4

Please note: The validity of the LPCB certification is contingent

upon the roller garage door being installed in accordance with the

requirements of LPS 1175 (see section 2 for further details).

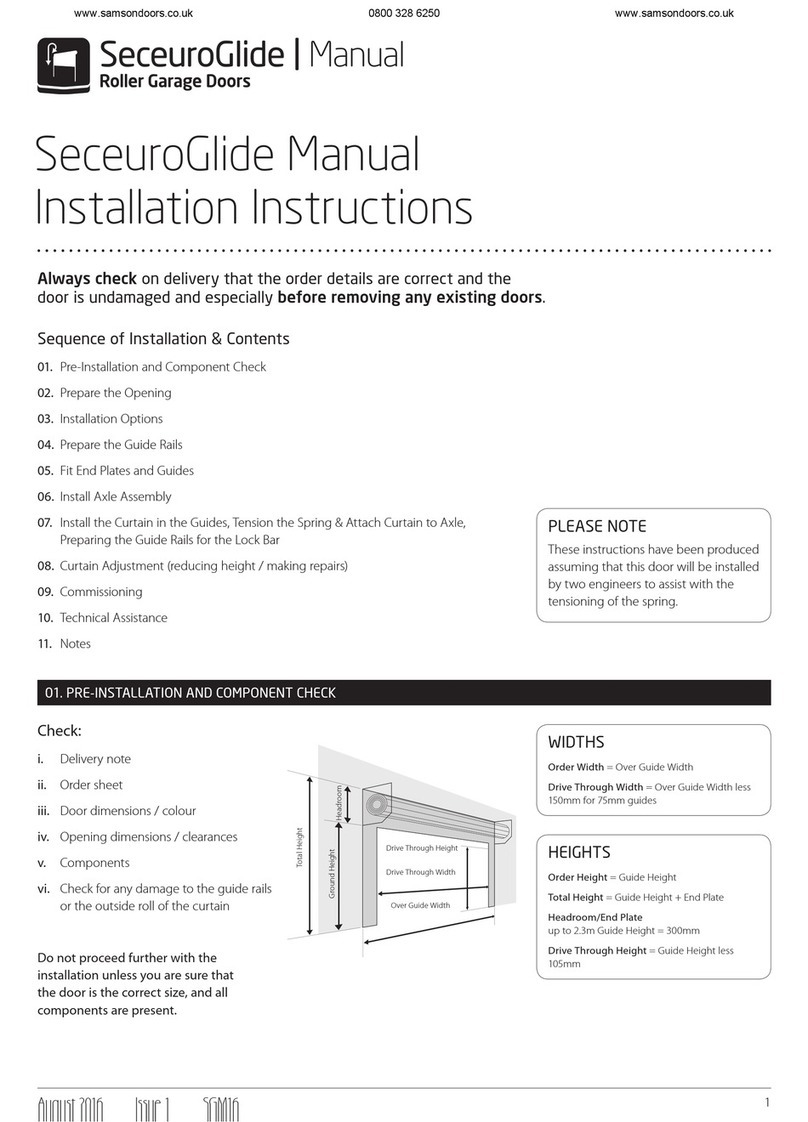

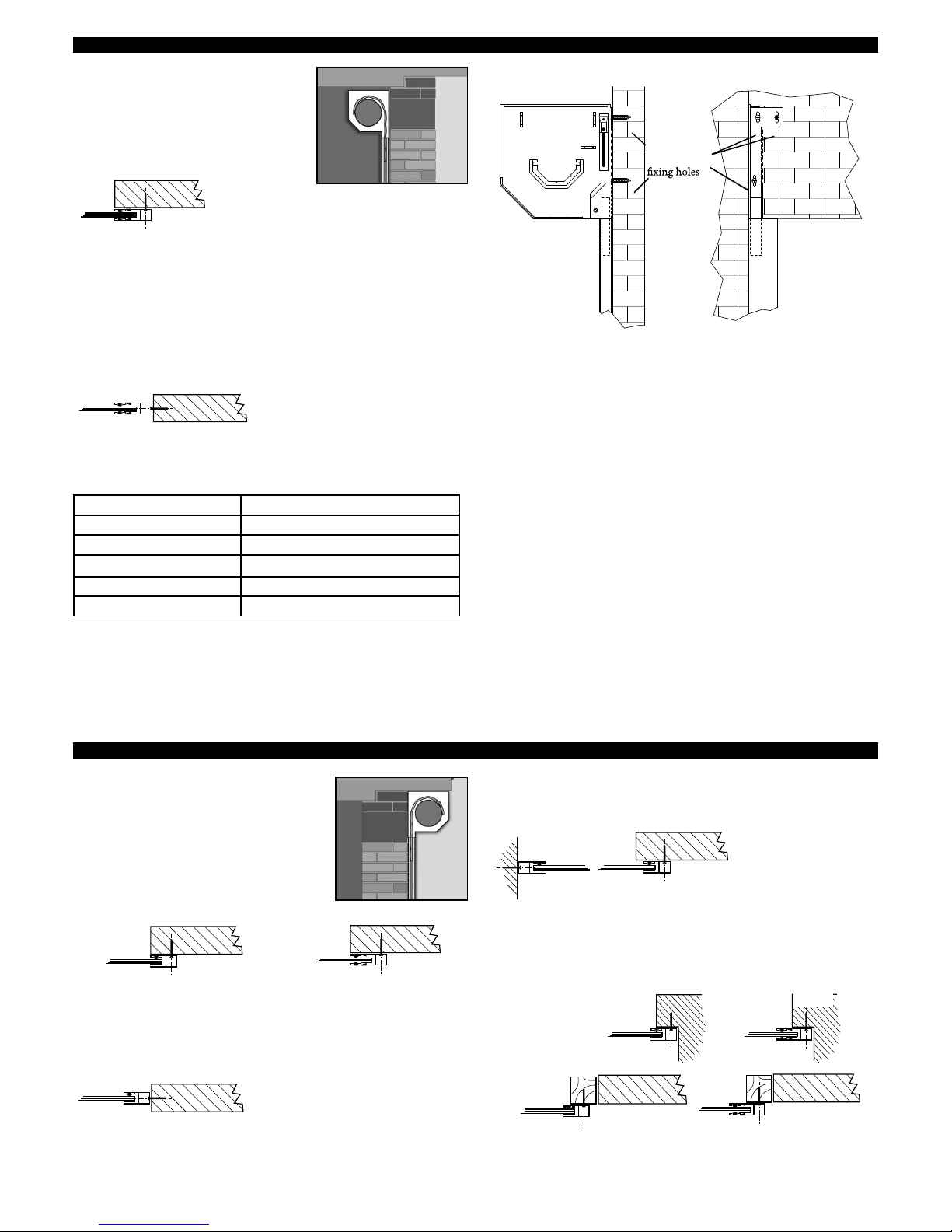

If the guides require cutting down refer to the information at

