2

CDKa/CKPa

We reserve the right to alter specifications. 20080315 www.swegon.com

Technical description

Design

The CDK and CKP consists of two parts: an aerodynami-

cally shaped upper section with a connection spigot have

including a rubber sealing ring, and a removable non-

perforated diffuser face. Between the upper cone and the

diffuser face there is a slot which can be adjusted in two

positions. The diffuser face of the CDK is unperforated

and on CKP it is perforated in CKP is perforated. Both

CDK and CKP are equipped with acoustic insulation.

Materials and surface treatment

The upper part is manufactured in galvanized sheet steel.

The diffuser face is made of sheet steel. The whole dif-

fuser is painted inside and out with our pure white stand-

ard paint, RAL 9010. The unit is also available in other

standard colours: Dusty grey 7037, white aluminium RAL

9006, jet black RAL 9005, grey aluminium RAL 9007 and

signal white RAL 9003 (NCS 0500).

Accessories

Commissioning box:

ALS made of galvanized sheet steel. Includes removable

commissioning damper, fixed measurement unit and

acoustic insulation with a reinforced surface layer, to Fire

Resistance Class B-s1,d0 according to EN ISO 11925-2.

Frame:

SAR C. For the aesthetic installation with lowered diffuser.

Shielding strip:

SAV. To shield the spread pattern.

Planning

The diffuser has an aerodynamically shaped inlet spigot,

which means that it can handle extremely large airflows

at low sound levels.

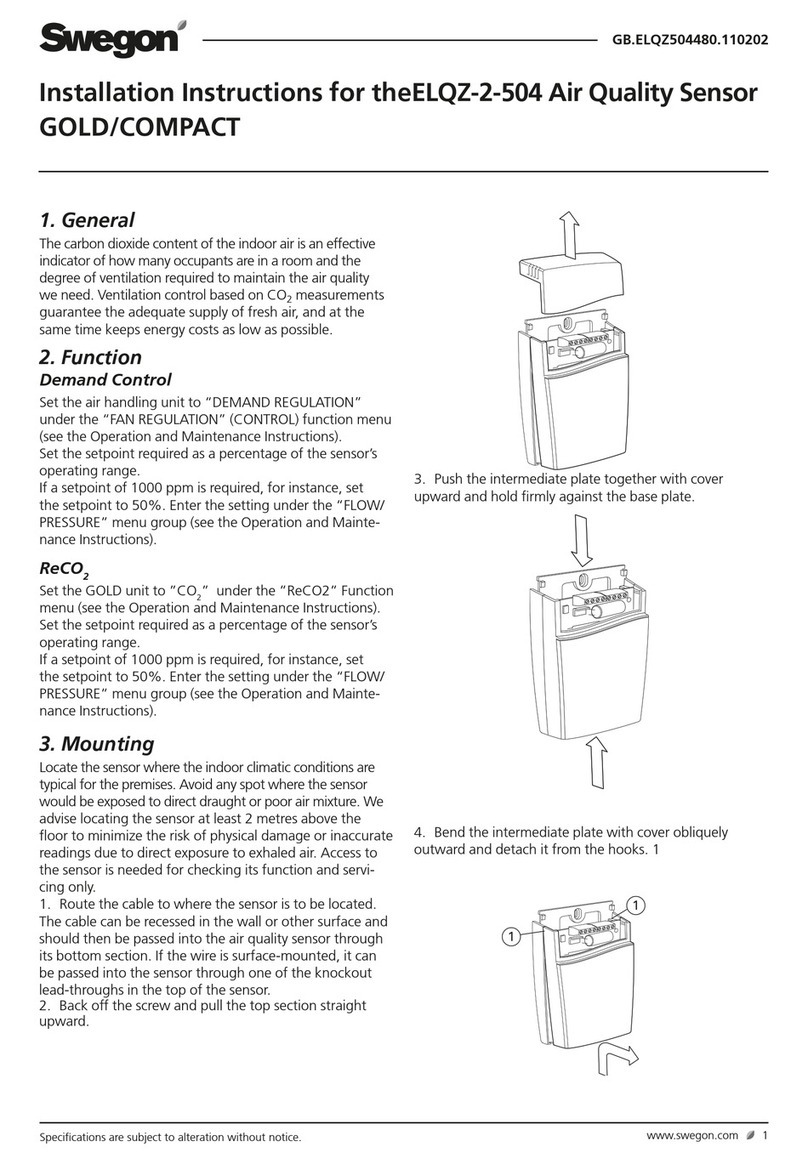

Installation

The inlet spigot of the diffuser is fixed to the connecting

duct with blind rivets. The diffuser face is removed by

turning the springs which grip the pins of the diffuser face

through ¼ turn (see Figure 1). When the ALS commission-

ing box is used, the spigot between the ALS and the CDK

can be extended using normal circular duct up to 500 mm

long without needing to extend either the measurement

tubes or the damper cords. See Figure 1.

