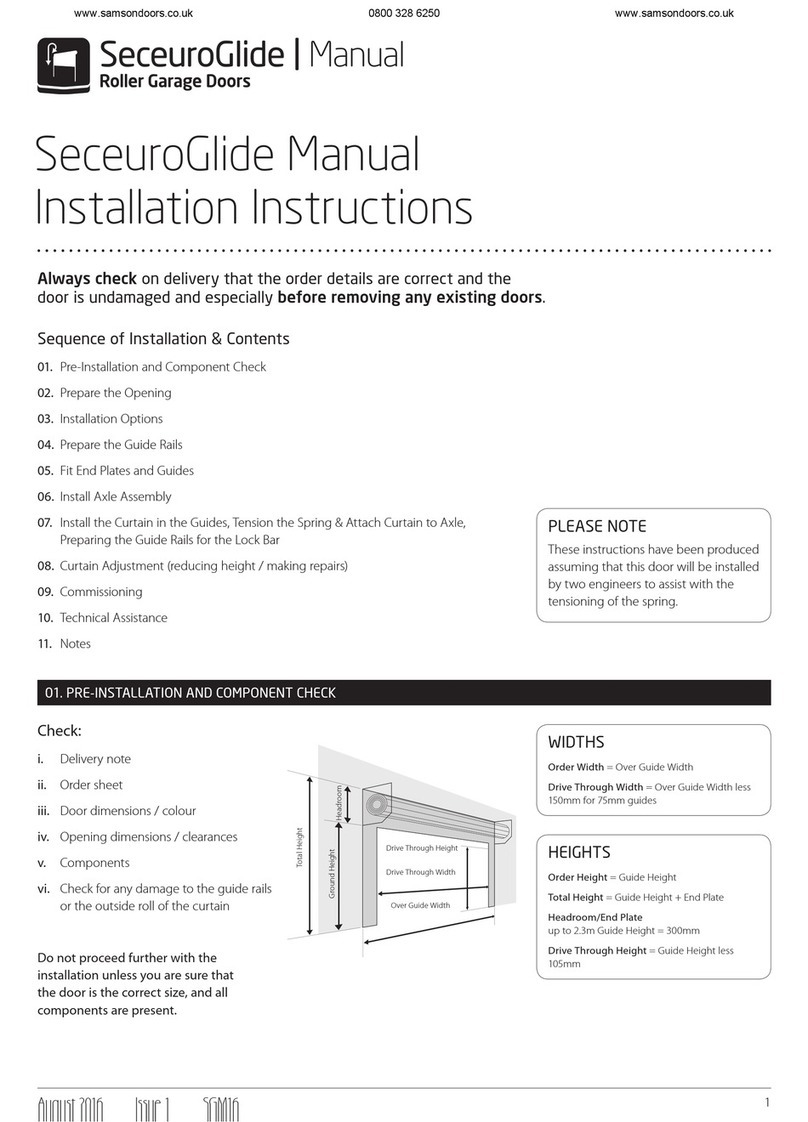

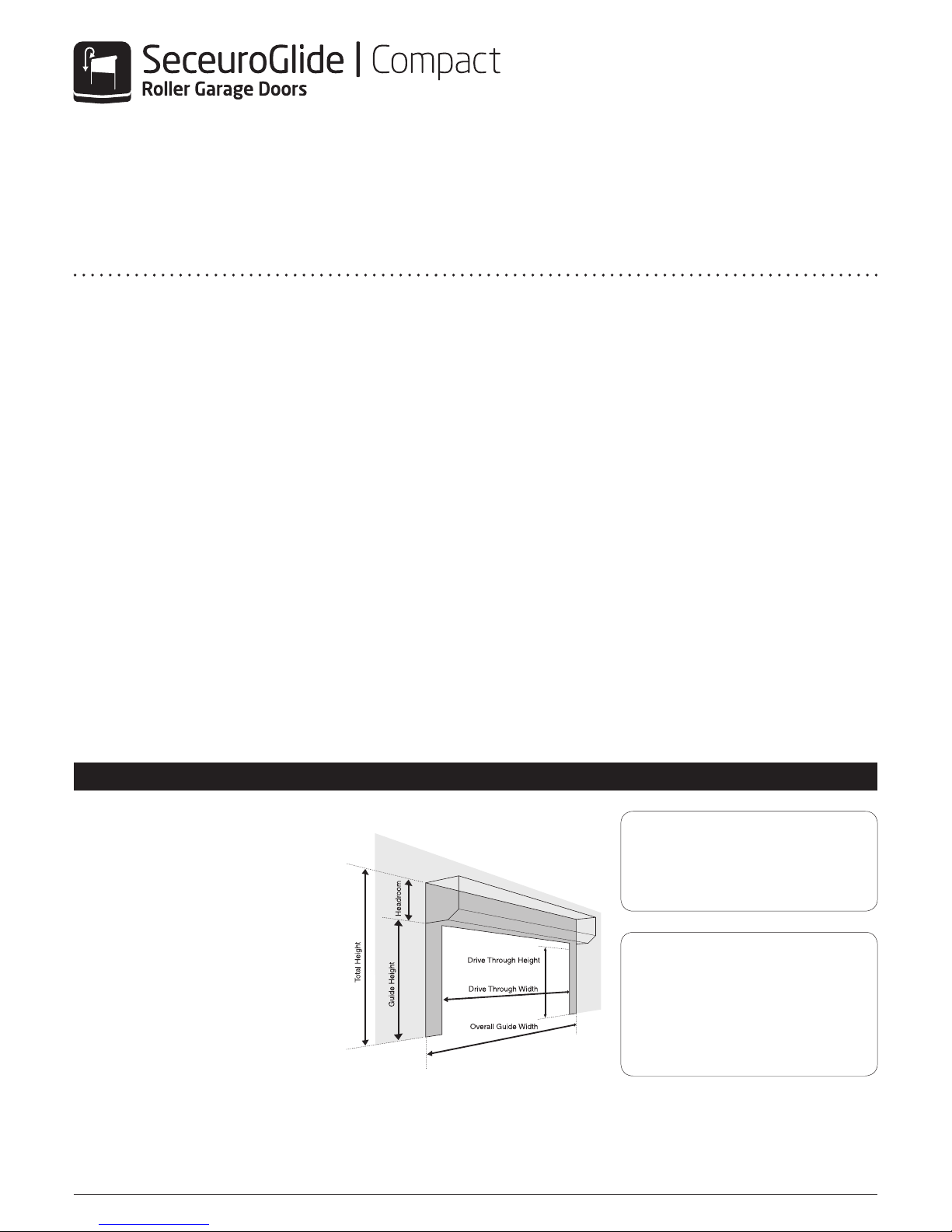

03. PREPARE THE OPENING

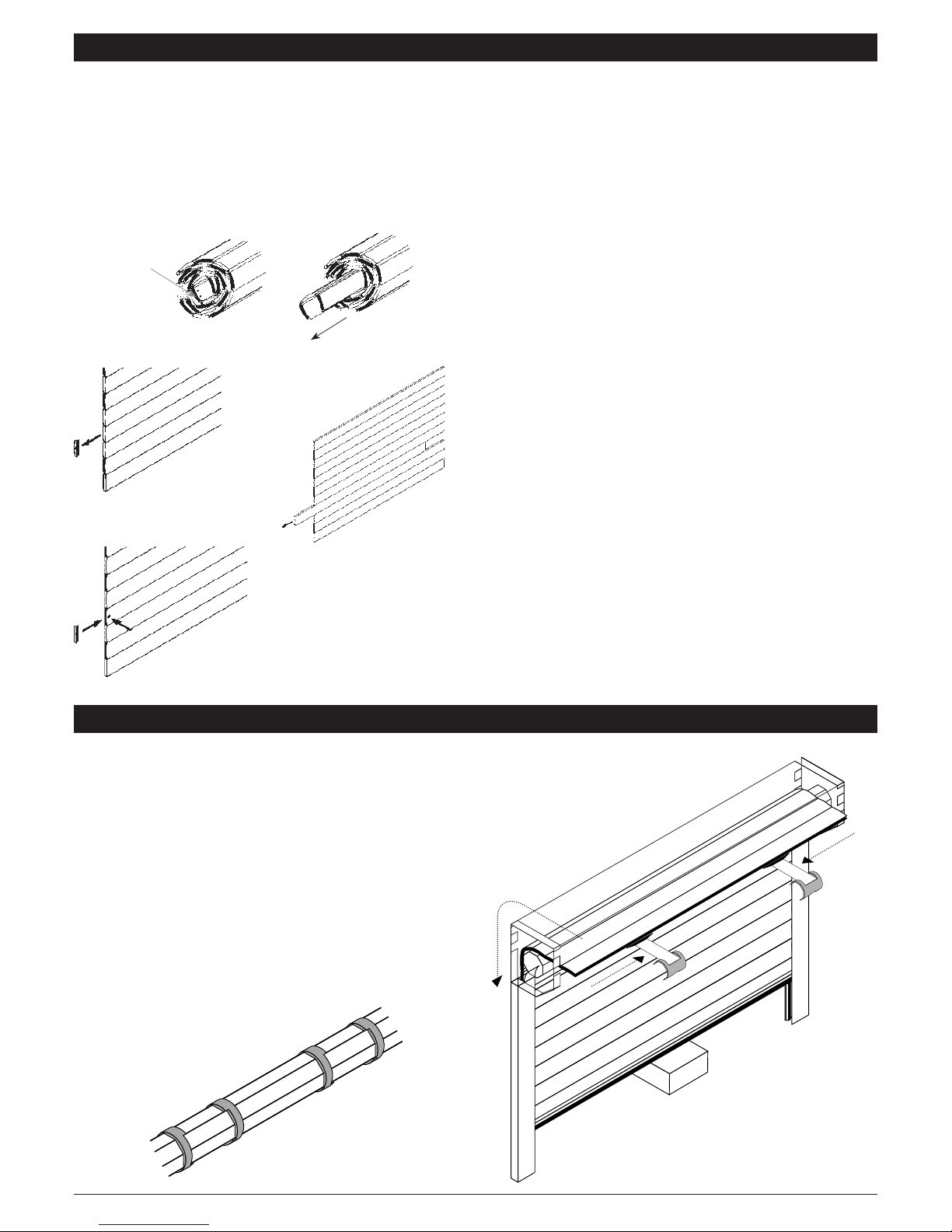

04. PREPARE THE GUIDE RAILS

Check:

i. Structure is sound/even & can carry the weight of the door

ii. No obstacles in fitting footprint eg. no sharp objects, pipes,

cables, bumps etc. sticking out from the pillars, lintel or header

to twist the guides, distort the fascia or catch on the curtain

iii. Floor is flat/level

If necessary install a sub-frame to ensure secure, flush and

level fixing (Recommended minimum 70 X 70 PAR).

If the guides require cutting down refer to the ‘Widths and

Heights’ information in Section 1. If face fixing where possible set

the guide height at least 50mm above the structural opening

height to maximise drive through height.

i. Position guides

ii. Drill guide fixing holes (min 4) 7mm pilot hole 13mm outer

hole, avoid mortar joints and edges of bricks etc.

REVEAL

DRILL

OR FACE DRILL

GUIDE/ DOOR

HEIGHT

BOTTOM SLAT HANG

DOWN 50mm

DRIVE THROUGH

HEIGHT N.B. Guides are handed. If cutting guides cut excess length from

bottom of guide.