the start of Section 1 and also section 6 for reducing the curtain

height. If face fixing where possible set the guide height at least

55mm above the structural opening height to maximise drive

through height.

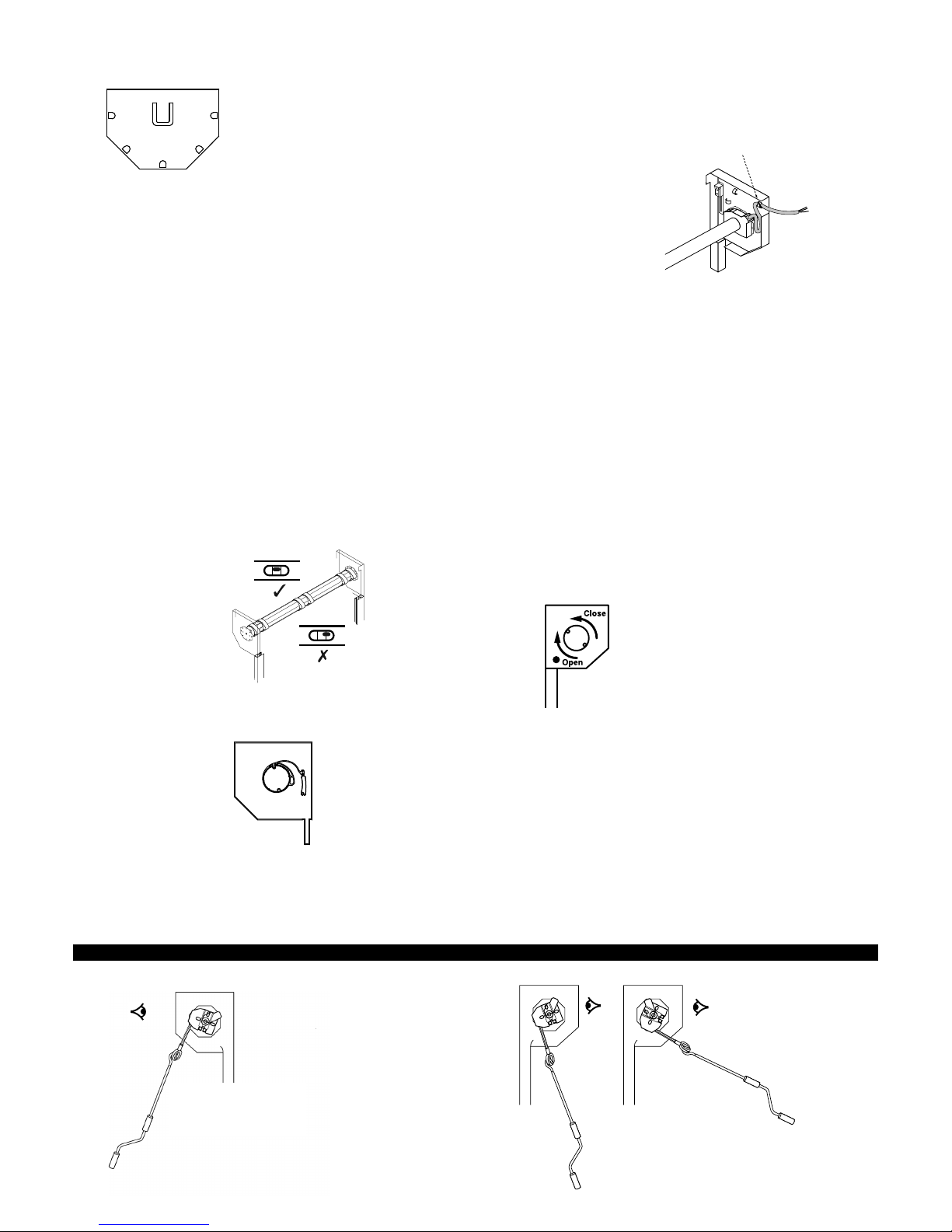

i) position guides

ii) drill guide fixing holes 7mm pilot hole 13mm outer hole

(min 4) avoid mortar joints and edges of bricks etc.