Commissioning with ALS

This must be carried out with the diffuser face in place.

The measurement tubes and the damper cords are pulled

out of the diffuser through the slots. The damper setting

is lockable. The k-factor is stated on the product label,

and is also in the relevant k-factor guide which can be

accessed at www.swegon.com. See Figure 1.

Maintenance

The diffuser can be cleaned when necessary using luke

warm water with added detergent. The duct system can

be accessed without the use of tools. The spreader plate

is removed by turning the springs which grip the pins

through ¼ turn. If the commissioning box ALS is used,

move the diffusion plate aside and the damper unit can

then be removed by unscrewing it from its fastening. See

Figure 1.

Environment

The Declaration of construction materials is available at

www.swegon.com.

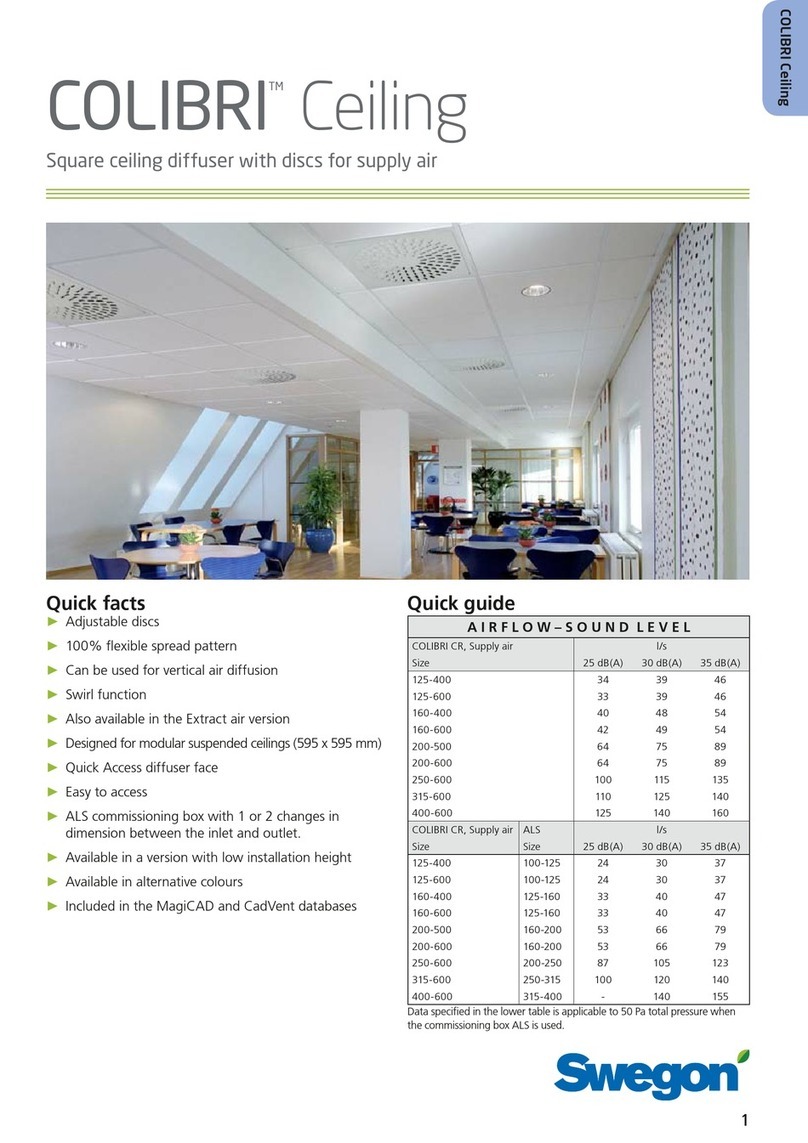

Sizing

Sound level dB(A) applies to rooms of 10 m2 equivalent

absorption area

The throw l0.2 is measured under isothermal flow condi-

tions

Recommended maximal under temperature is 10°.

All technical data applies to the following slot widths:

20 mm for sizes 100 and 125

30 mm for sizes 160, 200, 250 and 315.

The slot widths can be increased to:

30 mm for sizes 100 and 125

40 mm for sizes 160, 200, 250 and 315.

This increase in slot widths cause reductions in throw,

pressure drop and sound levels with ca 20%.

To calculate the width of the airstream, air velocities in

the area of occupation or sound levels in rooms with

other dimensions, please refer to our selection soft-

ware ProAir web and ProAc, which are both available

at www.swegon.com.

All the technical data applies to a 360° spread pattern.

•

•

•

•

•

•

•

Figure 1. Installation.