ETS 73

0548-990-51---60e_2017.06.indd 0548-990/52e

Page 2 of 85

Mounting and operating instructions

TABLE OF CONTENTS

1 GENERAL REMARKS .................................................................................................5

1.1 Target group.......................................................................................................5

1.2 Where to keep these instructions ......................................................................5

1.3 Adresses............................................................................................................5

1.4 Auxiliary tools and service performances ..........................................................6

2 SAFETY.......................................................................................................................7

2.1 Appropriate use .................................................................................................7

2.2 Safety notices ....................................................................................................7

2.3 Safety regulations ..............................................................................................7

2.3.1 Principles..............................................................................................7

2.3.2 Service..................................................................................................9

2.3.3 Safety devices ......................................................................................9

2.3.4 Malfunctions .........................................................................................9

2.3.5 Accessories/Spare parts.......................................................................9

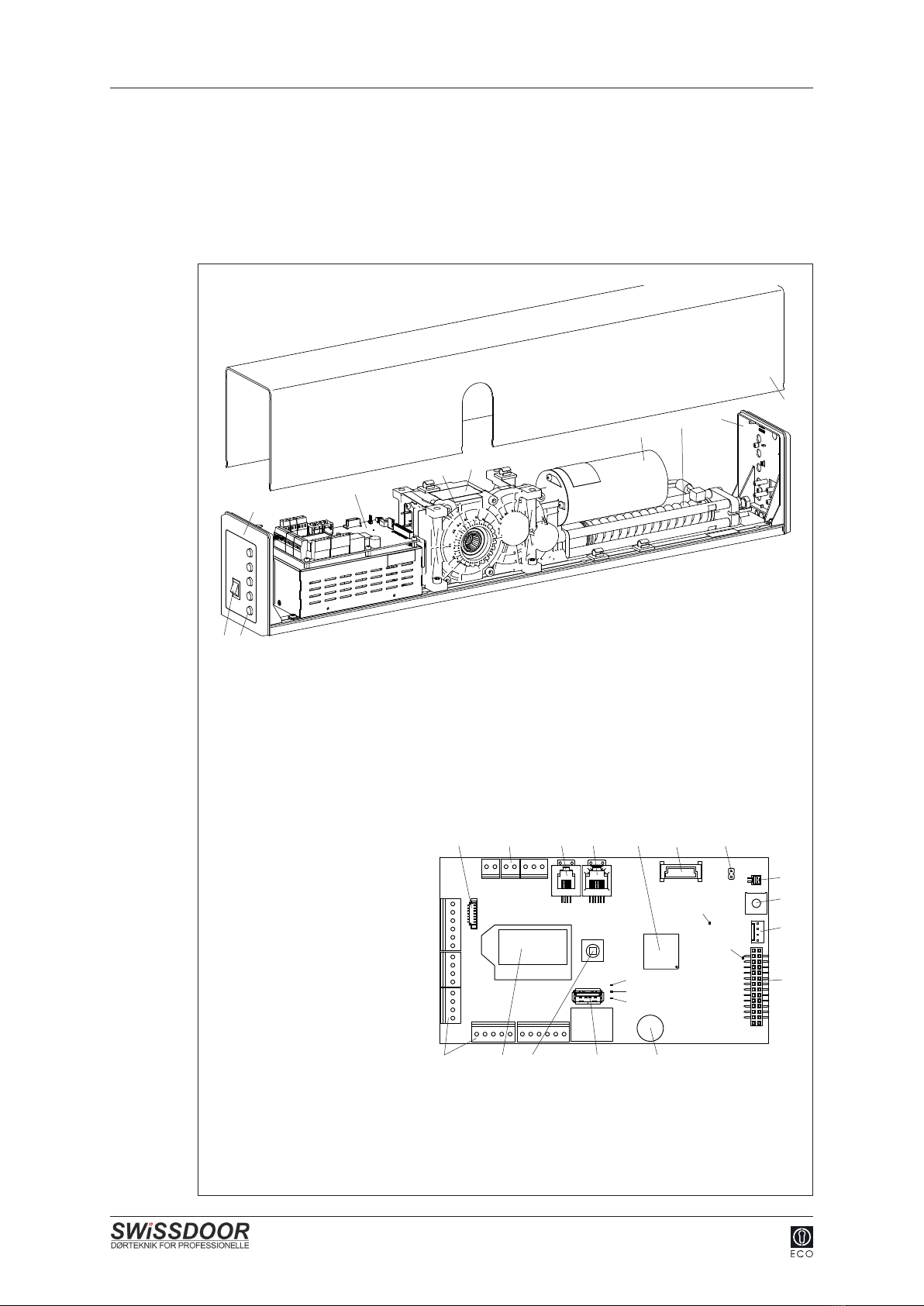

3 PRODUCT DESCRIPTION........................................................................................10

3.1 General remarks ..............................................................................................10

3.2 Standard application ........................................................................................ 11

3.3 Inverse application...........................................................................................12

3.4 Automatic closing sequence control ................................................................12

3.5 Rating plate......................................................................................................13

3.6 Technical data..................................................................................................13

3.7 Application limits without safety elements

according to EN 16005 ....................................................................................14

3.8 Maximum wind-load capacity...........................................................................15

4 MOUNTING ...............................................................................................................17

4.1 Preparation ......................................................................................................17

4.2 Mounting versions............................................................................................18

4.3 General............................................................................................................19

4.4 Normal rods pushing function / Lintel mounting...............................................20

4.5 Sliding rods pulling function / Lintel mounting..................................................23

4.6 Sliding rods pushing function / Lintel mounting ...............................................26

4.7 Sliding rods pushing function / Leaf mounting .................................................29

4.8 Adjusting the pre-stressing of the closing spring .............................................32

4.9 Setting the accelerating function (forceful closing) ..........................................34

4.9.1 Accelerating force...............................................................................34

4.9.2 Forceful closing range ........................................................................35

5 ELECTRICAL CONNECTIONS .................................................................................36

5.1 Power supply ...................................................................................................36

5.2 Cable layout.....................................................................................................38

5.2.1 Lintel mounting ...................................................................................38

5.2.2 Leaf mounting.....................................................................................38

5.2.3 Strain relief .........................................................................................39

5.3 External elements ............................................................................................39

5.4 Motorized lock..................................................................................................40

5.4.1 Motorised lock with direct connection to motor coil ............................40

5.4.2 Motorized lock with own evaluation control ........................................41

5.4.3 Motorized lock with separate evaluation control/power pack .............42