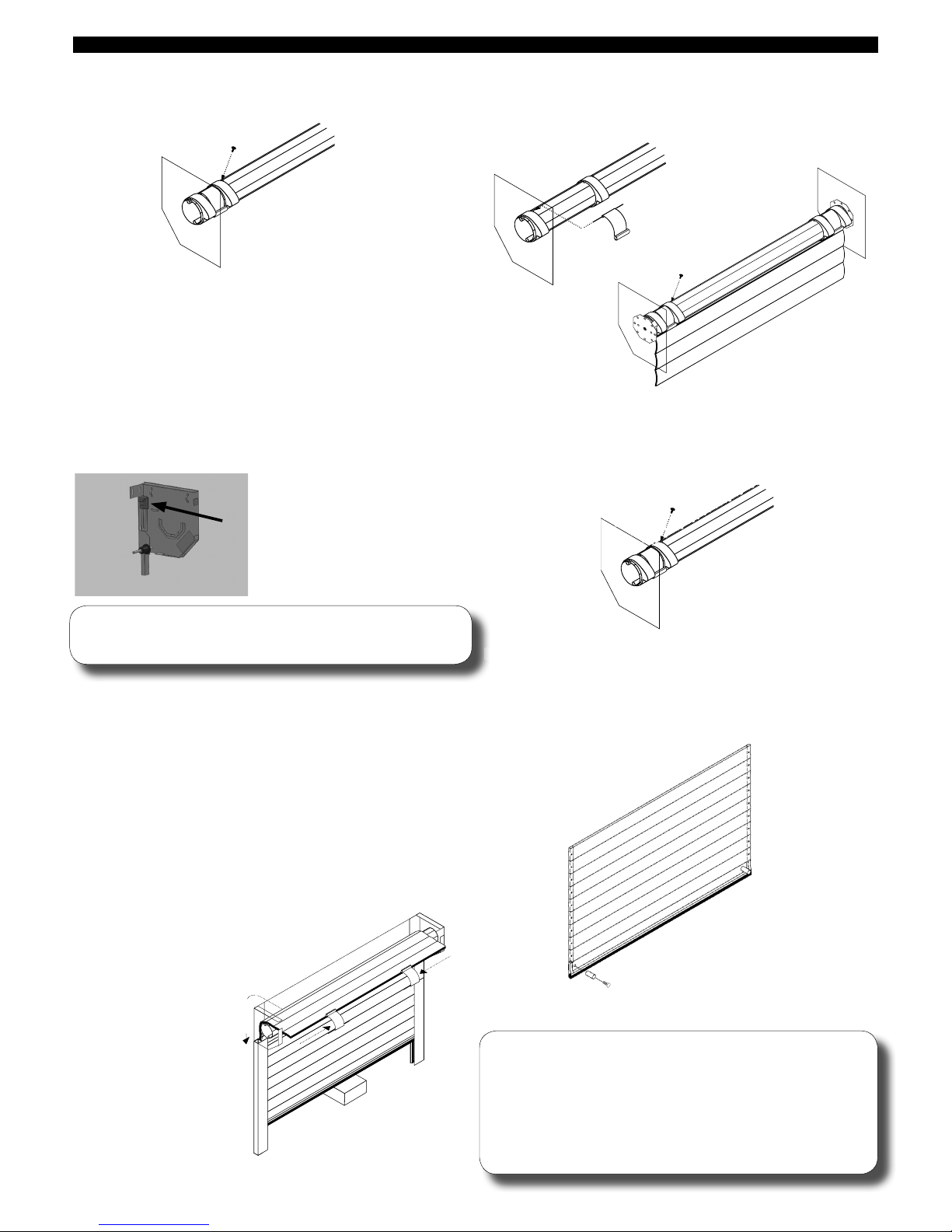

LPS 1175 compliant doors

Doors which are compliant with LPS 1175 will be supplied with a

bottom slat anchor system prefitted to the bottom slat and guide

rails.

Once the guide rails have been fastened in place the bottom slat

anchor guide insert must be fastened to the floor as shown below.

