Safety Instructions

General Safety Instructions

lUse the controller only for its intended use as designed by the manufacturer, any misuse of the

controller may lead to undesired damage and may affect your warranty coverage. Consult with the

manufacturer prior to any non-regular use of this equipment.

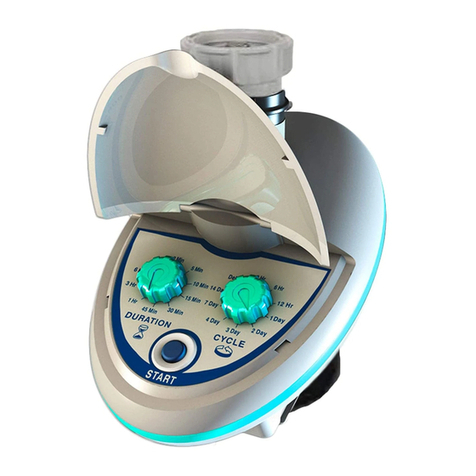

lThe terminals enclosure lid of the unit must remain closed at all times.

lOnly a qualified technician may remove this lid and only when the controller is properly disconnected

from its power source.

lServicing the unit can be done only by qualified technician.

lMake sure that the filters controlled by the controller are disconnected from the water system whenever

servicing the controller.

lIn case the controller is connected to an external AC power supply unit, make sure that the power

supply connection is done only by a licensed electrician and the connection complies with your local

standards for High Voltage out-doors connection.

lPlease note: The filter enters into a flushing mode automatically, without early warning.

lNo change or modification to the equipment is permitted without a written notification given in advance

by the manufacturer or by its representative, on the manufacturer’s behalf.

lAlways observe standard safety instructions and good engineering practices whilst working in the filter’s

vicinity.

Electricity Instructions

lElectric wiring should be performed by an authorized electrician only, using standardized and approved

components.

lInstall a lockable main power cut-off switch close to the control panel.

lIf due to site constraints, the control panel is installed without a clear line-of sight of the filter, an addi-

tional lockable power disconnect cut-off switch should be installed near each filter unit.

lUse only the built-in transformer.

lIn case the controller is supplied with a power supply cable connected to it, the controller is for indoor

installations only!

lIn order to use the controller for outdoor installation, a licensed electrician must disconnect the power

supply cable, and connect the controller according to the instructions given in the installation chapter of

this document and in compliance with all the safety instructions and the local standards for High Voltage

out-door connection.

lIf the plug does not comply with your local regulation, it must be replaced with suitable plug by licensed

electrician only.

lHazardous Live voltages connected to the following output terminals :

lFilter Motor Control terminal (230VAC/115)

l24VAC for solenoid control and for 24VAC auxiliary (24VAC IS CONSIDERED HAZARDOUS LIVE IN WET

LOCATIONS!).

4 AMCFlushing Controller User Guide

Contents