REVEAL FIX

INTERNAL SIDE

3mm 7mm

FACE FIX

INTERNAL SIDE 13mm

7mm

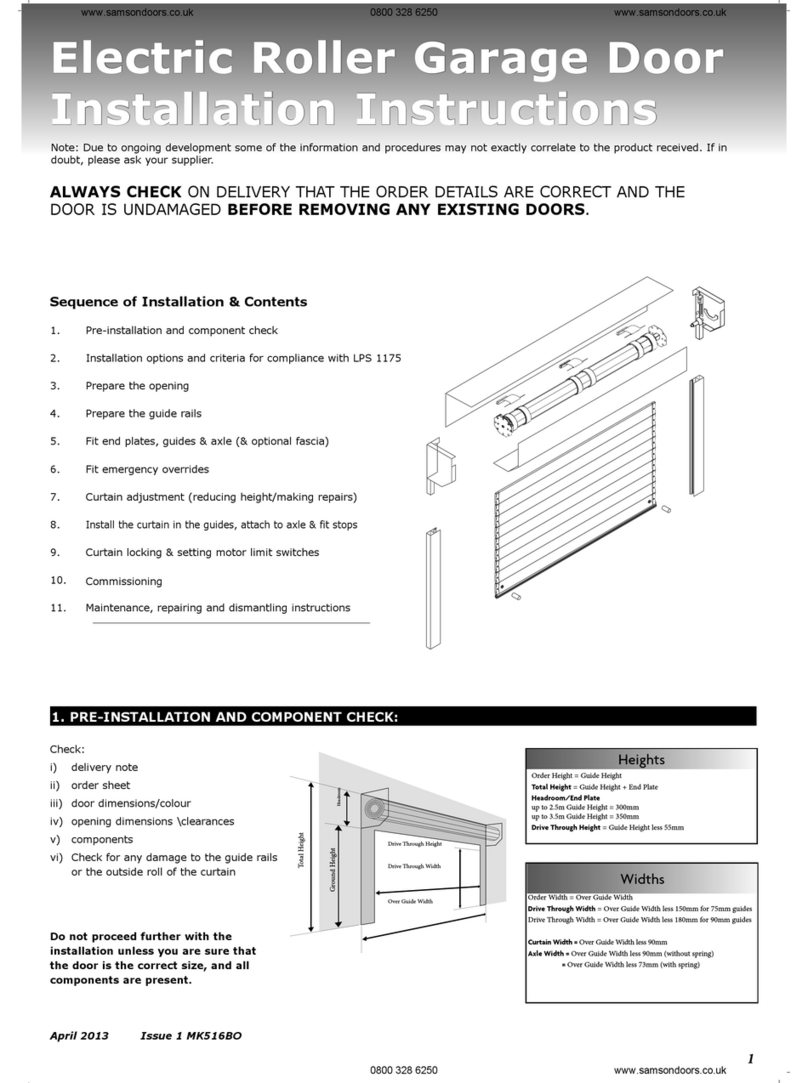

05. FIX GUIDE RAILS & AXLE ASSEMBLY

N.B. Before positioning check that there are no sharp objects or

bumps sticking out from the pillars, lintel or header to twist the

guides or distort the fascia.