Bottom Slat

Hang Down

55mm

Drive Through

Height

Guide/Door

Height

REVEAL FIX

INTERNAL

SIDE

7mm

13mm

75mm

4. PREPARE THE GUIDE RAILS:

FACE

DRILL

FACE FIX

13mm

7mm

75mm

INTERNAL

SIDE

N.B. 90mm guides are handed

90mm

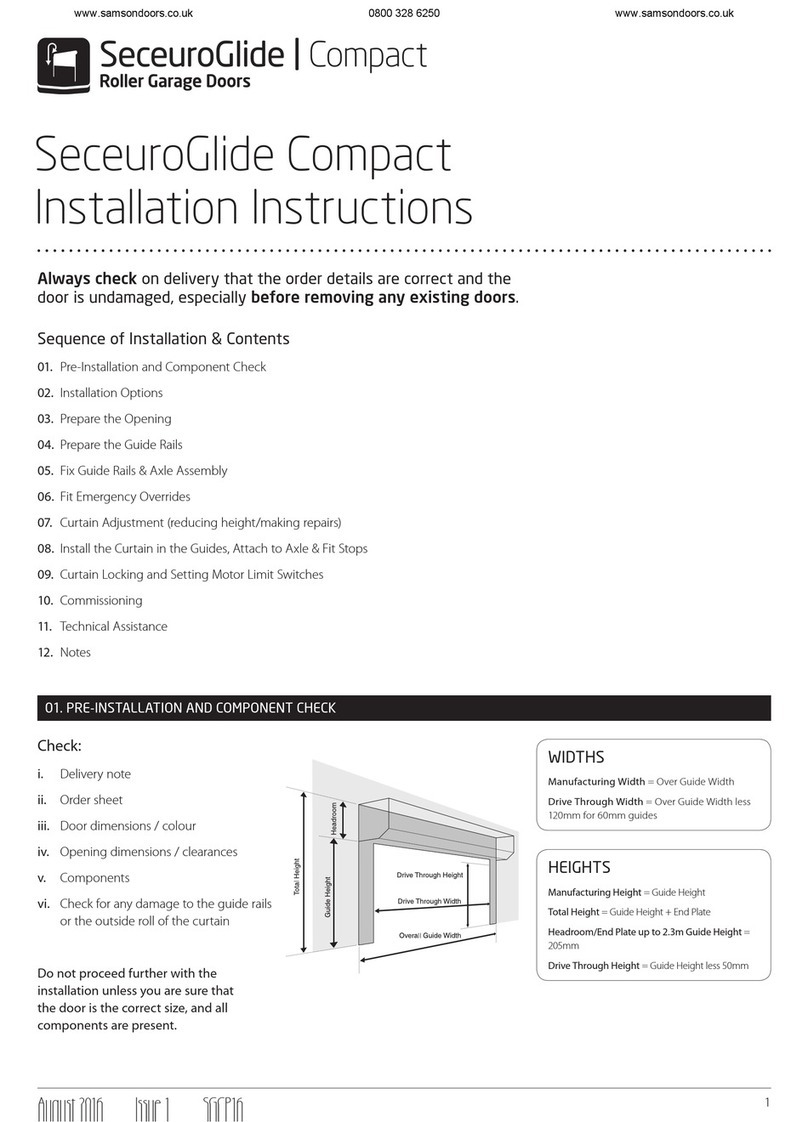

Check:

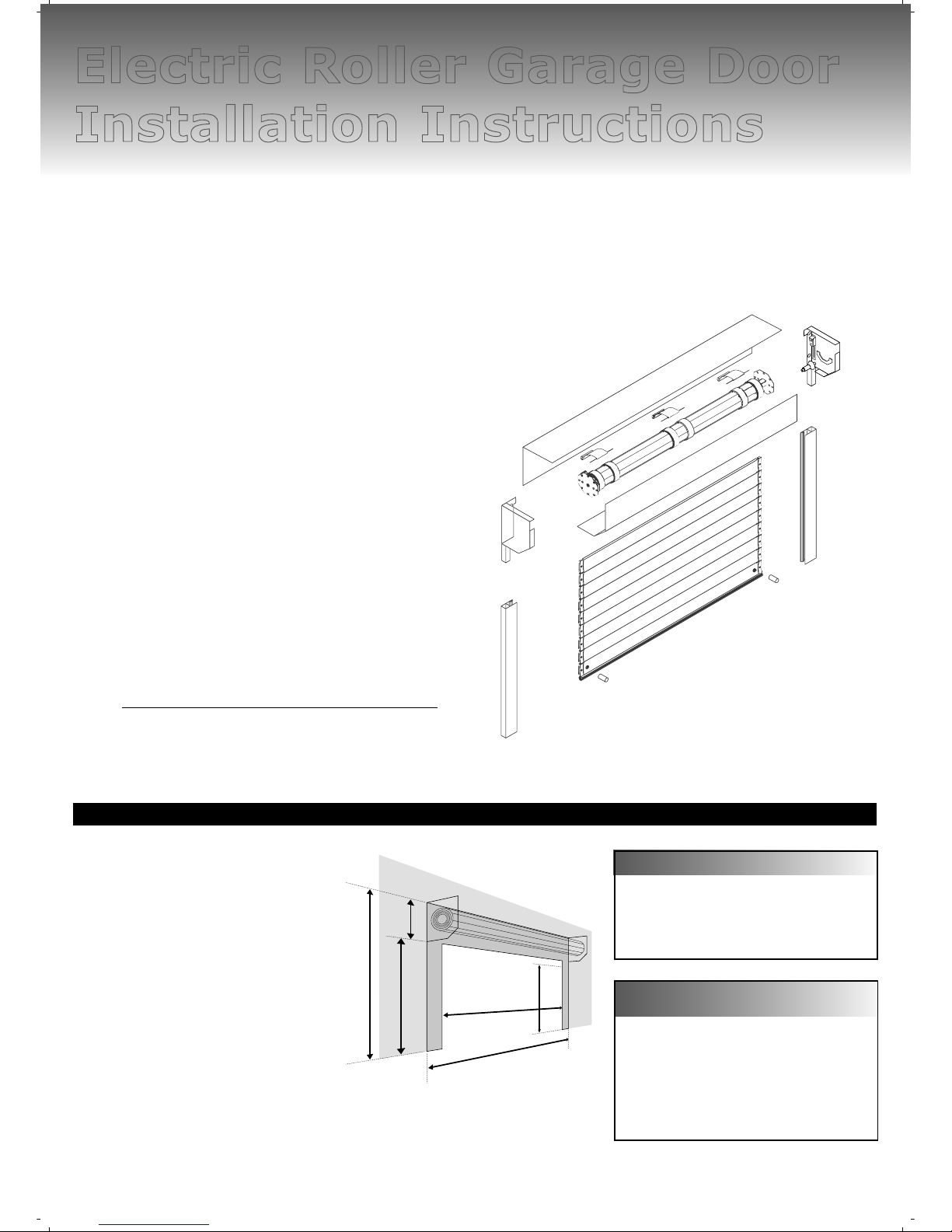

i) structure is sound/even & can carry the weight of the door

(curtain weight is approximately 5kg/m2 and allow an extra

15kg for the guides, end plates and axle assembly).

