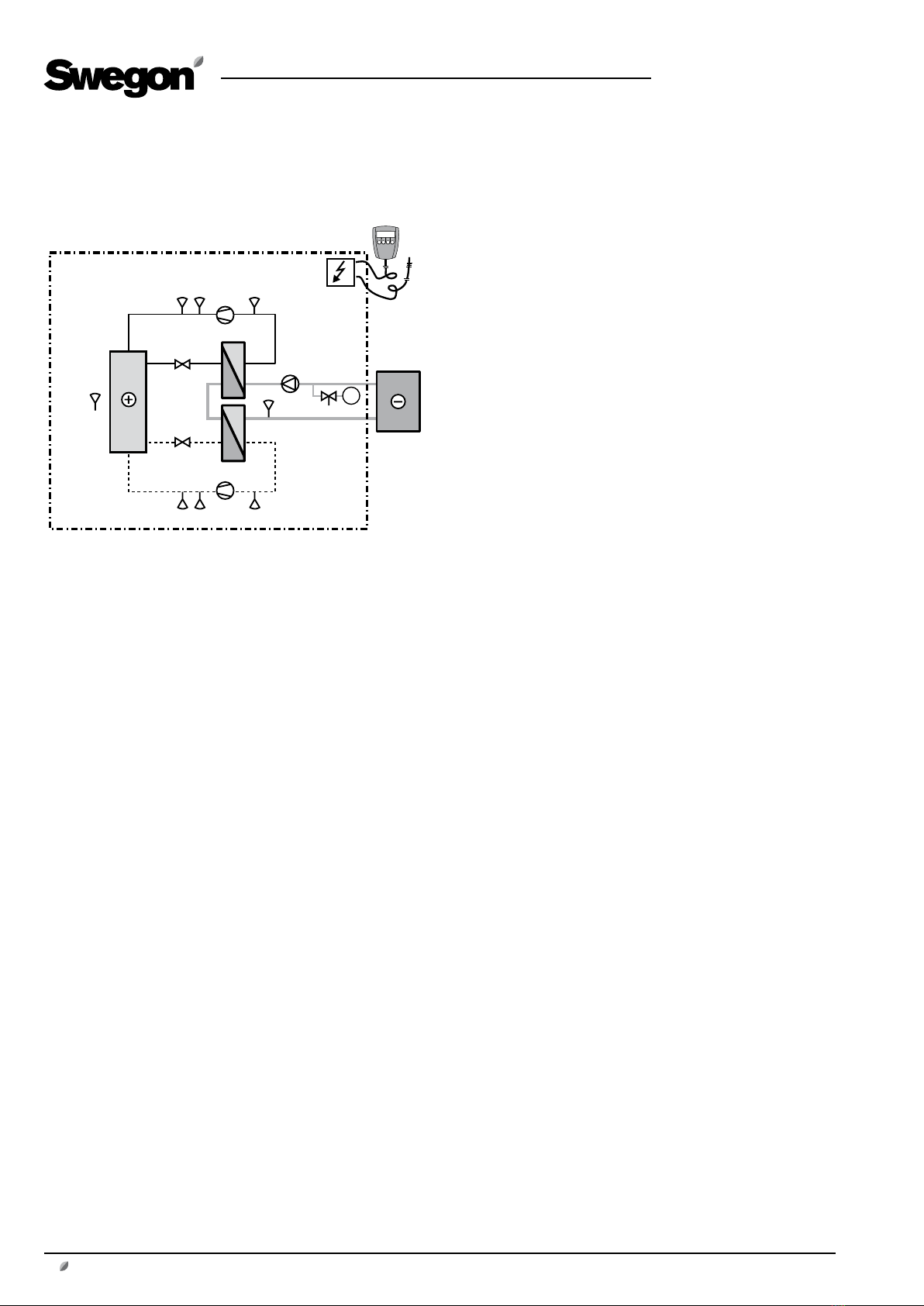

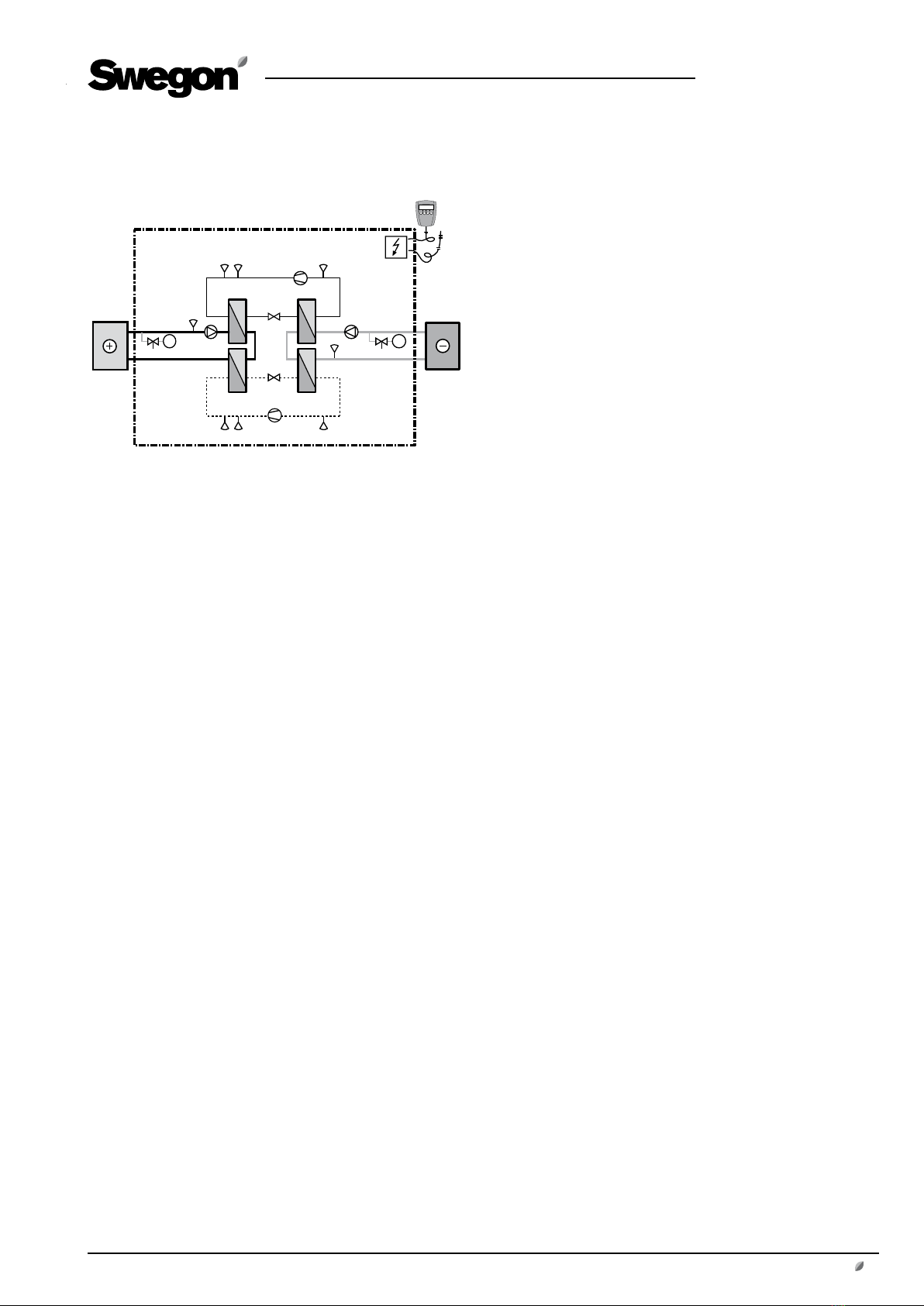

Fig. 10

4.2 Other electrical connections

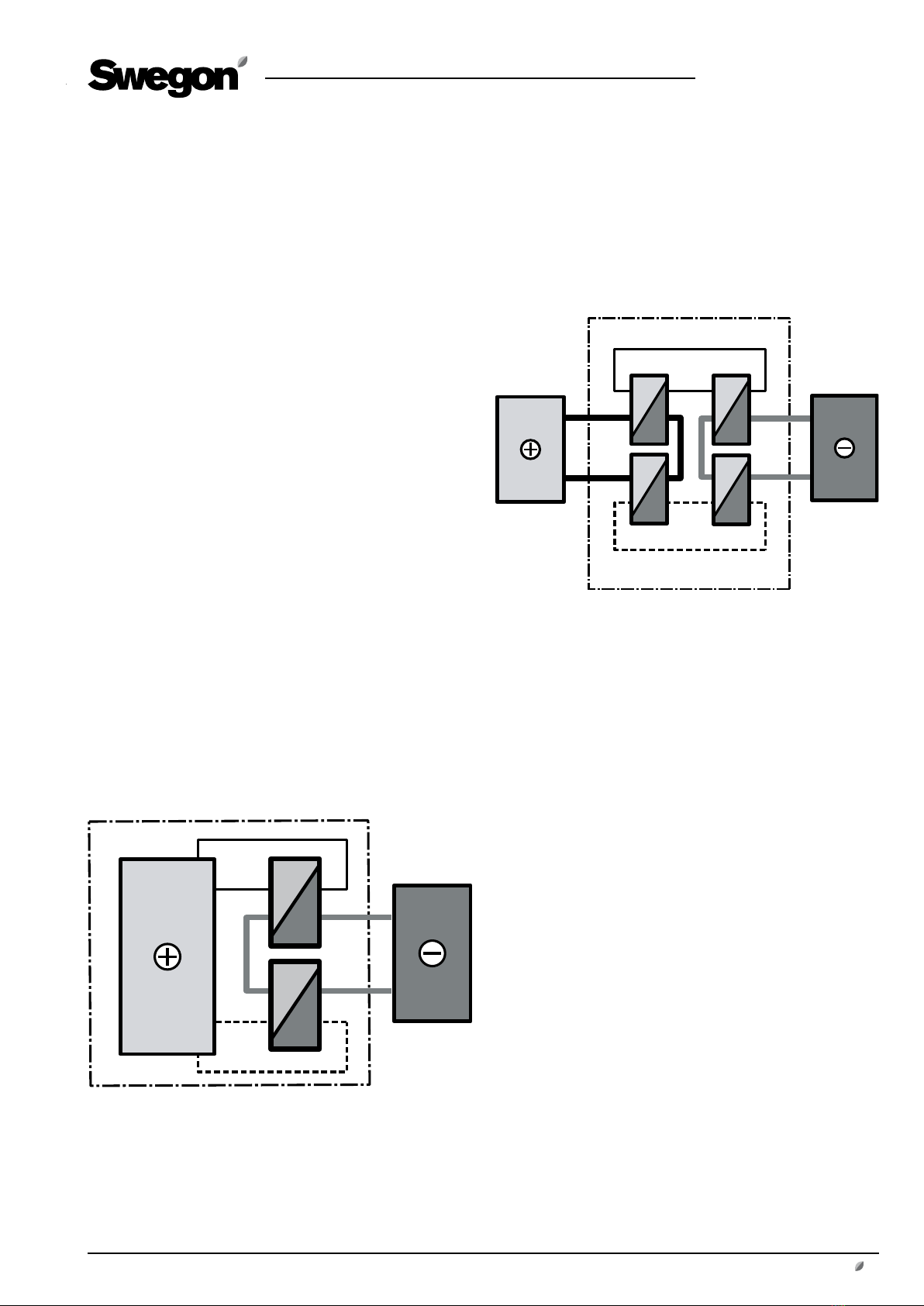

4.2.1 GOLD, Version B

General

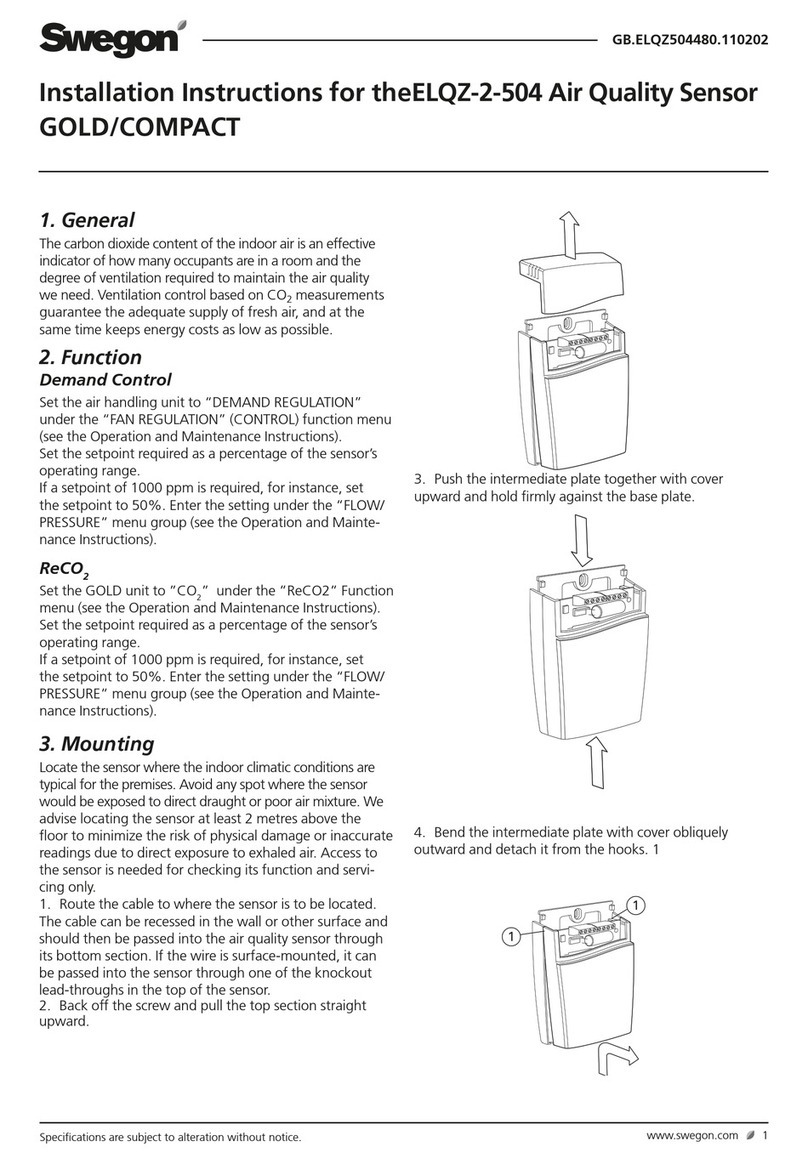

The Cooler is supplied with two alternative accessories for

controlling the cooling load.

Extra interference protection is required for the Cooler

variants operating where the cooling load is controlled by

an external 0 –10 V DC signal.

To meet the provisions stipulated in the EMC Directive,

concerning insensitivity to interference, the analogue

inputs must be protected by a Ferrit block, 019 210.

Communication cable 019 007 is the accessory, that must

be used when the Cooler operates together with the

Version B GOLD ventilation unit. See the individual instruc-

tions.

Design

The ferrit block, 019 210, is designed for snapping

around wires.

The block consists of two ferrit-halves, enclosed in a

plastic casing that can be opened.

The plastic casing has ”hinges” and a simple lock that make

it easy to open and close around relevant wires.

Dimensions: H = 15 mm, W = 15 mm, L = 29 mm and

diameter of the openings = 6.6 mm.

Communication cable 019 007 is a 5 m long flat cable,

with a type RJ 1 modular connection fitted at both ends.

The cable transfers normal communication signals bet-

ween the control unit and the GOLD unit (Version B), but

not 4 V DC. Both types of control have their own 4 V DC

supply.

Important: Do not use an ordinary bus cable! If the 4 V DC

connections are interconnected, this will cause malfunc-

tions.