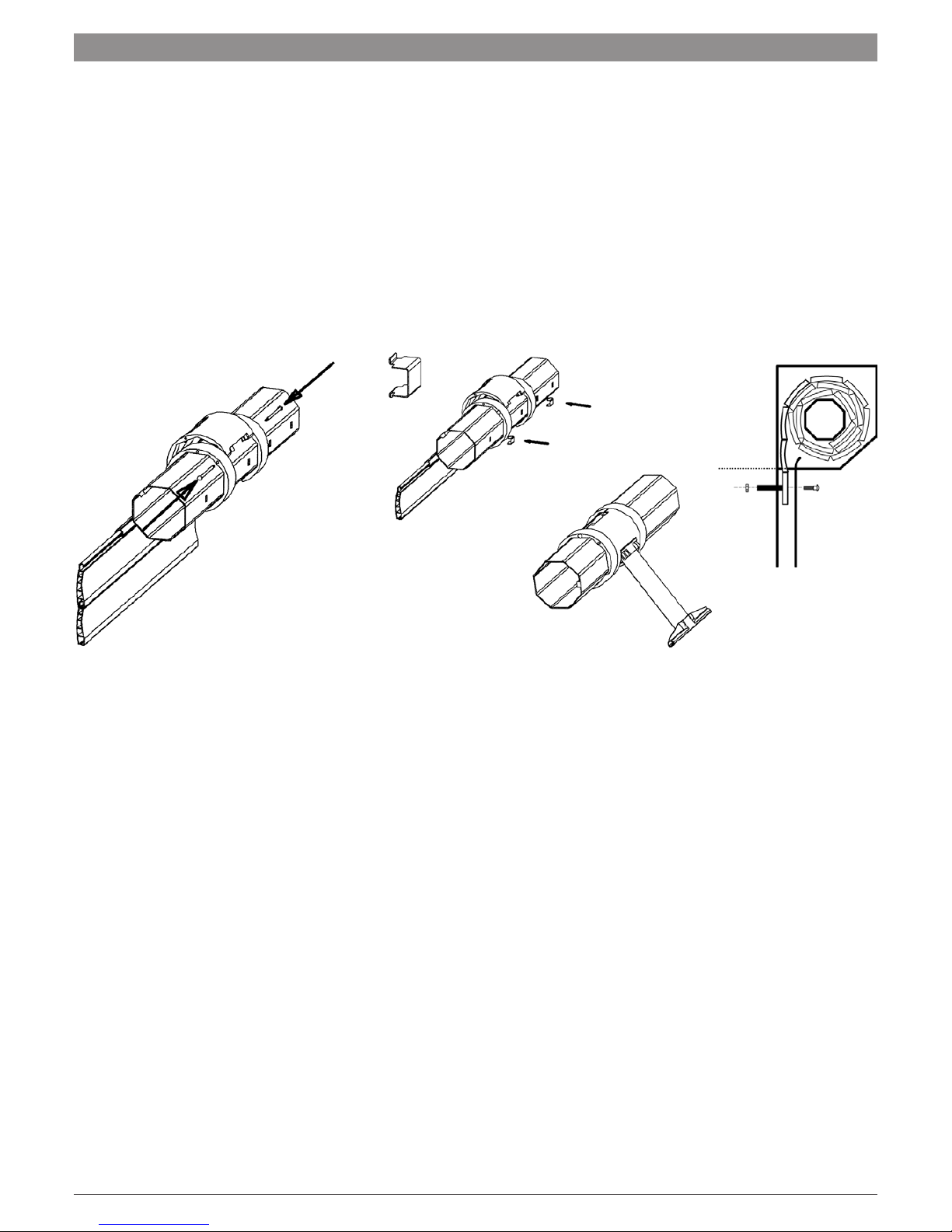

i. Slot end plate lugs into guides (see Drawing A) remembering

the guides are handed (check guide terminals are in place, see

Drawing B)

ii. Position guides and fascia against opening

iii. Hold or prop securely the assembly in position

iv. Drill fixing holes (min 4 in guides and 2 in each end plate)

v. Fix guides/end plates with minimum No. 12 x 21/2”

countersunk screws (and plugs) to masonry/timber or 12 x

1” self tapping screws to steel. Fix fascia every metre with

minimum 12 x 1” screws. Penny washers supplied must be

used to spread fixing load on end plates and fascia

vi. Stick brush strip to inside bottom edge of 90° fascia (optional

see Drawing B)

N.B. Extreme care should be taken while manoeuvring the

door into place to avoid the possibility of snapping the end

plate lugs. It is imperative that fixings are put through the end

plates into the wall as the aluminium lugs are not designed to

carry the weight of the door.

A

Lug

N.B. Axle assembly

must be level