ii) no obstacles in fitting footprint e.g. no sharp objects, pipes,

cables, bumps etc. sticking out from the pillars, lintel or

header to twist the guides, distort the fascia or catch on the

curtain

iii) floor is flat/level

If necessary install a sub-frame to ensure secure, flush and level

fixing. (Recommended minimum 70 X 70 PAR)

3. PREPARE THE OPENING:

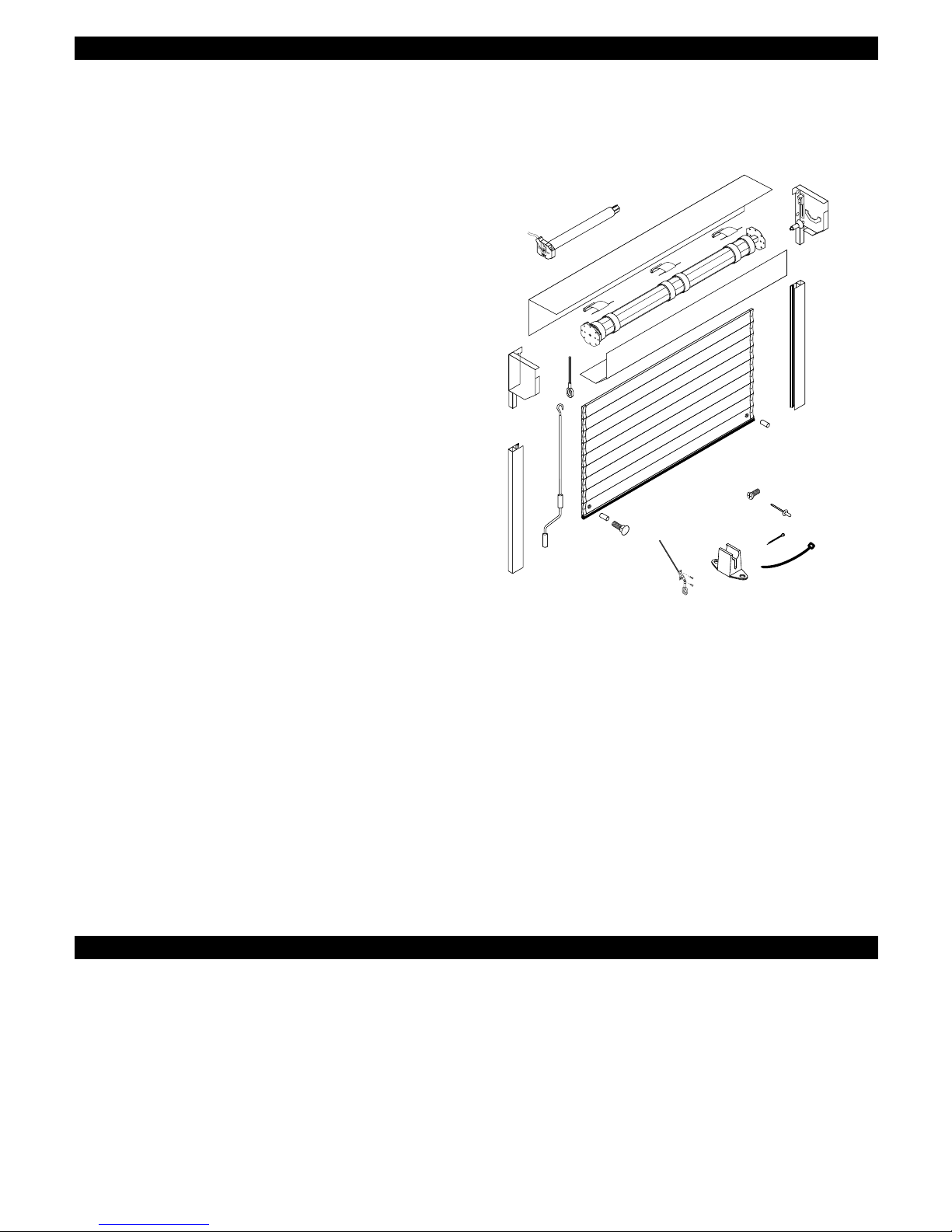

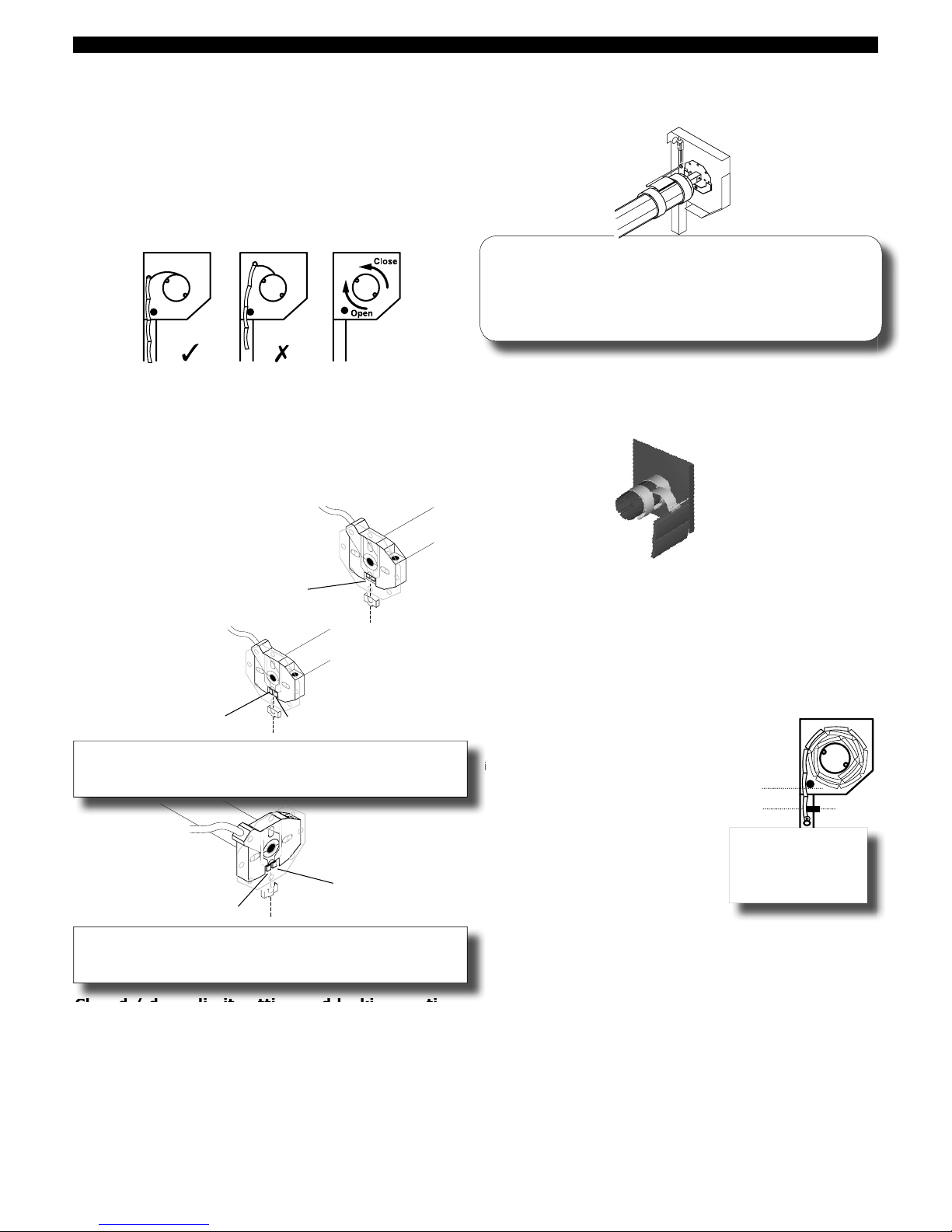

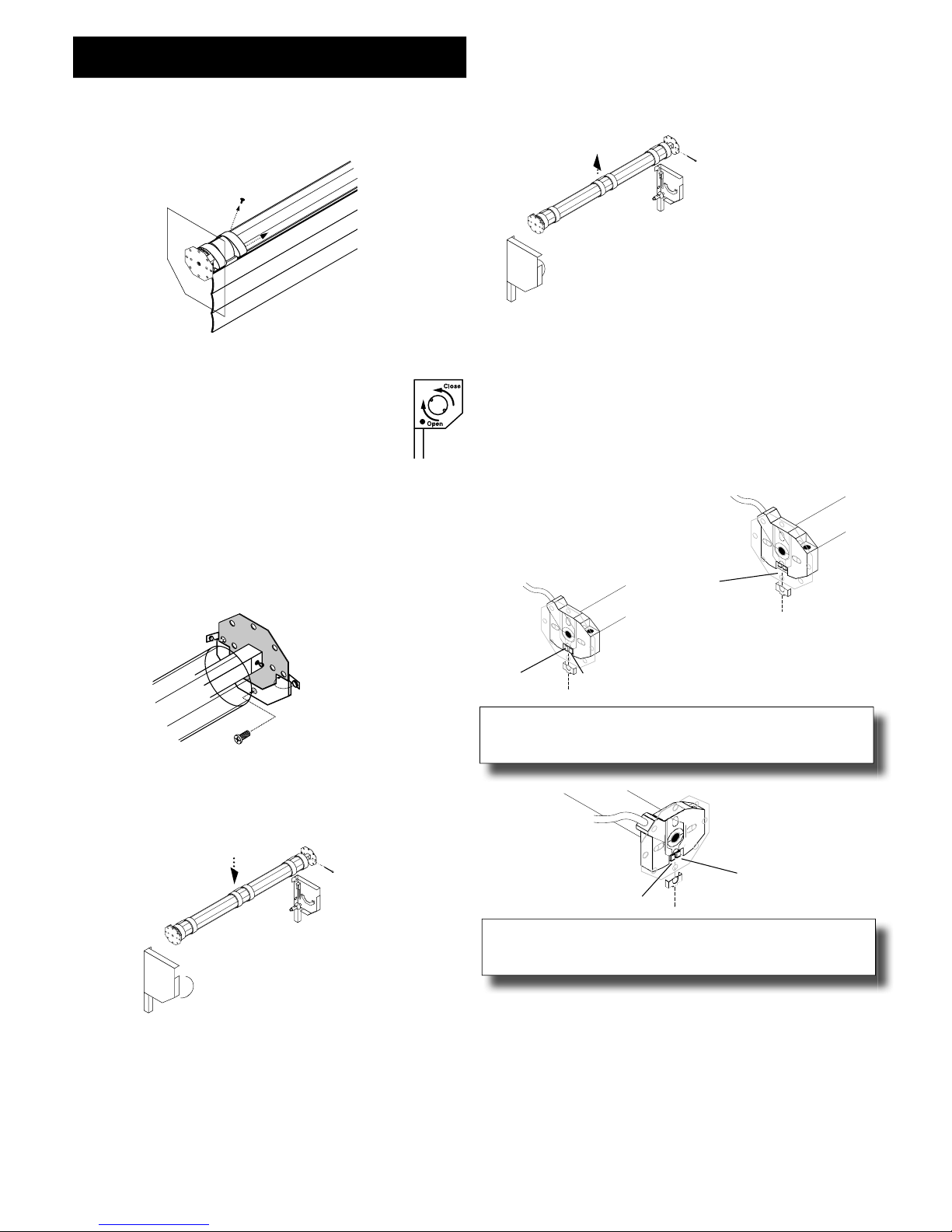

5. FIT END PLATES, AXLE ASSEMBLY, GUIDES (& OPTIONAL FASCIA):

N.B. When fitting doors with 300mm end plates and the guide

height is more than 2300mm it is important that you check that

the lintel does not bow inwards or have any projections that may

catch on the curtain. If in doubt pack the guides and end plates out

by at least 10mm.

i) slot end plates into guides (and fix optional fascia if supplied) -

see drawing A

If using 90mm guides make sure the back face of the end

plate is in line with the back of the guide.

3 rivets should be used to fasten the fascia to each end plate.

Doors compliant with LPS1175 will be supplied with penny

washers which the rivets must be fastened through.

ii) position guides, end plates (and optional fascia) against/in

opening

iii) hold or prop securely in position

iv) drill fixing holes (minimum of 4 in guides and 2 in each end

plate if not LPS 1175 compliant)

v) fix guides/end plates with minimum No. 12 x 21»´

countersunk screws (and plugs) to masonry/timber or 12 x

´VHOIWDSSLQJVFUHZVWRVWHHO)L[IDVFLDHYHU\PHWUHZLWK

PLQLPXP[´VFUHZV3HQQ\ZDVKHUVPXVWEHXVHGWR

spread fixing load on fascia. If there is nothing to fix to, 50 x

20 box section should be ordered to reinforce the fascia and

prevent deflection which may damage the curtain. Drill and

pop rivet from inside the fascia ensuring that the rivet leaves a

smooth surface.

vi) ease open top of guides – see drawing C

Before proceeding any further check:

a) back faces of guides and end plates are flush and untwisted – see drawing B

b) that the distance between the outside edges of the guides is 90mm more than the curtain

width

c) ensure that the distance between the outer edges of the end plates is

equal to the stated overall width of the door.

Drawing B

Drawing A

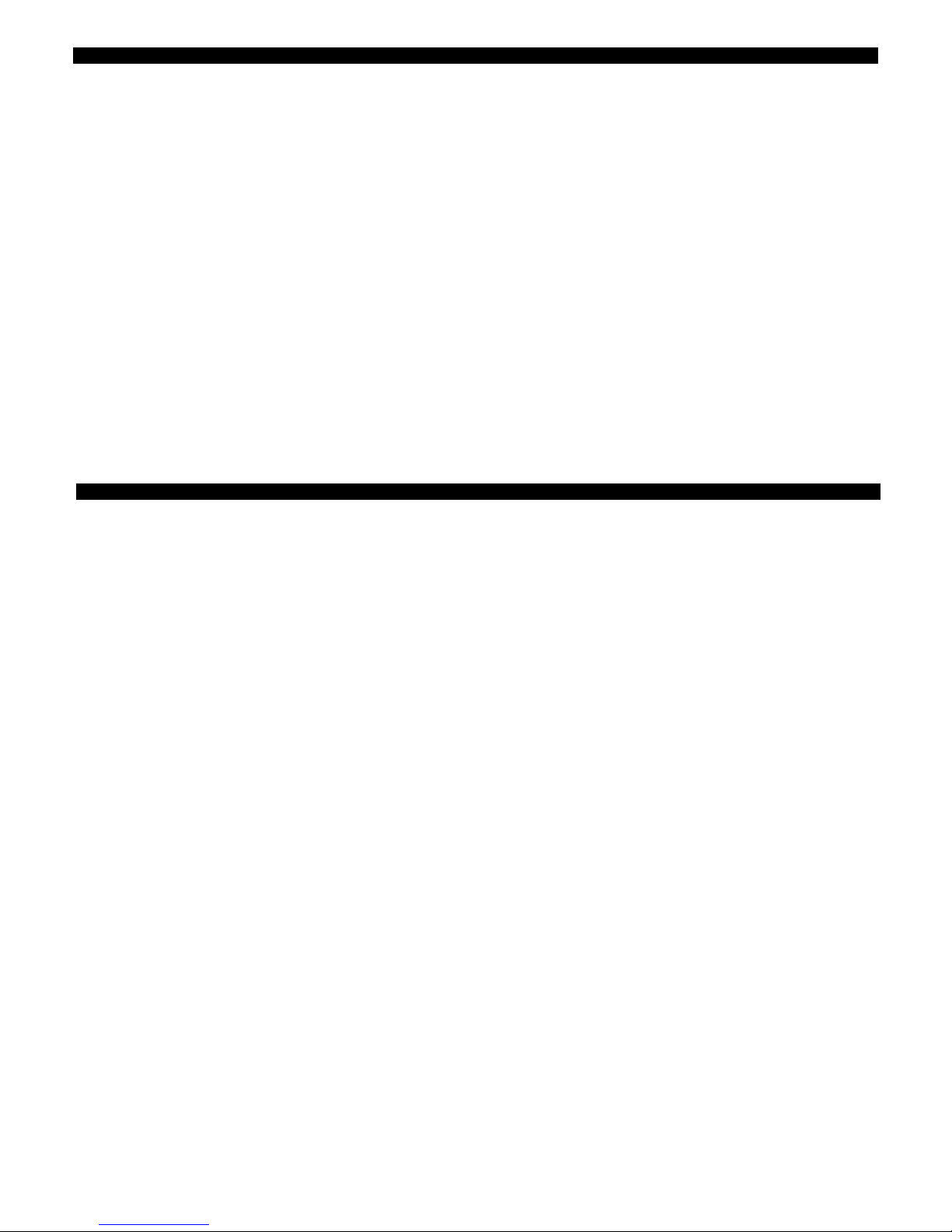

The dummy end octagonal

fixing plate is supplied in the

accessory box. The plate must

be fitted to the appropriate

end plate (not the motor side)

before installation of the axle.

Drawing C

REVEAL

DRILL

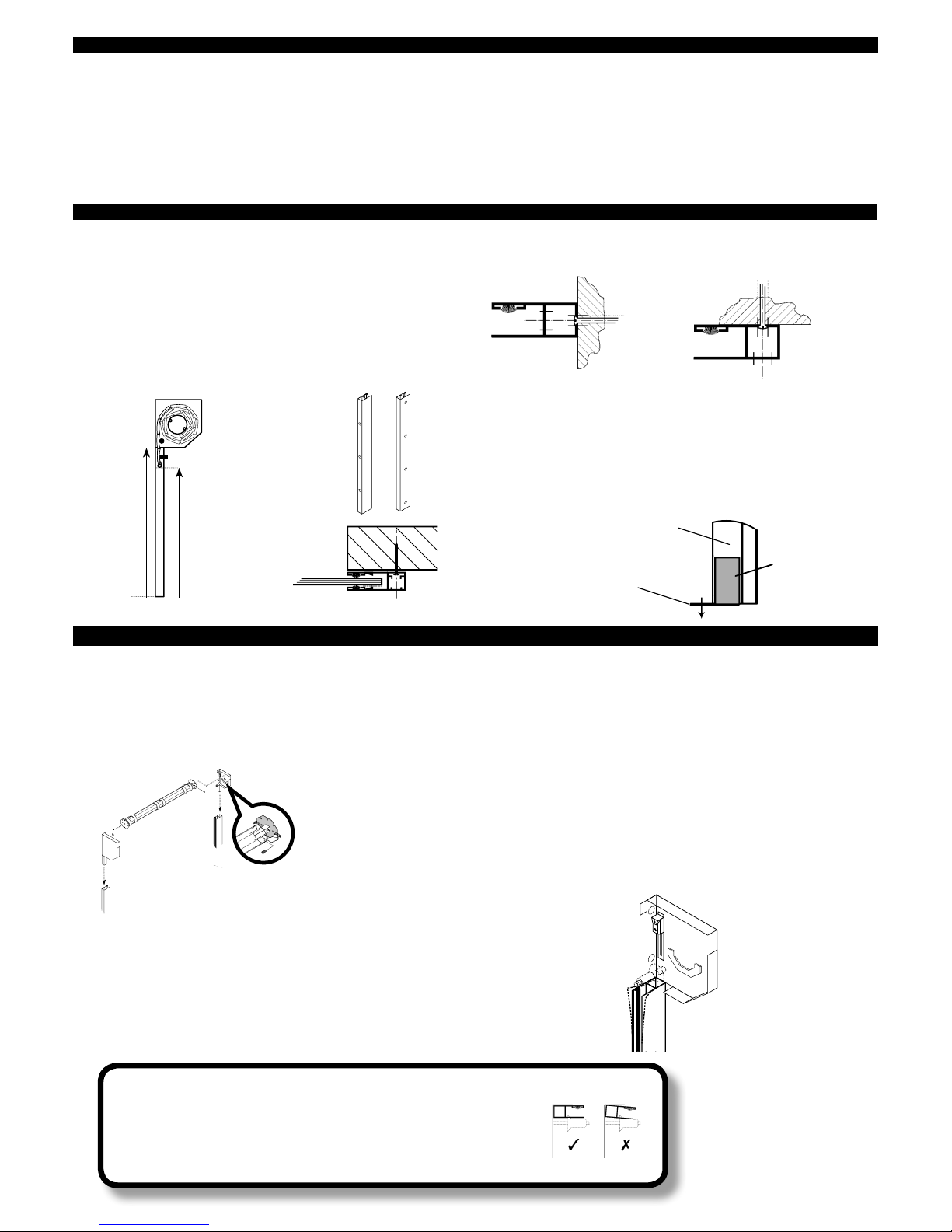

FIXED TO FLOOR WITH

MINIMUM OF 1 1/2 INCH No.12

GUIDE INSERT FIXED TO GUIDE

GUIDE RAIL

High winds and high temperatures can cause increased deflection of the door. It is the installer's responsibility to ensure that the door is

packed off the wall sufficiently to allow for door movement during these extreme weather conditions.